A Continuous Polymerization Reactor for the Production of Mesophase Carbon Microspheres

A technology of mesophase carbon microspheres and polymerization reactors, applied in chemical/physical/physical-chemical stationary reactors, inert gas generation, carbon preparation/purification, etc., can solve the problem of inability to operate continuously for a long time and high product cost , the inner wall of the kettle is coking and hanging on the wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

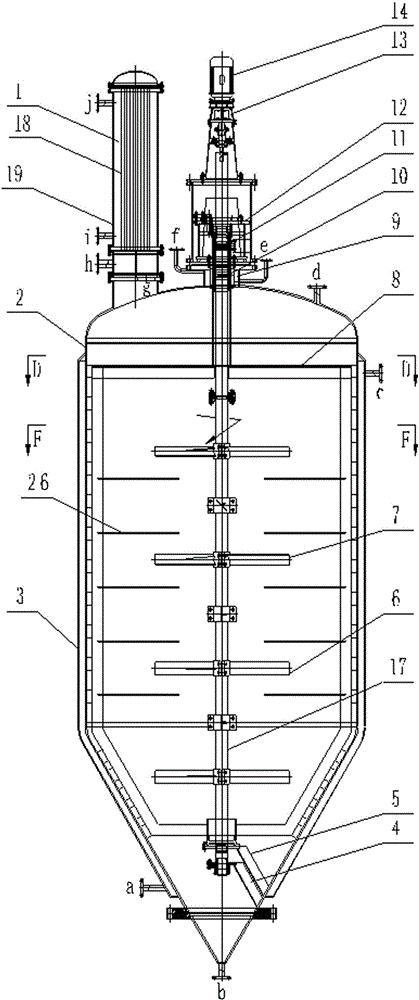

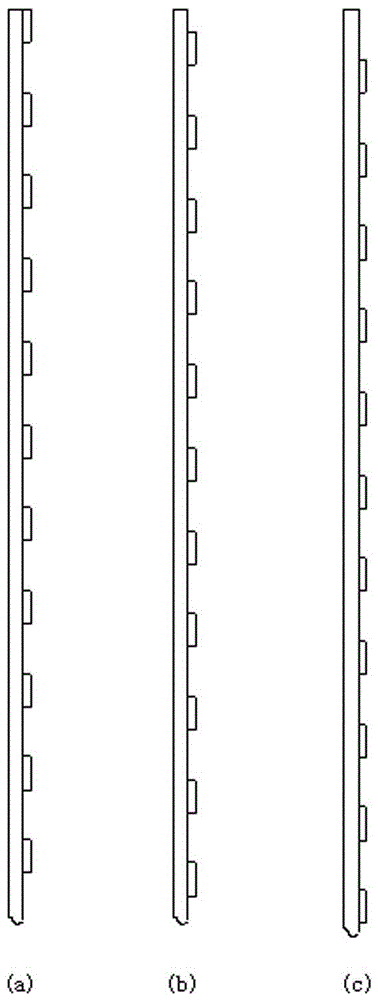

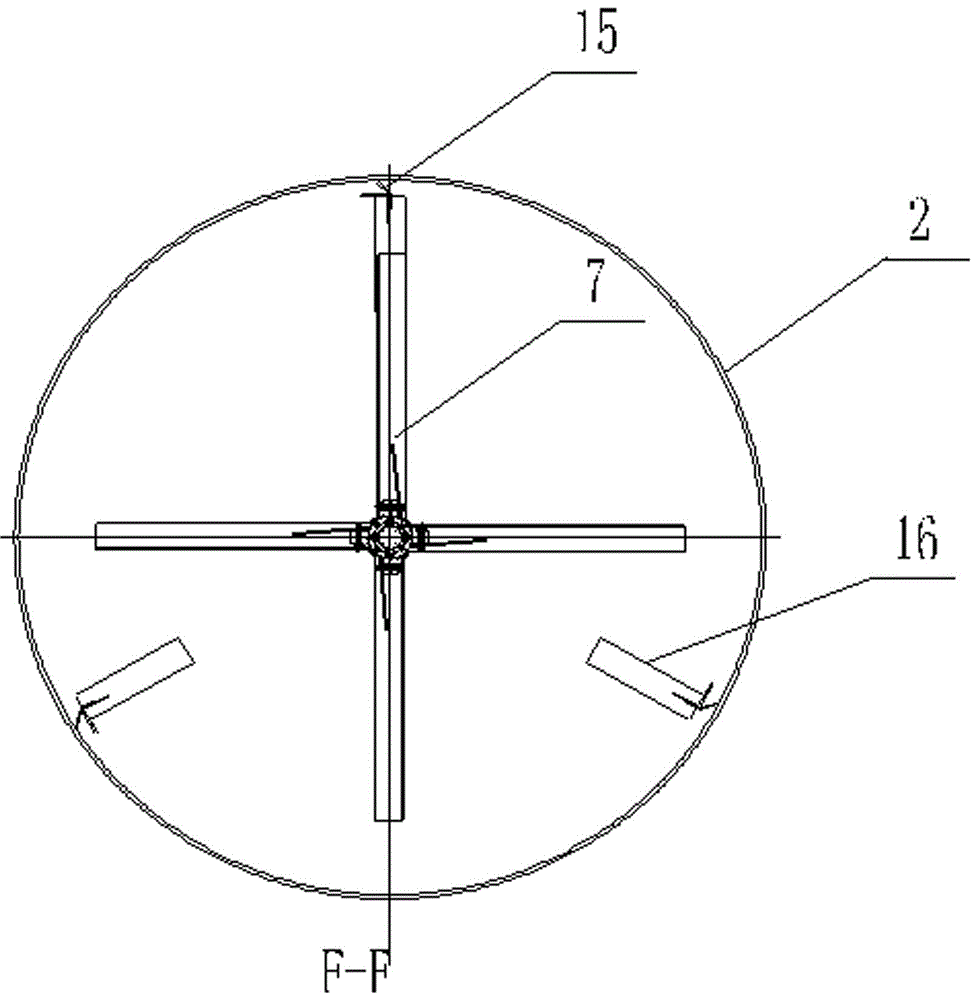

[0028] The continuous polymerization reactor structure for the production of mesophase carbon microspheres is as follows figure 1 , 2 As shown in and 4, it includes a shell 2, a quick warmer 1 arranged on the top of the shell, and a double stirring transmission device 12; the top of the shell 2 is provided with a nitrogen port d, the bottom is provided with a discharge port b, and a jacket is provided on the outside 3. The housing 2 is equipped with a frame-type agitator 8 and a split-flow main agitator, which are assembled together with the double agitation transmission device 12; the rapid temperature riser 1 is a tubular heat exchanger, and the bottom There is a material inlet h and a material outlet g, and the material outlet g communicates with the inside of the shell 1; the outer side of the frame mixer 8 is fixed with a scraper group in contact with the inner wall of the shell 2, and the inner side is fixed with multi-layer horizontal baffles 16 The paddle group of the...

Embodiment 2

[0043] The structure of the continuous polymerization reactor used to produce mesophase carbon microspheres is the same as in Example 1, the difference is that:

[0044] The outer diameter of the tubes of the tube-and-tube heat exchanger is 19mm, and the number of tubes is 30;

[0045] Method is with embodiment 1, and difference is:

[0046] The material to be polymerized at a temperature of 350 ° C is passed into the material inlet of the rapid temperature increaser, and enters the column tube from the bottom of the rapid temperature increaser, and exchanges heat with the molten salt entering the rapid temperature increaser, within 5 seconds. The material to be polymerized is preheated to 420°C, and then enters the shell from the material outlet; the material to be polymerized is medium-temperature coal tar pitch;

[0047] Turn on the double stirring transmission device, so that the frame stirrer and the split-type main stirrer rotate in reverse, and the rotation speed is re...

Embodiment 3

[0049] The structure of the continuous polymerization reactor used to produce mesophase carbon microspheres is the same as in Example 1, the difference is that:

[0050] The outer diameter of the tubes of the tube-and-tube heat exchanger is 19mm, and the number of tubes is 80;

[0051] Method is with embodiment 1, and difference is:

[0052] The material to be polymerized at a temperature of 380°C is passed into the material inlet of the rapid temperature increaser, and enters the column tube from the bottom of the rapid temperature increaser, and exchanges heat with the molten salt entering the rapid temperature increaser, within 1 second. The material to be polymerized is preheated to 460°C, and then enters the shell from the material outlet; the material to be polymerized is medium-temperature coal tar pitch;

[0053] Turn on the double stirring transmission device, so that the frame stirrer and the split-type main stirrer rotate in reverse, and the rotation speed is 70r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com