A new type of waste mud mud-water separation material with high solid phase content and its preparation method

A waste mud and mud-water separation technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of waste mud mud-water separation efficiency and high solid phase waste mud solid phase separation. Low efficiency, no mention of high solid phase waste mud treatment and other issues, to achieve the effect of shortening the flocculation sedimentation time, strengthening the flocculation nucleation ability, and improving the efficiency of mud-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Application engineering: This product is applied to the waste mud (mainly composed of bentonite particles, fine sand particles and clay particles, etc.) produced by Hangzhou Metro Line 6, and the high-solid slurry is processed by mechanical centrifugal separation and stirring sedimentation. Phase content of waste mud slurry treatment.

[0022] Table 1 shows the composition of the new high-solid waste mud-water separation material, and see Table 2 for the application effect.

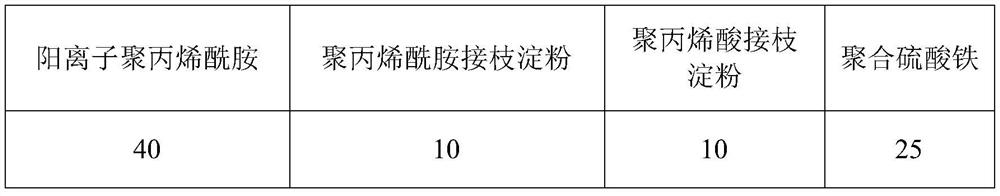

[0023] Table 1 Composition of new waste mud and water separation materials with high solid content (unit: part)

[0024]

[0025] Table 2 Field application effect of waste mud and water separation agent with high solid content

[0026]

Embodiment 2

[0028] Application engineering: This product is applied to the waste mud (main components are bentonite particles, fine sand particles, etc.) Mud agent treatment.

[0029] Table 3 shows the composition of the new high-solid content waste mud mud-water separation material, and see Table 4 for the application effect.

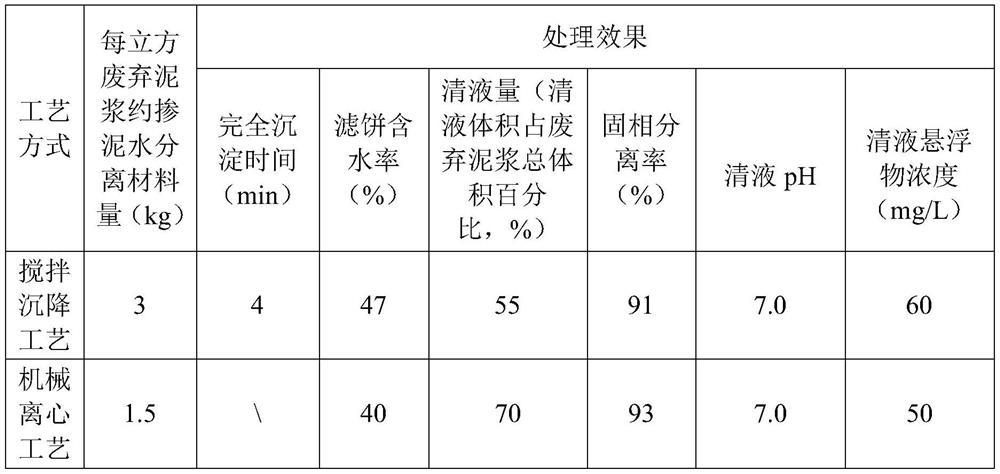

[0030] Table 3 Composition of new waste mud and water separation materials with high solid content (unit: part)

[0031]

[0032] Table 4 Field application effect of waste mud and water separation agent with high solid content

[0033]

Embodiment 3

[0035] Application engineering: This product has been applied to waste mud (mainly composed of bentonite particles, fine sand particles, etc.) Mud slurry treatment.

[0036] Table 5 shows the composition and composition of the new high solid content waste mud mud-water separation material, and see Table 6 for the application effect.

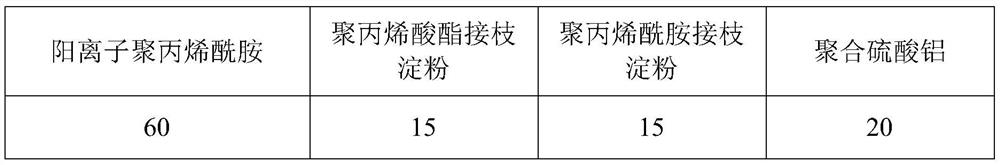

[0037] Table 5 Composition of new waste mud and water separation materials with high solid content (unit: part)

[0038] Cationic polyacrylamide polyacrylic acid grafted starch polyacrylamide grafted starch PAC 50 15 15 30

[0039] Table 6 Field application effect of waste mud and water separation agent with high solid content

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com