Crushing equipment for recycling building waste materials

A technology for crushing equipment and construction waste, applied in grain processing, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as air pollution and inconvenient use, and achieve the effect of reducing pollution and facilitating transportation and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

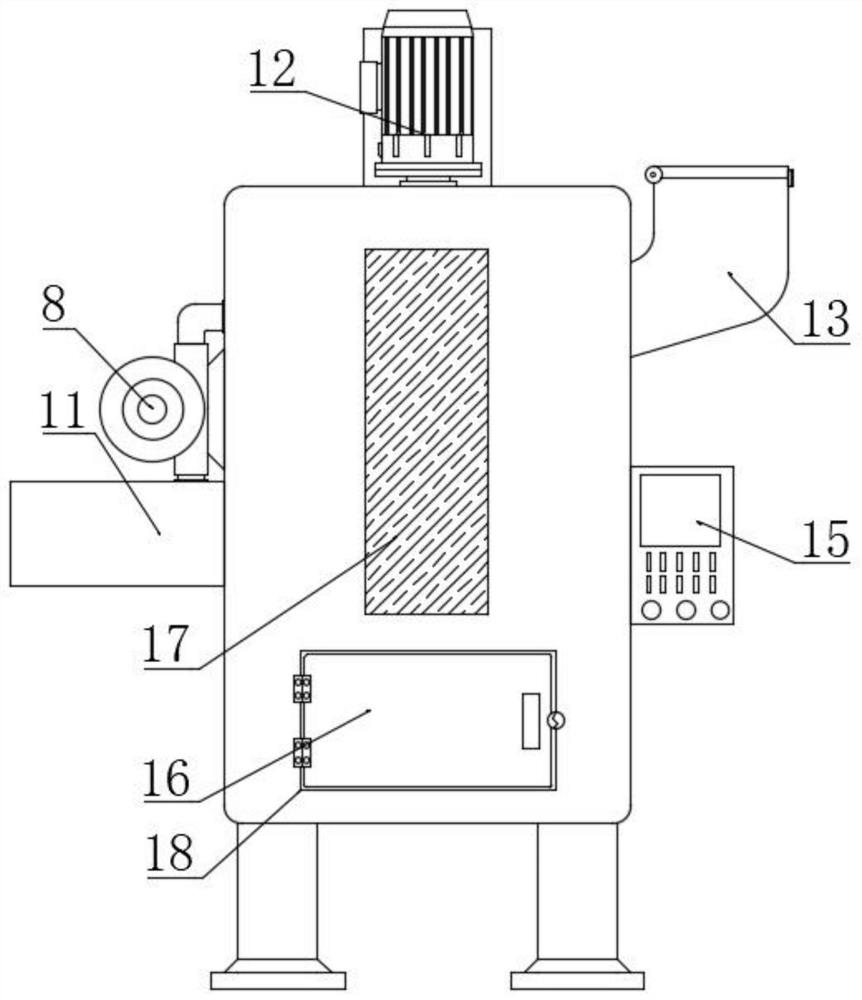

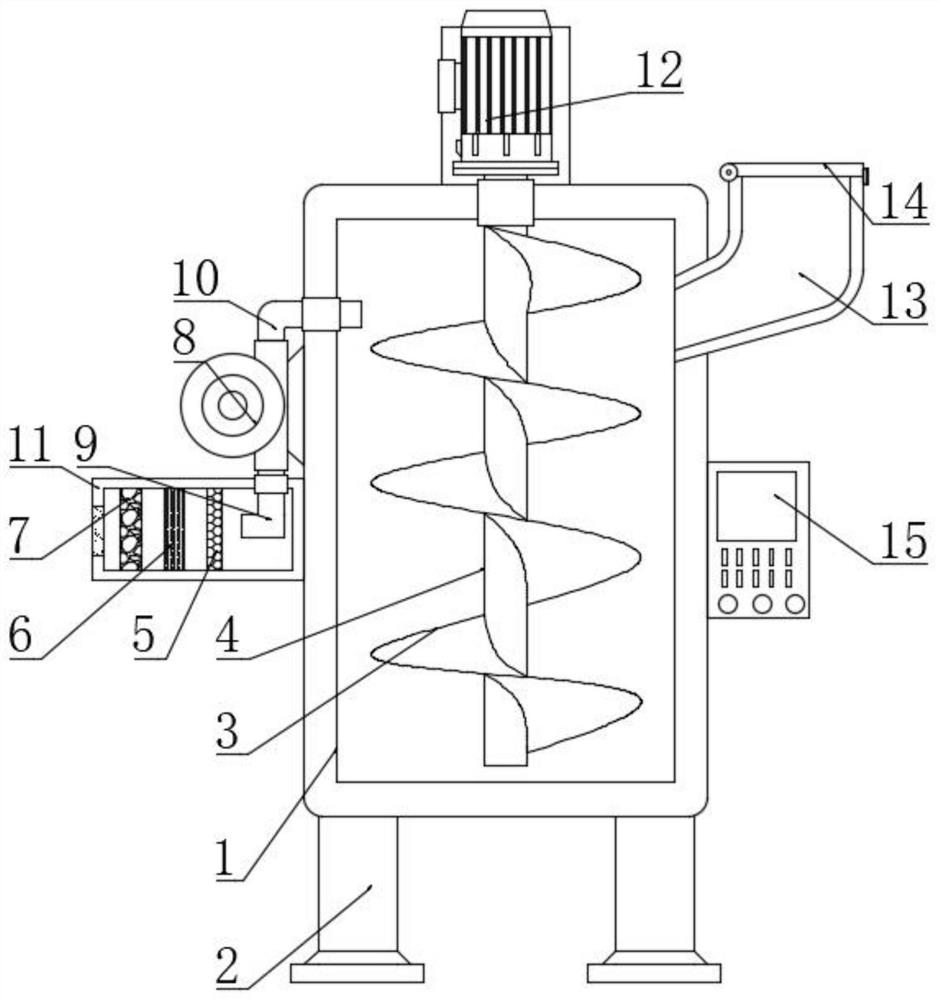

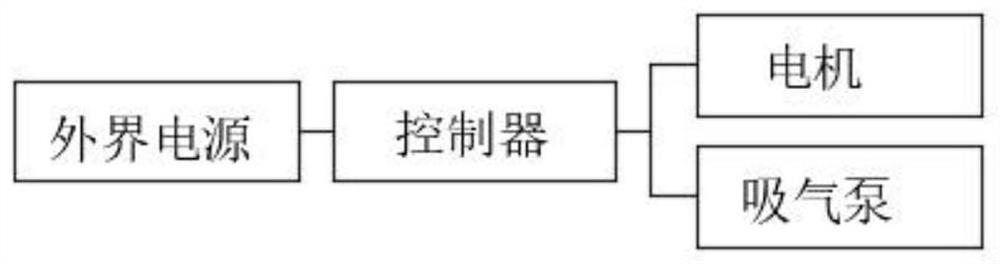

[0021] see Figure 1-3 , the present invention provides the following technical solutions: a crushing equipment for recycling construction waste, comprising a crushing box 1, the left side of the crushing box 1 is fixedly connected with a box body 11 and an air suction pump 8, and the air suction pump 8 is located in the box Above the body 11, the air outlet end of the air suction pump 8 communicates with the box body 11 through the first connecting pipe 9, and the other end of the air suction pump 8 communicates with the crushing box 1 through the second connecting pipe 10, so The box body 11 is provided with activated carbon adsorption net layer 7, sponge net plate 6 and filter net plate 5 successively from left to right. The setting of the mesh plate 5, the suction pump 8 sucks the dust in the crushing box 1, the filter mesh plate 5 performs preliminary filtration of the dust, the sponge mesh plate 6 filters the dust again, and the activated carbon adsorption mesh layer 7 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com