Modification agent for tin-silver-copper solder or tin-copper solder smelting and using method

A modification agent, tin-silver-copper technology, applied in the field of modification agent for tin-silver-copper solder or tin-copper solder smelting, can solve problems affecting the reliability of alloy solder joints, etc., to improve uneven shrinkage, small size, and improve modification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

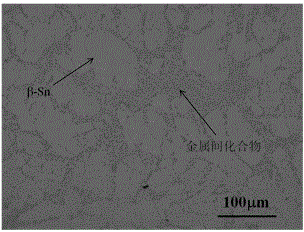

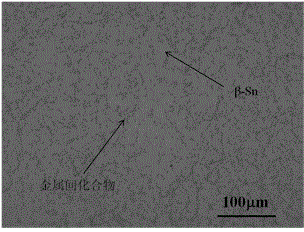

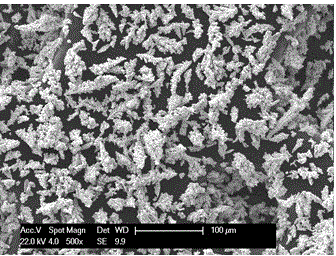

[0032]A modifier used for smelting SnAgCu solder (the weight ratio of Ag in the solder is 3%, the weight ratio of Cu is 0.5%, and the rest is Sn), wherein the weight percentage of Co is 7%, the rest is Cu, and the particle size of alloy powder The diameter is 10 μm. Cool the SnAgCu solder from the melting temperature of 500°C to 300°C and keep it warm. Before casting or powder spraying, add the modified agent powder and the SnAgCu solder in a weight ratio of 1:100, and apply a frequency of 50KHz and a magnetic field strength of 6kA / m. Stir with an alternating magnetic field, and remove the modifier after 5 minutes for casting or powder spraying.

Embodiment 2

[0034] A modifier used for smelting SnAgCu solder (the weight ratio of Ag in the solder is 3%, the weight ratio of Cu is 0.5%, and the rest is Sn), wherein the weight percentage of Co is 8%, the rest is Cu, and the particle size of alloy powder The diameter is 20 μm. Cool the Sn-3%Ag-0.5%Cu solder from the melting temperature of 500°C to 290°C and keep it warm, and add the modifier powder and the Sn-3%Ag-0.5%Cu solder according to the weight ratio of 1 before casting or powder spraying. : 100 mixed, and applied frequency is 50KHz, the alternating magnetic field of magnetic field intensity 6kA / m is stirred, and after 5 minutes, removes modificator and carries out casting or powder spraying.

Embodiment 3

[0036] A modifier used for smelting SnAgCu solder (the weight ratio of Ag in the solder is 3%, the weight ratio of Cu is 0.5%, and the rest is Sn), wherein the weight percentage of Co is 9%, the rest is Cu, the grain size of alloy powder The diameter is 50 μm. Cool the SnAgCu solder from the melting temperature of 500°C to 280°C and keep it warm. Before casting or powder spraying, add the modifier powder and Sn-3%Ag-0.5%Cu solder according to the weight ratio of 1:100, and apply the frequency of 60KHz, alternating magnetic field with a magnetic field strength of 6kA / m is used for stirring, and after 5 minutes, the modifier is removed for casting or powder spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com