Modification method of Au/TS-1 catalyst

A TS-1, catalyst technology, applied in the field of modification of selective oxidation catalysts, can solve the problems of poor repeatability and poor performance of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

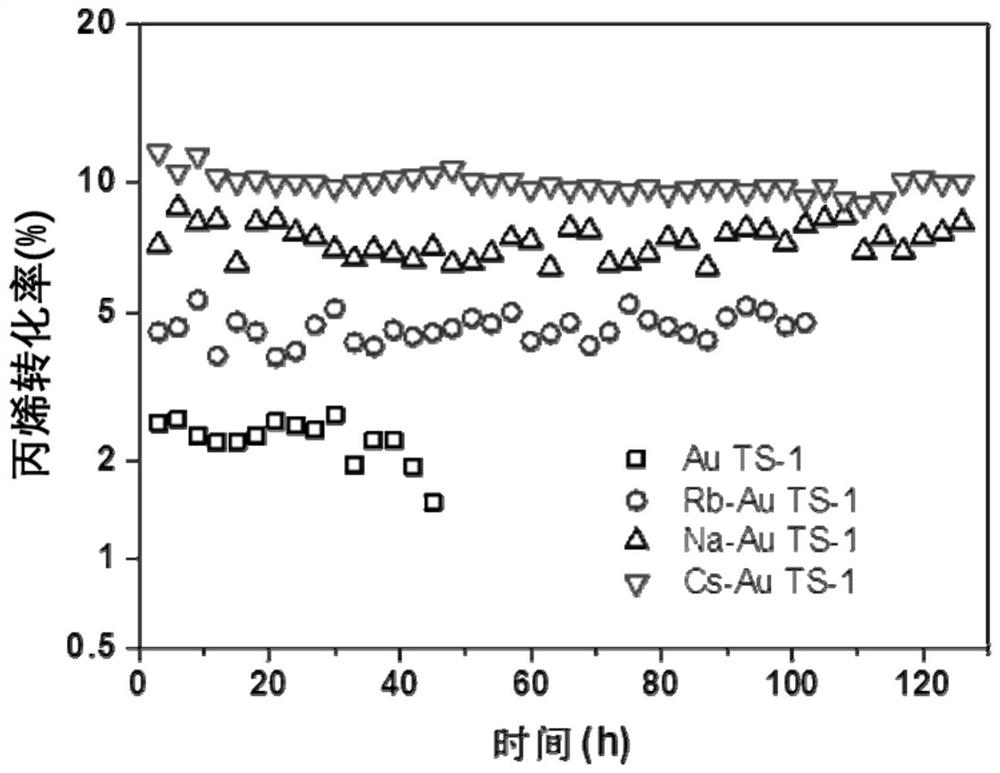

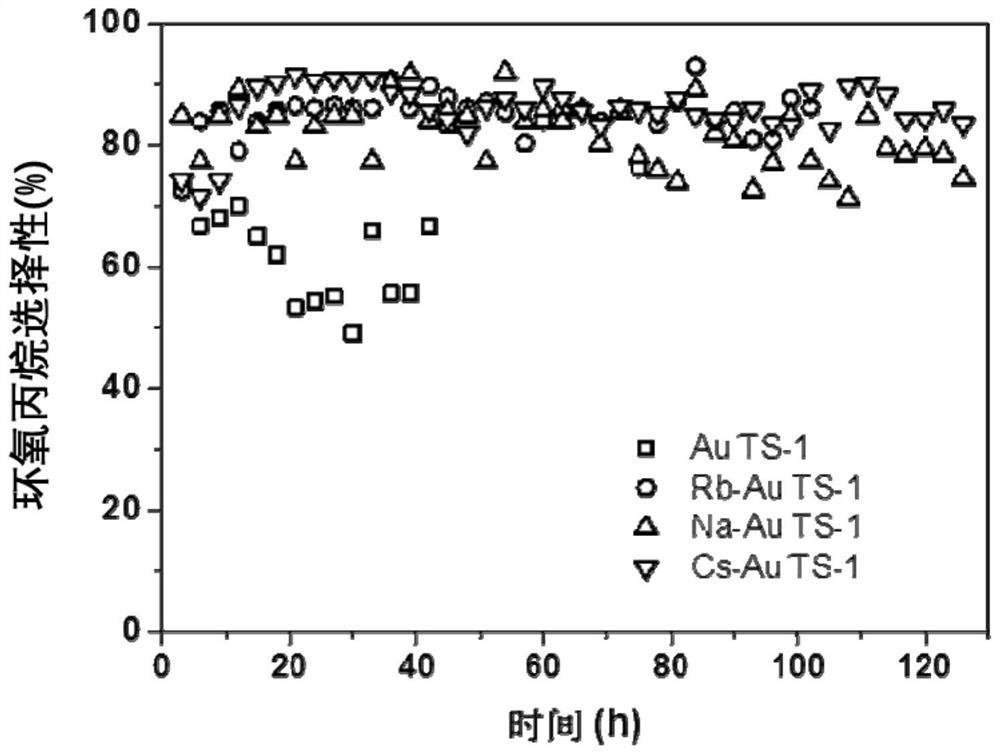

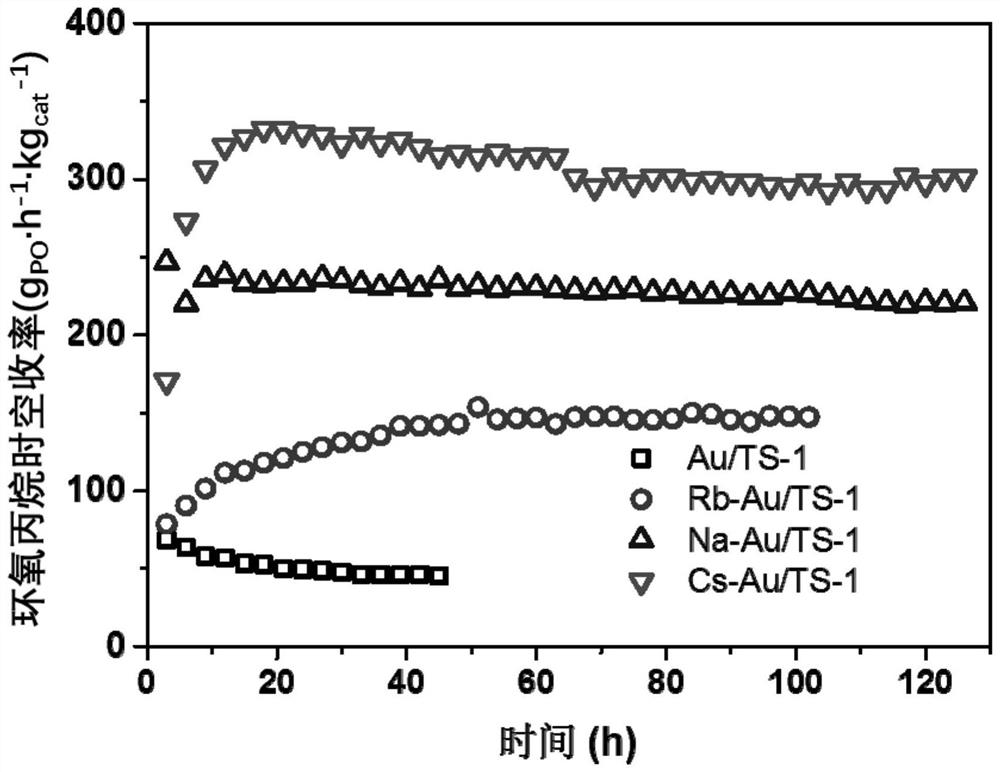

Examples

Embodiment 1

[0073] Step 1) Preparation of Au / TS-1

[0074] At 40°C, add 8 mL of 20 mg / mL HAuCl to 22 g of deionized water 4 solution and 1 g of commercially available TS-1 powder to obtain a mixture. The mixture was stirred for 30 minutes to obtain a homogeneous mixture. The Cs of 10wt% (mass percentage concentration) is then added dropwise in the mixture 2 CO 3 solution, make the pH of the mixed solution reach 7-8, and continue to stir for 1.5 hours; then again with 10wt% Cs 2 CO 3 The solution adjusted the pH=8 of the mixed solution, and continued to stir for 3.5 hours to make the HAuCl 4 The Au ions in the mixture of solution and TS-1 powder were fully precipitated on the carrier TS-1. Then the liquid was poured by centrifugation, the solid was collected, and washed three times with 100 g of deionized water in total, and then the washed solid was dried under vacuum at 30° C. until the sample had constant weight to obtain Au / TS-1 sample 1.

[0075] Step 2) Prepare X 2 CO 3 -Au / ...

Embodiment 2

[0093] Step 1) Preparation of Au / TS-1

[0094] At 40°C, add 8 mL of 20 mg / mL HAuCl to 22 g of deionized water 4 solution, stirred for 30 minutes; then 10wt% Cs was added dropwise 2 CO 3 solution, so that the pH of the mixed solution reaches 7-8. Then, 1.000 g of TS-1 powder was added and stirred for 1.5 hours. Then again with 10wt%Cs 2 CO 3 The solution was adjusted to pH=8 of the mixed solution, and stirring was continued for 3.5 hours. The liquid was poured by centrifugation, the solid was collected, and washed three times with a total of 100 g of deionized water. The washed solid was dried under vacuum at 30° C. until the sample had constant weight, and Au / TS-1 sample 2 was obtained.

[0095] Step 2) Prepare X 2 CO 3 -Au / TS-1

[0096] Take Au / TS-1 sample 2, prepare according to the same process as step 2) in Example 1, and obtain the target product——X2 CO 3 - Au / TS-1 sample B series.

[0097] Step 3) X 2 CO 3 -Activation treatment of Au / TS-1

[0098] Follow th...

Embodiment 3

[0106] Step 1) Preparation of Au / TS-1

[0107] At 40°C, add 8 mL of 20 mg / mL HAuCl to 22 g of deionized water 4 Solution and TS-1 powder 1.000g, stirred for 30 minutes. Then add 10wt% NaOH solution dropwise to make the pH of the mixed solution reach 7-8, and stir for 1.5 hours; then adjust the pH of the mixed solution to 8 with 10wt% NaOH solution again, and continue stirring for 3.5 hours. The liquid was poured by centrifugation, the solid was collected, and washed three times with 100 g of deionized water in total, and then the washed solid was dried under vacuum at 30° C. until the sample had constant weight, and Au / TS-1 sample 3 was obtained.

[0108] Step 2) Prepare X 2 CO 3 -Au / TS-1

[0109] Take Au / TS-1 sample 3, prepare according to the same process as step 2) in Example 1, and obtain the target product——X 2 CO 3 -Au / TS-1 sample C series.

[0110] Step 3) X 2 CO 3 -Activation treatment of Au / TS-1

[0111] Follow the same process as step 3) in Example 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com