Self-supporting nitrogen-doped metal catalyst and preparation method thereof

A metal catalyst and nitrogen doping technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high price and scarcity obstacles, and achieve simple equipment, increased active sites, high conductivity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

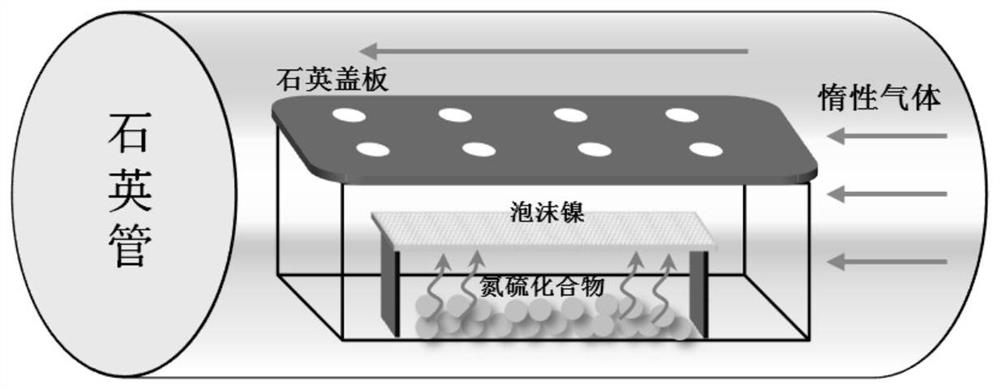

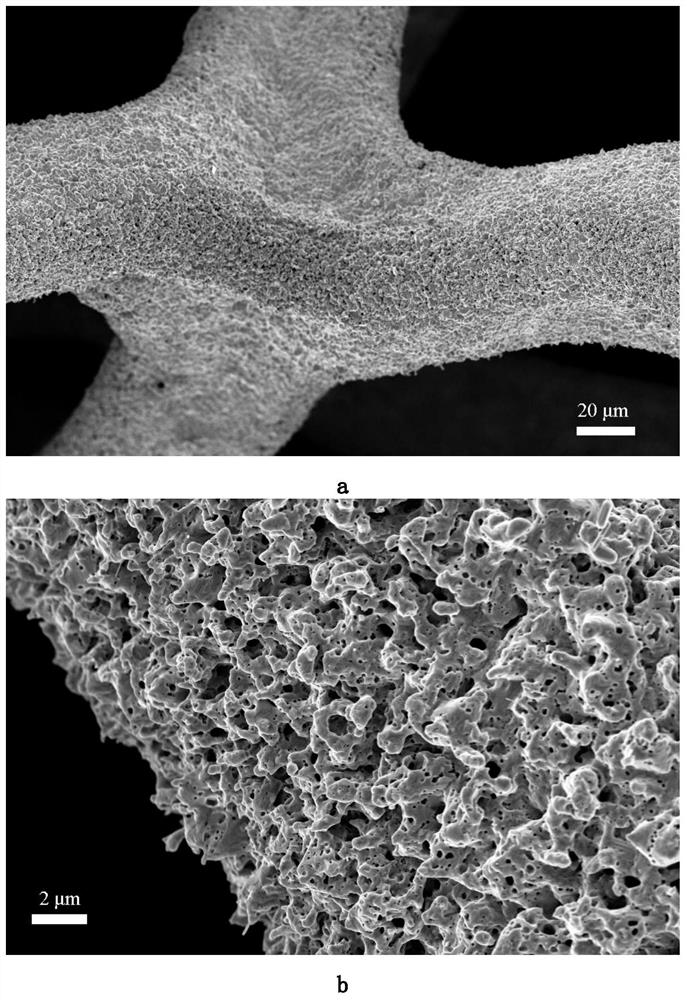

[0046] Use acetone, ethanol, and deionized water to ultrasonically clean foamed nickel for 30-60 minutes in order to remove surface oil and adsorbed impurities, then soak in 0.05mol / L HCl solution for 5 minutes, and then use deionized water to ultrasonically clean for 30-60 minutes , and then put it in a vacuum oven at 50-80°C for later use.

[0047]Take 100mg of the above-mentioned treated foamed nickel and put it on the porous quartz support in the porcelain boat, fill the bottom of the support with 600mg of fully ground thiourea powder, the distance between the two is 1cm, cover the upper part of the porcelain boat with a cover plate with holes and put it in Carry out calcination at 550°C in a tube furnace filled with an inert atmosphere, the heating rate is 10°C / min, slowly anneal after holding for 2 hours, take it out, the cooling rate is 5°C / min, and then put it into CS 2 Ultrasound in the solution for 20min, then soak in ethanol solution for ultrasonication for 2h, take...

Embodiment 2

[0056] According to the method described in embodiment 1, nickel foam is pretreated.

[0057] Take 100mg of treated foamed nickel and put it on the porous quartz support in the porcelain boat, fill the bottom of the support with 300mg of fully ground thiourea powder, the distance between the two is 2cm, cover the upper part of the porcelain boat with a perforated cover plate and put it in an inert Carry out calcination at 500°C in a tube furnace with an atmosphere, the heating rate is 10°C / min, after holding for 2 hours, cool down to 350°C for 1 hour, take it out, and then use it directly, avoiding the process of taking out and enriching sulfur.

[0058] After testing, the prepared sample has a catalytic activity comparable to that of the sample in Example 1.

Embodiment 3

[0060] According to the method described in embodiment 1, nickel foam is pretreated.

[0061] Take 100mg of processed nickel foam and put it on the porous quartz support in the porcelain boat, fill the bottom of the support with 300mg of fully ground methionine, the distance between the two is 2cm, cover the upper part of the porcelain boat with a perforated cover plate and put it in an inert Carry out calcination at 500°C in a tube furnace with an atmosphere, the heating rate is 10°C / min, slowly anneal after holding for 1 hour, take it out, the cooling rate is 5°C / min, put into CS 2 Ultrasound in the solution for 20min, then soak in ethanol solution for ultrasonication for 2h, take it out, put it in a vacuum drying oven, dry it at 60°C for 10h, and take it out.

[0062] After testing, the prepared sample has a catalytic activity comparable to that of the sample in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com