Bottle anti-inverting extrusion-preventing device for bottle unscrambler assembly line

A technology of extrusion device and assembly line, applied in packaging, packaging bottles, packaging protection, etc., can solve the problems of inconvenient packaging of plastic bottles, affecting products, and bottle jams, etc., so as to facilitate packaging processing, improve work efficiency, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

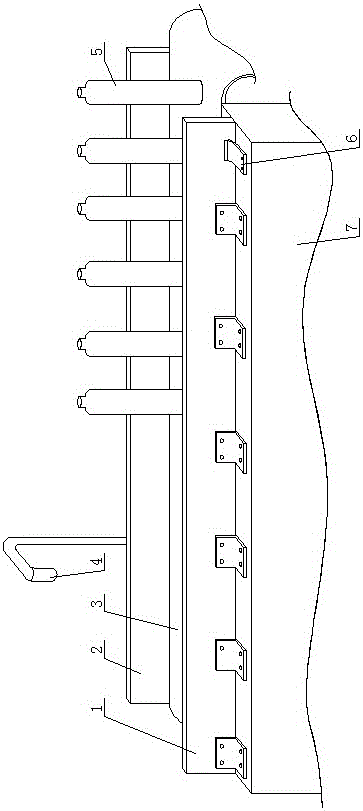

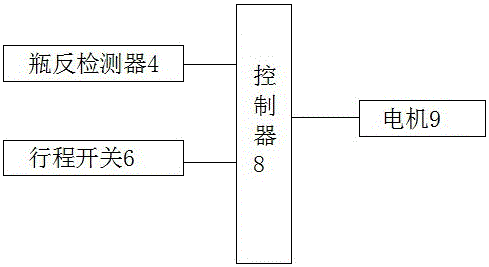

[0026] The bottle unscrambling assembly line anti-bottle anti-extrusion device of the present invention comprises a support 7, a bottle unscrambling plate, a travel switch 6 and a bottle reverse detector 4. The bottle unscrambling plate includes a front bottle unscrambling plate 1 and a rear bottle unscrambling plate 2. The bottle unscrambler 1 and the rear bottle unscrambler 2 are relatively fixed on the top of the conveyor belt 3 through the bracket 7 to form a U-shaped transmission channel. The inner end, the inner end of the front bottle unscrambling plate 1 is not fixedly connected with the support 7, the plastic bottle 5 can be squeezed and the inner end of the front bottle unscrambling plate 1 deviates to the outside during the bottle clamping process, in order to ensure that the plastic bottle 5 can Squeeze to the front bottle unscrambling plate 1, the transverse distance between the front unscrambling bottle plate 1 and the rear bottle unscrambling plate 2 is greater t...

Embodiment 2

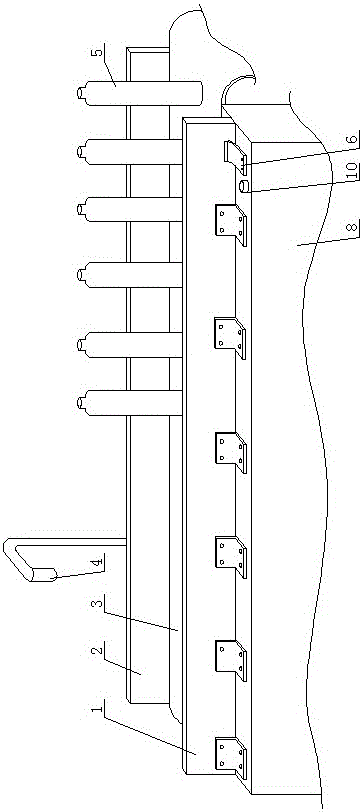

[0031] This embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the travel switch 6 is a non-automatic reset travel switch 6, and a start switch 10 is connected to the travel switch 6. The start switch 10 is fixed on the travel switch 6 place, and after the inner end of the front side plate triggers the travel switch 6 to close, the contact in the travel switch 6 can be started by the start switch 10 to disconnect.

[0032] In the bottle unscrambling assembly line, the plastic bottle 5 in the bottle unscrambling machine is transferred to the baler for packaging, and the transmission of the plastic bottle 5 between the bottle unscrambler and the baler is realized by the conveyor belt 3. The extrusion device is located between the bottle unscrambler and the baler. When the bottle is jammed, the plastic bottle 5 squeezes the inner end of the front bottle unscrambler 1 and drives the front bottle unscrambler ...

Embodiment 3

[0034]This embodiment is a further improvement on the basis of Embodiment 2. The difference between this embodiment and Embodiment 2 is: a bottle picking device is provided at the conveying channel, and the bottle picking device includes a high-pressure blower 14, an air duct 13 and a return channel 15. There is a ventilation hole 12 on the front bottle unscrambling plate 1, and a bottle passing groove 11 is opened on the rear bottle unscrambling plate 2 for the plastic bottle 5 to pass through. On the front and rear sides, the return channel 15 is a U-shaped return channel mainly composed of a conveyor belt and two baffles relatively located on the left and right sides of the conveyor belt 3, and the bottle inlet of the return channel 15 is located The outer side is connected with the bottle passing tank 11, and the bottle outlet of the return channel 15 is connected to the bottle inlet end of the bottle unscrambler; the air inlet of the air duct 13 is communicated with the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com