Braking device for vehicle

a technology for braking devices and vehicles, applied in the direction of braking systems, etc., can solve the problem of not restricting cbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

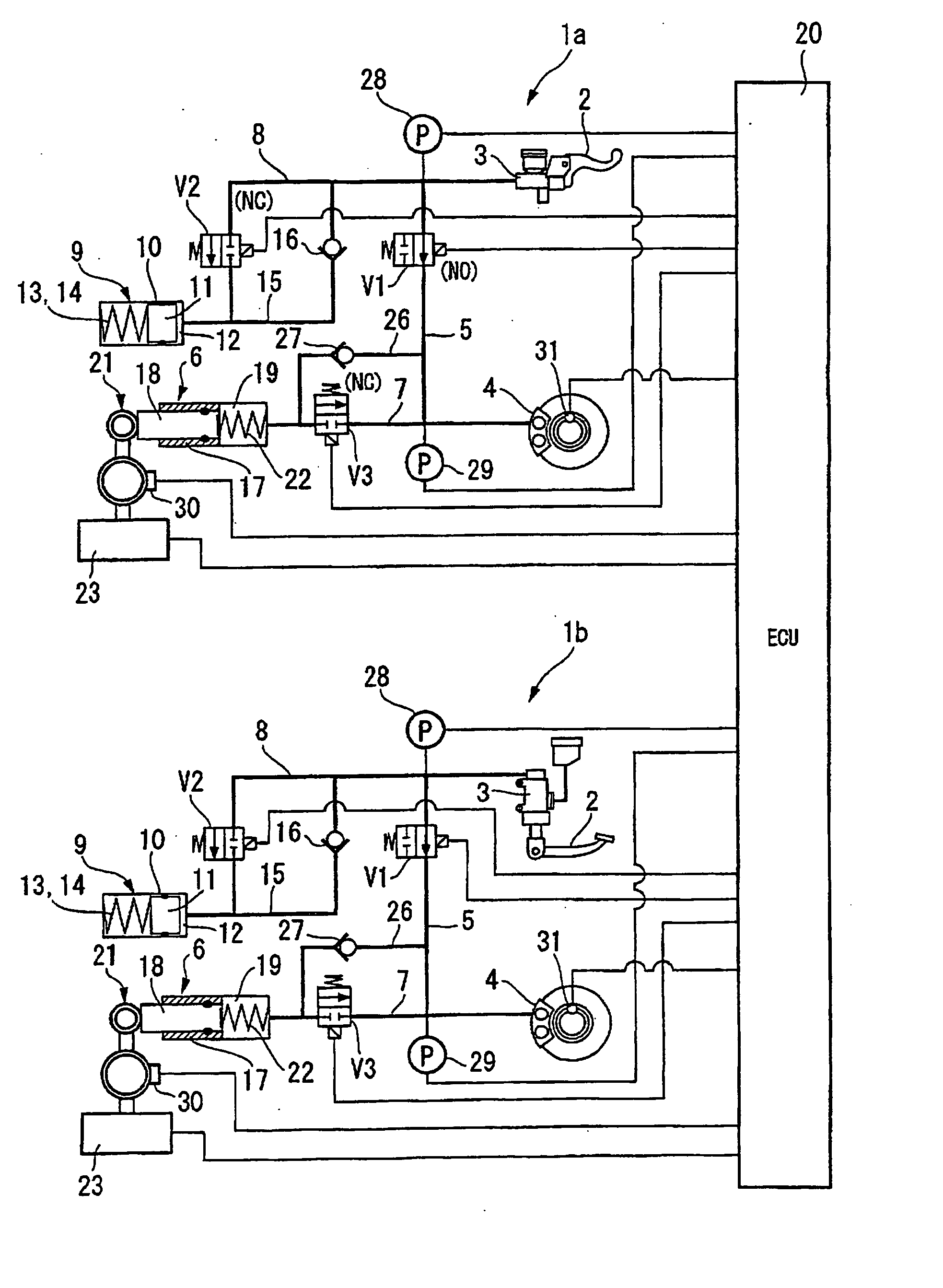

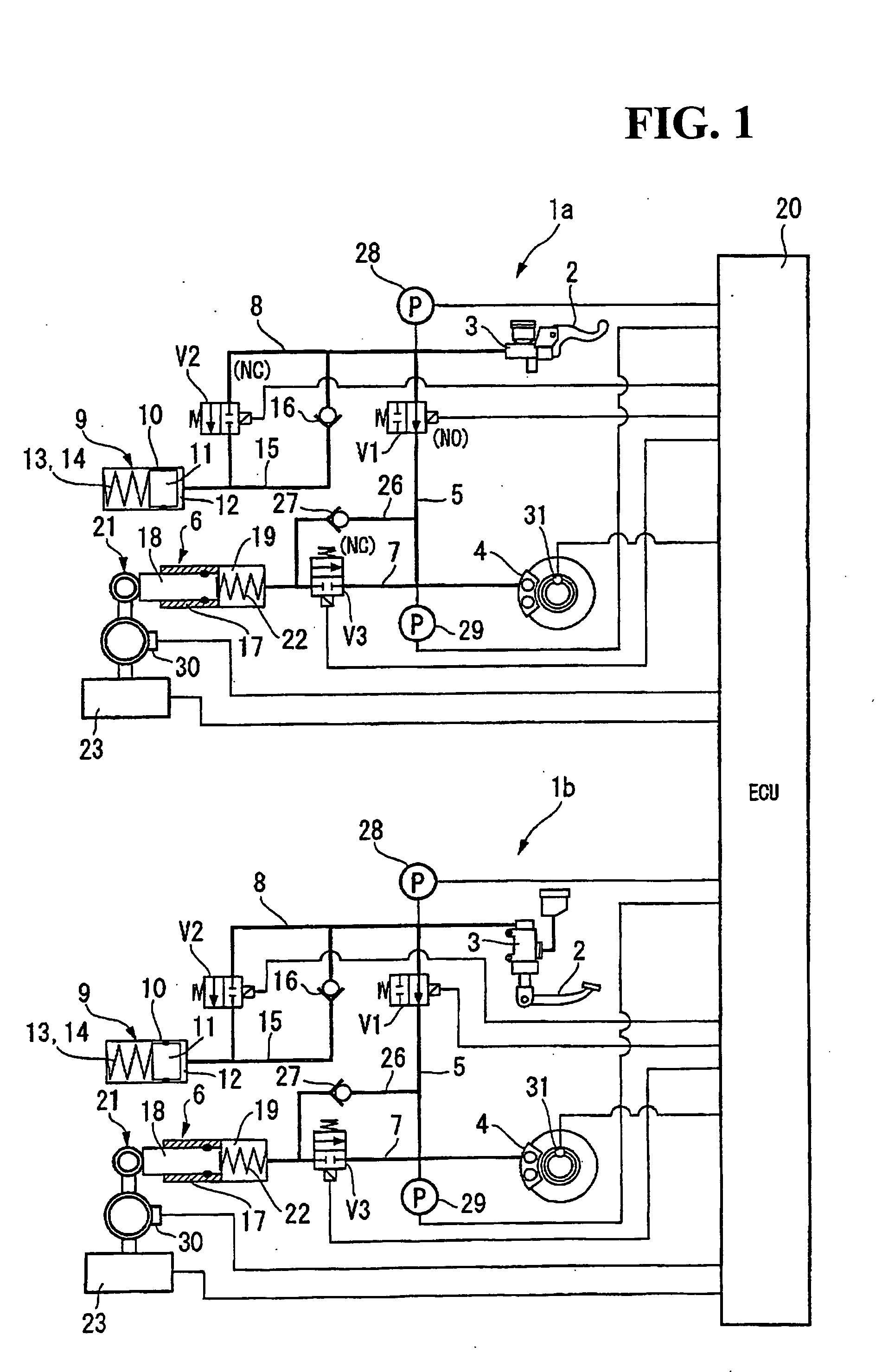

[0033]FIG. 1 shows a hydraulic circuit diagram of a braking device for a vehicle according to the present invention. This embodiment is the braking device according to the present invention as applied to a motorcycle. The braking device includes front and rear brake circuits 1a and 1b, which are independent of each other, and each of which is subject to control by a controller (ECU) 20.

[0034] In a case of this braking device, the front and rear brake circuits1a and 1b are configured to respectively use a brake lever and a brake pedal, which are brake operating sections 2 and 2, for their respective brake operations. Except for this respect, the basic configuration of the front brake circuit 1a is substantially identical to that of the rear brake circuit 1b. For this reason, the detailed descriptions will hereinbelow be given only for the rear brake circuit 1b. As for the front brake circuit 1a, the identical parts thereof as those of the rear brake circuit 1b are designated by the s...

second embodiment

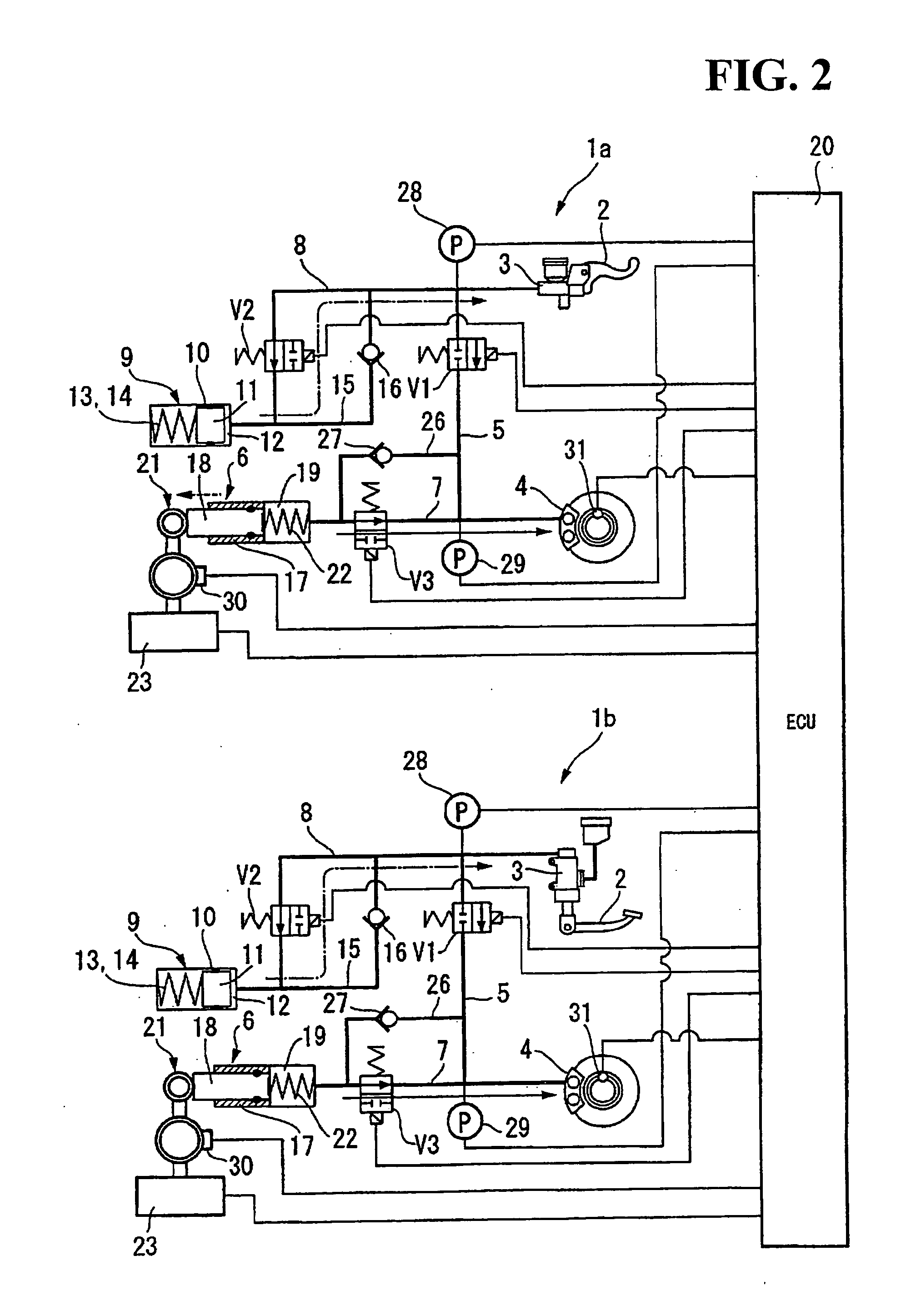

[0071] In the case of a second embodiment shown in FIG. 6, braking characteristics (hydraulic pressure characteristics) during the combined braking for the front wheel are varied depending on the resistance of the road surface being high or low. Accordingly, effective combined braking can always be achieved according to the conditions of the road surface.

[0072] In addition, during the normal driving of the vehicle, the braking device described above closes the first solenoid on-off valve V1, and opens the second and third solenoid on-off valves V2 and V3 as shown in FIG. 2. Thereby, the bi-wire system is used (by disconnecting the brake master cylinder 3 from the brake caliper assembly 4) for braking. As opposed to the foregoing, during the normal driving, the braking device may open the first solenoid on-off valve V1, and close the second and third solenoid on-off valves V2 and V3 as shown in FIG. 1 so as to exert a pressure in the brake master cylinder 3 directly on the brake cali...

third embodiment

[0075] Moreover, the braking device does not need currents for holding the solenoid on-off valves V1 to V3 during normal braking or when braking is not activated. Thus, the corresponding amount of further reduction in power consumption is made possible. This is because the normally-open type valve is used as the first solenoid on-off valve V1, and because the normally-closed type valves are used as the second and third solenoid on-off valves V2 and V3.

[0076] The present invention is not limited to the above embodiments, and various design changes may be made to the invention without departing from the spirit and scope of the invention. For example, the descriptions have been given above for the embodiment as applied to the motorcycle using the bi-wire system and the ABS. However, the present invention may also be applied to the motorcycle which does not use the bi-wire system or the ABS. Moreover, the descriptions have been given above for the braking device which starts the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com