Compression automatic chip discharging machine for machine tool

An automatic chip removal and chip removal technology, applied in conveyors, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of large chip accumulation volume, affecting production efficiency, and troublesome chip cleaning, reducing the number of dumping and facilitating cleaning. The effect of cutting chips and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

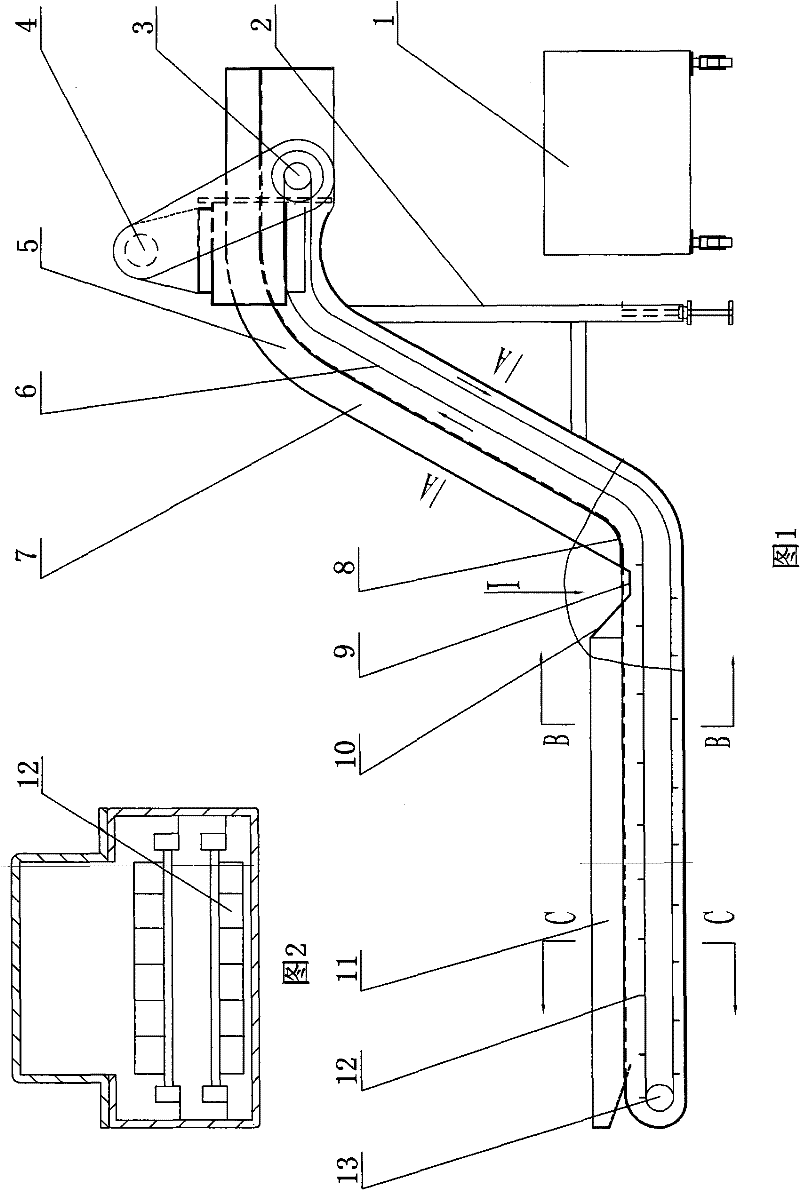

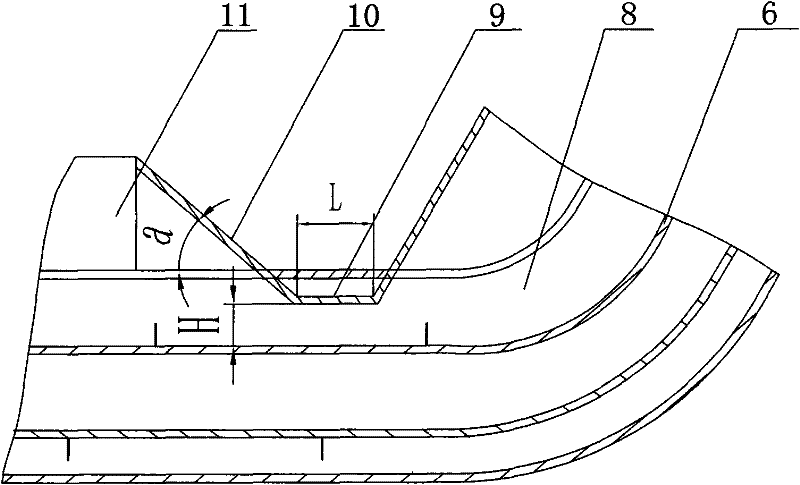

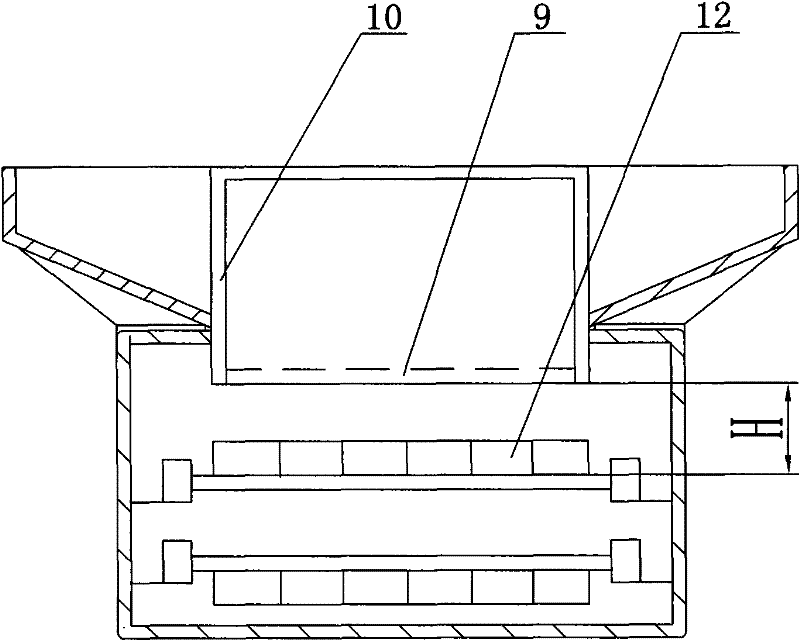

[0014] The present invention includes a body 5, the body 5 is composed of a horizontal chute 11 with an open top and an inclined chute 7 with a closed top, a chain plate conveyor belt 6 is arranged between the support shaft 13 of the horizontal chute 11 and the drive shaft 3 of the inclined chute 7, and the chain The plate conveyor belt 6 is provided with a W-shaped chip pusher 12; the adjustable leg 2 is arranged below the inclined chute 7, and a horizontal extruding plate 9 is arranged on the top of the intersection of the inclined chute 7 and the horizontal chute 11, and the horizontal extruding plate An inclined chip guide plate 10 is arranged between 9 and the horizontal chute 11, and an extrusion working chamber 8 is formed between the bottom of the inclined chute 7 and the chain conveyor belt 6.

[0015] The included angle α between the inclined chip guide plate 10 and the horizontal can be 15°-75°.

[0016] The length L of the horizontal extrusion plate 9 may be 0-120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com