Profile steel truss double-skin wall structure and construction method thereof

A truss and profiled steel technology, applied in profiled steel truss double-skin wall structure and its construction field, can solve the problems of small thickness, overall stiffness of double-skinned wall structure and low ability to resist lateral pressure of concrete, etc. Strength performance and waterproof performance, the effect of high vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

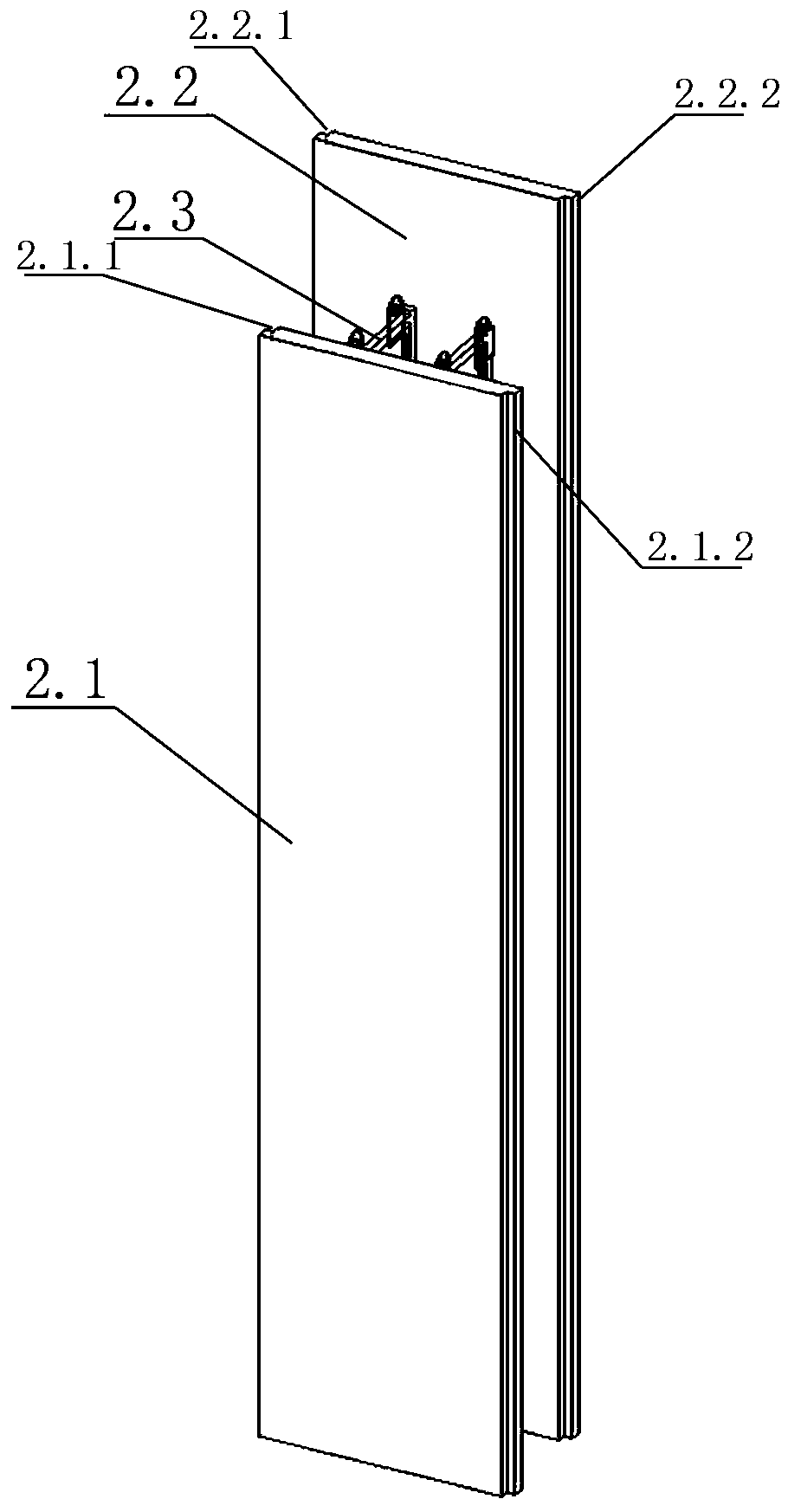

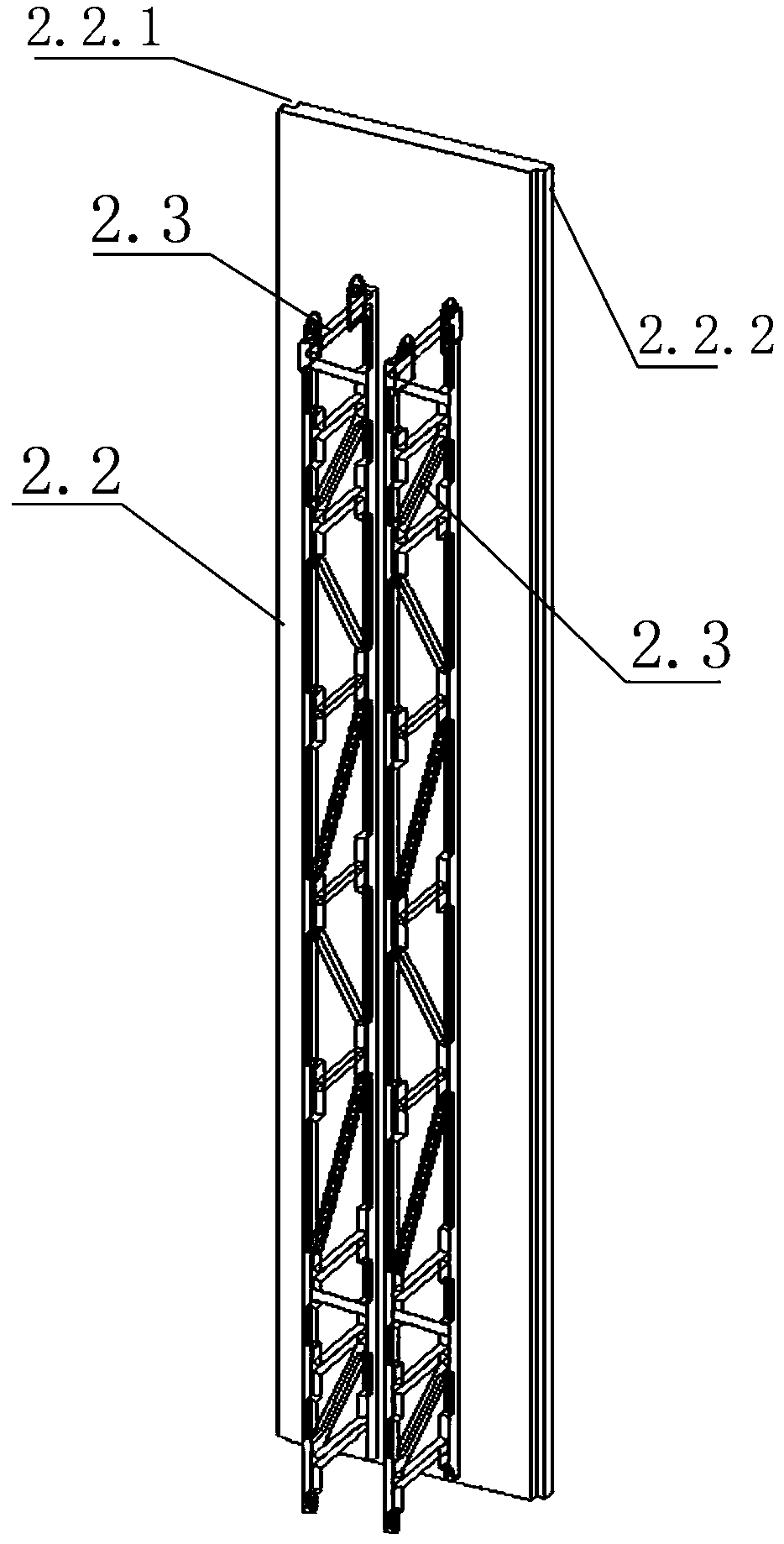

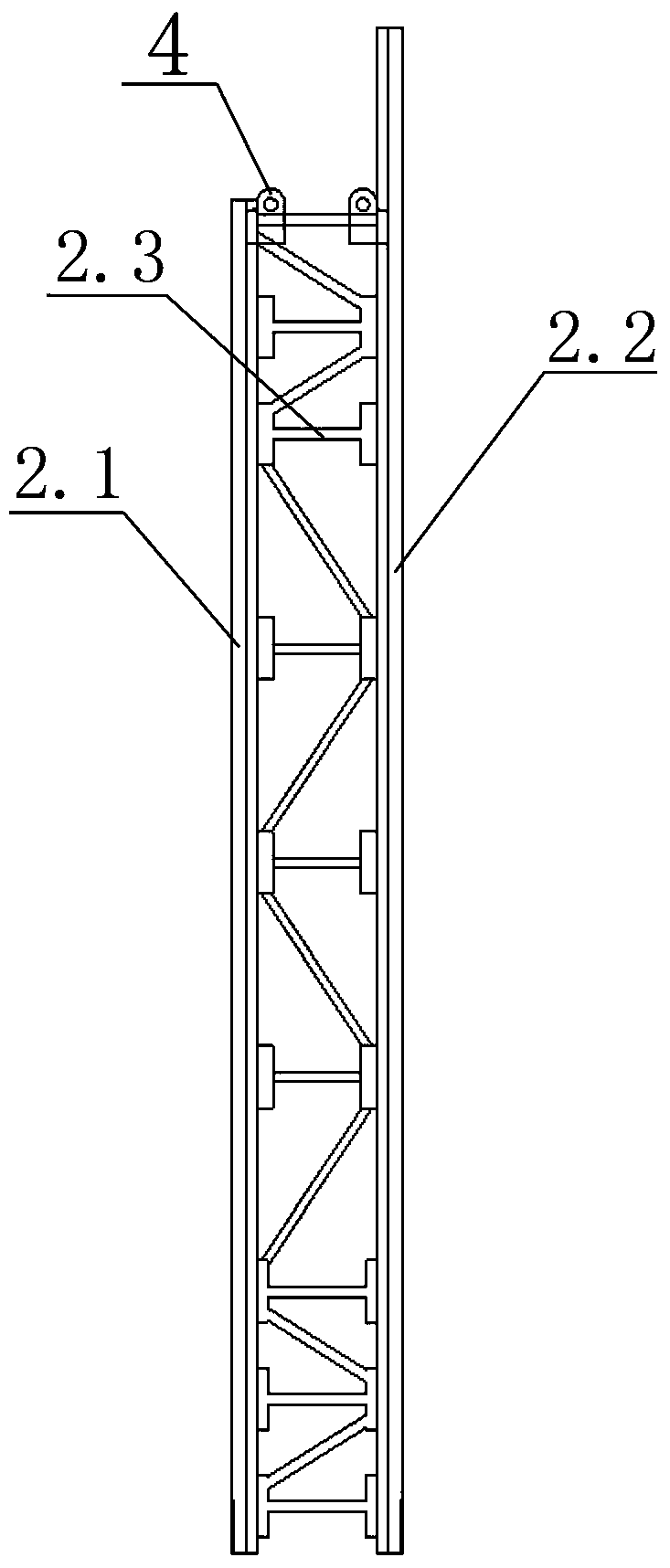

[0040] Such as Figure 1-6As shown, this type steel truss double skin wall structure includes a main structure 1, a double skin wall structure unit 2 and a cast-in-place concrete layer 3; wherein, there is a group of double skin wall structure units 2, which are spliced and connected along the transverse direction; The concrete layer 3 is poured in a group of double skin wall structural units 2; the double skin wall structural unit 2 includes a first prefabricated concrete slab 2.1 and a second prefabricated concrete slab 2.2; the first prefabricated concrete slab 2.1 and the second Two prefabricated concrete slabs 2.2 are arranged at parallel longitudinal intervals; between the first prefabricated concrete slab 2.1 and the second precast concrete slab 2.2, a group of steel trusses 2.3 are arranged at parallel intervals along the transverse direction; wherein, each steel truss 2.3 passes vertically The chord on one side of the steel truss 2.3 is poured in the first prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com