A metal-coated composite powder electroplating process

An electroplating process and composite powder technology, applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of rough coating, low deposition rate, powder agglomeration, etc., and achieve convenient recycling, fast electrodeposition speed, Coating smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

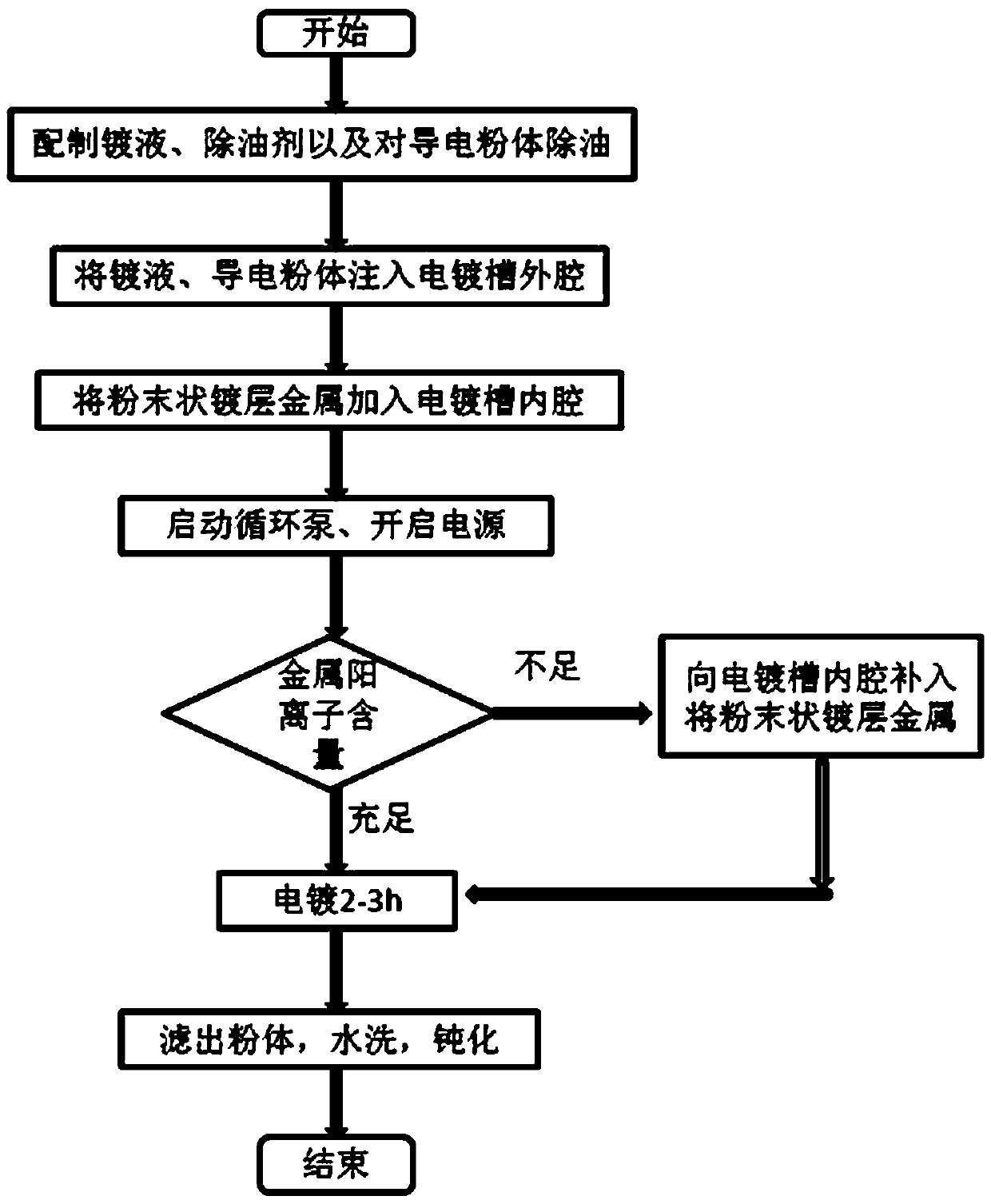

[0029] Example 1: A metal-coated composite powder electroplating process. This example takes the preparation of copper-coated graphite powder as an example to illustrate, as shown in image 3 As shown, the specific operation steps are as follows:

[0030] Pre-plating treatment:

[0031] Degreasing: Prepare a degreasing agent containing 150g / L sodium hydroxide, 30g / L sodium carbonate, 35g / L sodium phosphate and water, then add 100g graphite powder to the degreasing agent and stir at 60°C for 30min , and then filter the graphite powder, wash it with deionized water, and dry it for later use.

[0032] Degreasing can reduce the surface tension of the powder when it comes into contact with the plating solution.

[0033] Plating solution preparation: each substance was prepared into a plating solution according to the following contents: copper sulfate 1.1mol / L, sulfuric acid 12mmol / L, glacial acetic acid 20mmol / L, emulsifier OP-10 1.5g / L, glyoxylic acid 20g / L.

[0034] plating: ...

Embodiment 2

[0039] Example 2: A metal-coated composite powder electroplating process. This example takes the preparation of copper-coated graphite powder as an example to illustrate, as image 3 As shown, the specific operation steps are as follows:

[0040] Pre-plating treatment:

[0041] Degreasing: Prepare a degreasing agent containing 150g / L sodium hydroxide, 30g / L sodium carbonate, 35g / L sodium phosphate and water, then add 100g graphite powder to the degreasing agent and stir at 60°C for 30min , and then filter the graphite powder, wash it with deionized water, and dry it for later use.

[0042] Degreasing can reduce the surface tension of the powder when it comes into contact with the plating solution.

[0043] Plating solution preparation: each substance was prepared into a plating solution according to the following contents: copper sulfate 1.2mol / L, sulfuric acid 8mmol / L, glacial acetic acid 25mmol / L, emulsifier OP-10 0.8g / L, glyoxylic acid 26g / L.

[0044] plating:

[0045] ...

Embodiment 3

[0049] Example 3: A metal-coated composite powder electroplating process. This example takes the preparation of copper-coated graphite powder as an example to illustrate, as image 3 As shown, the specific operation steps are as follows:

[0050] Pre-plating treatment:

[0051] Degreasing: Prepare a degreasing agent containing 150g / L sodium hydroxide, 30g / L sodium carbonate, 35g / L sodium phosphate and water, then add 100g graphite powder to the degreasing agent and stir at 60°C for 30min , and then filter the graphite powder, wash it with deionized water, and dry it for later use.

[0052] Degreasing can reduce the surface tension of the powder when it comes into contact with the plating solution.

[0053] Plating solution preparation: each substance was prepared into a plating solution according to the following contents: copper sulfate 1.0mol / L, sulfuric acid 6mmol / L, glacial acetic acid 19mmol / L, emulsifier OP-10 0.7g / L, glyoxylic acid 30g / L.

[0054] plating:

[0055] Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com