A chemical fiber titanium dioxide washing system and washing method

A washing method, titanium dioxide technology, applied in the direction of chemical instruments and methods, separation methods, titanium dioxide, etc., can solve the problems of not giving a water washing plan and reducing the method of permeation, so as to reduce the pressure on environmental protection and improve the product yield , the effect of increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

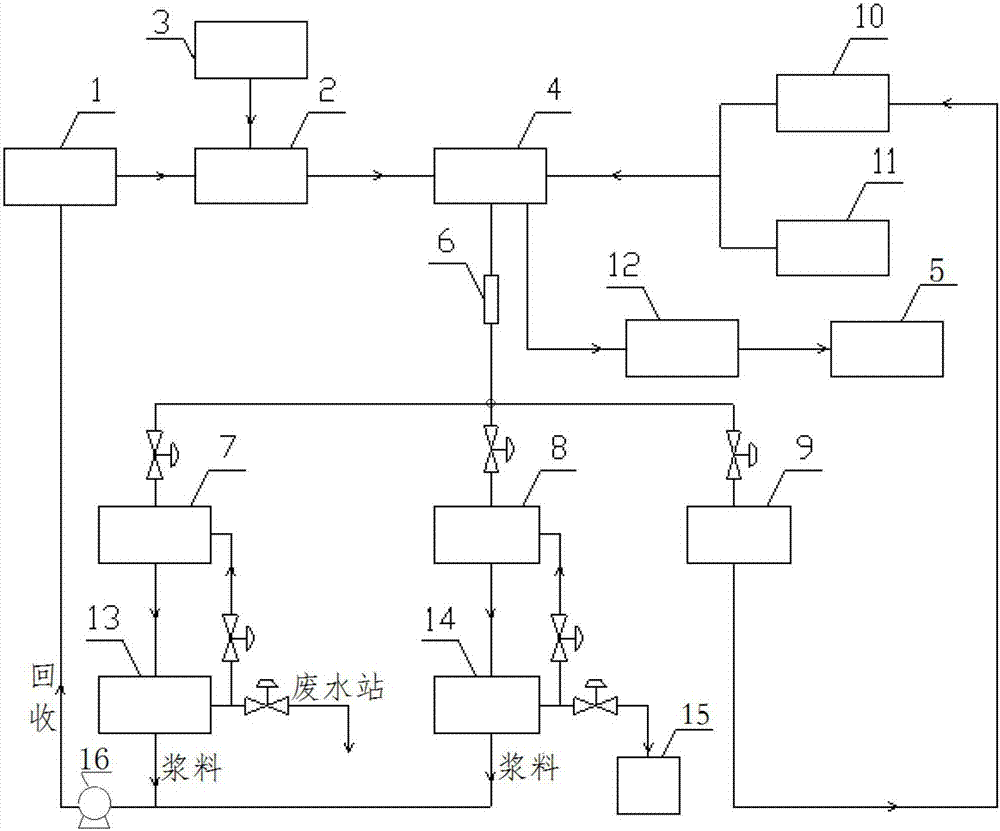

Method used

Image

Examples

Embodiment 1

[0048] The frame filter press 4 of the present embodiment is 150m 2 equipment, the volume of the first filter 13 and the second filter 14 is 200m 3 , after treatment, the slurry concentration of tank 1 is 290g / L, and the volume of modification tank 2 is 130m 3 , can be modified 100m each time 3 Slurry, (NH 4 ) 2 CO 3 The concentration is 100g / L.

[0049] Step 1. Transfer the finished surface treatment material into the treated tank 1, and control the pH at 6.5-7.

[0050] Step 2. Transfer the treated slurry to modification tank 2, feed 100m 3 , by TiO 2 The amount of mass content 0.5% is metered from ammonium salt metering tank 3 (NH 4 ) 2 CO 3 Solution 1.45m 3 , stirred for 30 minutes; then fed to the frame filter press 4 for 45 minutes, and the end pressure of the feed was 552kPa, showing that the feed volume was 21.5m 3 , The feed end pressure is generally controlled at 350-550kPa.

[0051] Step 3. Carry out forward washing and backwashing in sequence:

[0052...

Embodiment 2

[0060] The frame filter press 4 of the present embodiment is 75m 2 equipment, the volume of the first filter 13 and the second filter 14 is 200m 3 , after treatment, the slurry concentration of tank 1 is 273g / L, and the volume of modification tank 2 is 130m 3 , can be modified 100m each time 3 Slurry, (NH 4 ) 2 CO 3 The concentration is 100g / L.

[0061]Step 1. Transfer the finished surface treatment material into the treated tank 1, and control the pH at 6.8-8.0.

[0062] Step 2. Transfer the treated slurry to modification tank 2, feed 100m 3 , by TiO 2 The amount of mass content 1.0% is metered from ammonium salt metering tank 3 (NH 4 ) 2 CO 3 Solution 2.73m 3 , stirred for 30 minutes; then fed to the frame filter press 4 for 25 minutes, and the end pressure of the feed was 495kPa, showing that the feed volume was 11.8m 3 .

[0063] Step 3. Carry out forward washing and backwashing in sequence:

[0064] 1), open the solenoid valve valve of the high-salt liquid s...

Embodiment 3

[0072] The frame filter press 4 of the present embodiment is 150m 2 equipment, the volume of the first filter 13 and the second filter 14 is 200m 3 , after treatment, the slurry concentration of tank 1 is 283g / L, and the volume of modification tank 2 is 130m 3 , can be modified 100m each time 3 Slurry, (NH 4 ) 2 CO 3 The concentration is 100g / L.

[0073] Step 1. Transfer the finished surface treatment material into the treated tank 1, and control the pH at 6.8-8.5.

[0074] Step 2. Transfer the treated slurry to modification tank 2, feed 100m 3 , by TiO 2 The amount of mass content 1.0% is metered from ammonium salt metering tank 3 (NH 4 ) 2 CO 3 Solution 2.26m 3 , stirred for 30 minutes; then fed to the frame filter press 4 for 45 minutes, the end pressure of the feed was 534kPa, and the feed volume was 22.1m 3 .

[0075] Step 3. Carry out forward washing and backwashing in sequence:

[0076] 1), open the solenoid valve valve of the high-salt liquid sealing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com