Laboratory exhaust gas purification treatment equipment

A waste gas purification and laboratory technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of fast adsorption and saturation time of acid waste gas, short use time of filler, easy pulverization and adhesion, etc. Improved condensing efficiency, low operating cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

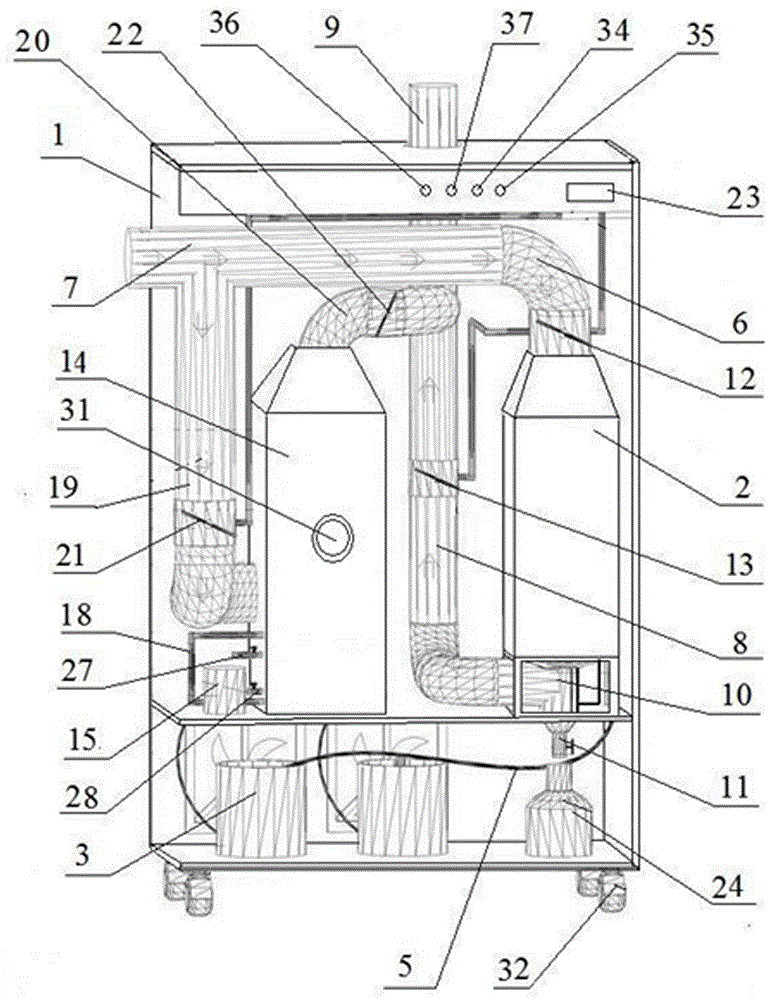

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

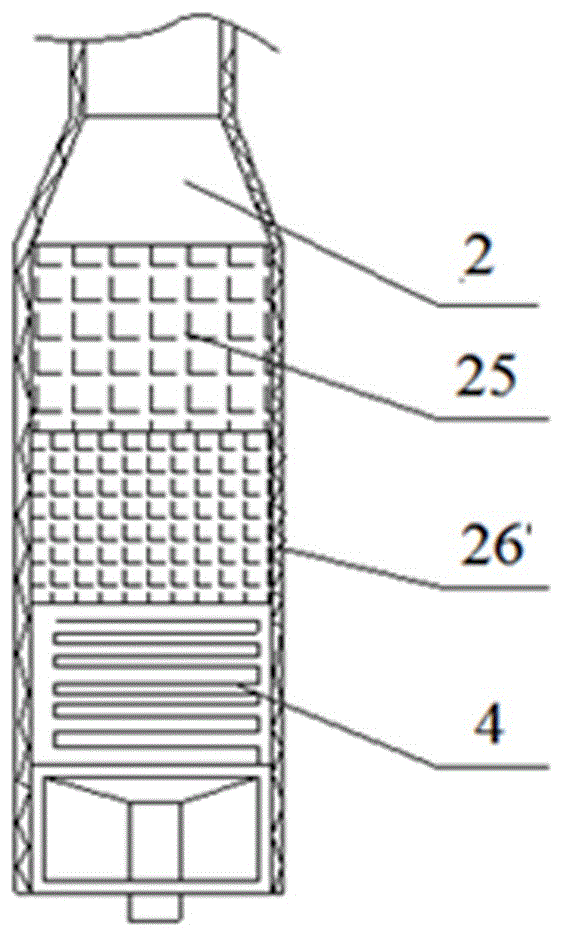

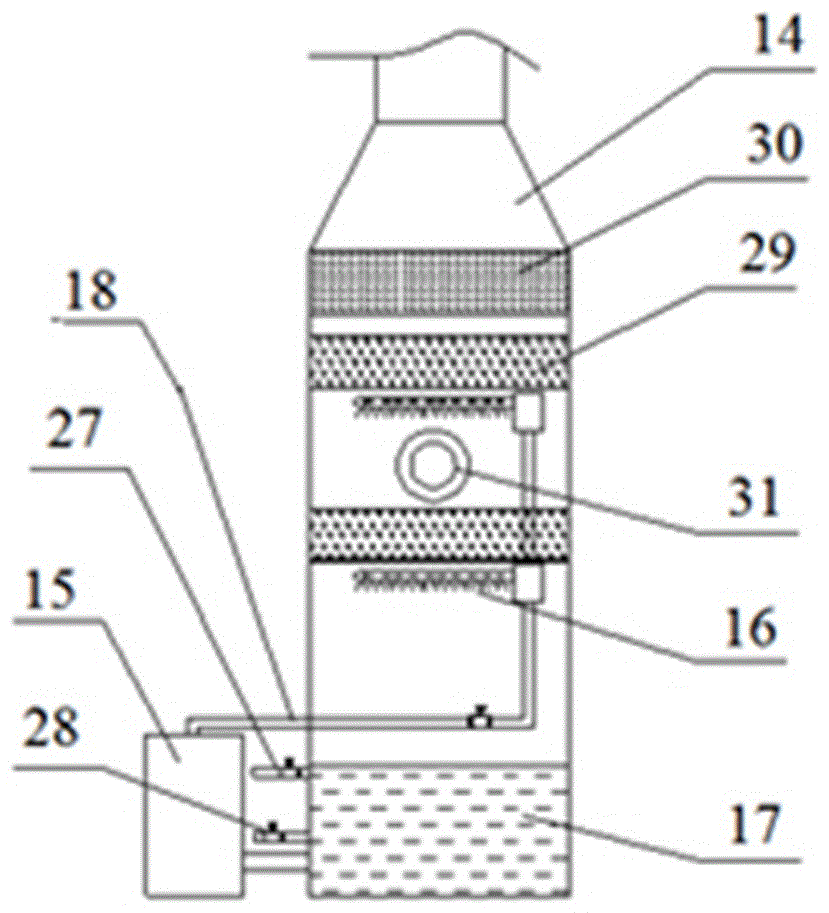

[0026] As shown in Figure 1, the laboratory waste gas purification treatment equipment includes a housing 1 with a gas inlet and a discharge port, a condensation treatment box 2 with an air inlet and an air outlet, a compressor 3, a condenser, and an evaporator 4 . The compressor 3 , the condenser, and the evaporator 4 form a circulation loop by means of the refrigerant pipeline 5 , and a bearing wheel 32 is provided under the shell 1 . Such as figure 2 As shown, the interior of the condensation treatment box 2 is sequentially provided with a multi-layer stainless steel hollow grid sheet 25, a temperature sensor, and an evaporator 4 from top to bottom, and the inner wall is wrapped with a thermal insulation layer 26. The temperature sensor is connected with the temperature display screen 23 on the casing 1 and the temperature regulator to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com