Patents

Literature

41results about How to "Grow up fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

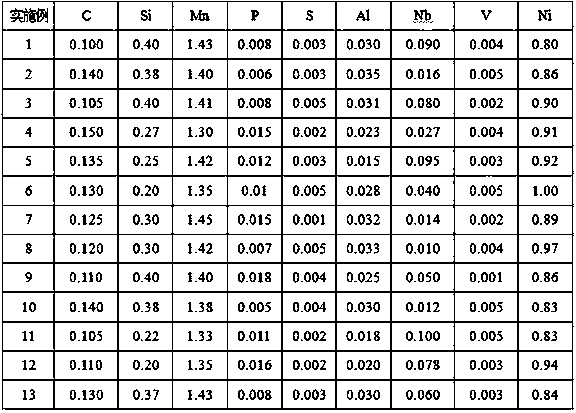

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Ecological freshwater farming method for penaeus vannamei boone

ActiveCN104137797AConducive to survivalConvenient for predationClimate change adaptationPisciculture and aquariaFresh water organismEconomic benefits

The invention relates to the field of freshwater farming of penaeus vannamei boone and discloses an ecological freshwater farming method for the penaeus vannamei boone. The method mainly comprises the steps of performing a pond, cleaning the pond, planting submerged plants, injecting water, cultivating water fleas, desalinating fry, performing fry stocking, performing reasonable feeding and alternately catching the penaeus vannamei boone out of the pond. Compared with the prior art, chemicals are basically not used in the whole farming process, water is not changed in quantity to guarantee that the farmed penaeus vannamei boone is high in survival rate, high in disease resistance and growth speed and more delicious in taste, and therefore high economic benefits can be achieved.

Owner:防城港市海鑫鑫水产科技有限公司

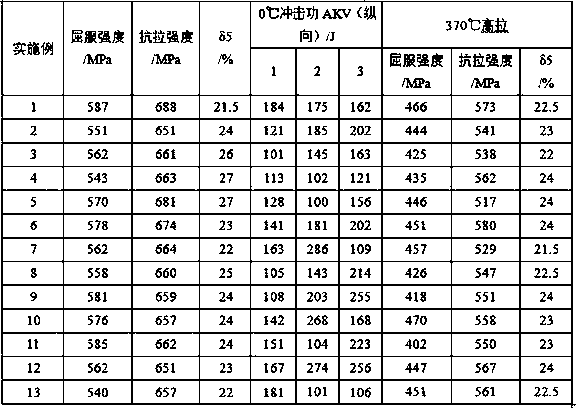

High-strength low-crack sensitive slab and manufacture method thereof

The invention relates to a high-strength low-crack sensitive slab and a manufacture method thereof. The slab is prepared from the following chemical components in percentage by weight: 0.06-0.09 percent of C, 0.1-0.3 percent of Si, 1.35-1.55 percent of Mn, 0.02-0.04 percent of Nb, 0.02-0.04 percent of V, 0.01-0.02 percent of Ti, 0.15-0.25 percent of Ni, 0.1-0.2 percent of Cr, 0.15-0.25 percent of Cu, 0.02-0.04 percent of Al, not more than 0.006 percent of N, not more than 0.016 percent of P, less than 0.004 percent of S and the balance of Fe and impurities. The manufacture method of the high-strength low-crack sensitive slab comprises the following sequential steps of: heating a casting blank; descaling; controlling rolling; controlling cooling, straightening, and the like. The slab of the invention can reach the thickness of 80 mm, and the yield strength over 420 MPa and has excellent comprehensive mechanical performance, simple and convenient production process and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for recovering iron in low-iron Bayer process red mud

The invention discloses a method for recovering iron in low-iron Bayer process red mud. The method comprises the steps that de-alkalization treatment is conducted on the Bayer process red mud by adopting calcium oxide to mix the de-alkalization red mud with activated carbon; the mixture is mixed with a binding agent to be pressed into tablets; the tablets are placed into a graphite crucible, high-temperature treatment is conducted under the condition that argon is introduced all the time in a vacuum electromagnetic sensing furnace, the tablets are cooled down along with the furnace, grinding is conducted, and iron slags are separated through magnetic sorting. The method has the advantages that the recovery rate and grade of iron are higher than 80%, the processed Bayer red mud can be usedfor producing building materials, recovered iron is conformed to demands of industrial steel melting, the problem of excessively high red mud accumulation amount is effectively solved, and an excellent guiding meaning is achieved on the recovery of iron in the low-iron Bayer process red mud.

Owner:KUNMING UNIV OF SCI & TECH

Method for quickly depositing lithium carbonate from lithium bicarbonate solution

ActiveCN101182012AIncrease sedimentation rateHigh recovery rateCarbonate preparationHydrogenOrganic solvent

The invention provides a method for rapidly precipitating lithium carbonate from lithium bicarbonate solution. The method adopts a heatable negative pressure device, uses water-soluble organic solvents such as ethanol, propanol, etc., controls the temperature at 80-180°C, and stirs under the condition of negative pressure in the container at 0.01-0.10MPa to carry out isovolumic reaction, so that bicarbonate Lithium decomposes, precipitates lithium carbonate, and the precipitated mother liquor can be recycled and reused. The present invention not only overcomes the problems of "wall-hanging effect" of precipitation and "concentration entrainment effect" of water-soluble impurity ions in the ordinary evaporation and precipitation process, but also accelerates the precipitation rate: the precipitation process only takes about 20 minutes, which is faster than the ordinary evaporation and precipitation method. 2 to 3 times; the precipitation rate of lithium is improved: the single precipitation rate of lithium carbonate reaches more than 87%, and the total lithium recovery rate reaches more than 94%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Feed for promoting growth of calves and preparation method thereof

InactiveCN104472892APromote digestion and absorptionImprove conversion rateAnimal feeding stuffAnimal scienceLagenaria

A feed for promoting growth of calves and a preparation method thereof are disclosed. The feed comprises the following raw materials, by weight, 300-400 parts of soyabean protein powder, 200-300 parts of corn bran, 200-300 parts of barley flour, 6-8 parts of soy sauce, 3-4 parts of mature vinegar, 2-3 parts of star aniseed powder, 2-3 parts of chilli sauce, 30-40 parts of pork jelly, 20-30 parts of fish gel, 70-80 parts of coagulated pig blood, 40-50 parts of coagulated duck blood, 20-30 parts of green pepper, 10-20 parts of onion, 10-15 parts of cottonseed oil, 50-60 parts of lagenaria siceria powder, 20-40 parts of mangosteen powder, 3-4 parts of Ligusticum wallichii, 2-3 parts of white peony root, 2-3 parts of Poria cocos, 1-2 parts of cortex lycii, 8-15 parts of coix seed oil, 5-10 parts of aloe freeze-dried powder, 3-5 parts of white carbon black, 50-60 parts of zoysia japonica, 40-50 parts of zoysia matrella, 20-30 parts of Cucurbita pepo L, 10-20 parts of spearmint, 5-10 parts of cypress leaf, 2-4 parts of gynostemma pentaphylla powder, 30-60 parts of rice bran, 20-30 parts of a phagostimulant and a proper amount of water.

Owner:合肥桂和农牧渔发展有限公司

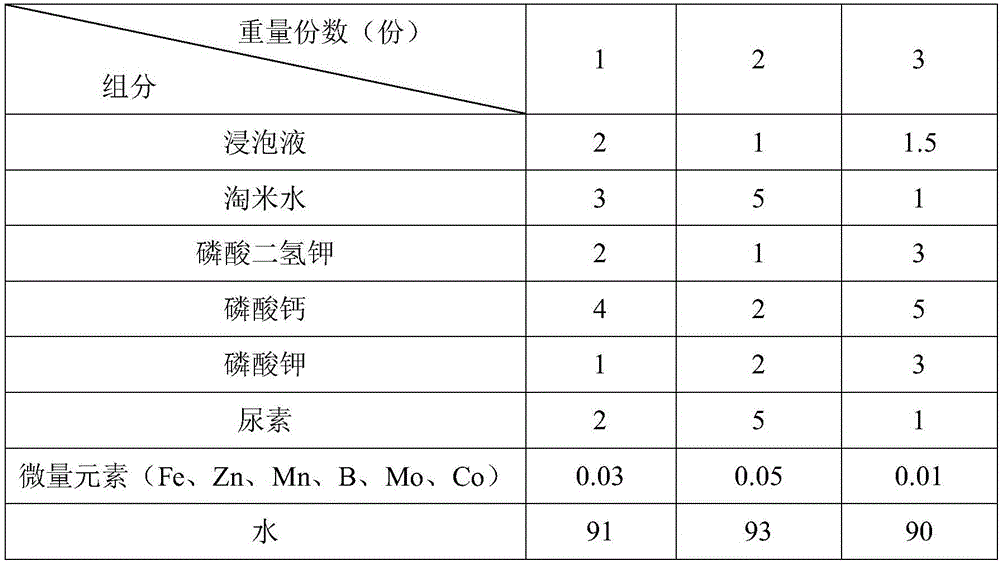

Horticultural plant cultivation method

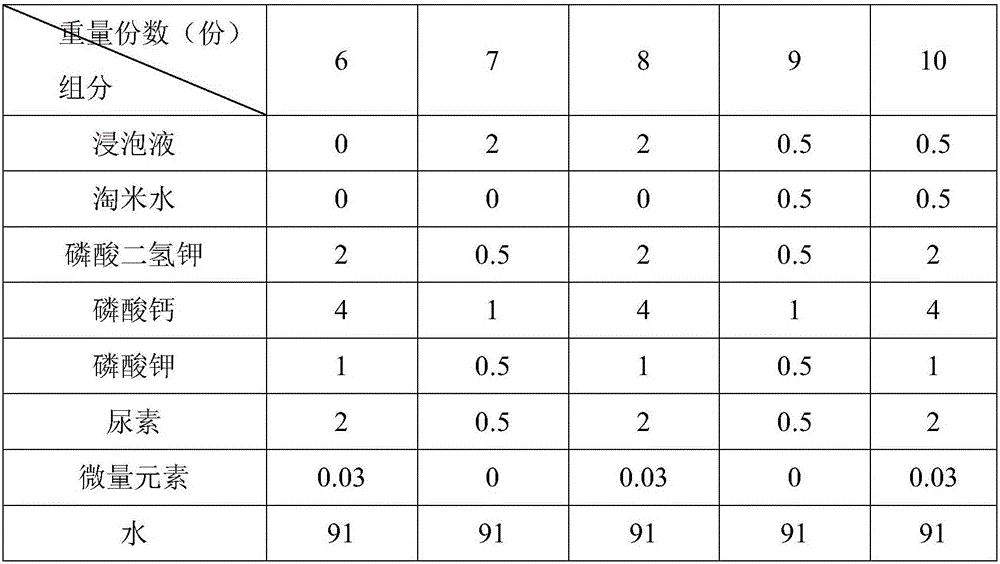

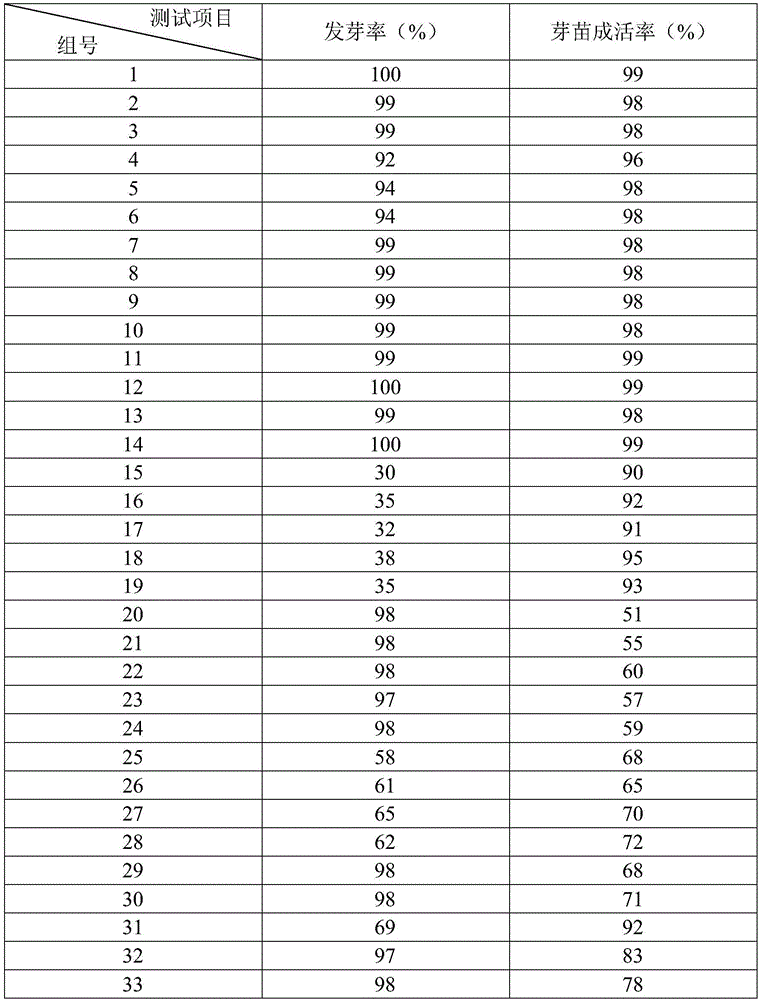

InactiveCN106718606APromote germinationGrow up fastBiocideBioloigcal waste fertilisersWater bathsRoot growth

The invention discloses a horticultural plant cultivation method. The horticultural plant cultivation method includes the steps of firstly, selecting seeds, subjecting the seeds to primary ultrasonic wave treatment and removing impurities from the treated seeds; secondly, stirring the seeds in a thermostat water bath at 70-80 DEG C and subjecting the stirred seeds to secondary ultrasonic wave treatment; thirdly, treating the seeds obtained in the second step by first bactericide; fourthly, immersing the seeds obtained in the third step in a clean container, soaking at 35-45 DEG C to obtain soaking liquid, and subjecting the soaked seeds to tertiary ultrasonic wave treatment; fifthly, treating holes by second bactericide, sowing, earthing up and shading; sixthly, diluting the soaking liquid, watering, earthing up, forming bud seedlings within 6-8 days and lighting; seventhly, watering the bud seedlings with an appropriate amount of nutrient solution, and transplanting after the bud seedlings develop into saplings within 5-7 days; eighthly, treating tree pits by third bactericide, applying root growth-promoting liquid on the inner walls of the tree pits and the roots of the saplings, transplanting the saplings into the tree pits, earthing up and watering the saplings with the nutrient solution daily.

Owner:杭州花泽园艺工程有限公司

Anthurium planting method

InactiveCN104488540AShorten the growth cycleImprove product qualityPlant cultivationCultivating equipmentsGreenhouseAnthurium superbum

The invention discloses an anthurium planting method. The method includes the following steps that (1) cutting propagation anthurium daughter plants are planted in a greenhouse; (2) all grown-out flower buds of anthurium are picked within 2-8 growing months of the anthurium; (3) new leaves of lower portions of stems of the anthurium are picked within 2-8 growing months of the anthurium. According to the anthurium planting method, the flower buds and the new leaves of the lower portions of the stems are picked within 2-8 growing months of the anthurium, old leaves of the anthurium can absorb more nutrients, the old leaves of the anthurium can rapidly grow to be enlarged and thickened, the root system of the anthurium is strong, the nutrient daily intake can be rapidly increased, unnecessary nutrient waste can be avoided, the anthurium growing period is shortened, and whole product qualities of the anthurium are improved.

Owner:SICHUAN DECHANG TUOXIN CITY GARDEN GREENING ENG CO LTD

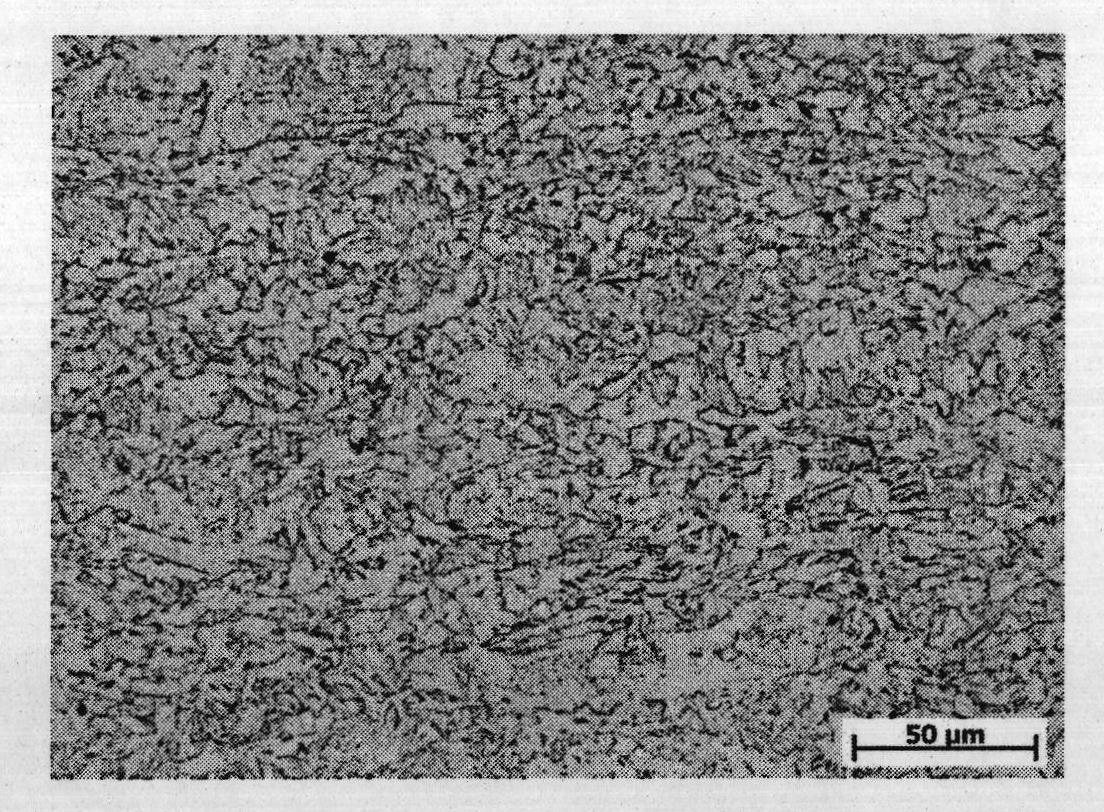

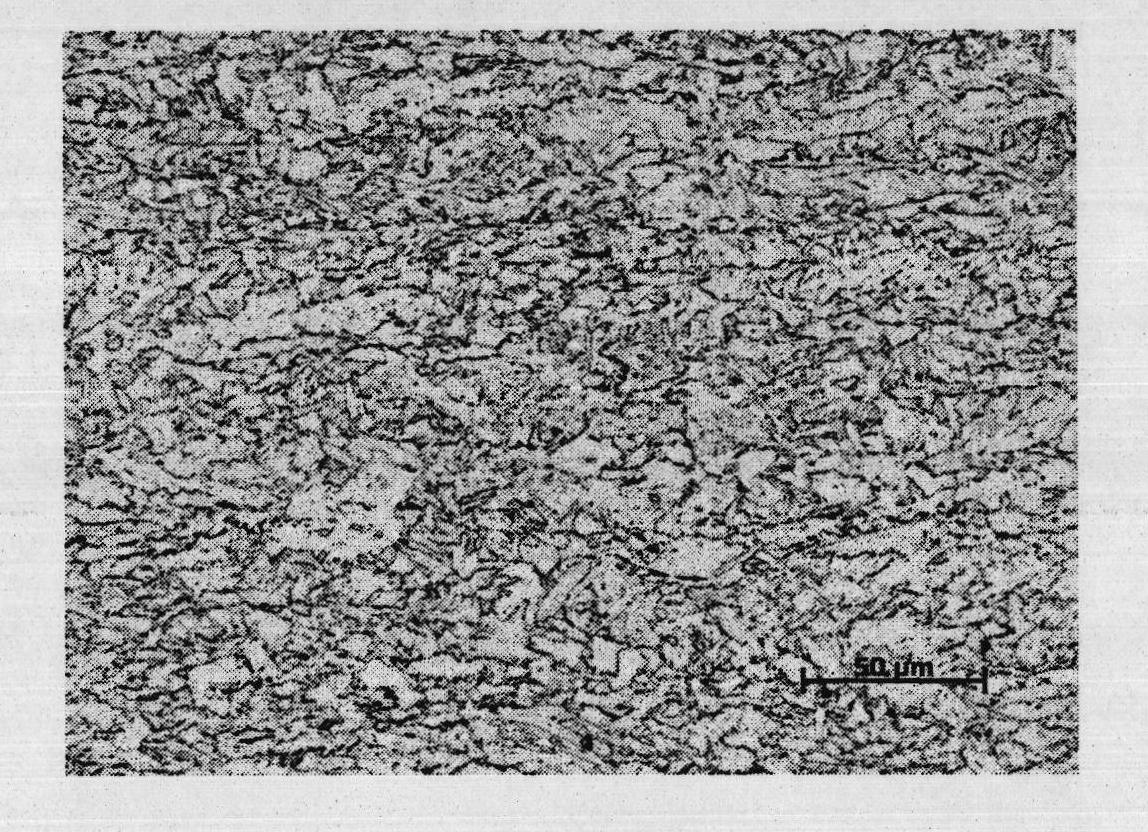

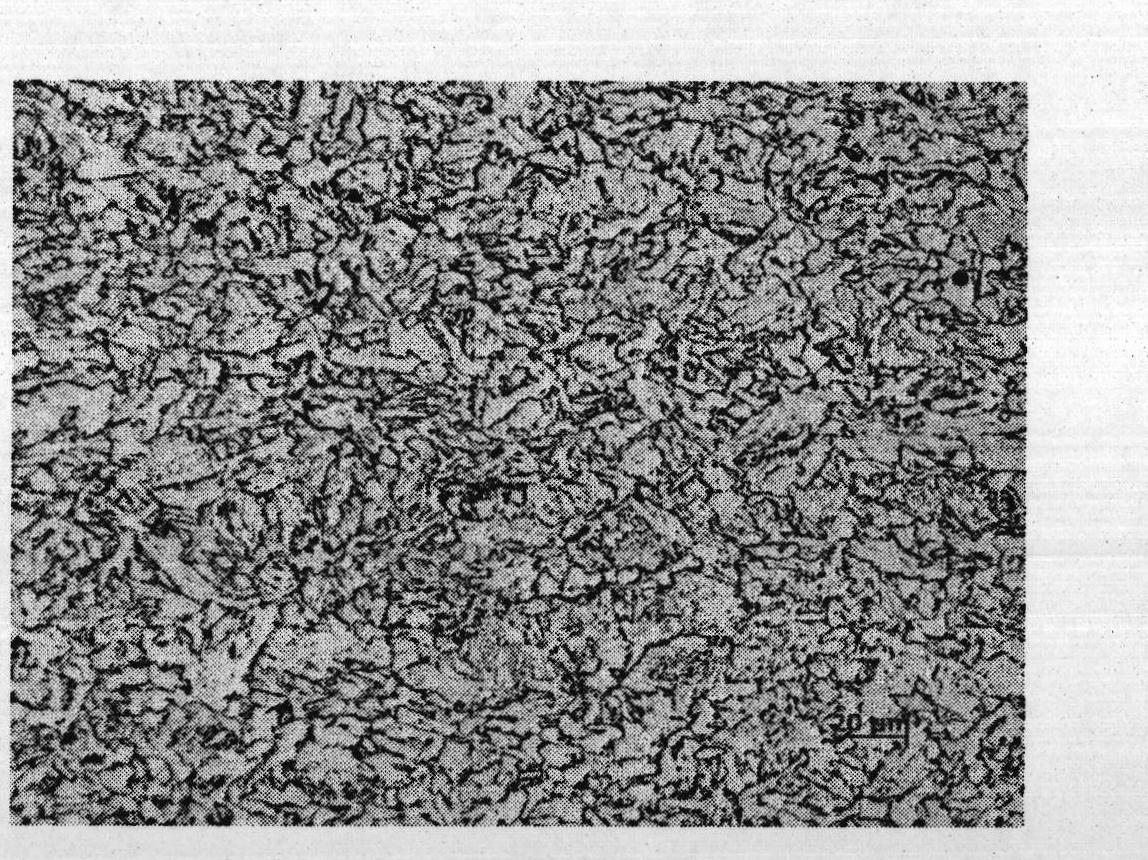

Production method for big-thickness ultrawide DIWA353 steel plates

InactiveCN110499458AImprove low temperature toughnessGuaranteed StrengthSheet steelTreatments procedures

The invention discloses a production method for big-thickness ultrawide DIWA353 steel plates, and belongs to the technical field of metallurgy. The production method comprises the procedures of smelting, casting, heating, rolling, water cooling and heat treatment. The smelting procedure comprises electric furnace initial smelting, LF furnace refining and VD furnace vacuum treatment; the heat treatment procedure adopts normalization and tempering treatment processes; the normalization temperature is 950+-10 DEG C; the heating time is 4.5-5 h; the insulation time is 0.8-1 min / mm; the furnace iscooled to 910+-10 DEG C; the insulation time is 1.2-1.5 min / mm; the water cooling is performed by 6-8 min after normalization; and the red returning temperature of steel plates is not higher than 600DEG C. The produced steel plates are higher in purity, uniform in component, compact in internal, smooth in surface, free of recess and excellent in mechanical performance, and can be used for manufacturing high-pressure boiler drums, nuclear energy containers and other high-pressure resisting containers.

Owner:WUYANG IRON & STEEL

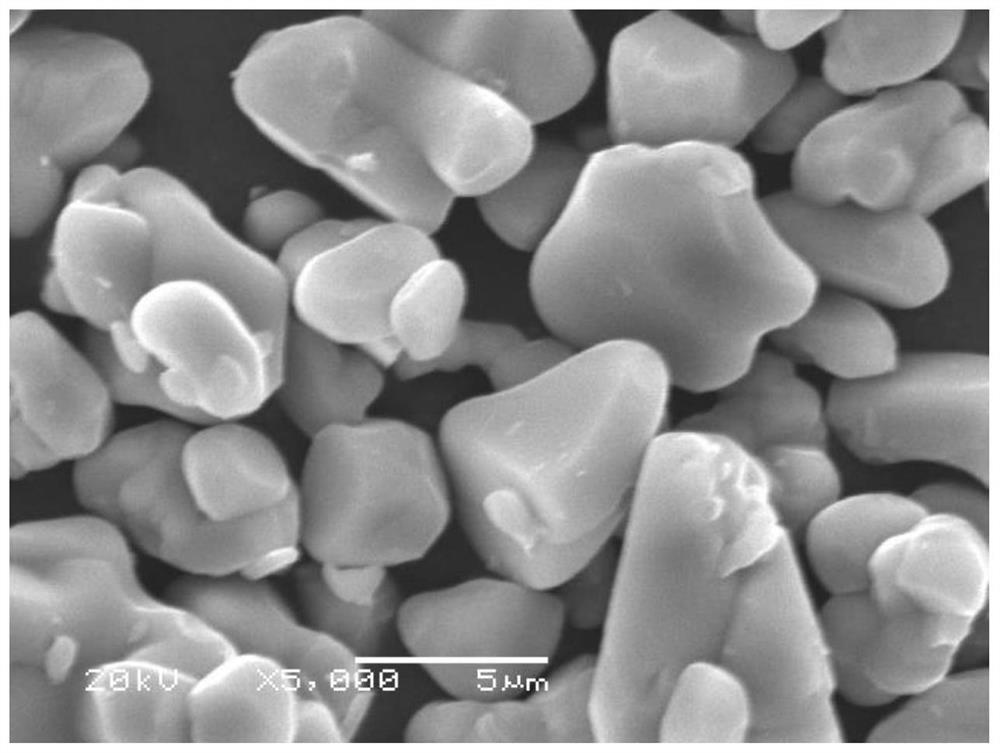

Al2O3-SiC-C brick containing reclaimed materials and preparation method of Al2O3-SiC-C brick

InactiveCN111253166AImprove refractory materialsIncrease the service life of the furnaceThermal dilatationBrick

The invention discloses an Al2O3-SiC-C brick containing reclaimed materials, belonging to the field of refractory materials. The Al2O3-SiC-C brick containing reclaimed materials comprises the following components by weight: 20-30 parts of reclaimed material particles, 30 to 40 parts of high-alumina bauxite particles, 10 to 20 parts of corundum particles, 10 to 20 parts of fine corundum powder, 5-15 parts of fine silicon carbide powder, 5-15 parts of crystalline flake graphite, 0-5 parts of an additive, and 2-6 parts of a binding agent. The Al2O3-SiC-C brick has the advantages of favorable slagerosion resistance, favorable molten iron scouring resistance, high high-temperature breaking strength, excellent thermal shock resistance, stable high-temperature thermal expansion coefficient and stable residual expansion rate, and can prolong the service life of a ladle when used as the working lining of the ladle.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

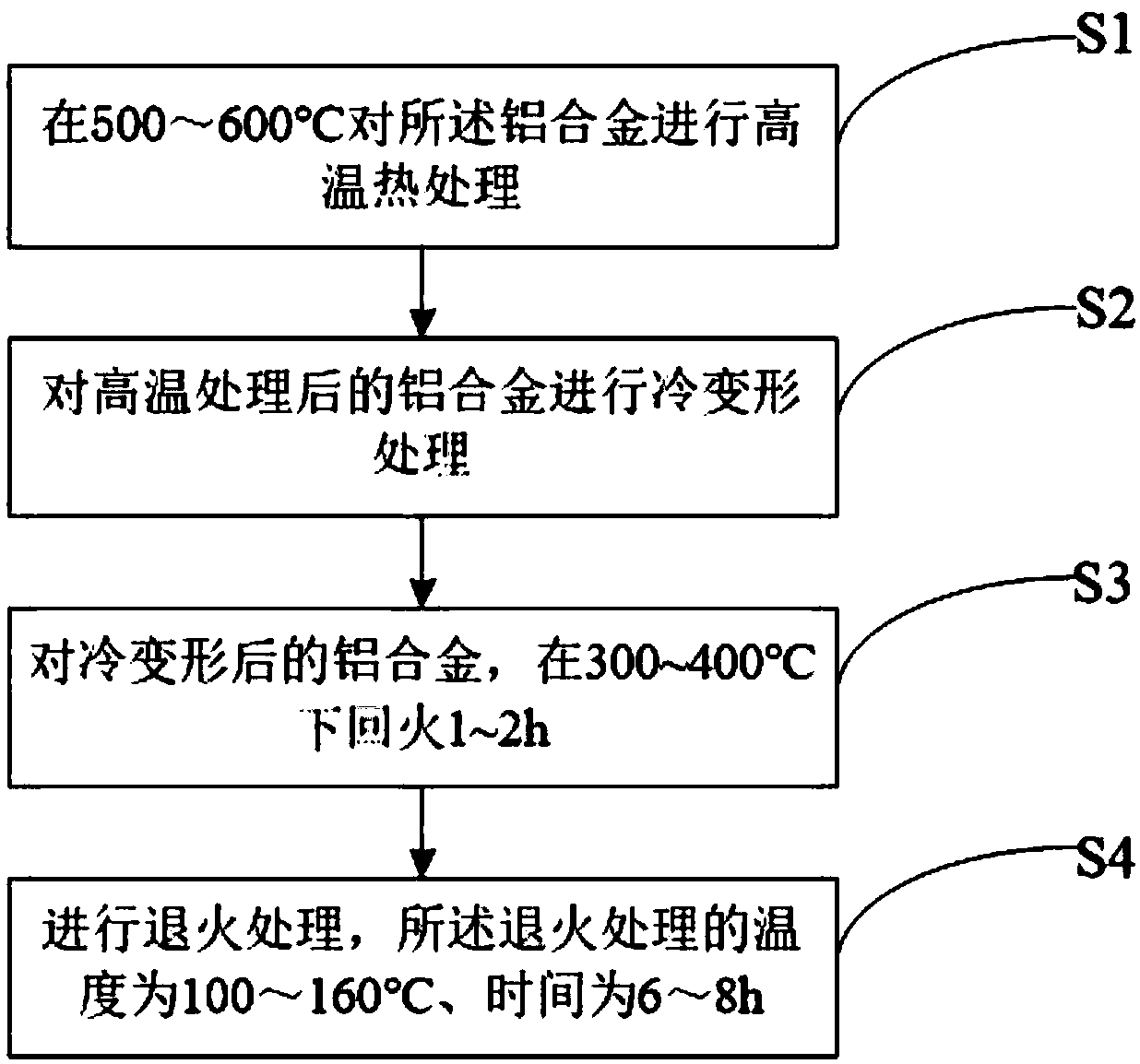

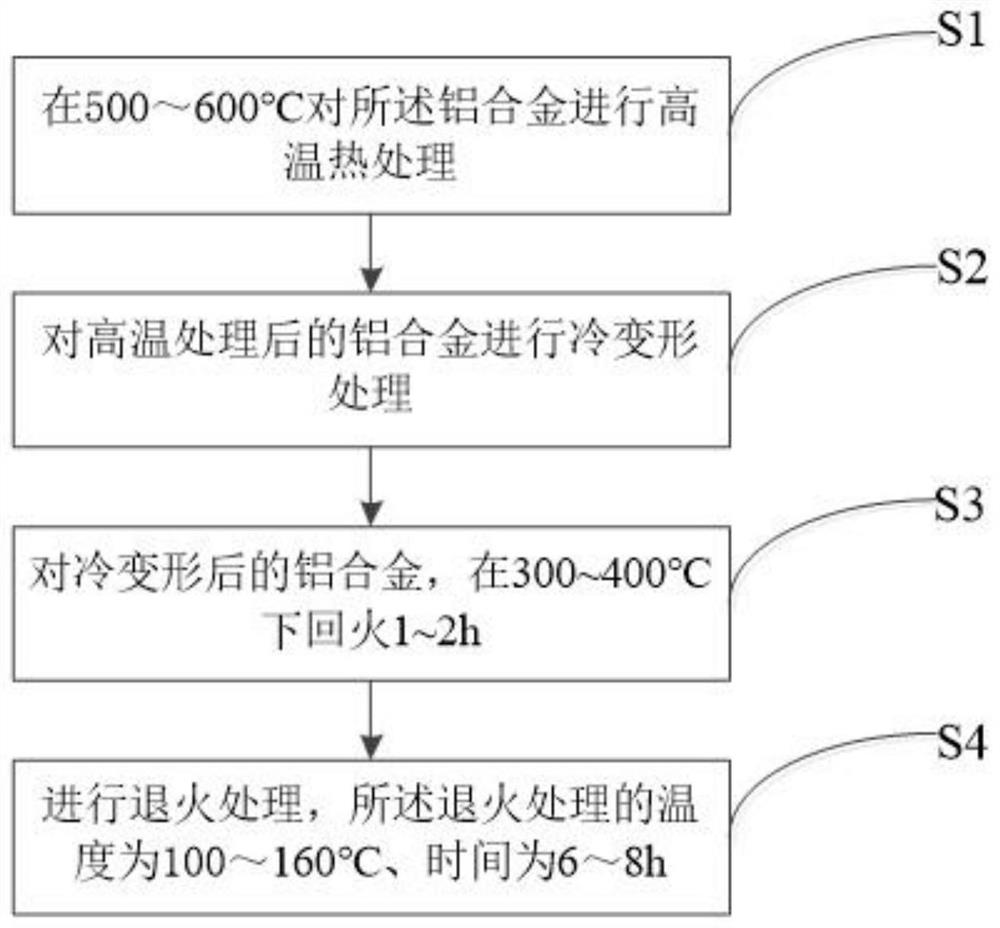

Aluminum alloy and heat treatment method thereof

The invention discloses heat treatment method of an aluminum alloy. The aluminum alloy comprises, by mass, 8%-10% of metal fibers, 5.5%-7.2% of Mg, 1.0%-2.5% of Zn, 0.8%-1.8% of Cu, 0.08%-0.18% of Sc,0.08%-0.18% of Zr, 0.12%-0.22% of Y, 0.02%-0.07% of Si, 0.02%-0.07% of Mn, 0.01%-0.03% of Er, 0.01%-0.03% of Ce, no more than 0.15% of impurities, and the balance Al. The heat treatment method comprises the steps that S1, high-temperature heat treatment is conducted on the aluminum alloy at the temperature of 500-600 DEG C, and after high-temperature heat treatment, quenching is conducted on thealuminum alloy with PAG quenching liquid, so that the aluminum alloy subjected to high-temperature treatment is obtained, wherein the content of PAG polymers in the PAG quenching liquid is 15-60 wt%,the temperature of the PAG quenching liquid is 40-80 DEG C, and the stirring speed of the PAG quenching liquid is 100-200 r / s; S2, cold-deformation treatment is conducted on the aluminum alloy subjected to high-temperature treatment, so that the aluminum alloy subjected to cold deformation is obtained; S3, the aluminum alloy subjected to cold deformation is tempered at the temperature of 300-400 DEG C for 1-2 h; and S4, afterwards, annealing treatment is conducted on the aluminum alloy at the temperature of 100-160 DEG C for 6-8 h, and thus, the strength of the aluminum alloy is improved. Theinvention further provides the aluminum alloy prepared through the heat treatment method.

Owner:益阳仪纬科技有限公司

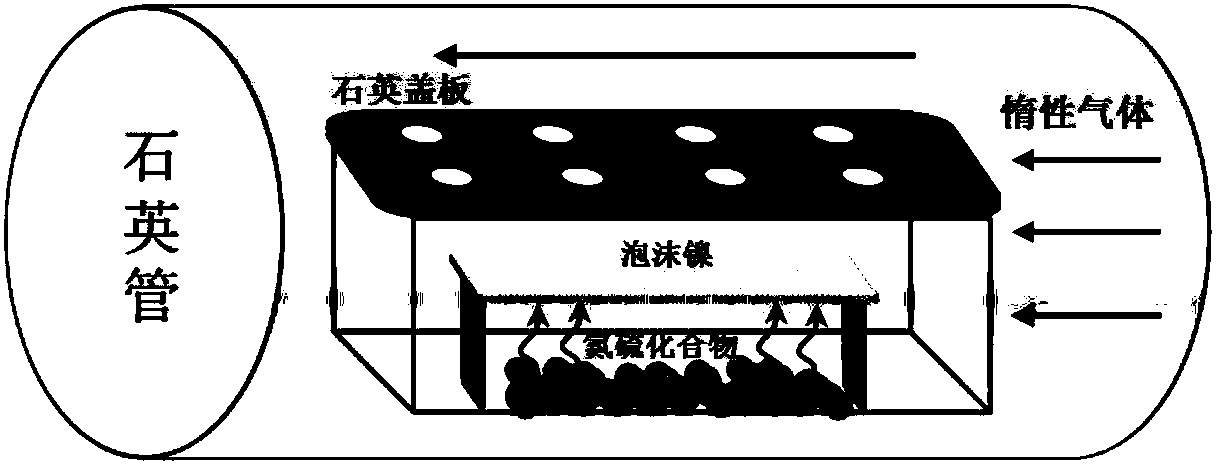

Self-supporting nitrogen-doped metal catalyst preparation method

The invention provides a self-supporting nitrogen-doped metal catalyst preparation method, which comprises: sequentially placing a ball-milled nitrogen sulfur compound, a quartz porous mesh frame andfoamed nickel in a high temperature porcelain boat from bottom to top, and covering the high temperature porcelain boat by using a porous quartz cover plate; and placing the high temperature porcelainboat in a quartz tube, calcining in an inert atmosphere, and carrying out desulfurization treatment on the product to obtain the self-supporting nitrogen-doped metal catalyst. According to the present invention, the prepared self-supporting nitrogen-doped metal catalyst has high water electrolysis efficiency, and can simultaneously perform OER and HER reactions, wherein the coupling reaction of the two reactions has the synergistic effect so as to improve the catalytic efficiency of total hydrolysis.

Owner:UNIV OF SCI & TECH OF CHINA

Efficient cold-rolled non-oriented electrical steel produced through CSP process and production method

ActiveCN113913694AExcellent magnetic propertiesInhibit normal growthProcess efficiency improvementElectrical steel

The invention provides efficient cold-rolled non-oriented electrical steel produced through a CSP process and a production method. The efficient cold-rolled non-oriented electrical steel comprises the following components: less than or equal to 0.0030% of C, 1.00-1.70% of Si, less than or equal to 0.0050% of Als, 0.10-0.30% of Mn, 0.01-0.3% of Sn, less than or equal to 0.050% of P, less than or equal to 0.0080% of S, less than or equal to 0.0030% of N, less than or equal to 0.0030% of Nb, less than or equal to 0.0030% of V, less than or equal to 0.0030% of Ti and the balance of Fe and inevitable impurities. Compared with the prior art, the method for producing the efficient cold-rolled non-oriented electrical steel through the CSP process has the advantages that by controlling chemical components in the steel and adopting a proper production process, excellent surface quality, low iron loss, high magnetic induction, low manufacturing cost and efficient production are realized.

Owner:MAANSHAN IRON & STEEL CO LTD

Pig breeding method

InactiveCN108935301ADay-to-day managementThe right time to inoculateAnimal feeding stuffPig farmsVaccination

The invention belongs to the technical field of livestock breeding, in particular to a pig breeding method, comprising the following steps: (1) selecting a pig farm; (2) cluster management; (3) feeding management; (4) disease prevention. The invention also discloses a self-made fermented feed used in the breeding process and a preparation method thereof. The self-made fermented feed comprises a biological starter, glucose, water, taro, soybean dregs, wheat bran, distiller's grains and sweet potato. The preparation method comprises the following steps: (1) weighing the dosage of each component,pulverizing and sieving with 80 mesh sieve; (2) sealed fermentation; (3) after fermentation, using the feed for feeding. The feed provided by the invention is reasonable in feeding, proper in daily management, suitable in vaccination time, low in morbidity rate and fast in growth, and is favorable for healthy growth of pigs; reasonable size of the pigsty is conducive to the movement of pigs, porkquality and taste good; the self-made fermented feed has the advantages of balanced nutrition, high digestibility and absorption rate, low cost and simple preparation method.

Owner:仁怀市古立家畜养殖专业合作社

Aluminum alloy containing graphene and heat treatment method for aluminum alloy

The invention discloses a heat treatment method for aluminum alloy containing graphene. The aluminum alloy comprises the following ingredients of, in percentage by mass, 8-10% of metal fibre, 5.5-7.2%of Mg, 2.0-3.5% of Fe, 1.2-2.6% of graphene, 0.08-0.18% of Sc, 0.08-0.18% of Zr, 0.12-0.22% of Y, 0.02-0.07% of Si, 0.02-0.07% of Mn, 0.01-0.03% of Er, 0.01-0.03% of Ce, less than or equal to 0.15% of impurities and the balance Al. The heat treatment method comprises the steps that S1, the aluminum alloy is heated to 300-400 DEG C, heat preservation is performed for 4-8 h, the temperature is raised to 500-600 DEG C, heat preservation is performed for 3-6 h, the temperature is reduced to 100-200 DEG C, and heat preservation is performed for 2-3 h; S2, water quenching treatment is performed, wherein the temperature of water is 25-60 DEG C; S3, the aluminum alloy after water quenching is subjected to tempering with the temperature being 300-400 DEG C; S4, then annealing treatment is performed, the temperature of annealing treatment is 100-200 DEG C, and the time is 6-10 h. By means of the heat treatment method provided by the invention, the strength of the aluminum alloy containing graphene is improved, the maximum strength of the aluminum alloy can be improved to 685, in addition, the invention further comprises the aluminum alloy prepared by the heat treatment method.

Owner:益阳仪纬科技有限公司

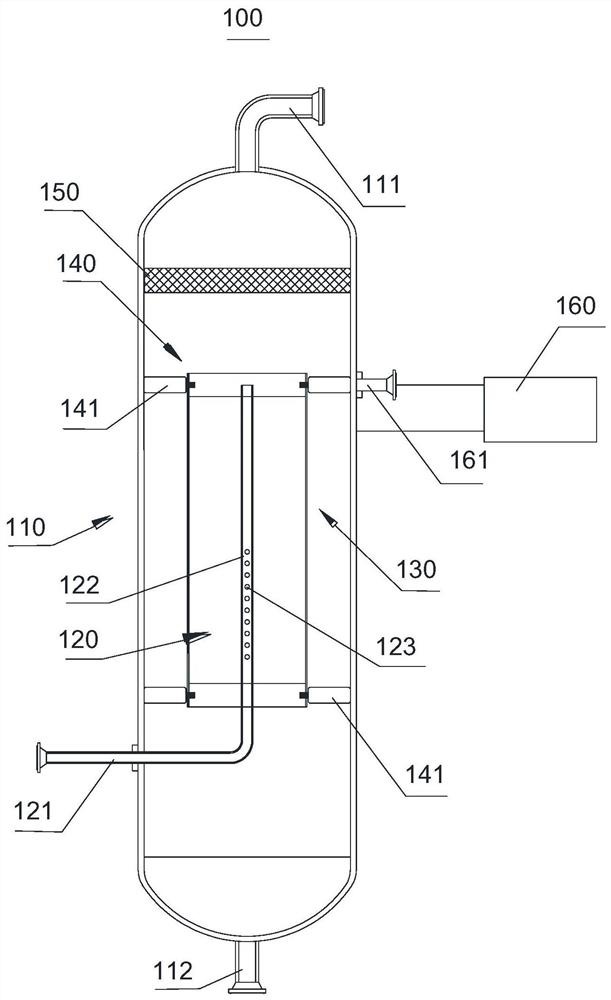

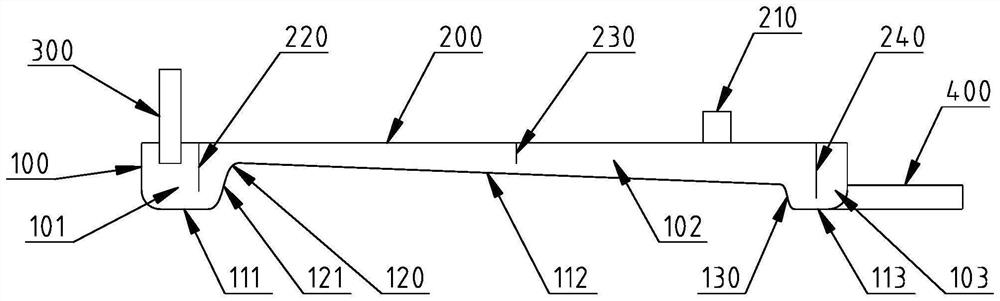

Deasphalting device and method

ActiveCN113265269AReduced backmixingImprove removal efficiencyRefining by electric/magnetic meansHydrocarbon oils treatmentElectrically conductiveEngineering

The invention relates to the technical field of petroleum processing, and provides a deasphalting device and a method, the deasphalting device comprises a tank body, a feeding distributor, a power line and a conductive hollow cylindrical electrode, the hollow cylindrical electrode is arranged in the tank body, the feeding distributor comprises a discharging section and a conveying section which are connected with each other, the discharging section is located in the hollow cylindrical electrode, the conveying section extends out of the tank body from the lower part of the tank body, a plurality of discharging holes are formed in the discharging section corresponding to the lower part of the hollow cylindrical electrode, the hollow cylindrical electrode is not in contact with the wall surface of the tank body and the feeding distributor, one end of the power line is connected with the hollow cylindrical electrode, and the other end of the power line extends out of the tank body. According to the deasphalting method, the deasphalting device provided by the invention is adopted for deasphalting treatment, and the method and the device have a relatively good effect of removing the asphalt in the raw oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

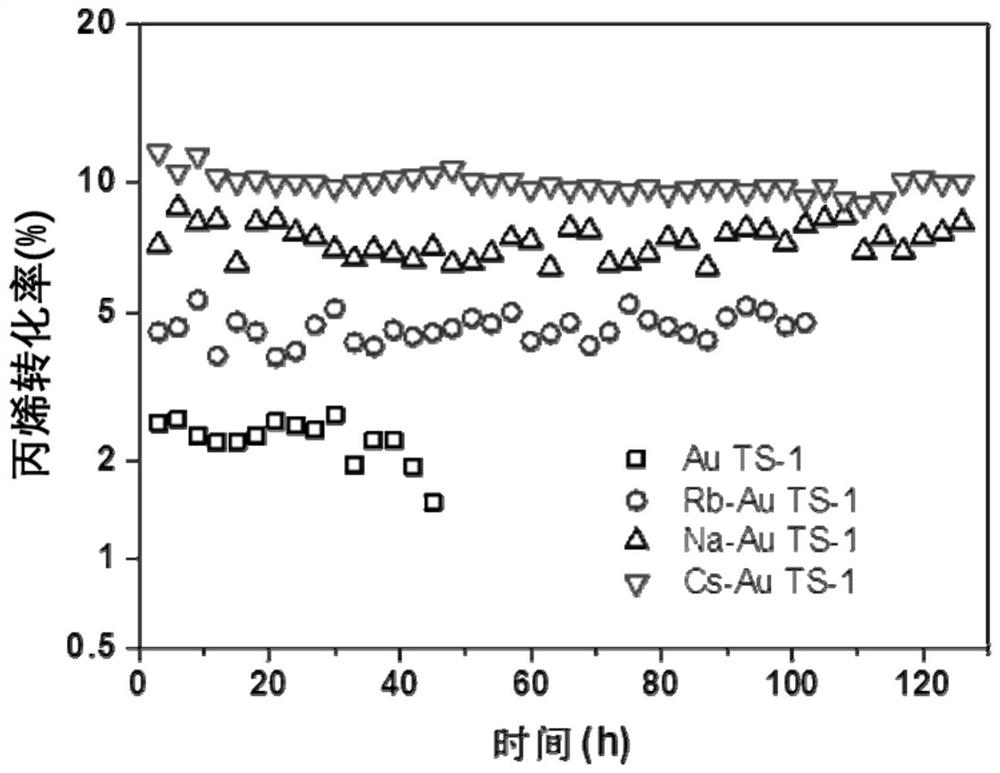

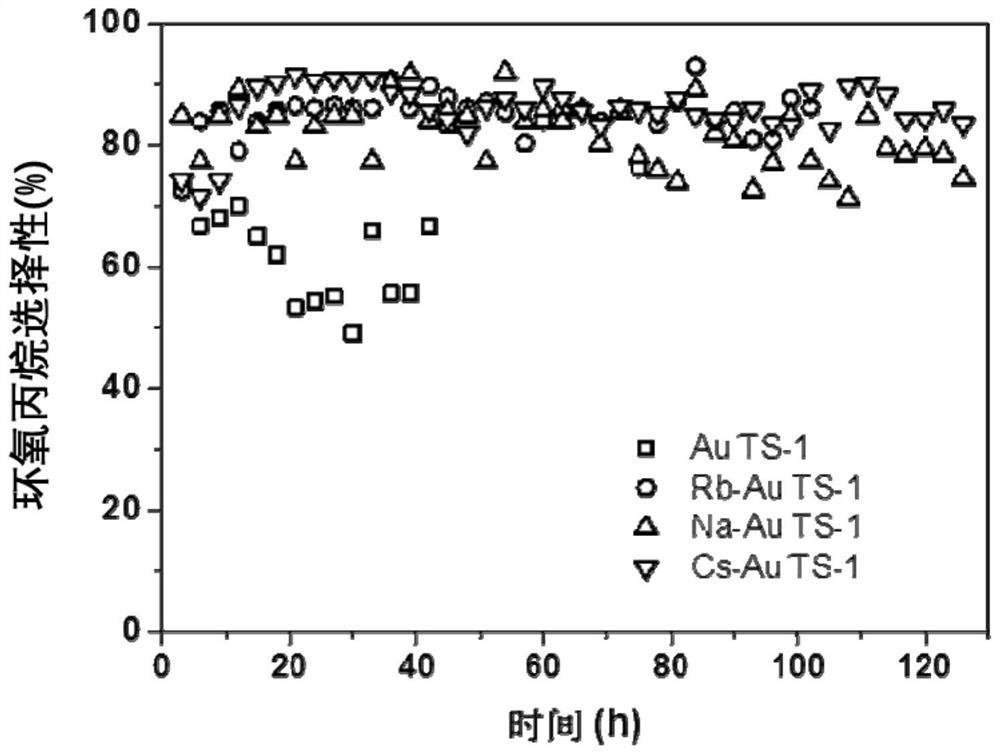

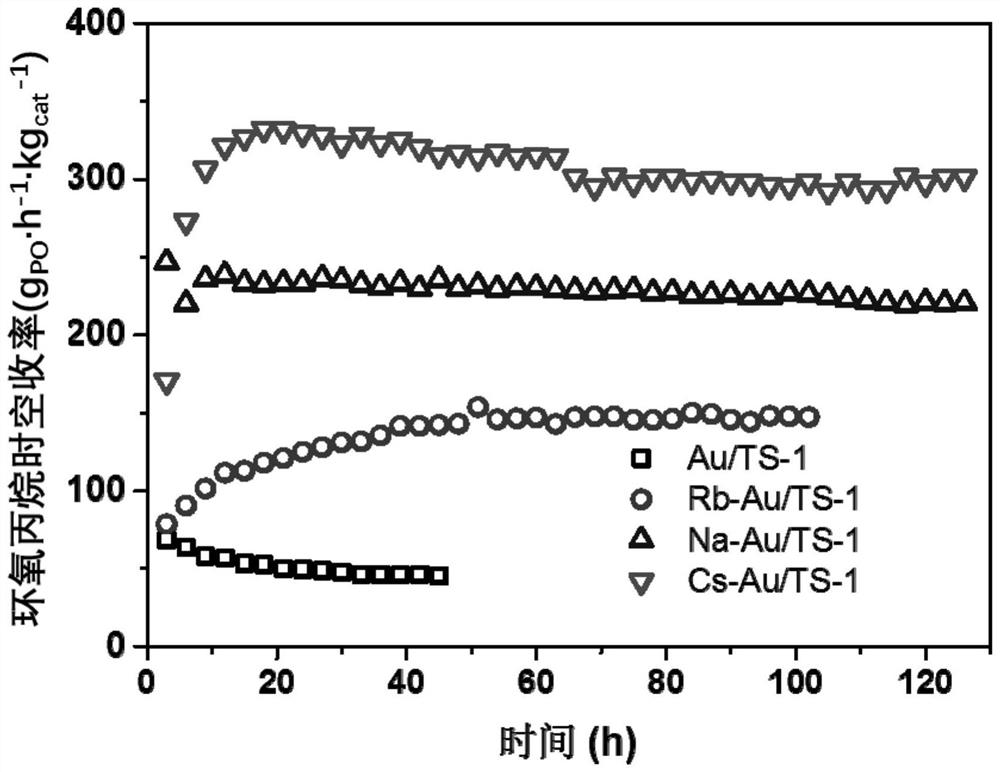

Modification method of Au/TS-1 catalyst

PendingCN111822044AImprove stabilityExtend your lifeOrganic chemistryMolecular sieve catalystsPtru catalystPhysical chemistry

The invention relates to the field of chemical catalysis, in particular to a modification method of a selective oxidation catalyst. The modification method comprises the following steps: (1) loading an active component Au on a carrier TS-1 to prepare an Au / TS-1 catalyst; (2) impregnating the Au / TS-1 catalyst with a solution of alkali metal carbonate X2CO3, and then drying to obtain a modified catalyst X2CO3-Au / TS-1, wherein the molar ratio of the X2CO3 to the active component Au loaded on the Au / TS-1 catalyst ranges from 20: 1 to 1: 5; and (3) carrying out activation treatment on the modifiedcatalyst X2CO3-Au / TS-1 before the reaction. According to the present invention, the method for modifying Au / TS-1 through alkali carbonate impregnation is adopted, and the prepared X2CO3-Au / TS-1 catalyst has characteristics of high catalytic performance and long service life; and the preparation method has good repeatability.

Owner:CHENGDU ZHONGKE CATALYSIS TECH CO LTD

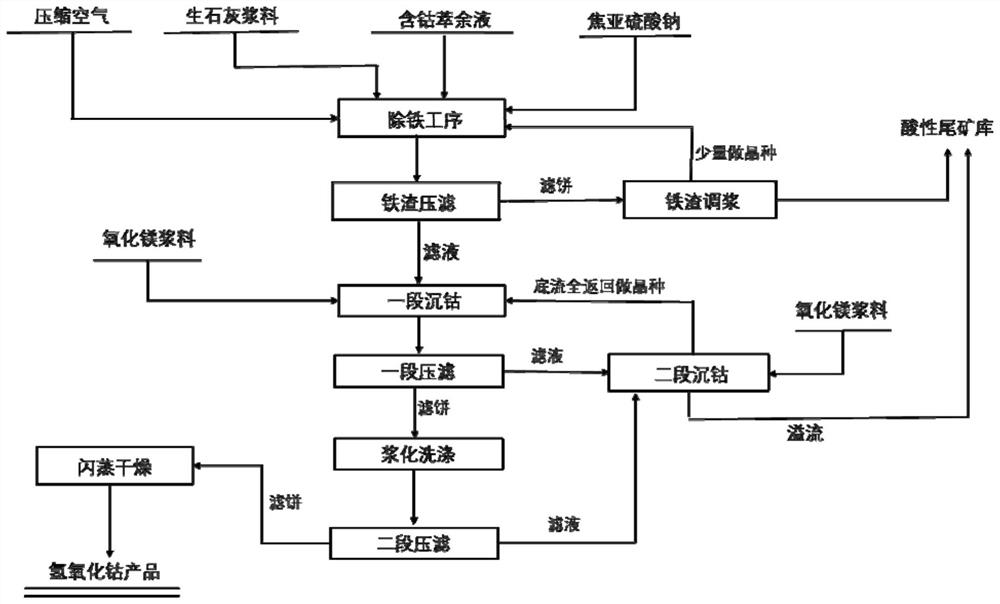

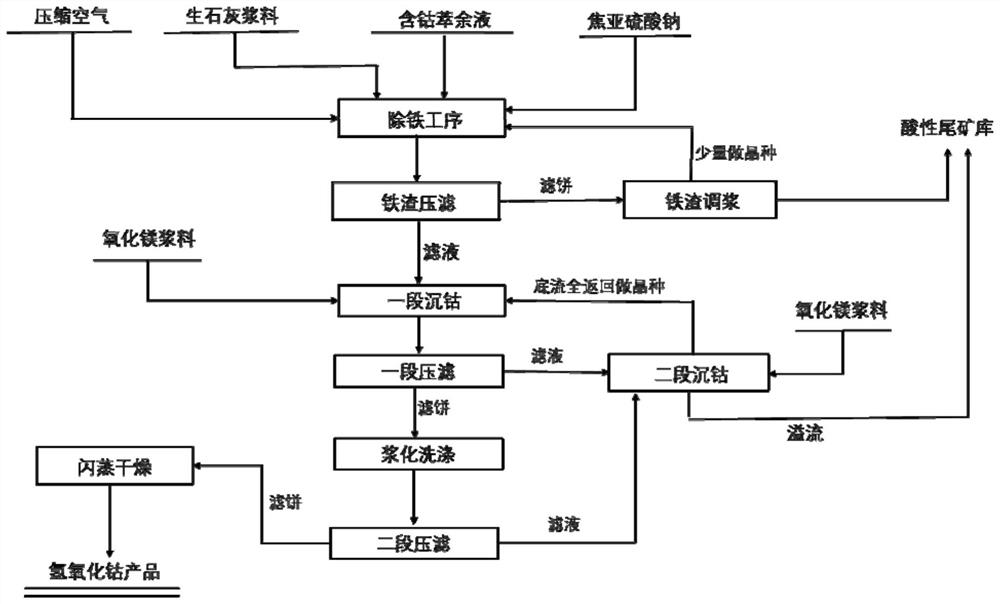

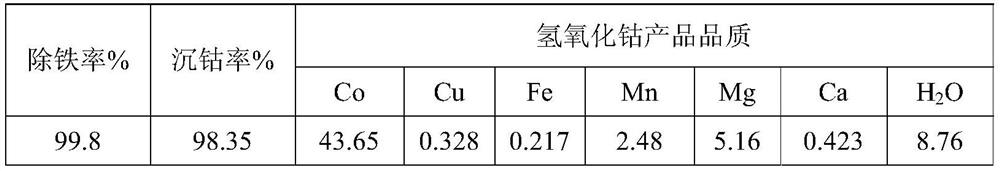

Method for producing crude cobalt hydroxide from cobalt-containing low-copper raffinate industrially

InactiveCN113955811AImprove overall outputHigh recovery rateProcess efficiency improvementCobalt oxides/hydroxidesSodium metabisulfiteSlag

The invention relates to a method for producing crude cobalt hydroxide from cobalt-containing low-copper raffinate industrially, which adopts related processes such as iron removal, first-stage cobalt precipitation, second-stage cobalt precipitation, filter-pressing slurrying washing, flash drying and the like, optimizes an iron removal process, adopts a sodium pyrosulfite solution as an iron removal adding agent and returns part of iron slag as an iron removal reaction seed crystal. Thus, theiron removal effect is greatly improved. Meanwhile, the quality index of the second-stage cobalt precipitation slag is improved through process improvement, the second-stage cobalt precipitation slag is completely used as first-stage cobalt precipitation reaction seed crystals, rapid formation and growth of first-stage cobalt precipitation reaction crystal nucleuses are effectively promoted, the first-stage cobalt precipitation efficiency is improved, and the utilization efficiency of magnesium oxide is improved; the total output and the one-time recovery rate of cobalt hydroxide products are greatly improved, and a series of problems of poor iron removal effect, low cobalt hydroxide cobalt content, low product one-time recovery rate, high auxiliary material unit consumption and the like under the condition of the prior art are solved.

Owner:北方矿业有限责任公司

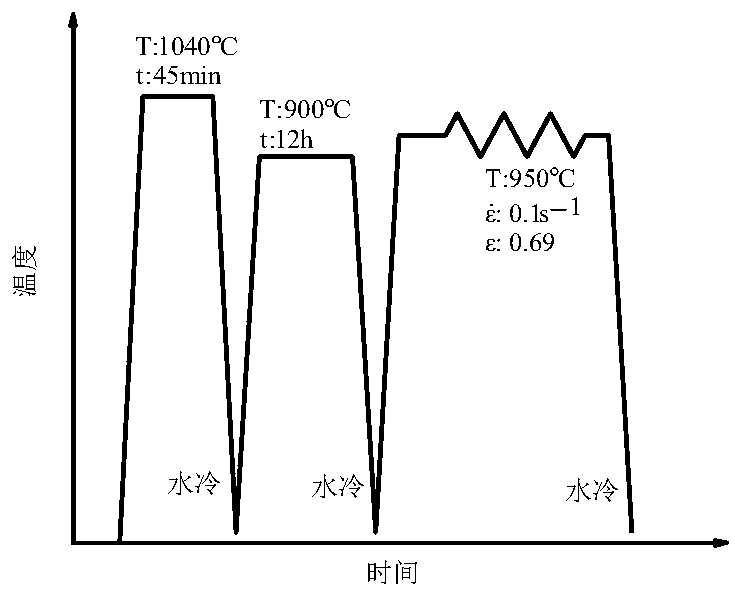

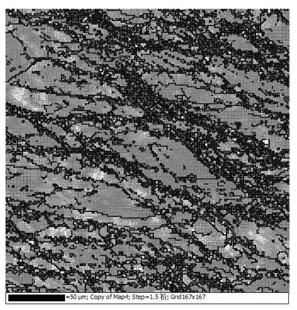

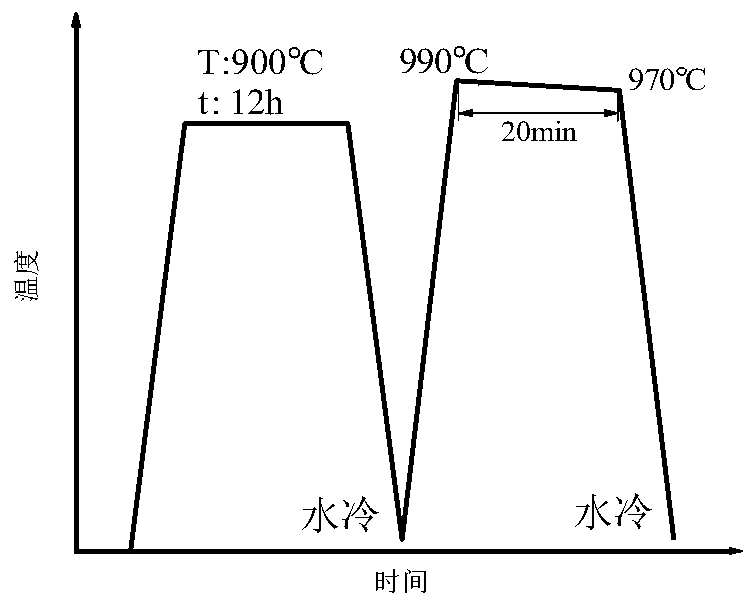

Method for obtaining GH4169 alloy ultra-fine grain forging

The invention discloses a method for obtaining a GH4169 alloy ultra-fine grain forging. The method includes the following steps that (1), a GH4169 forging stock is subjected to solution treatment andaging treatment in sequence, and a uniform structure with a certain quantity of delta phases is obtained; (2), the forging stock obtained after solution treatment and aging treatment is subjected to forging deformation, the deformation temperature is controlled with 950 DEG C-1,010 DEG C, the strain rate is not smaller than 0.05s<-1>, and the equivalent strain is not smaller than 0.35; (3), the obtained forging is subjected to aging treatment again, the aging temperature is controlled within 880 DEG C-920 DEG C, and the aging time is 9 h-24 h; and (4), the forging is subjected to recrystallization heat treatment in a continuous cooling manner, the cooling initial temperature is controlled within 990 DEG C-1,030 DEG C, the cooling rate is 1 DEG C / min-3 DEG C / min, and the cooling final temperature is controlled within 950 DEG C-990 DEG C. By means of the method, the GH4169 alloy ultra-fine grain forging can be obtained, and an effective way is provided for manufacturing high-quality forgings.

Owner:CENT SOUTH UNIV

High fiber feed for raising chickens

InactiveCN108835440AImprove resistanceImprove digestionFood processingAnimal feeding stuffAnimal scienceDigestion

The invention relates to the field of raising chickens, in particular to high fiber feed for raising chickens. The high fiber feed is specifically prepared from the following components: 54 to 56 percent of maize, 19 to 21 percent of soya bean meal, 14 to 16 percent of wheat bran, 4 to 6 percent of konjaku flour, 2 to 4 percent of cold-resisting traditional Chinese medicinal powder, 0.5 to 2 percent of dried small shrimp and 0.5 to 2 percent of shellfish. By adding the cold-resisting traditional Chinese medicinal powder into the feed, the resistance of chickens to influenza is improved; by adding various cellulose ingredients, the digestion ability of the chickens is promoted, so that the chickens grow quickly; and the reproductive requirements of eggs are met by adding the shellfish.

Owner:无为县昆山星年养殖专业合作社

A kind of softening and annealing process method of copper sealing gasket

The invention provides a red copper sealing washer softening annealing technology method. The red copper sealing washer softening annealing technology method comprises the steps that a red copper sealing washer is cleaned with gasoline, air-dried and put into a vacuum furnace, and the vacuum furnace is vacuumized till the vacuum degree is 1.33-13.3 Pa; heating is conducted for temperature rising,and the temperature rising speed is controlled to be 180-300 DEG C / h; the heat preservation time is 90-150 min after the temperature reaches 600-650 DEG C; and then furnace cooling is conducted, and the red copper sealing washer is taken out of the furnace at any temperature below 100 DEG C and then air-cooled to the room temperature. According to the red copper sealing washer softening annealingtechnology method, the surface Vickers hardness is not higher than HV45 after the red copper sealing washer is annealed, the problem that the hardness is slightly high in conventional annealing is solved, and the first time pass rate of a softening annealing furnace is increased.

Owner:西安长峰机电研究所

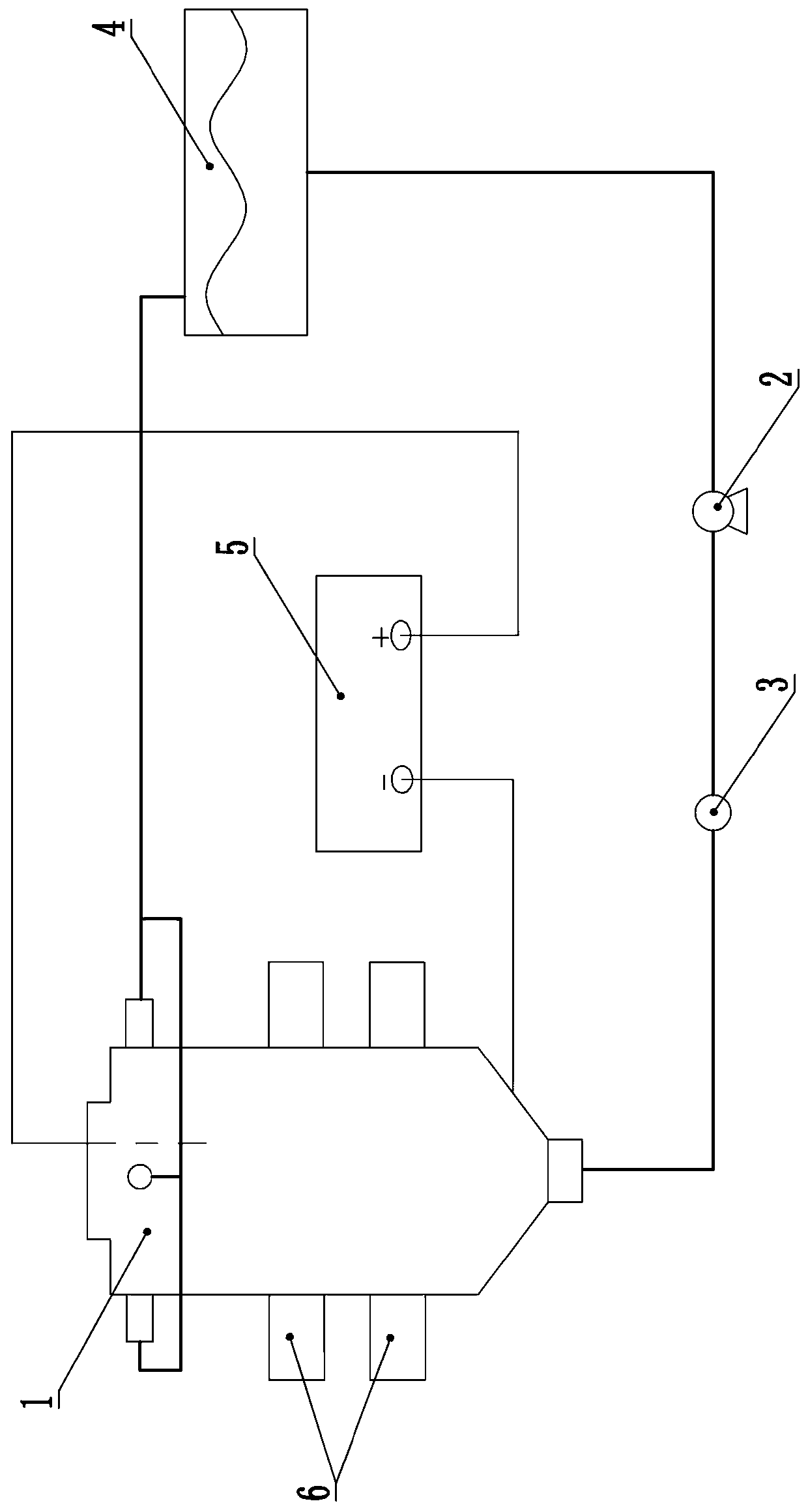

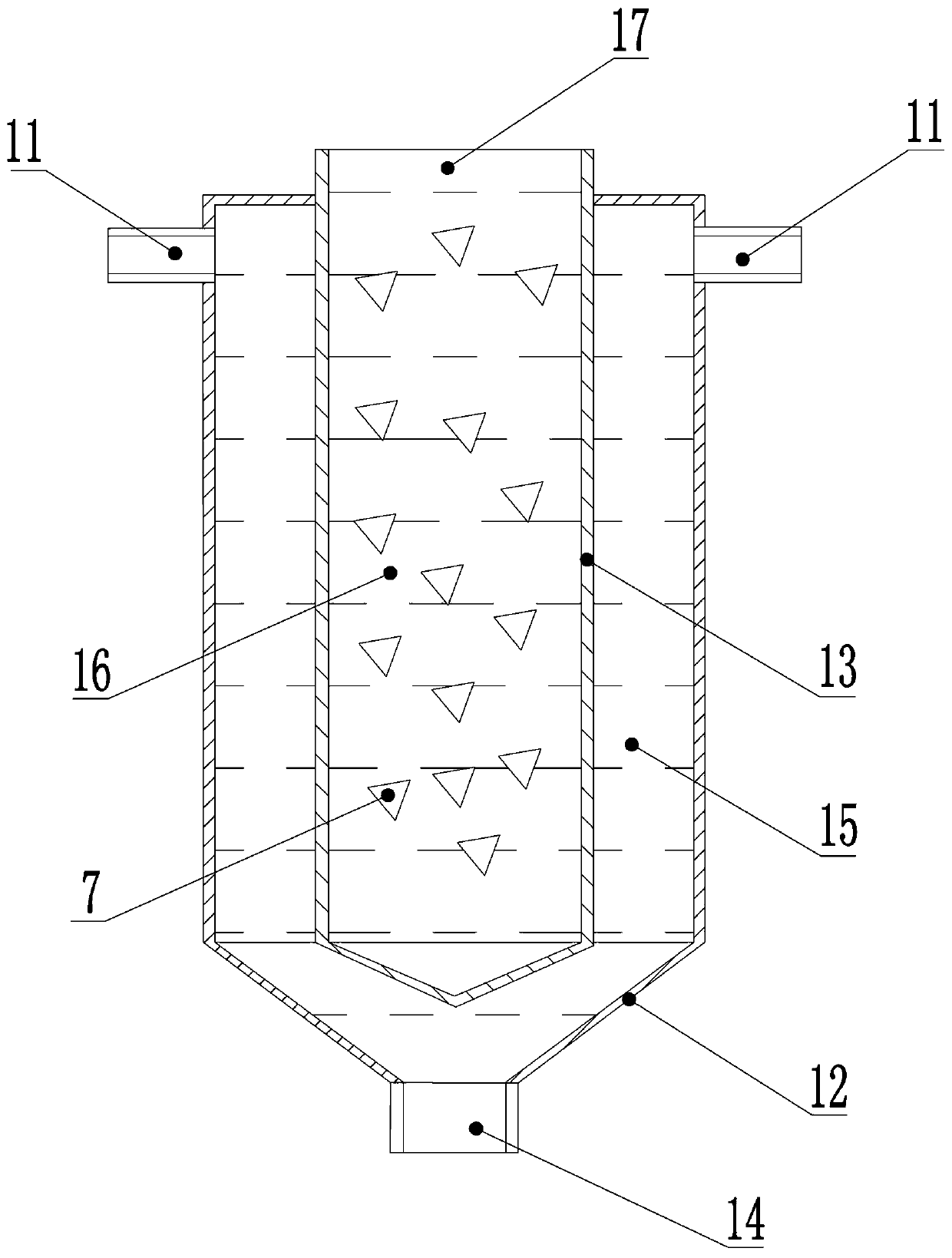

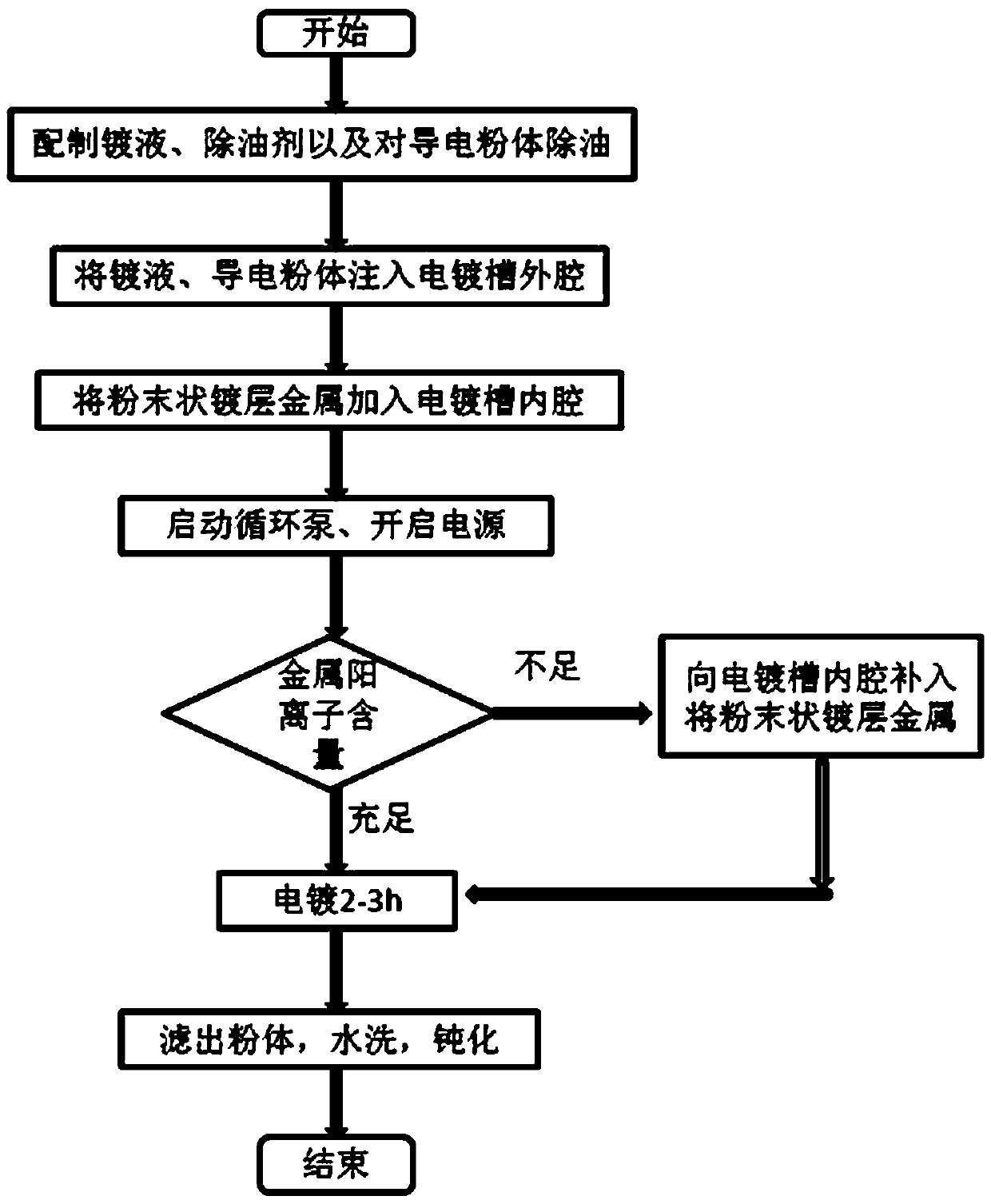

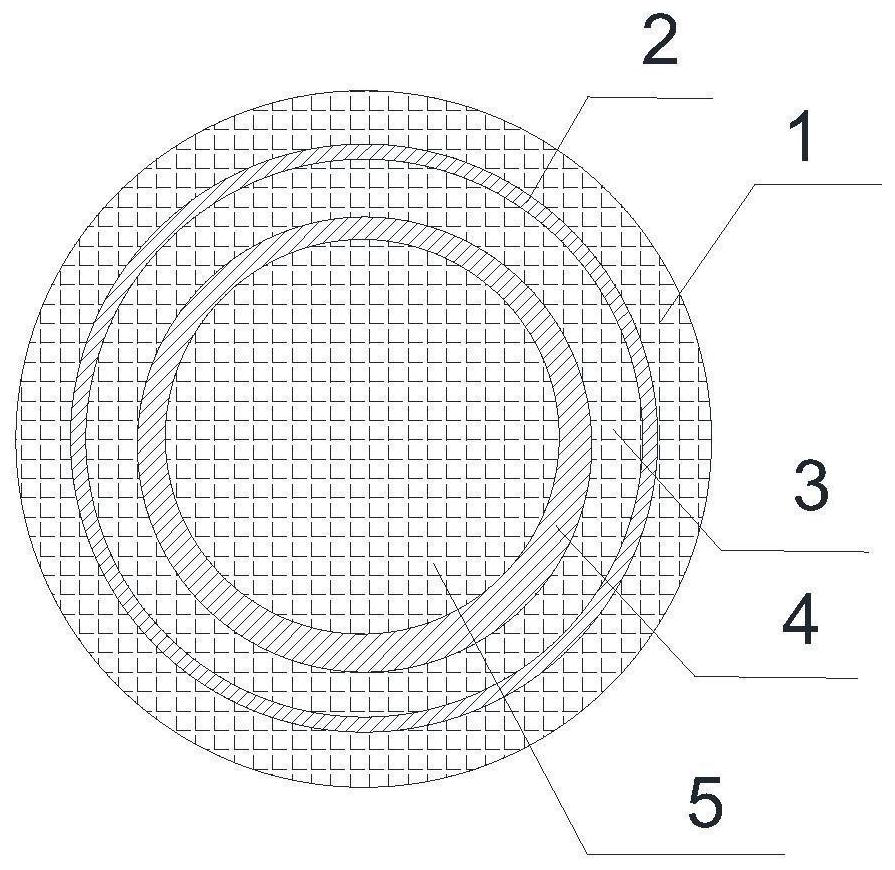

A metal-coated composite powder electroplating process

ActiveCN108326292BImprove bindingConvenient supplementTransportation and packagingMetal-working apparatusCirculator pumpElectroplating

The invention discloses a metal-coated composite powder electroplating process in the technical field of core-shell material production technology, aiming to solve the technical problems of low deposition rate, rough, non-dense coating and powder agglomeration in the existing process; the process includes The following steps are as follows: first prepare the degreasing agent and degrease the conductive powder and prepare the plating solution; then inject the prepared plating solution and the degreasing conductive powder into the outer cavity of the electroplating tank; then add powder in the inner cavity of the electroplating tank Plating metal; then start the circulating pump to circulate the plating solution and turn on the power for electroplating; finally filter out the powder, wash with water, and passivate. The invention can conveniently and cheaply coat a layer of metal phase on the outside of the conductive powder to form a well-bonded core-shell composite material, and the process of the invention has the advantages of fast deposition rate, smooth and dense coating.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

A kind of aluminum alloy and heat treatment method thereof

The invention discloses heat treatment method of an aluminum alloy. The aluminum alloy comprises, by mass, 8%-10% of metal fibers, 5.5%-7.2% of Mg, 1.0%-2.5% of Zn, 0.8%-1.8% of Cu, 0.08%-0.18% of Sc,0.08%-0.18% of Zr, 0.12%-0.22% of Y, 0.02%-0.07% of Si, 0.02%-0.07% of Mn, 0.01%-0.03% of Er, 0.01%-0.03% of Ce, no more than 0.15% of impurities, and the balance Al. The heat treatment method comprises the steps that S1, high-temperature heat treatment is conducted on the aluminum alloy at the temperature of 500-600 DEG C, and after high-temperature heat treatment, quenching is conducted on thealuminum alloy with PAG quenching liquid, so that the aluminum alloy subjected to high-temperature treatment is obtained, wherein the content of PAG polymers in the PAG quenching liquid is 15-60 wt%,the temperature of the PAG quenching liquid is 40-80 DEG C, and the stirring speed of the PAG quenching liquid is 100-200 r / s; S2, cold-deformation treatment is conducted on the aluminum alloy subjected to high-temperature treatment, so that the aluminum alloy subjected to cold deformation is obtained; S3, the aluminum alloy subjected to cold deformation is tempered at the temperature of 300-400 DEG C for 1-2 h; and S4, afterwards, annealing treatment is conducted on the aluminum alloy at the temperature of 100-160 DEG C for 6-8 h, and thus, the strength of the aluminum alloy is improved. Theinvention further provides the aluminum alloy prepared through the heat treatment method.

Owner:益阳仪纬科技有限公司

Piglet feed

InactiveCN106333064AImprove palatabilityImprove digestion utilizationFood processingAnimal feeding stuffAnimal scienceGrape seed

The invention discloses a piglet feed comprising a decoction and dry materials. The mass ratio of the decoction and the dry materials is 1:(1-2). The decoction is rice soup. The dry materials comprise, by weight, 40-50 parts of fish meal, 10-20 parts of bone meal, 20-40 parts of corn, 30-40 parts of soybean meal, 5-10 parts of grape seeds, 15-35 parts of watermelon seeds, 10-20 parts of auricularia auricular, 5-15 parts of fern root noodles, 4-12 parts of sorghum, 15-20 parts of orange peel, 4-8 parts of yeast, 1-5 parts of walnut powder, 2-5 parts of fructus forsythiae, 10-15 parts of mulberry leaves, 0.5-1 part of aspartic acid, 2-7 parts of garlic, 3-5 parts of semen cuscutae, 1-2 parts of rhizoma paridis, 2-3 parts of nacre, 40-50 parts of bran, 1-3 parts of salt, 1-2 parts of cyrtomium rhizome and 5-10 parts of radish leaves. The dry materials and the decoction are mixed and stirred evenly and then used for feeding livestock, and the feed is good in palatability, high in digestion utilization rate and low in acid-binding capacity, effectively adjusts intestinal flora balance, enhances immunity and promotes quick growth of piglets.

Owner:杨波

Method for quickly depositing lithium carbonate from lithium bicarbonate solution

ActiveCN101182012BIncrease sedimentation rateHigh recovery rateCarbonate preparationOrganic solventEvaporation

The invention provides a method of rapid precipitation of lithium carbonate in lithium bicarbonate solution. The method adopts a heatable negative-pressure apparatus and water-soluble organic solvents such as ethanol and propanol, etc., to conduct a constant volume reaction by stirring under the controlled temperature at 80-180 DEG C and the negative pressure of an container of 0.01-0.10 MPa so as to dissolve the lithium bicarbonate and precipitate the lithium carbonate; the precipitation mother liquor is recoverable for reuse. The invention not only overcomes the problems of a 'wall-cling effect' in an ordinary evaporation and precipitation course and a 'concentration and entrainment effect' of water-soluble impurity ions, but also quickens the precipitation speed with the precipitation course only consuming around 20 min, which is 2 to 3 times of an ordinary evaporation and precipitation method and the precipitation rate of the lithium is enhanced with a single precipitation rate ofthe lithium carbonate of above 87 percent and the overall recovery rate of the lithium of above 94 percent.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

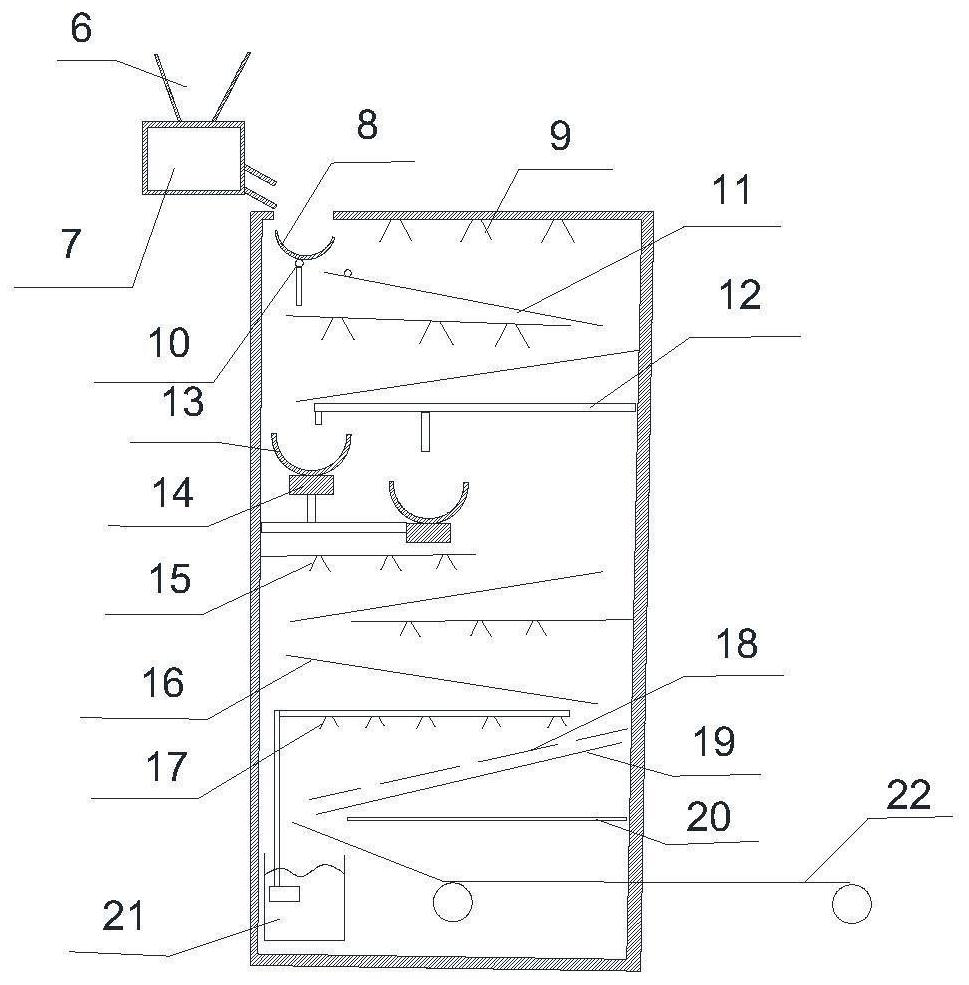

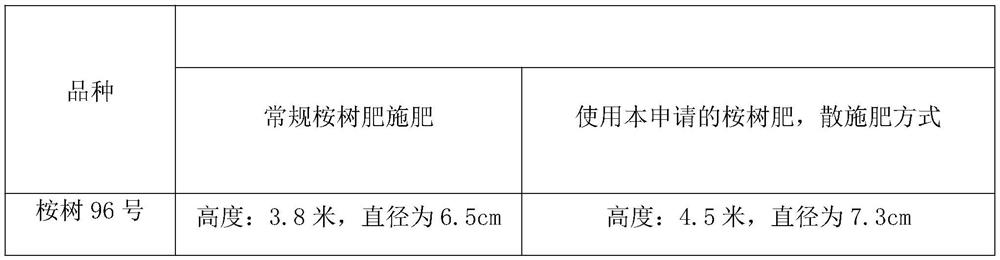

Production method of special fertilizer for eucalyptus

ActiveCN111943781BPromote growthActive nutrient transportCalcareous fertilisersBio-organic fraction processingTree trunkEnvironmental geology

The invention discloses a production method of a special fertilizer for eucalyptus, which belongs to the field of fertilizer preparation. The eucalyptus fertilizer produced by the invention can be provided according to the change of different fertilizer elements required by eucalyptus throughout the year. During January-April, nitrogen is mainly provided , rapid and dense growth leaves. From May to September, it mainly provides phosphorus to make the trunk grow rapidly and increase the sap of the trunk of the eucalyptus. In the later winter, it provides more potassium fertilizer to improve the transportation of water, so that the nutrient transportation of the tree is the same The tree is active, the growth of the tree is not limited by the season, and the growth is faster and better.

Owner:广西黎塘远东化肥有限责任公司

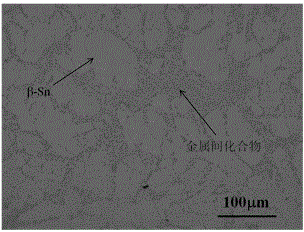

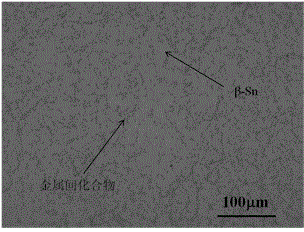

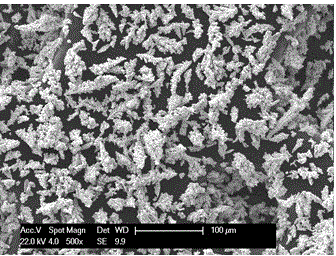

Modification agent for tin-silver-copper solder or tin-copper solder smelting and using method

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

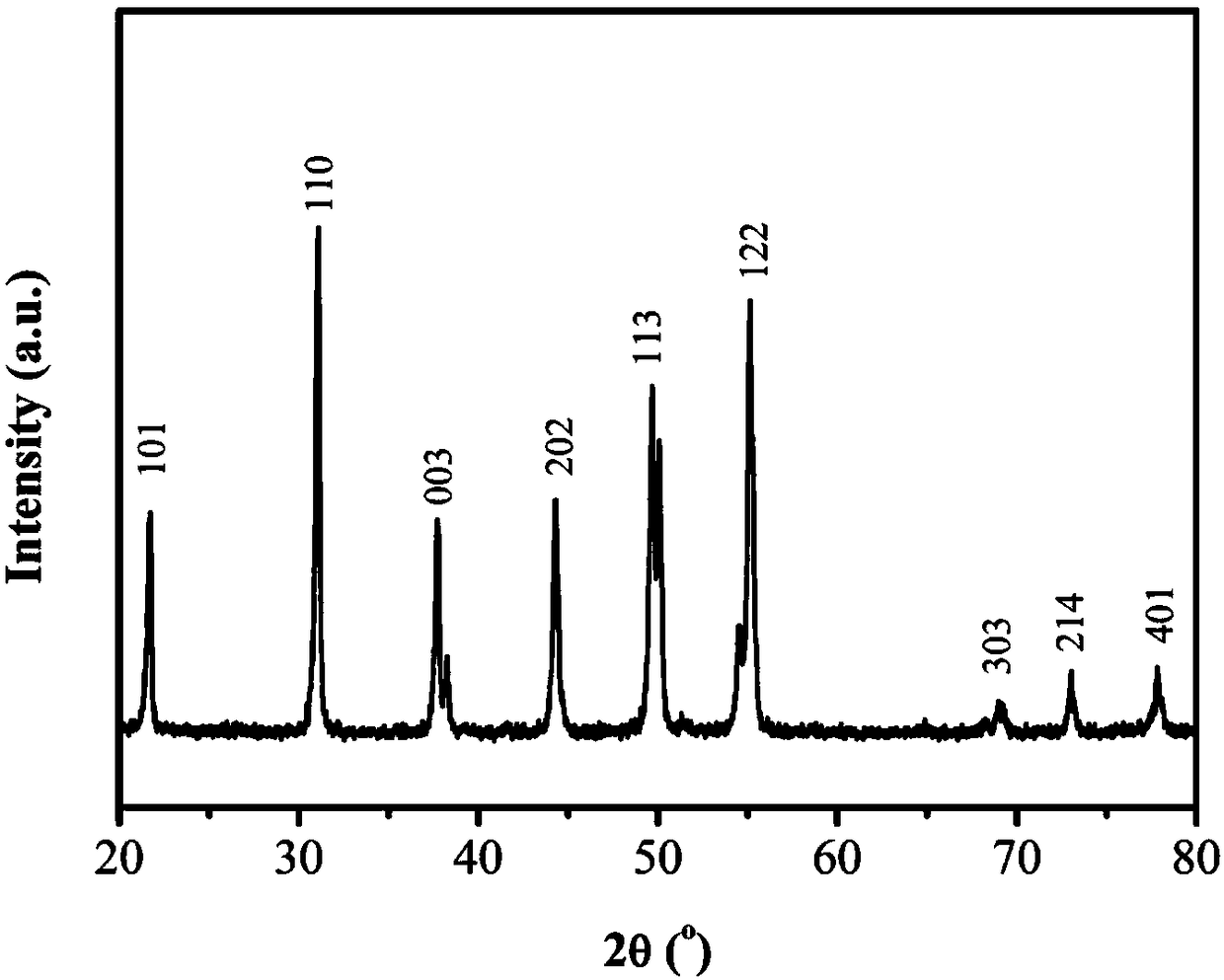

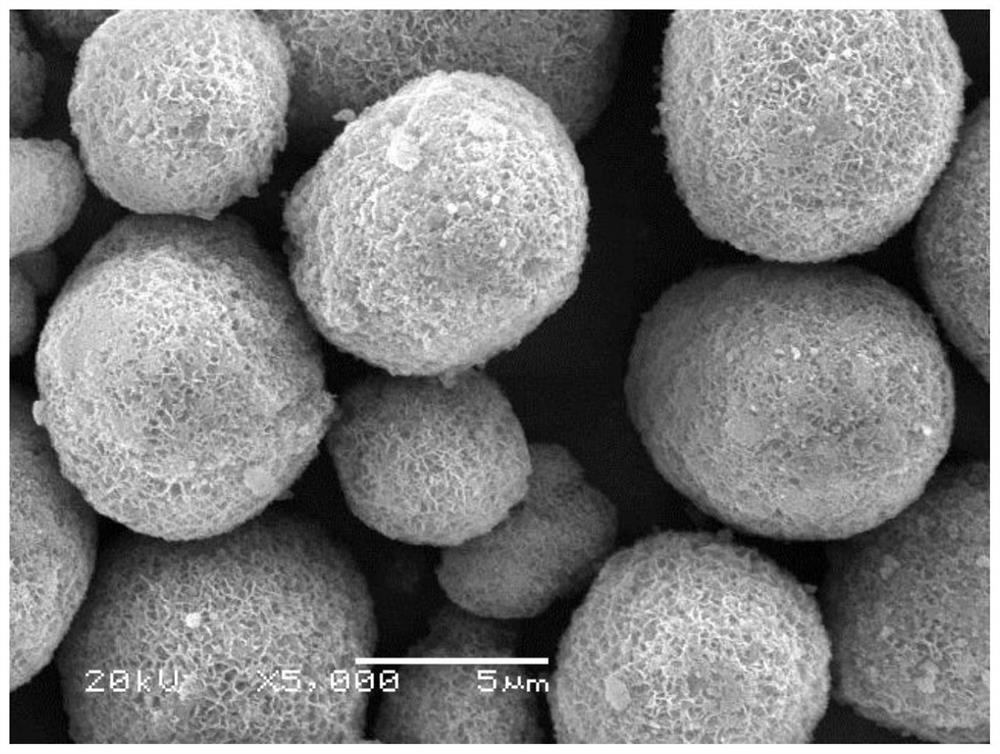

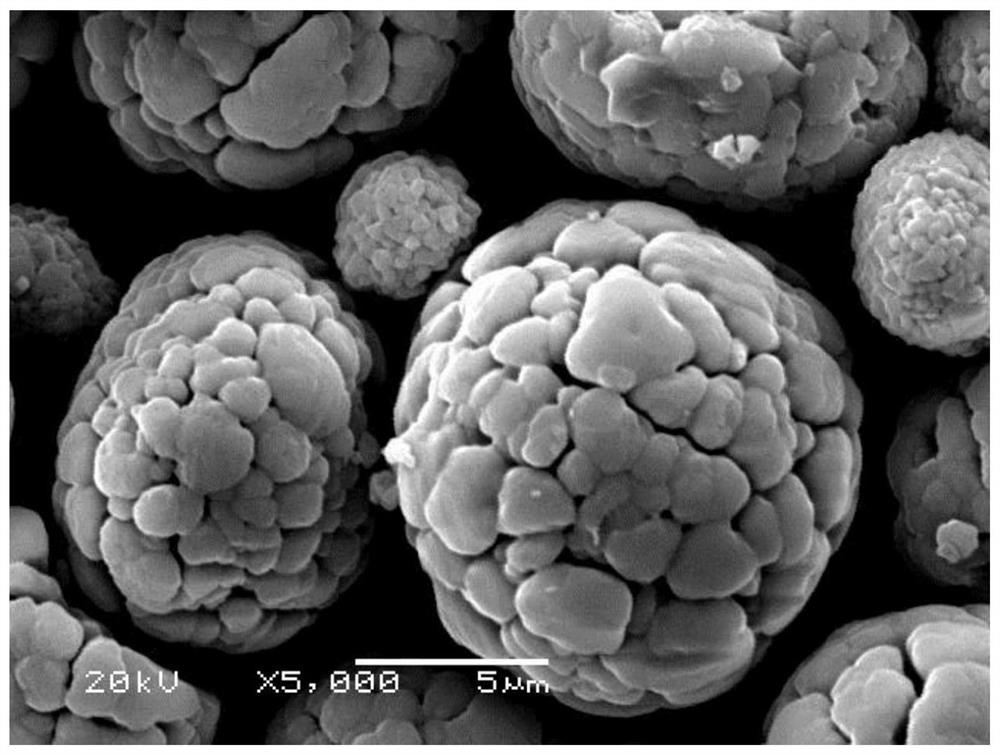

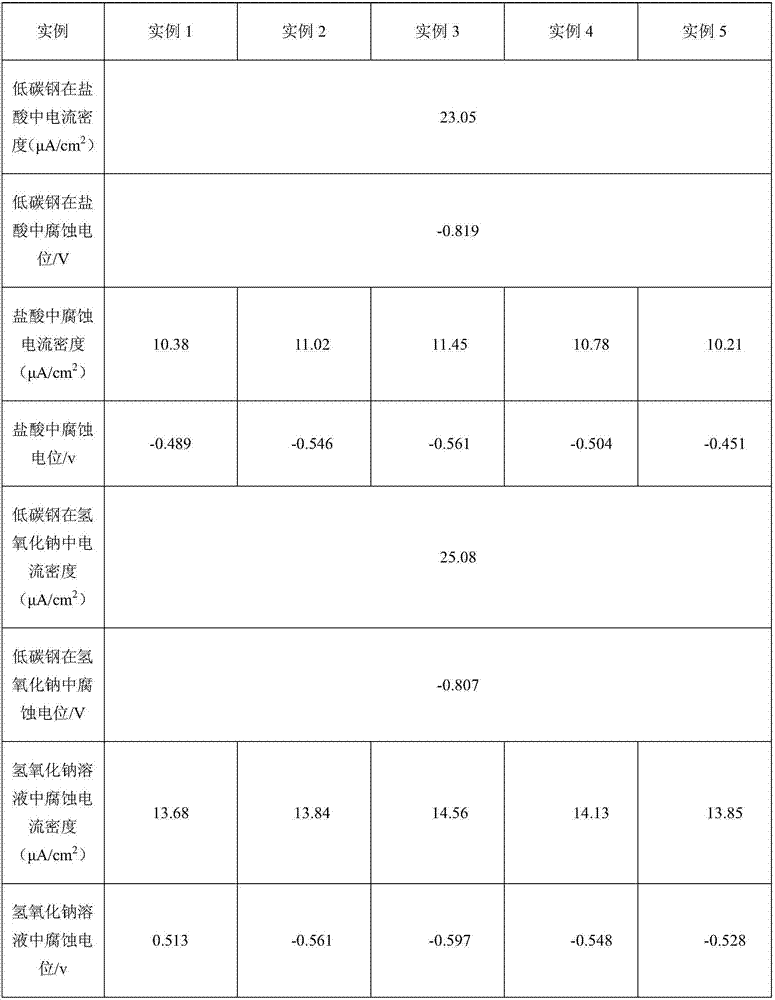

A kind of single crystal lithium ion battery ternary electrode material precursor, electrode material and its preparation method and application

ActiveCN110444757BReduce the temperatureGrow up fastSecondary cellsPositive electrodesSingle crystalLithium-ion battery

The invention provides a preparation method for a ternary electrode material precursor. The method comprises the following steps: A) a transition metal hydroxide and a hydrotropic agent are mixed andthen sintered to obtain the sintering product, wherein the hydrotropic agent comprises at least one of boron containing compounds, magnesium oxide and alumina; B) after a sintered product, a bubble capsule material and a dispersant are mixed, a bubble filling material is added in an air-tight, high temperature and high pressure environment, high pressure bubbles are enabled to enter the bubble capsule material, and then a single crystal lithium ion battery ternary electrode material precursor is obtained. The preparation method described in the invention is simple and controllable in technological flow, great in benefits for environment protection, and low in production cost. The single crystal lithium ion battery ternary electrode material precursor can be rapidly produced on a large scale.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A method for preparing acid and alkali-resistant nano Hastelloy coatings by magnetron sputtering and vacuum heat treatment

InactiveCN105331930BGrow up fastTightly boundVacuum evaporation coatingSputtering coatingSputteringAlloy

Owner:江苏尚大海洋工程技术有限公司

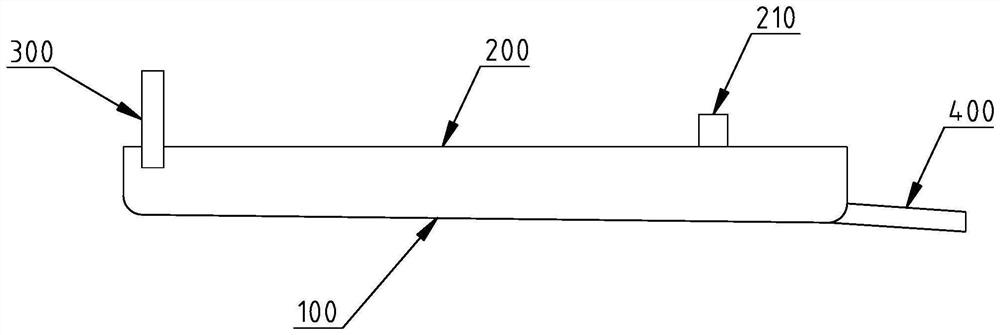

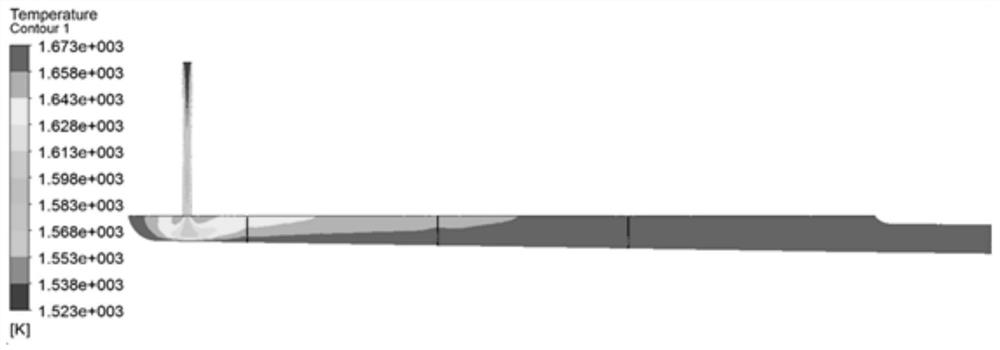

Glass clarification device and glass clarification method

PendingCN114477721ALow clarification temperatureReduce bubble defectsGlass furnace apparatusGlass productionMolten glassGlass manufacturing

The invention belongs to the technical field of glass manufacturing, particularly discloses a glass clarifying device and method, and aims to solve the problem of how to ensure a clarifying effect under a low-temperature clarifying condition. According to the glass clarifying device, the inclined plane is arranged in the middle of the bottom surface of the clarifying tank, the front end of the inclined plane is connected with the front-section bottom surface through the overflow weir structure, and the rear end of the inclined plane is connected with the rear-section bottom surface through the flow guide structure. Therefore, under the overflow action of the overflow weir structure, the molten glass can be uniformly distributed on the inclined plane in the transverse direction when the molten glass is controlled to be shallow; meanwhile, the inclined plane can control the depth of the molten glass at the inclined plane to be very shallow, so that the overall temperature of the molten glass is rapidly increased, rapid growth and accelerated floating of bubbles are facilitated, and the bubbles can be rapidly eliminated at a lower clarification temperature under the same clarification capability; in addition, under the flow guide effect of the flow guide structure, the glass liquid on the inclined plane can be collected, so that the glass liquid is mixed up and down and the liquid level is kept stable.

Owner:CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com