Patents

Literature

89results about How to "Suitable for industrial promotion and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

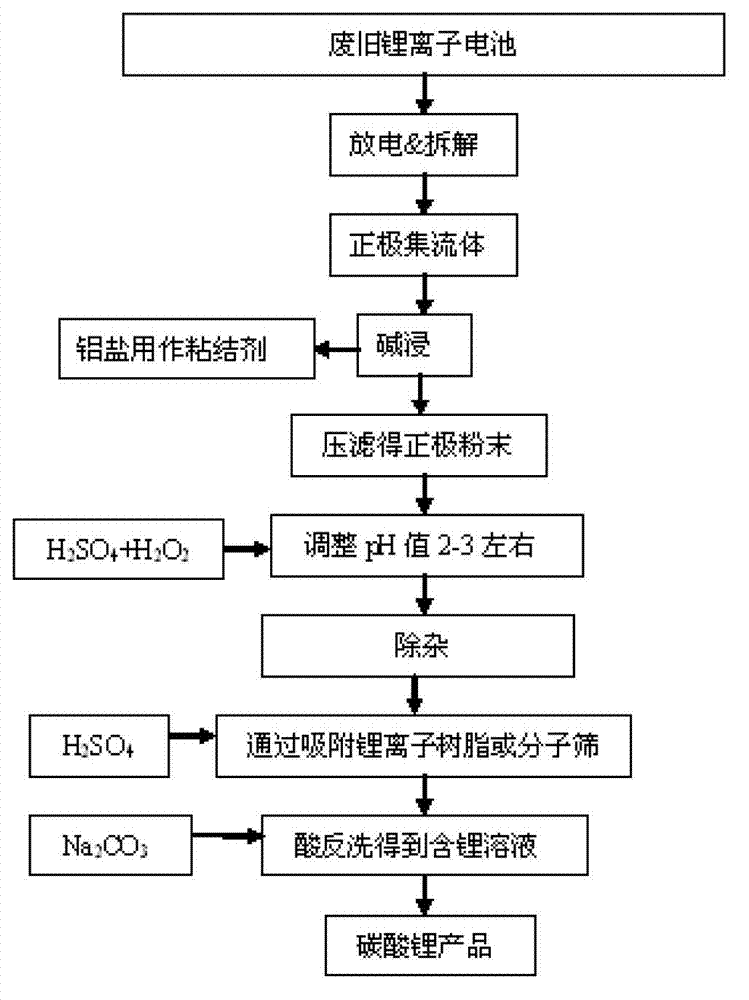

Method for separating and recovering lithium from waste lithium ion battery

ActiveCN103035977AEasy to recycleHigh purityWaste accumulators reclaimingBattery recyclingRecovery methodPhysical chemistry

The invention discloses a method for separating and recovering lithium from a waste lithium ion battery. The method comprises the following steps: dismounting after discharging the waste lithium ion battery, and removing a battery case; crashing a battery cell; leaching and filtering the crushed battery cell with inorganic acid and oxidant to obtain a filter liquor; regulating the pH of the filter liquor to be more than or equal to 8, then filtering to remove impurities and sediment to obtain a recovery liquor containing lithium ions; adsorbing the lithium ions in the recovery liquor through resin; and desorbing the resin to obtain the separated and recovered lithium salt. The recovery method provided by the invention is simple and efficient, has high purity of lithium and brings no pollution.

Owner:深圳市泰力废旧电池回收技术有限公司

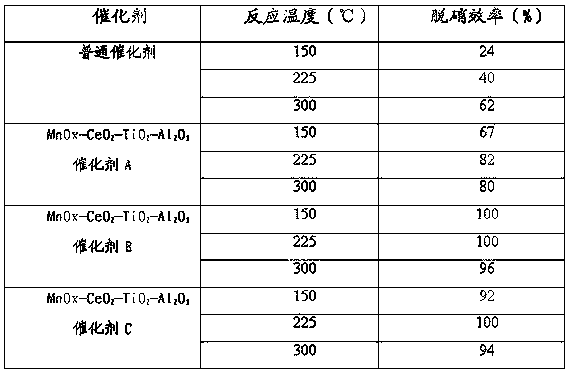

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

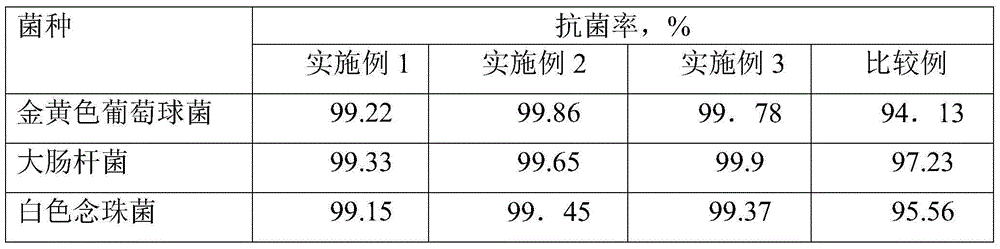

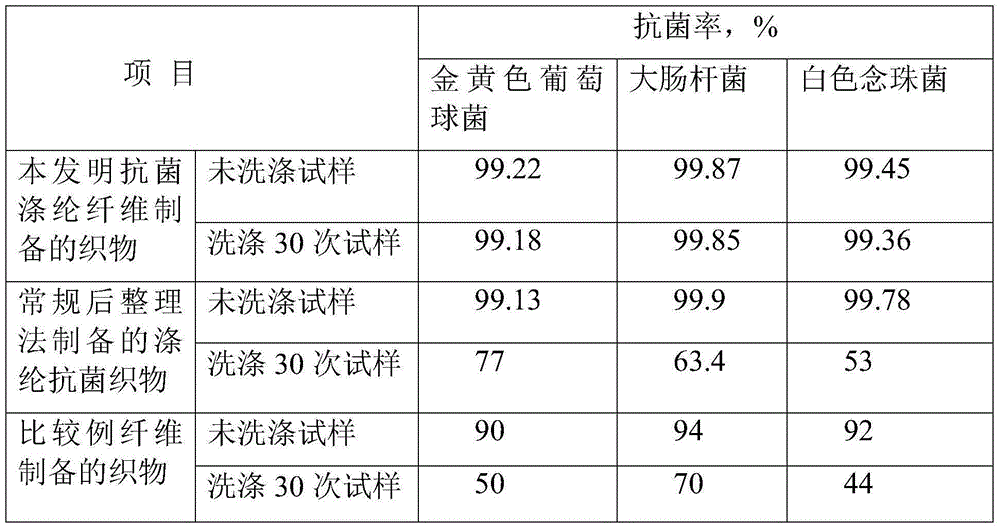

Antibacterial polyester fibers and preparation method thereof

InactiveCN105040142ASimple methodImprove antibacterialMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterChemistry

The invention belongs to the textile field and particularly relates to antibacterial polyester fibers. The antibacterial polyester fibers are prepared through melt spinning from the following materials in parts by weight: 100 parts of PET (polyester) chips and 2-5 parts of antibacterial polyester master batch, wherein the antibacterial polyester master batch is prepared from PET chips as well as a preprocessing nano-silver antibacterial agent with weight accounting for 2%-5% of that of the PET chips, an antioxidant with weight accounting for 2%-3% of that of the PET chips, a lubricant with weight accounting for 0.1%-2% of that of the PET chips and a dispersant with weight accounting for 1%-3% of that of the PET chips through melt blending and extruding, and the preprocessing nano-silver antibacterial agent is nano silver subjected to coating treatment through a hydroxypropyl-beta-cyclodextrin solution in a fluidized bed. According to the invention, uniform distribution with a small particle size of the nano-silver antibacterial agent in a PET base body is guaranteed, and the high-efficiency and long-acting antibacterial polyester fibers are prepared through melt spinning. A preparation method disclosed by the invention is simple and feasible, and is suitable for industrial popularization and application.

Owner:俞尧芳

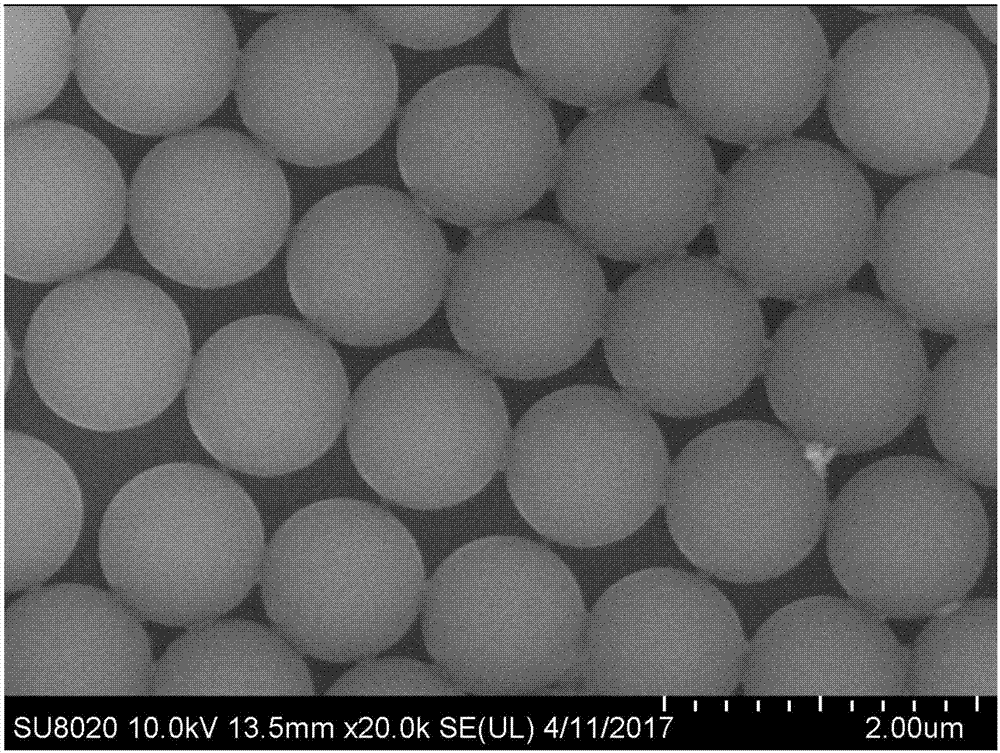

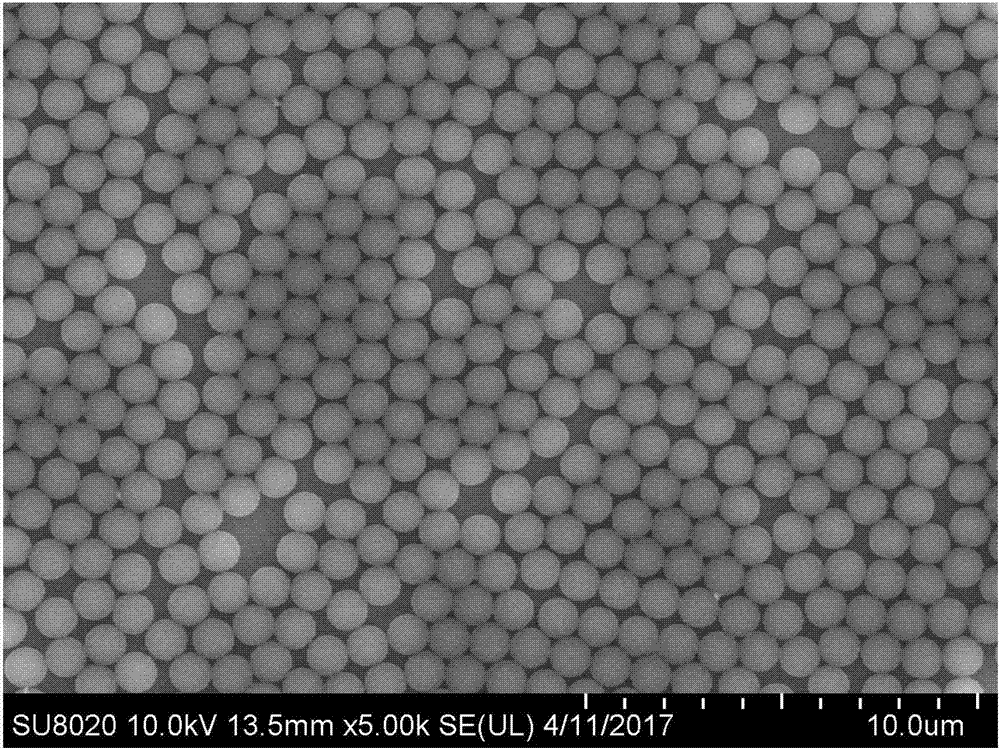

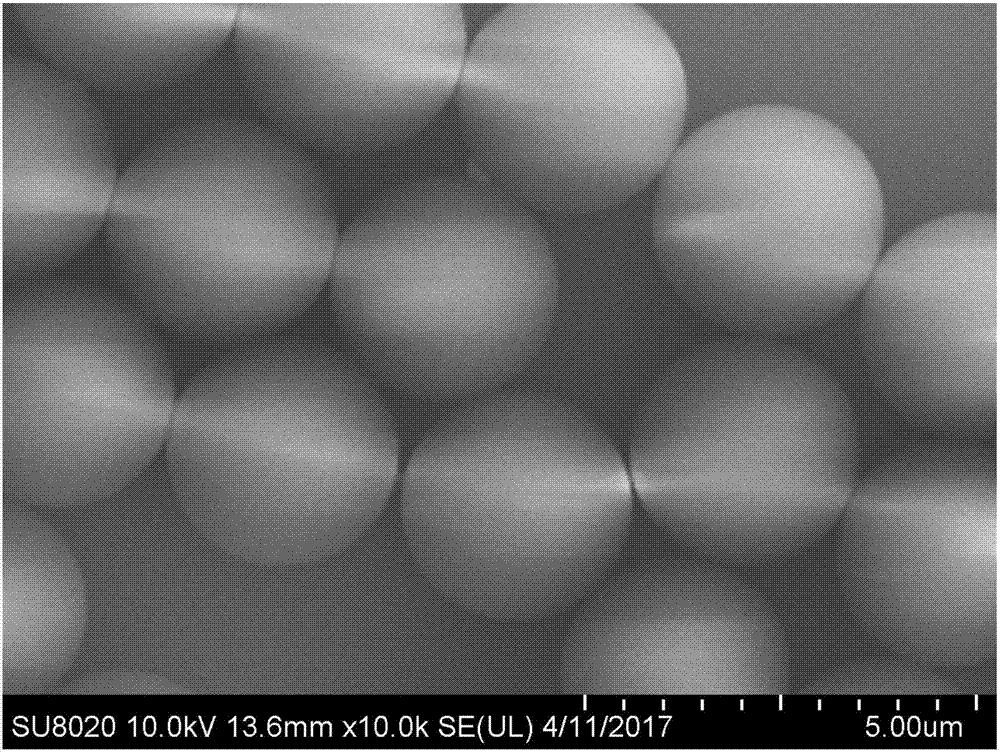

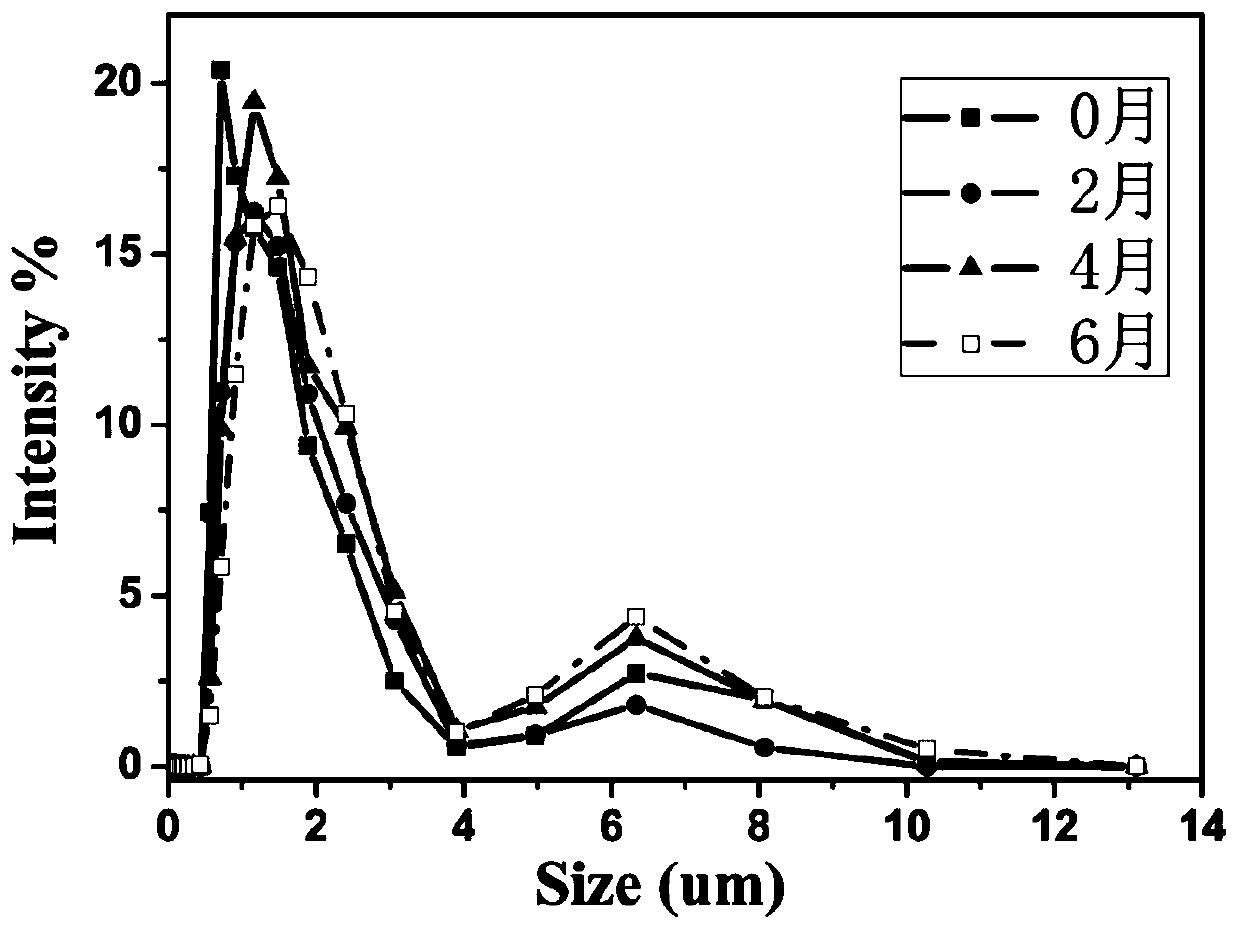

Preparation method of multilayer assembled micron-grade mono-disperse polystyrene magnetic composite microspheres

ActiveCN107245196AHighly uniform particle sizeUniform particle sizePolystyrene microsphereCationic polyelectrolytes

The invention belongs to the technical field of high molecular functional materials and provides a preparation method of multilayer assembled micron-grade mono-disperse polystyrene magnetic composite microspheres. The preparation method of the polystyrene magnetic composite microspheres comprises the following steps: preparing mono-disperse sulfo or carboxyl polystyrene microspheres with rich negative charges on surfaces by adopting dispersion polymerization; then utilizing electrostatic interaction among the mono-disperse sulfo or carboxyl polystyrene microspheres, strong cation polyelectrolyte and sodium citrate modified Fe3O4 nanoparticles to finally prepare the micron-grade mono-disperse polystyrene magnetic microspheres. According to the preparation method provided by the invention, the mono-disperse polystyrene magnetic microspheres with highly uniform grain diameter and a micron-grade grain diameter can be obtained; the application requirements in the fields of chemiluminescence immunity, cell separation, protein purification and the like can be met; the preparation method provided by the invention also has the advantages of simplicity and convenience for operation, energy saving and consumption reduction and is suitable for industrialized popularization and application.

Owner:成都爱兴生物科技有限公司

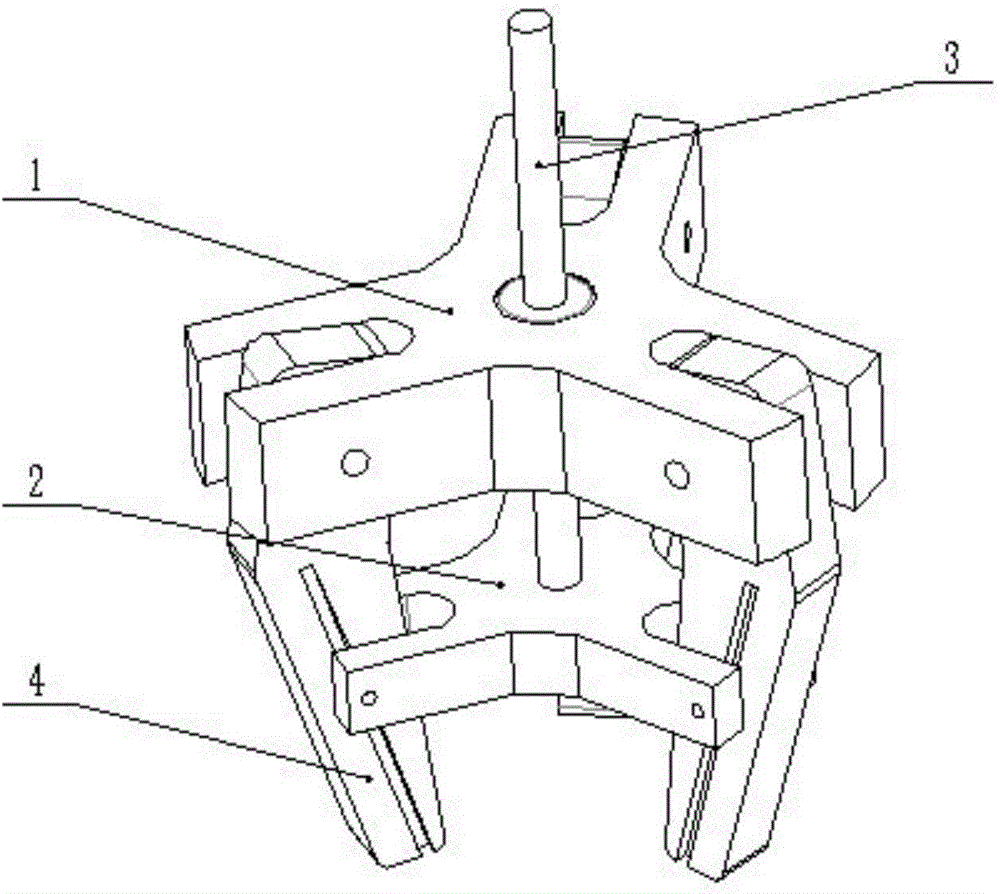

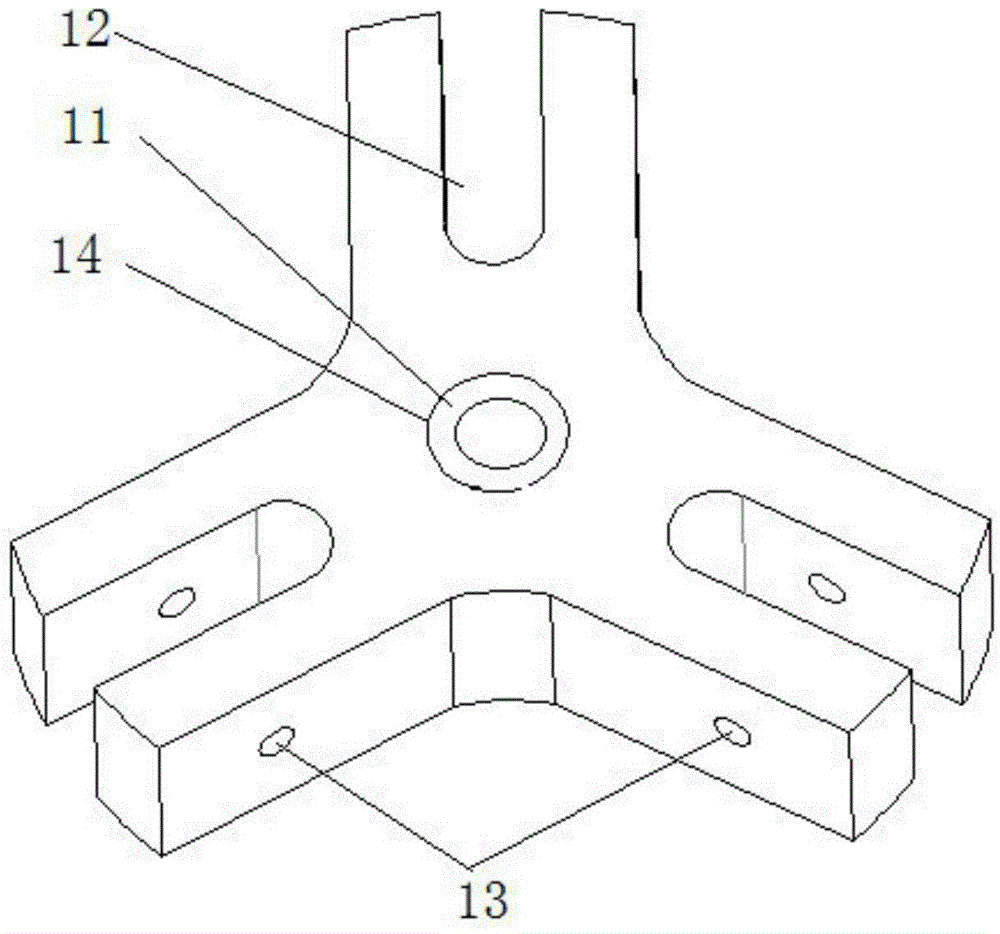

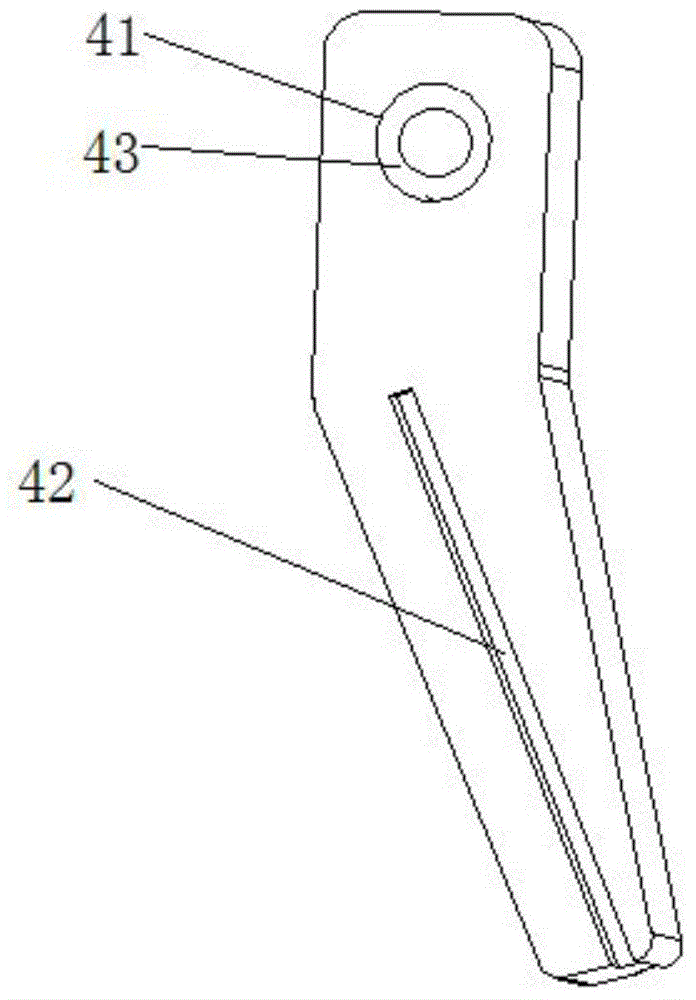

Three-claw gripping device

Owner:HEBEI UNIV OF TECH

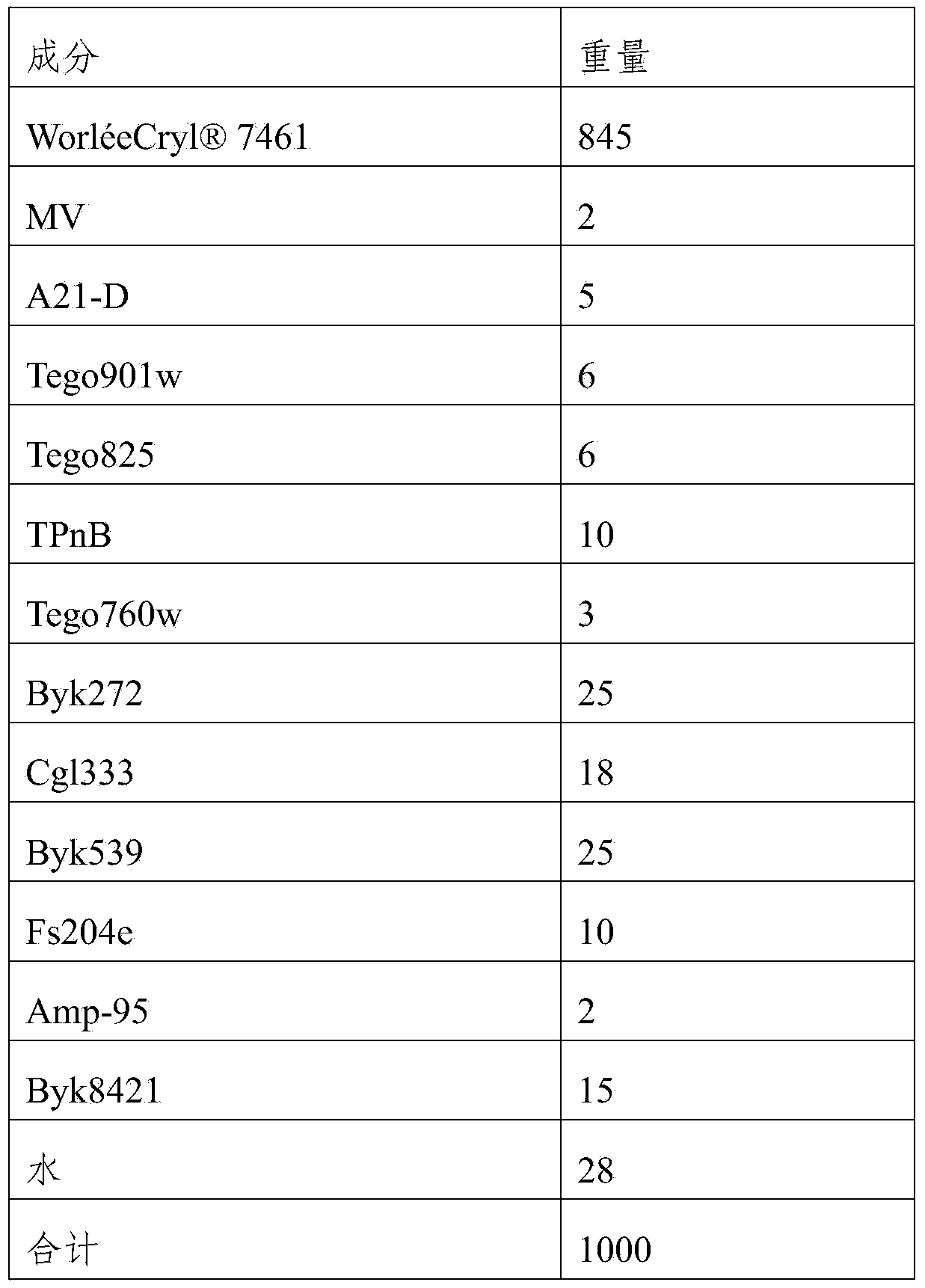

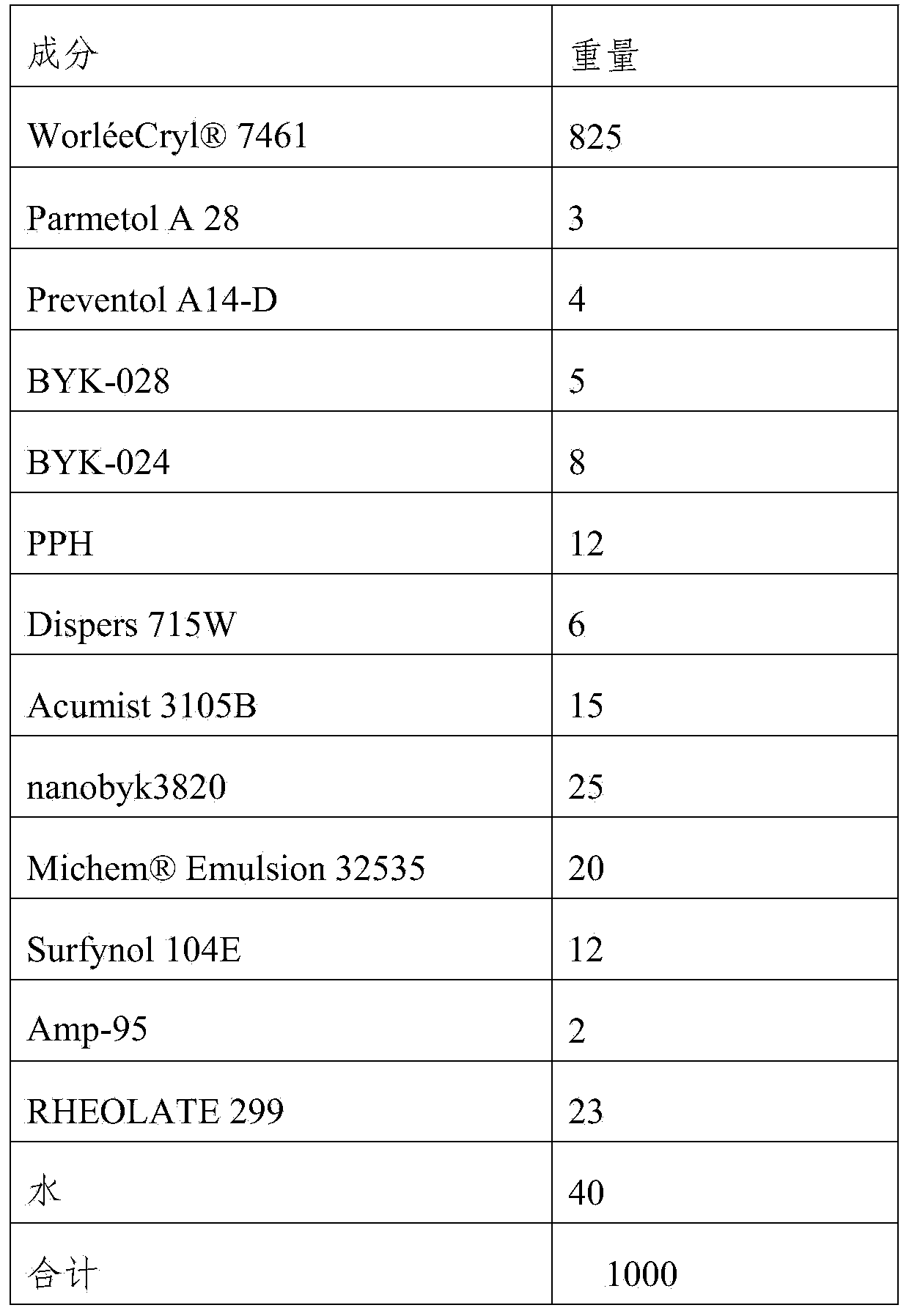

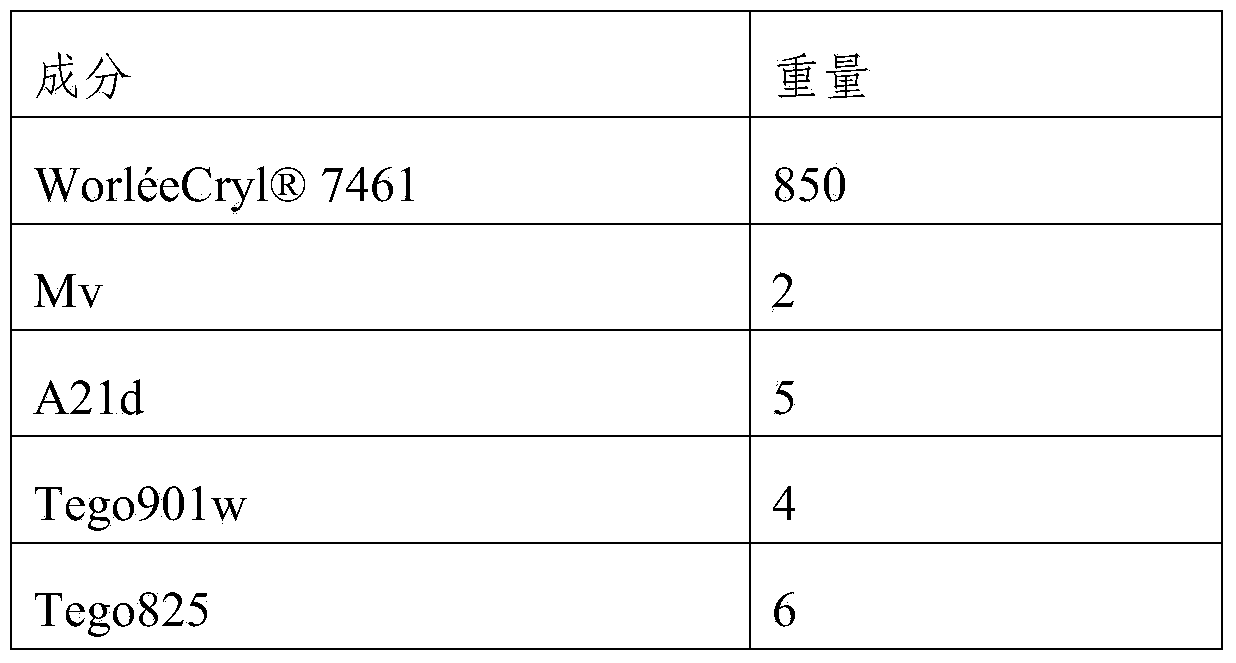

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

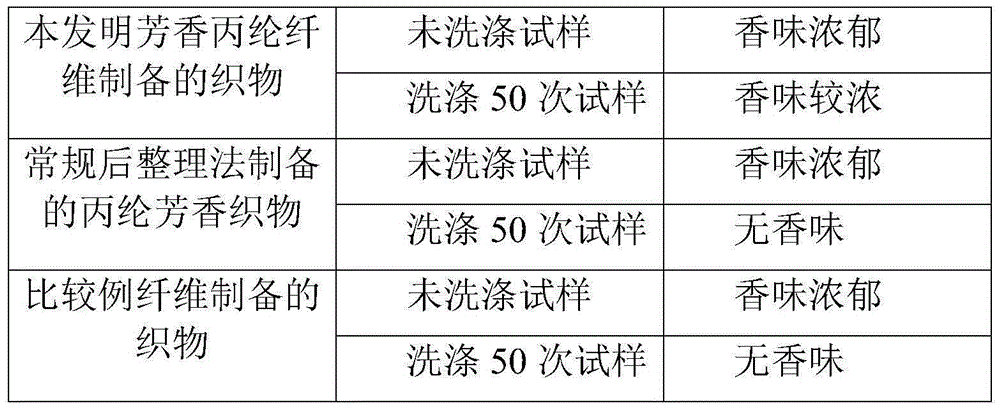

Aromatic polypropylene fiber and preparation method thereof

InactiveCN105002584ASolve the problem of uniform distribution of small particle sizeSimple methodMelt spinning methodsMonocomponent polyolefin artificial filamentFluidized bedLubricant

The invention belongs to the textile field, and particularly relates to aromatic polypropylene fiber. The aromatic polypropylene fiber is prepared from materials in parts by weight through melt spinning as follows: 100 parts of fiber-grade PP (propene polymer) slices and 1-4 parts of aromatic polypropylene master batch, wherein the aromatic polypropylene master batch is prepared from the fiber-grade PP slices as well as 3%-6% of preprocessed nano essence, 1%-3% of an antioxidant, 0.1%-1% of a lubricant and 0.5%-2% of a dispersing agent by weight of the fiber-grade PP slices through melt blending and extrusion, and the preprocessed nano essence is nano essence subjected to coating processing through a hydroxypropyl-beta-cyclodextrin solution in a fluidized bed. The problem of uniform distribution of nano essence with small particle sizes in a PP matrix is solved, efficient and long-acting aromatic polypropylene fiber is prepared through melt spinning, and a method is simple, easy to implement and suitable for industrial popularization and utilization.

Owner:俞尧芳

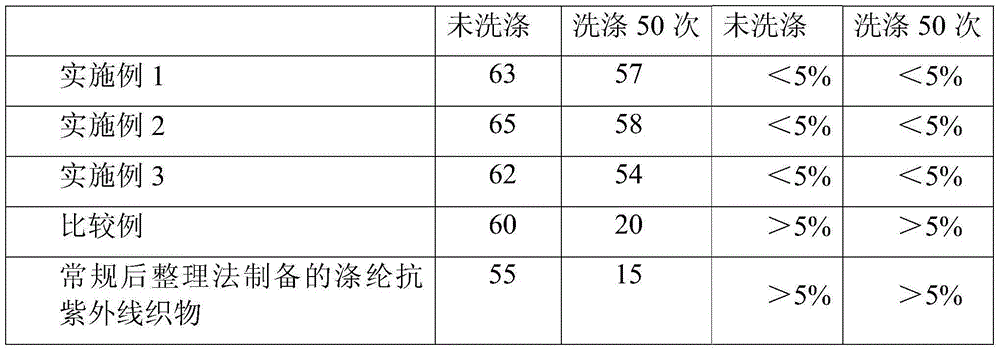

Anti-ultraviolet polyester fibers and preparation method thereof

InactiveCN105088389ASolve the problem of uniform distribution of small particle sizeSimple methodMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterUltraviolet

The invention belongs to the field of textiles, and in particular relates to anti-ultraviolet polyester fibers. The anti-ultraviolet polyester fibers are prepared by melt-spinning the following materials in parts by weight: 100 parts of PET chips and 1-5 parts of anti-ultraviolet polyester master batches, wherein the anti-ultraviolet polyester master batches are prepared by melt-blending and extruding the PET chips, and 2-5% of pre-treated nano-ceramic powder, 1-3% of an anti-oxidant, 0.5-2% of a lubricating agent and 0.4-3% of a dispersant based on the weight of the PET chips; and the pre-treated nano-ceramic powder is obtained by coating the nano-ceramic powder with a hydroxypropyl-beta-cyclodextrin solution. According to the anti-ultraviolet polyester fibers and the preparation method thereof, the problem about uniform distribution of small-particle nano-ceramic powder in a PET substrate is solved; high-efficiency and long-lasting anti-ultraviolet polyester fibers are prepared by melt-spinning; and the method disclosed by the invention is simple and feasible, and is applicable to industrial popularization and use.

Owner:俞尧芳

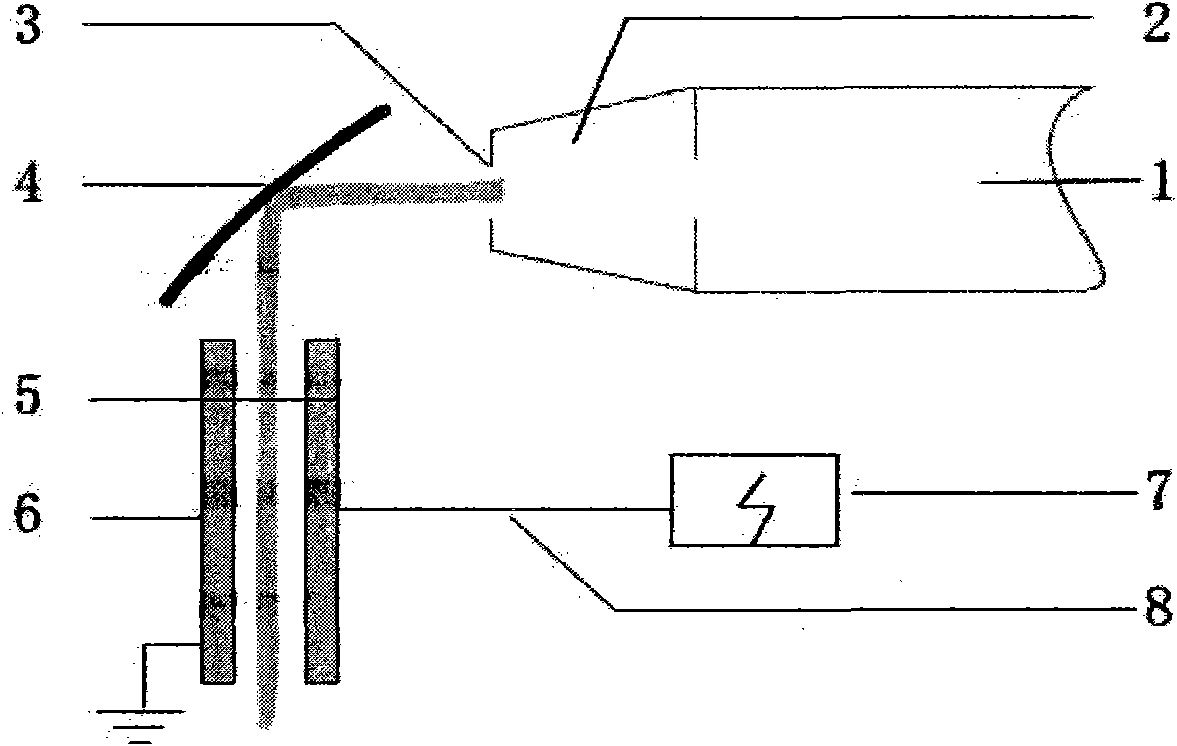

Flash spinning equipment

InactiveCN101876089ARelieve pressureImprove solubilityFlash-spinning methodsHigh pressureHigh voltage

The invention discloses flash spinning equipment. The equipment mainly comprises a high pressure kettle, a heating sleeve of the high pressure kettle, a transmission motor, a stirrer, a high voltage electric valve and a spinning nozzle, and is characterized in that: a kettle cover of the high pressure kettle is provided with a pressure relief hole and a pressure relief valve, so the high pressure kettle simultaneously has the functions of a low pressure kettle; and the bottom of the high pressure kettle is in direct pipe connection with the spinning nozzle through the high pressure electric valve. The flash spinning equipment has the advantages of simple structure, easy control and the suitability for industrial use.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation technique of complex fungicide repairing amino acid fermenting wastewater

ActiveCN104891677ALarge specific surface areaHigh tensile strengthBiological water/sewage treatmentFungicideEngineering

The invention relates to the technical field of microorganism, in particular to a preparation technique of complex fungicide repairing amino acid fermenting wastewater. The preparation technique includes steps of 1) preparing a carrier; 2) preparing complex fungicide liquid; 3) preparing complex algae solution; 4) preparing complex fungicide. The preparation technique is simple, feasible, easy to master, and applicable to industrial popularization and use.

Owner:内蒙古阜丰生物科技有限公司

Method for preparing tungsten disulfide/graphene heterostructure

InactiveCN106277059AImprove performanceImprove conduction abilityNanotechnologyTungsten compoundsProbe typeLithium-ion battery

The invention discloses a method for preparing a tungsten disulfide / graphene heterostructureby a liquid-phase ultrasonic method. The method comprises the following steps: by using a tungsten disulfide nanosheet ethanol dispersion solution and a graphene ethanol dispersion solution as raw materials, respectively proportionally measuring certain volumes of the tungsten disulfide nanosheet dispersion solution and graphene dispersion solution, and carrying out ultrasonic treatment at normal temperature for 30 minutes by using a probe-type ultrasonic facility with the ultrasonic power of 100-200W; mixing the two obtained dispersion solutions, and carrying out ultrasonic treatment at 50 DEG C for 6 hours by using a tank-type ultrasonic facility with the ultrasonic power of 200-600W, thereby obtaining a mixed dispersion solution; carrying out vacuum filtration on the mixed dispersion solution through a microporous filter membrane, and collecting the filter cake; and carrying out vacuum drying on the collected filter cake at 80 DEG C for 2 hours to obtain the black tungsten disulfide / graphene heterostructure. The preparation method is simple and controllable; and the prepared tungsten disulfide / graphene heterostructure has potential application value in the fields of semiconductor electronic devices, lithium ion batteries, catalytic hydrogen production, electromagnetic wave absorption and the like.

Owner:QIQIHAR UNIVERSITY

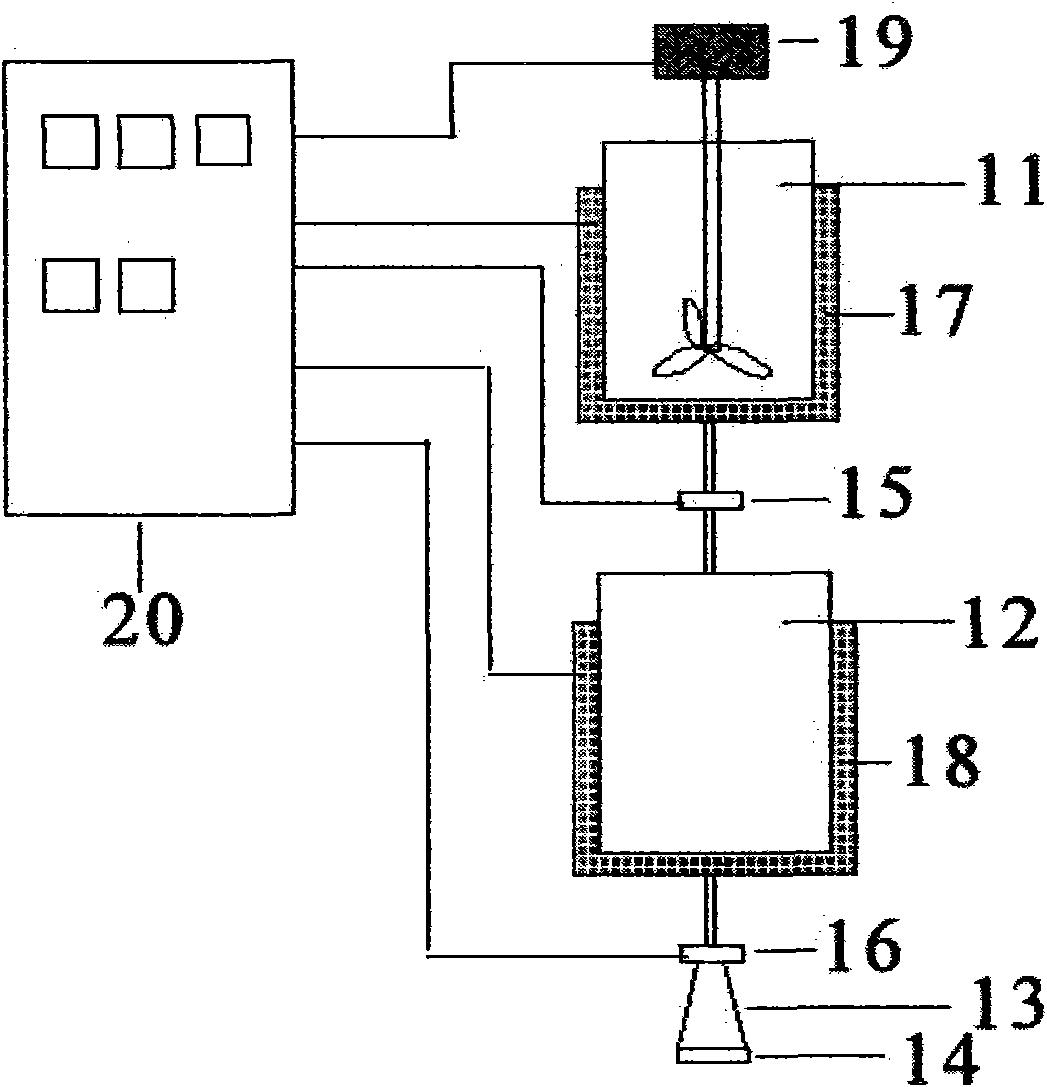

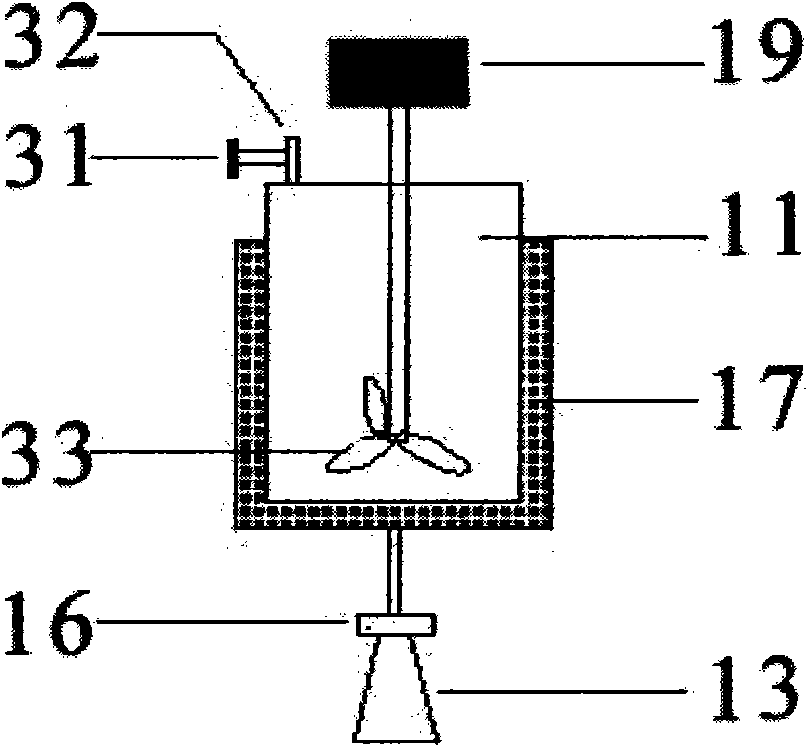

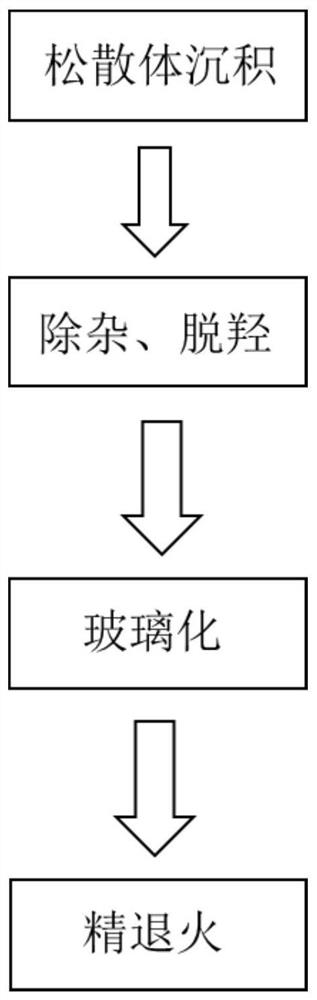

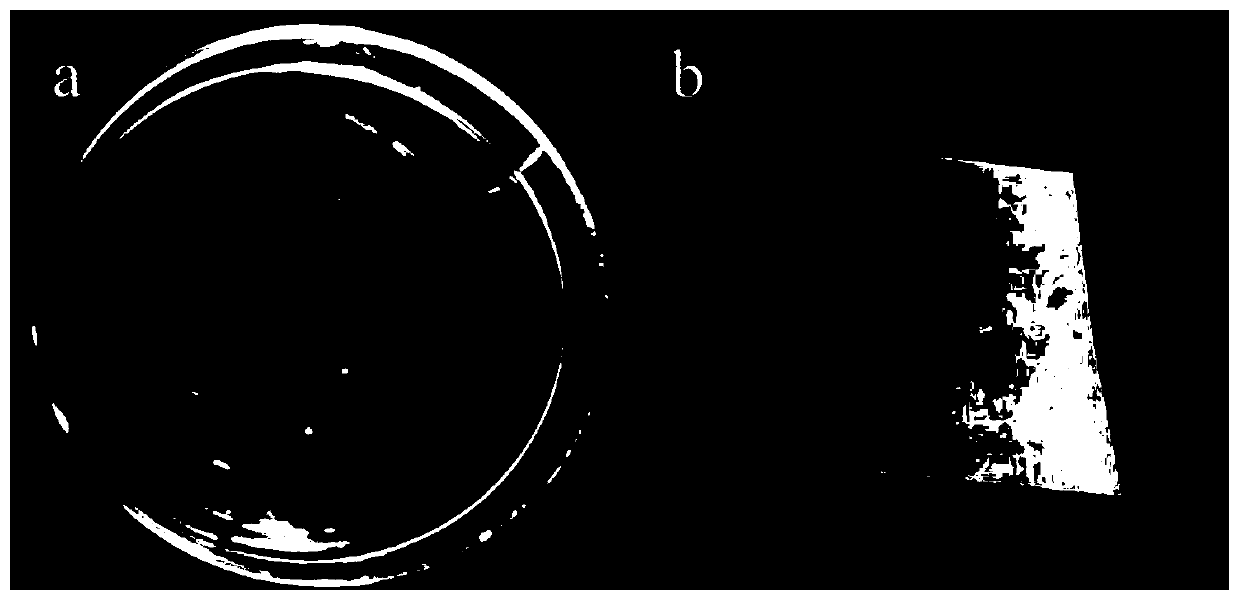

Chemical deposition method and device for high-purity low-hydroxyl high-uniformity quartz glass

PendingCN112876044AGuaranteed purityLow impurity contentGlass shaping apparatusVitrificationPhysical chemistry

The invention relates to a chemical deposition method of high-purity low-hydroxyl high-uniformity quartz glass, which comprises the following steps: (1) depositing a silicon source in a deposition cavity by adopting a vapor phase axial deposition method to obtain a low-density SiO2 loose body; wherein in the deposition process, the interior of the deposition cavity is controlled to be in a negative pressure environment, and the temperature is not higher than 500 DEG C; (2) in a closed environment filled with dehydroxylation airflow and oxygen, heating the low-density SiO2 loose body to 1100-1300 DEG C, so that the low-density SiO2 loose body is dehydrated, dehydroxylated and densified; then, placing the low-density SiO2 loose body in an inert gas environment, heating to 1470-1600 DEG C, and vitrifying the low-density SiO2 loose body to form transparent quartz glass; and (3) annealing the transparent quartz glass to obtain the high-purity low-hydroxyl high-uniformity quartz glass. The invention further discloses a device adopting the chemical deposition process. According to the chemical deposition method of the high-purity low-hydroxyl high-uniformity quartz glass, the production process is high in continuity, and the content of metal impurities in the produced quartz glass is extremely low.

Owner:江苏亨芯石英科技有限公司 +1

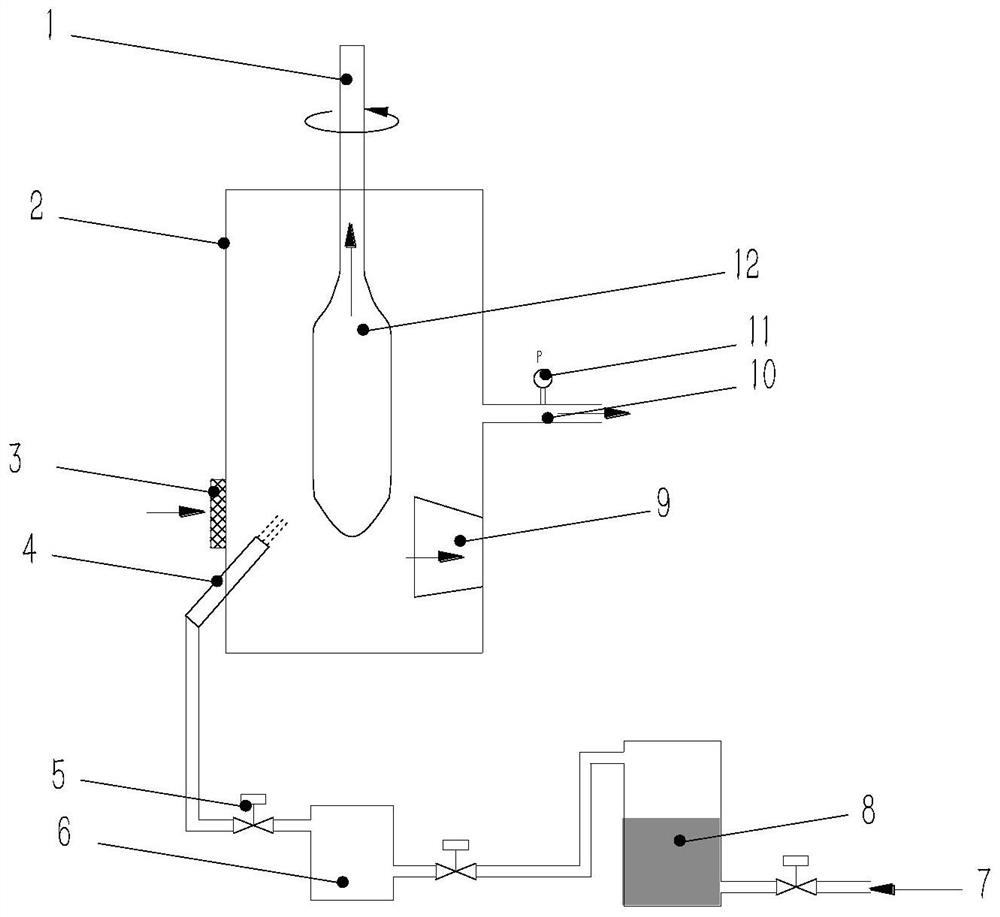

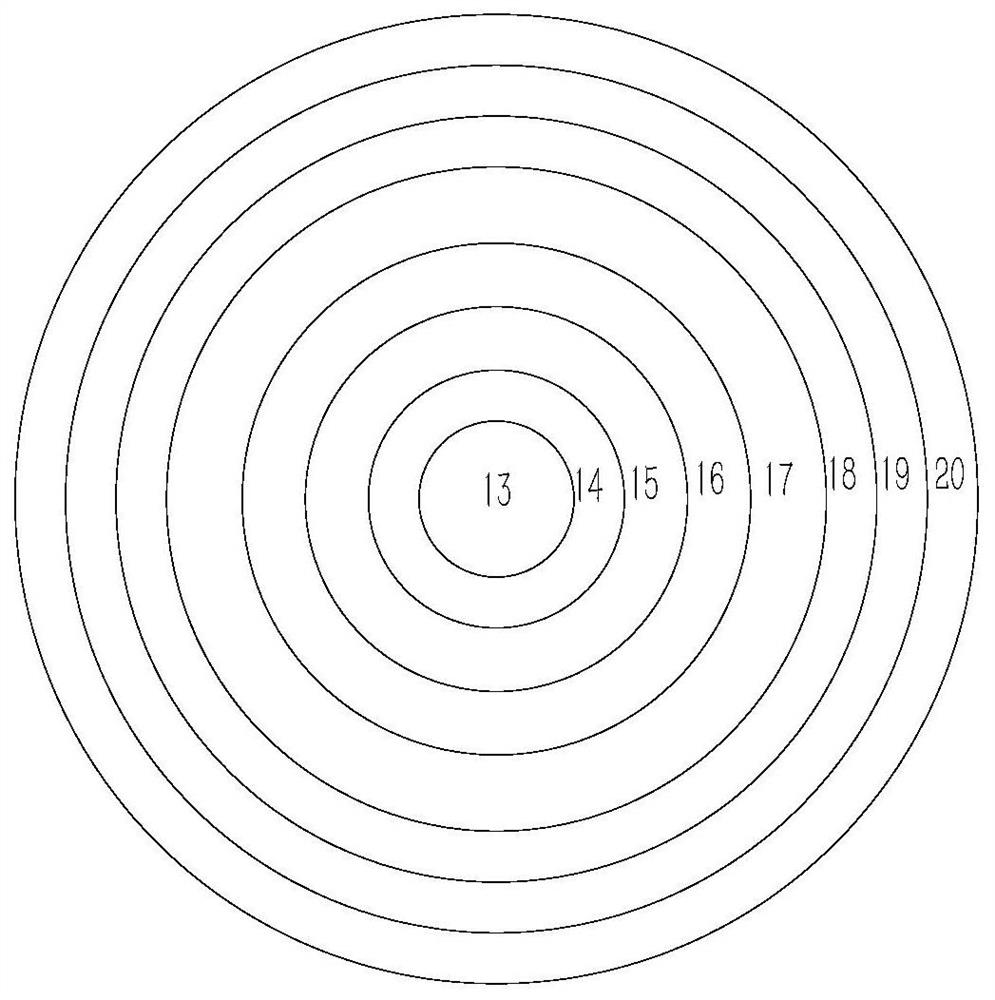

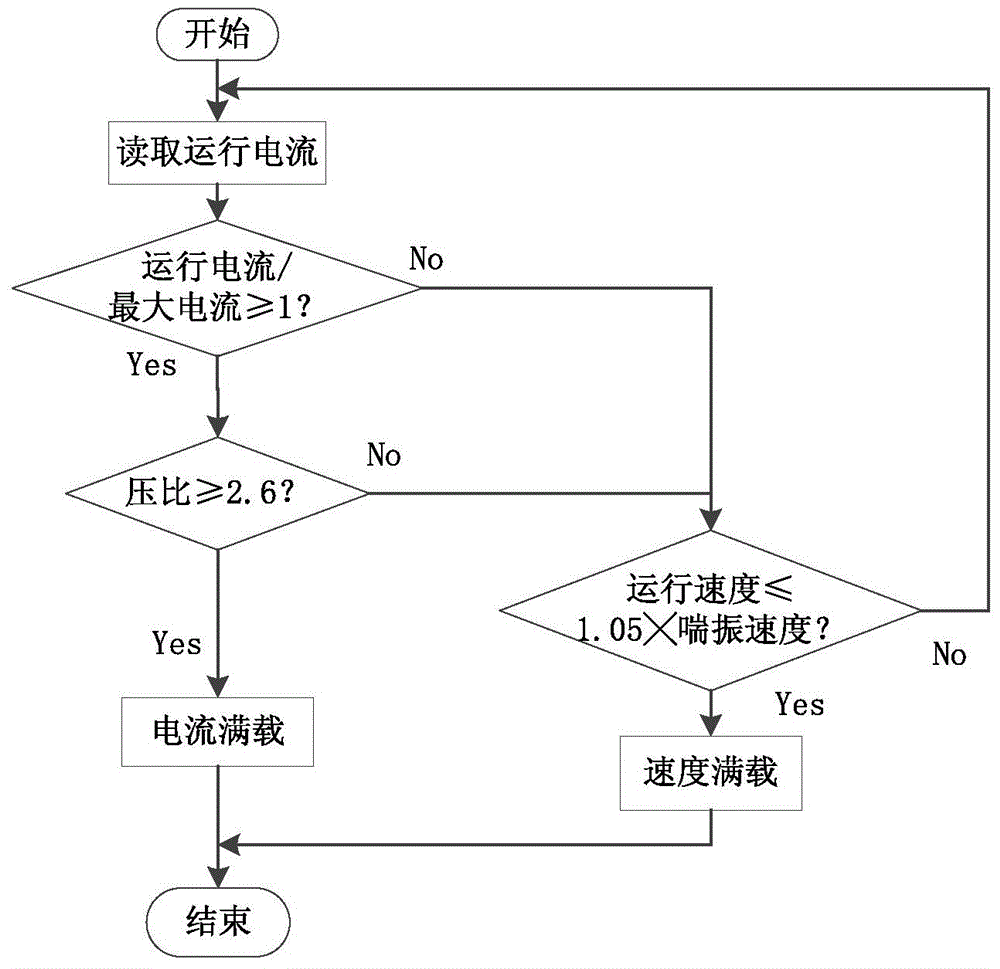

Method for judging running states of magnetic suspension cooling water units in freezing station control systems

ActiveCN104676995AIncrease loading capacityGood control effectRefrigeration safety arrangementControl systemLoad capacity

Owner:青岛中增能源科技有限公司

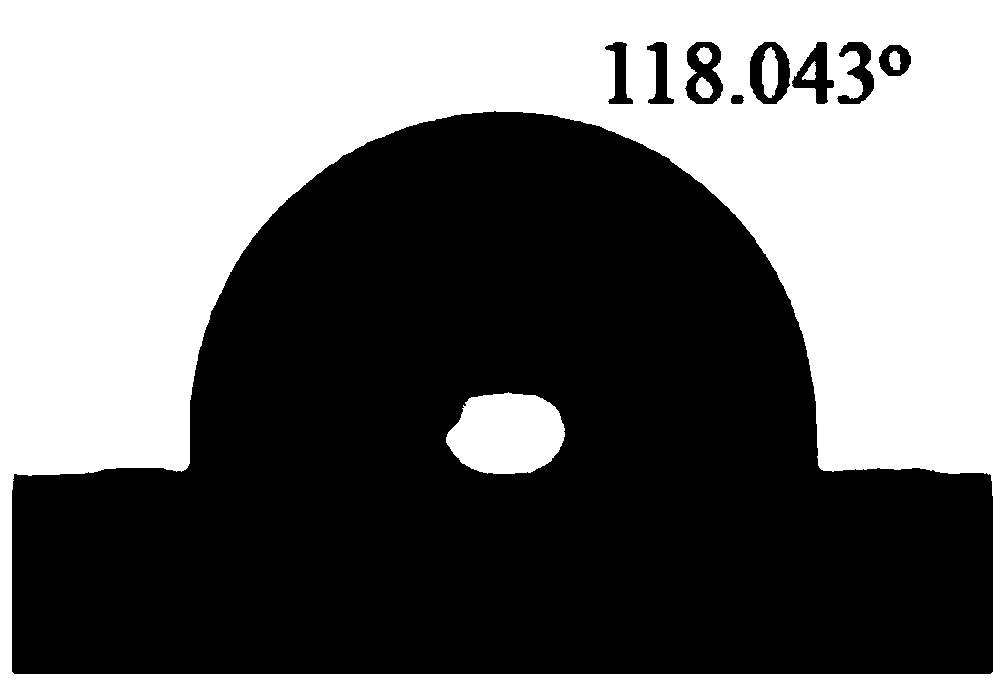

Preparation and application of waterborne polyurethane emulsion

InactiveCN110669201AUniform particle size distributionImprove stabilityPolyurea/polyurethane coatingsHydrophilic monomerPolyester

The invention belongs to the field of polymer functional materials and particularly relates to a preparation and application of waterborne polyurethane emulsion. An acetone method is adopted to enablemixed isocyanate to react with mixed polyester, a hydrophilic monomer, namely dimethylolpropionic acid (DMPA) is introduced, and under the combined action of a chain extender, namely trimethylolpropane (TMP), the waterborne polyurethane emulsion released by non-volatile organic compounds is prepared. Through various characterization means, it is verified that the waterborne polyurethane emulsionhas excellent stability and hydrophobic performance, has the characteristics of low production cost and excellent performance, and can be subjected to large-scale industrial production and application.

Owner:宜兴市华夏化工材料有限公司 +1

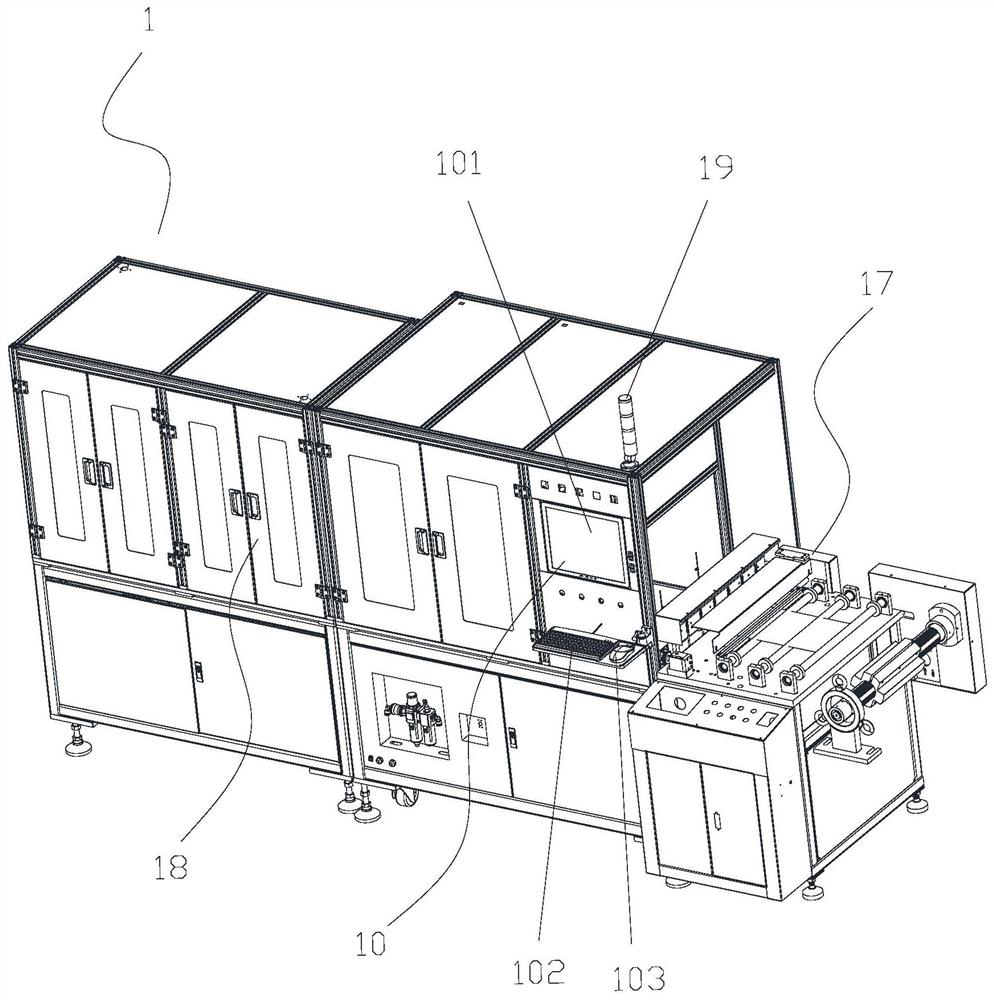

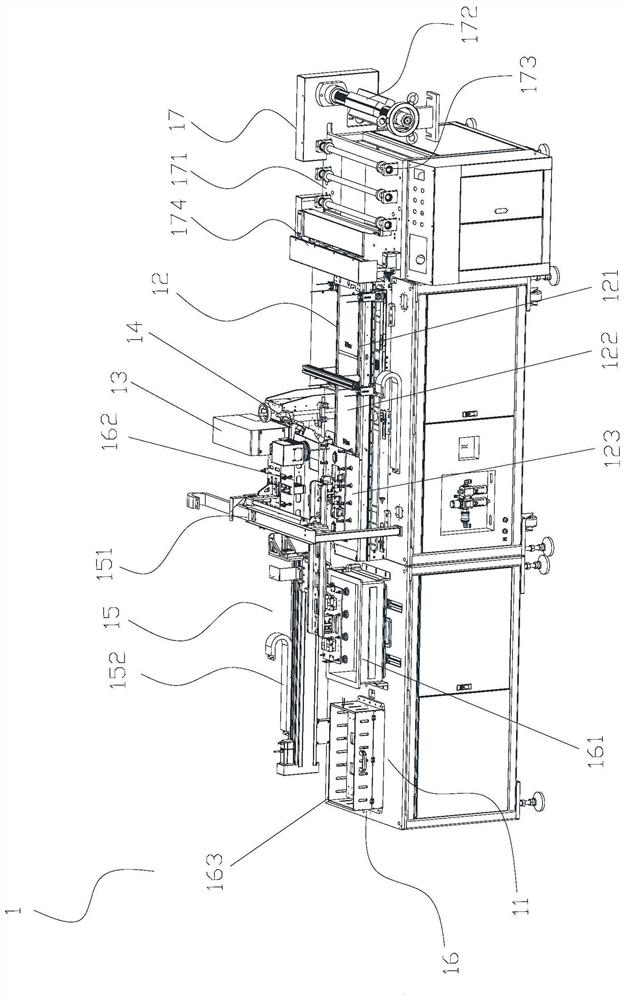

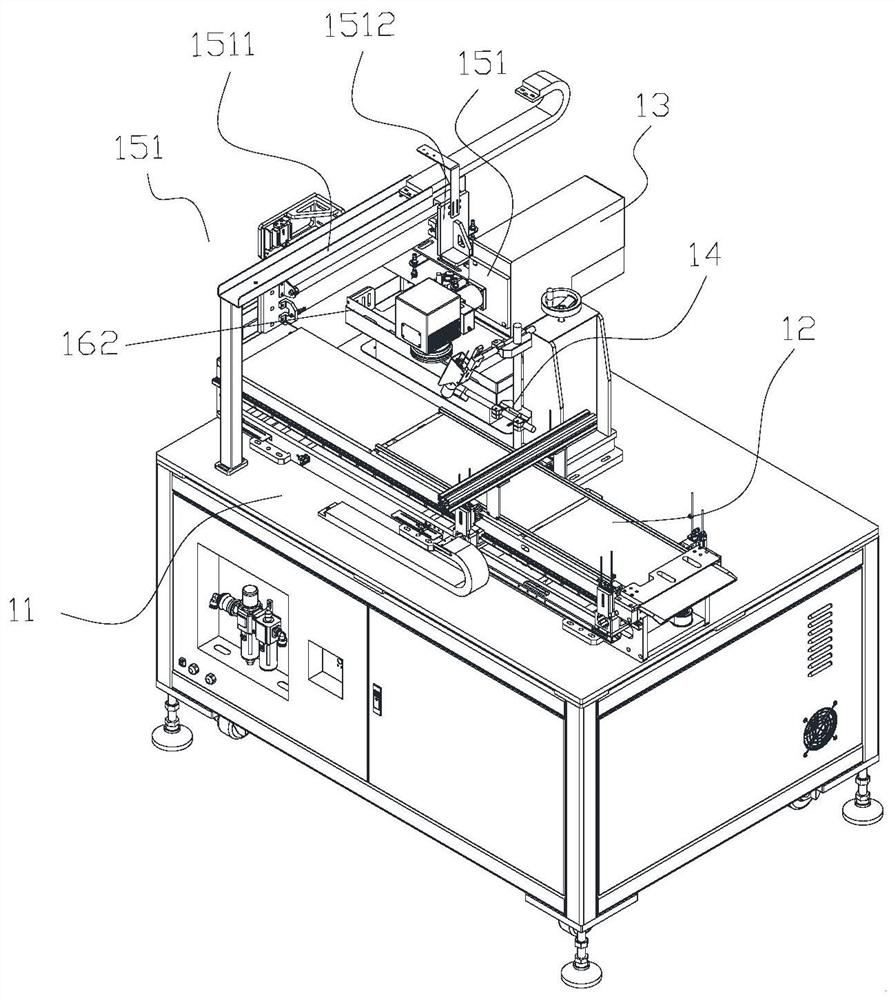

Two-dimensional code marking system

InactiveCN112046157AHigh degree of automationImprove processing efficiencyTypewritersOther printing apparatusComputer hardwareSoftware engineering

The invention discloses a two-dimensional code marking system, and relates to the technical field of automatic marking equipment. The two-dimensional code marking system comprises a control device anda workbench, and further comprises a product conveying unit, a laser coding unit, a code scanning detection unit, a carrying unit and a material box which are arranged on the workbench, wherein the product conveying unit, the laser coding unit, the code scanning detection unit and the carrying unit are electrically connected with the control device. The two-dimensional code marking system is highin automation degree, automatic plate cutting, automatic coding, automatic code scanning, automatic sorting and carrying and other operations can be conducted, the machining efficiency is greatly improved, and the two-dimensional code marking system is suitable for industrial application and popularization.

Owner:江苏创励安科技有限公司

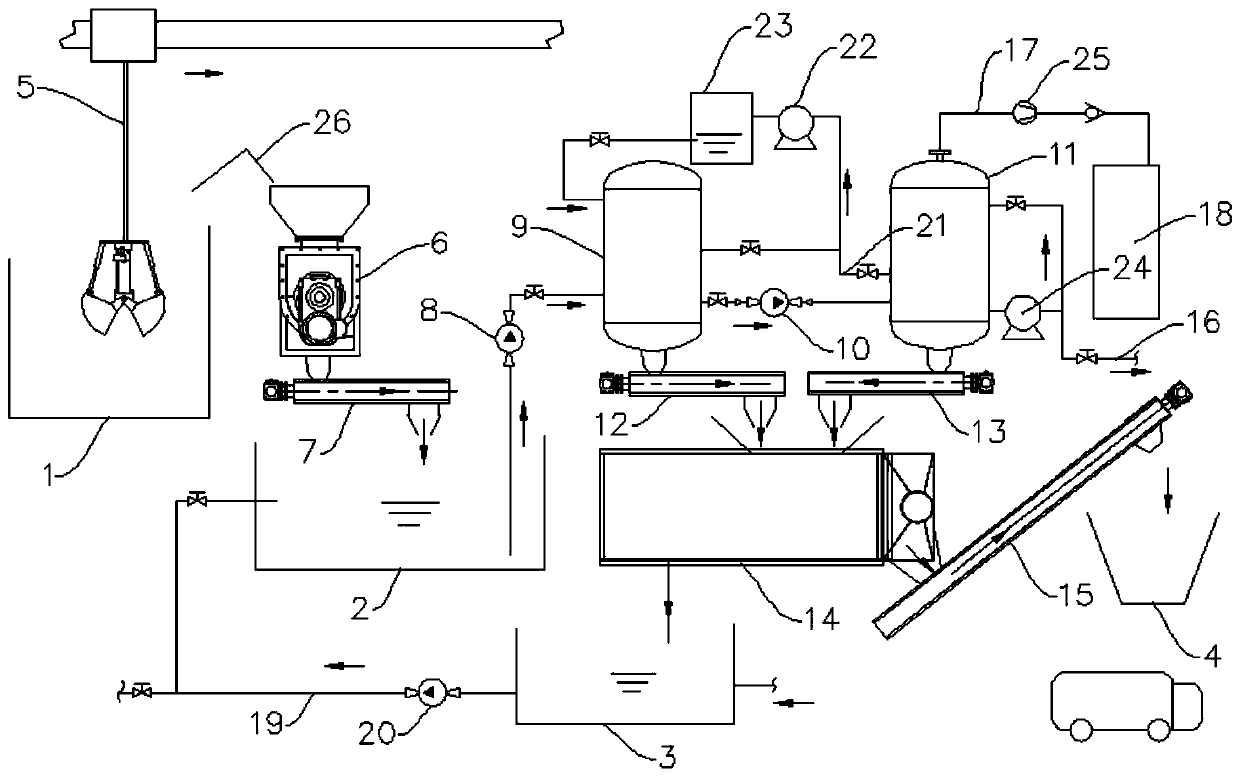

Complete set of device for processing kitchen waste and method thereof

PendingCN110938526AImprove processing efficiencyImprove system performanceBioreactor/fermenter combinationsBiological substance pretreatmentsFluid phaseSlurry

The invention relates to a complete set of device for processing kitchen waste and a method thereof. The device includes a garbage tank, a slurry tank, a clear liquid tank and a residue tank. A grab driving mechanism and a crusher are arranged near the garbage tank. The material crushed by the crusher is introduced into the slurry tank, the slurry tank is connected to a first feed pump, a first fermentation tank, a second feed pump and a second fermentation tank in sequence through the feed pipes, the bottom of the first and second fermentation tanks are respectively communicated with the inlets at the top of an extruder. A liquid phase outlet of the extruder is connected to the clear liquid tank, the extruded residue of the extruder can be sent to the residue tank, a liquid phase outlet of the second fermentation tank is connected to the clear liquid tank, the gas phase outlet of the second fermentation tank is connected to a biogas storage tank. The device has the advantage that thepre-processed kitchen waste can be converted into a COD-compliant clear liquid and high value-added biogas after crushing, pulping and two fermentations. The complete set of the device has good integrity, small land occupation and easy installation and maintenance, high processing efficiency of kitchen waste, and is suitable for industrial use.

Owner:武汉百信环保能源科技有限公司

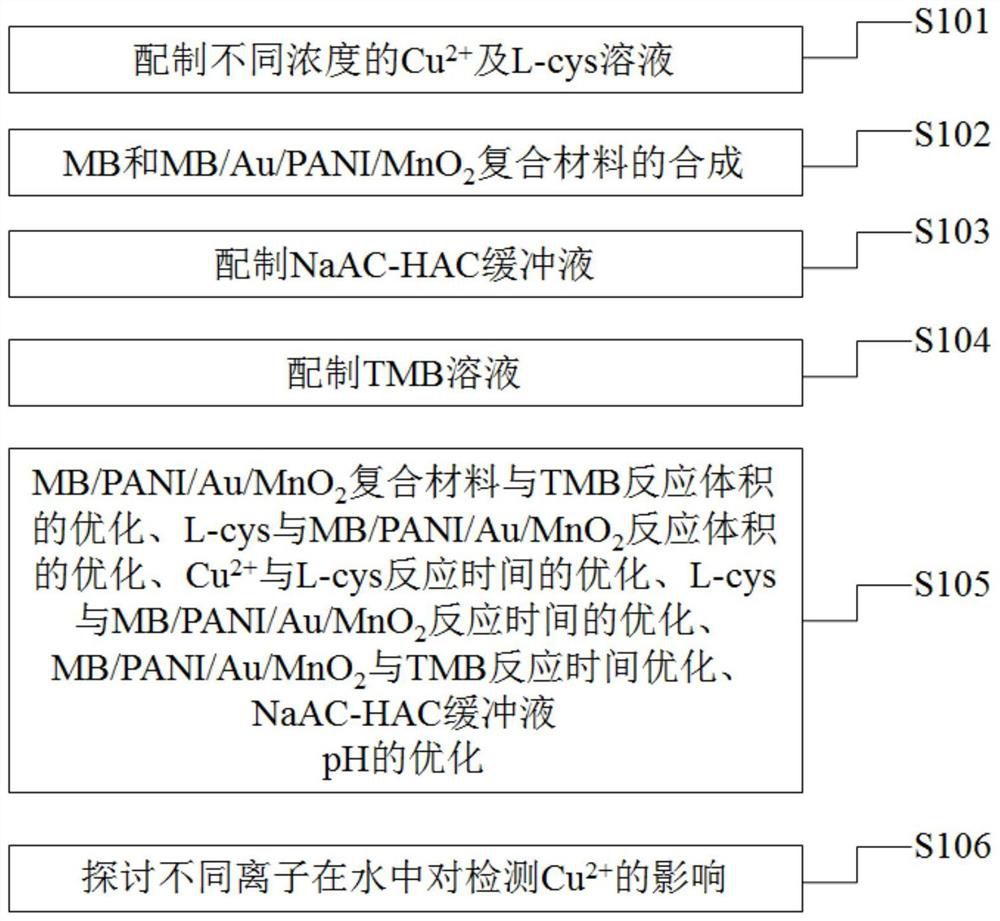

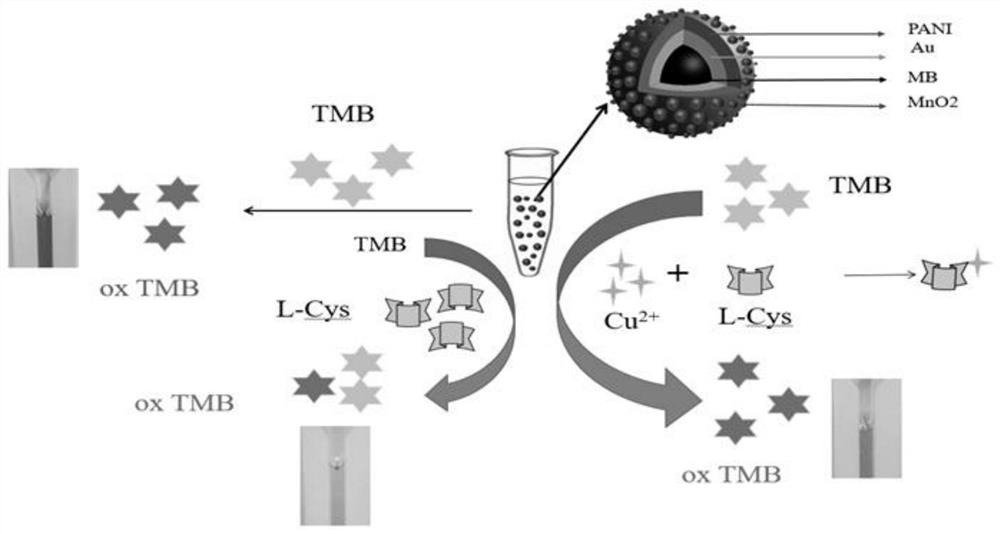

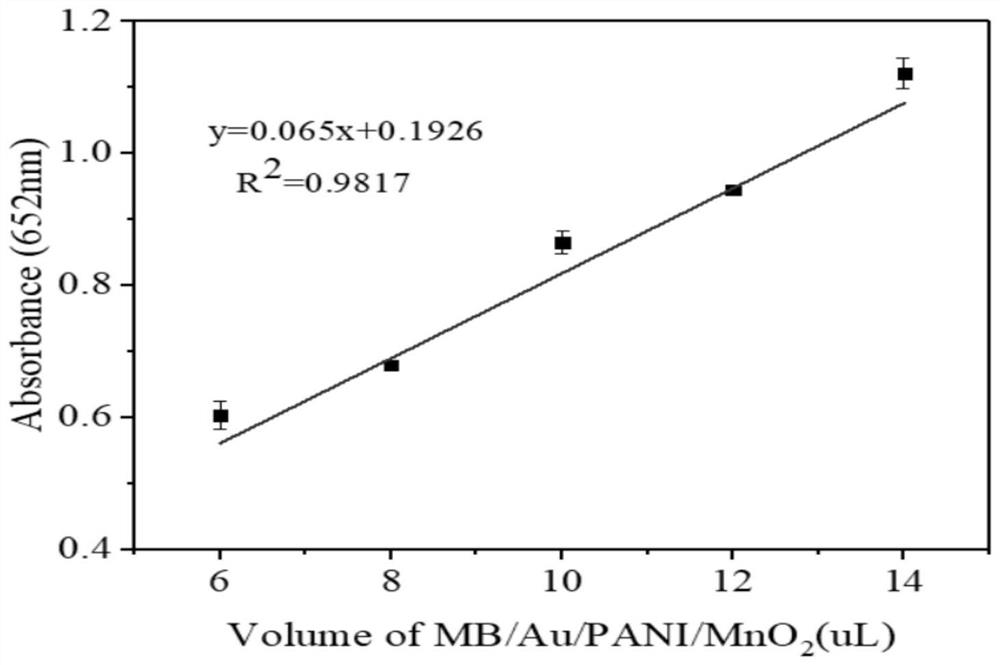

Copper ion colorimetric detection method based on MnO2 complex enzyme stimulant

PendingCN112557383AHigh analytical sensitivityAvoid expensiveMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsCu2 ionsBuffer solution

The invention relates to a copper ion colorimetric detection method based on a MnO2 complex enzyme stimulant and application. The method comprises the following steps: preparing copper ions and L-cyssolutions with different concentrations; synthesizing an MB and MB / Au / PANI / MnO2 composite material; preparing a NaAC-HAC buffer solution; preparing a TMB solution; optimizing conditions; and performing colorimetric detection on the copper ions. According to the copper ion colorimetric detection method based on the MnO2 complex enzyme stimulant and the application, the MB / Au / PANI / MnO2 composite material serves as the complex enzyme stimulant and has high catalytic performance, high-sensitivity and quantitative detection of copper ions is achieved, the selectivity and stability of target objectdetection are improved, the compound enzyme stimulant is replaced with other MnO2-doped compounds which can be applied to detection and analysis of a new target object, the universality is high, the detection method is simple and convenient, the cost is low, the raw materials are easy to obtain and non-toxic, and the method can be applied to actual sample detection and is suitable for industrial popularization.

Owner:GUIZHOU UNIV

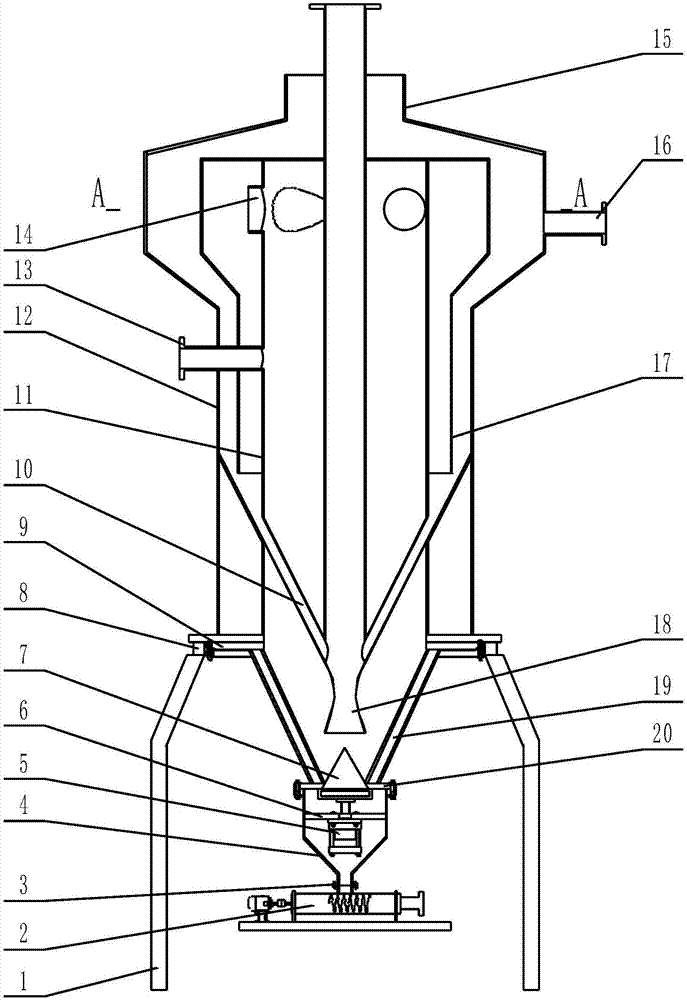

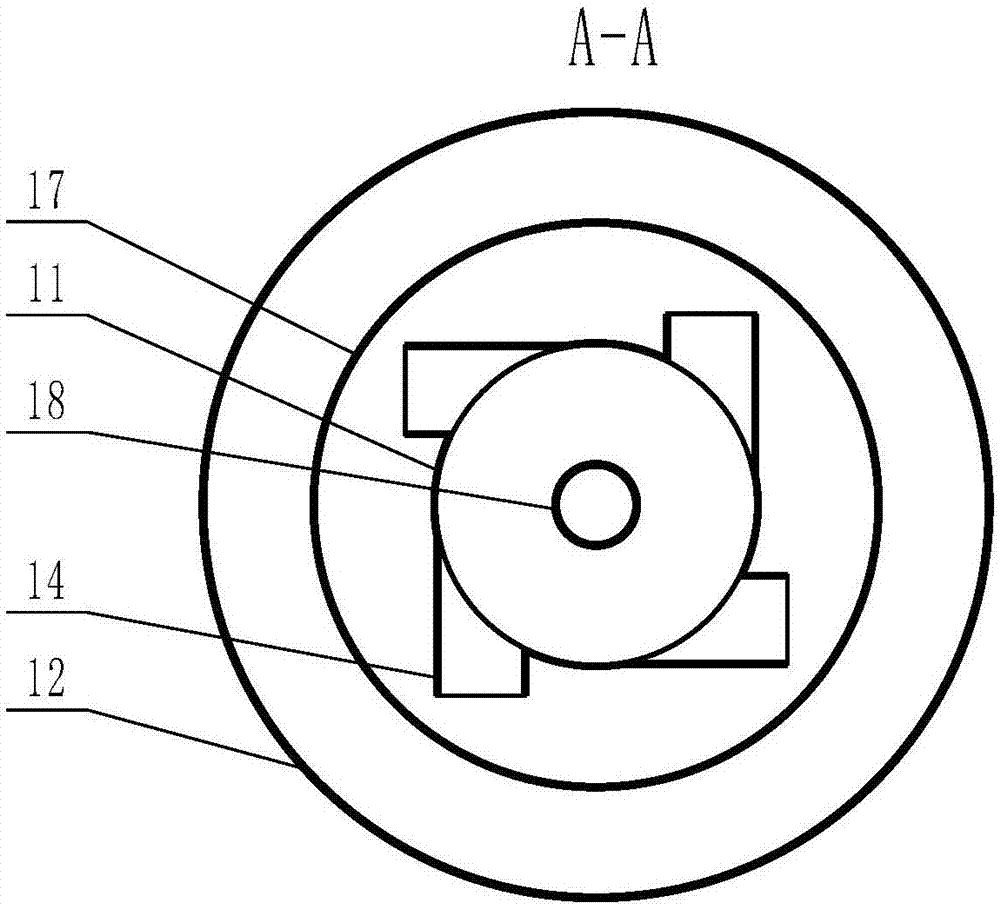

Flow-washing-type battery material dryer free of screen cloth

ActiveCN107514894AGood insulation effectEasy to transport materialsDrying gas arrangementsPistonAirflow

The invention relates to a flow-washing-type battery material dryer free of a screen cloth. The flow-washing-type battery material dryer free of the screen cloth is characterized in that the dryer comprises a support, a spiral material feeder, a first flange plate, a discharging pipe, an air cylinder, a material dropping plate, a sealing piston, a weighing device, a second flange plate, a Venturi branched tube, an airflow tank, a return air tank, a feeding pipe, a cyclone air outlet pipe, an air return pipe, a vacuum pumping pipe, a reflux tank, a Venturi tube and a third flange plate; the airflow tank comprises an upper airflow tank section and a lower airflow tank section, and the upper airflow tank section and the lower airflow tank section communicate with each other; the reflux tank is arranged at the outer side of the upper portion of the upper airflow tank section in a sleeving mode; the upper end of a space between the reflux tank and the upper airflow tank section is closed, and the lower end of the space is opened; and the reflux tank is of a cylinder structure with the cross section circle variable. According to the flow-washing-type battery material dryer, the return air tank, the reflux tank, the airflow tank and the Venturi tube are sequentially nested from outside to inside, so that the heat preservation effect of the dryer is made good; and moreover, heat is transmitted between the multiple layers of the pipes, after all layers of pipe walls are heated by hot air, the heat can be radiated outwards from the pipe walls, and powder drying is accelerated.

Owner:HEBEI UNIV OF TECH +1

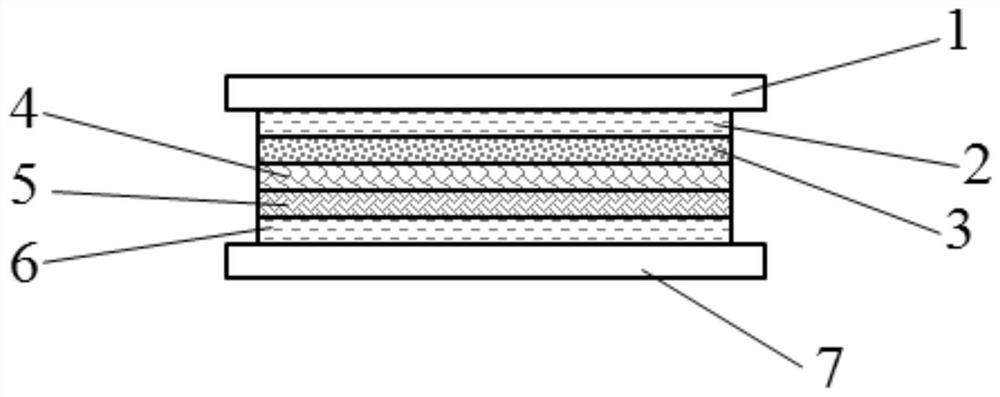

Programmable stepped electronic equipment heat dissipation temperature control film

PendingCN113105838AGuaranteed safe use temperatureGuaranteed stabilityFilm/foil adhesivesCooling/ventilation/heating modificationsTemperature controlElastomer

The invention discloses a programmable stepped electronic equipment heat dissipation temperature control film which comprises an upper release film layer, an upper acrylic acid adhesive layer, an elastomer heat conduction layer, a high-phase-change-point temperature control layer, a low-phase-change-point temperature control layer, a lower acrylic acid adhesive layer and a lower release film layer which are sequentially attached from top to bottom. The size of the upper release film layer and the size of the lower release film layer are not smaller than the size of the upper acrylic acid adhesive layer, the size of the elastomer heat conduction layer, the size of the high-phase-change-point temperature control layer, the size of the low-phase-change-point temperature control layer and the size of the lower acrylic acid adhesive layer. The high-phase-change-point temperature control layer and the low-phase-change-point temperature control layer are arranged, the stepped heat conduction-temperature control-temperature control process is completed, the heat dissipation requirement and the safety regulation condition of the shell can be met, the temperature of a heat source can be effectively reduced, what is guaranteed is that the shell temperature meets the basic human body contact safety regulation requirement, and the safe use temperature of materials is guaranteed; the stability of the material is guaranteed, the service life of the material is prolonged, and the whole structure is simple and suitable for industrial popularization and application.

Owner:SUZHOU ENBRIGHTECH

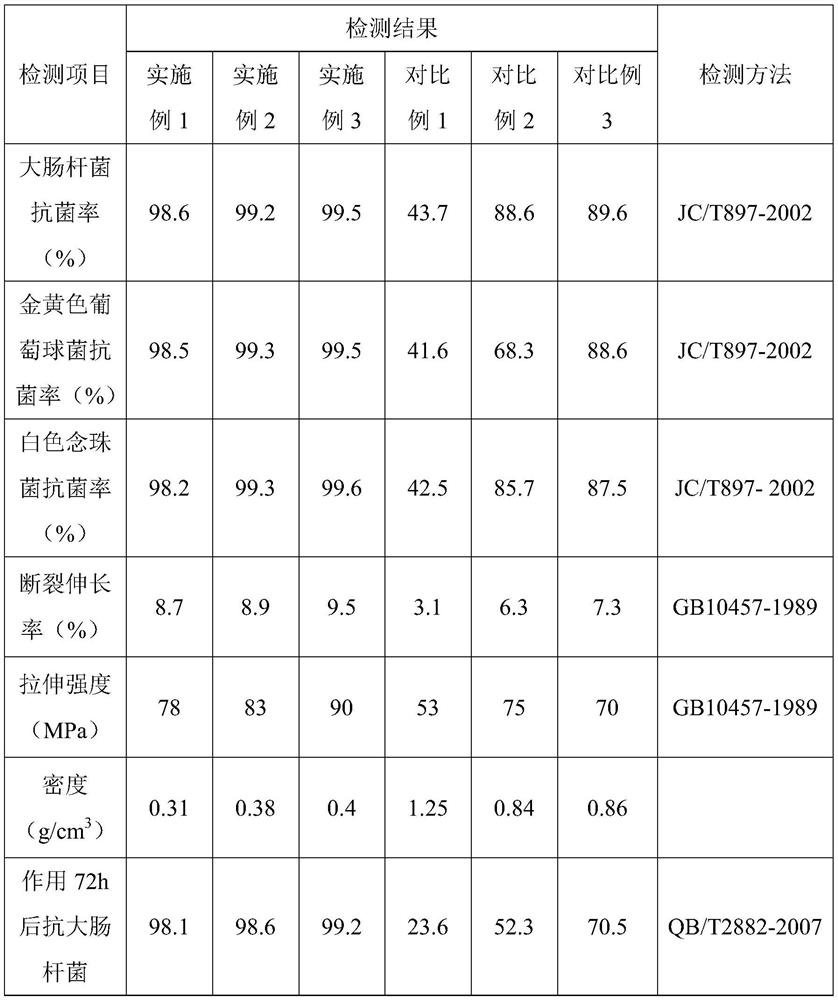

Graphene oxide/nano-copper composite antibacterial agent, antibacterial master batch and preparation methods thereof

The invention belongs to the technical field of graphene, and particularly relates to a graphene oxide / nano-copper composite antibacterial agent, an antibacterial master batch and preparation methods thereof, and aiming at overcoming the defects that an existing composite polylactic acid antibacterial agent is poor in antibacterial effect and stability, or complex in preparation process, numerous in raw materials and difficult to industrially apply. According to preparation method of the graphene oxide / nano-copper composite antibacterial agent,a copper sulfate solution reacts with a polyvinyl alcohol solution, on the premise that glucose is added to reduce copper ions into nano-copper particles, the nano-copper particles react with graphene oxide, and the graphene oxide / nano-copper composite antibacterial agent is obtained. The preparation method of the antibacterial agent is simple to operate, and raw materials are easy to obtain; the prepared antibacterial agent is good in antibacterial effect, low in cost, higher in stability and longer in antibacterial time; meanwhile, the antibacterial agent can be effectively combined with polylactic acid, so that the antibacterial property and the mechanical strength of the polylactic acid are improved, and the weight of the environment-friendly tableware is reduced.

Owner:深圳环能石墨烯科技有限公司 +1

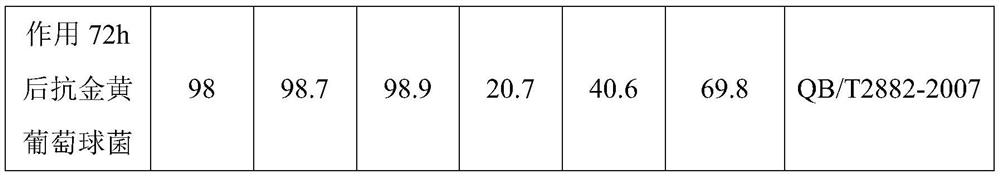

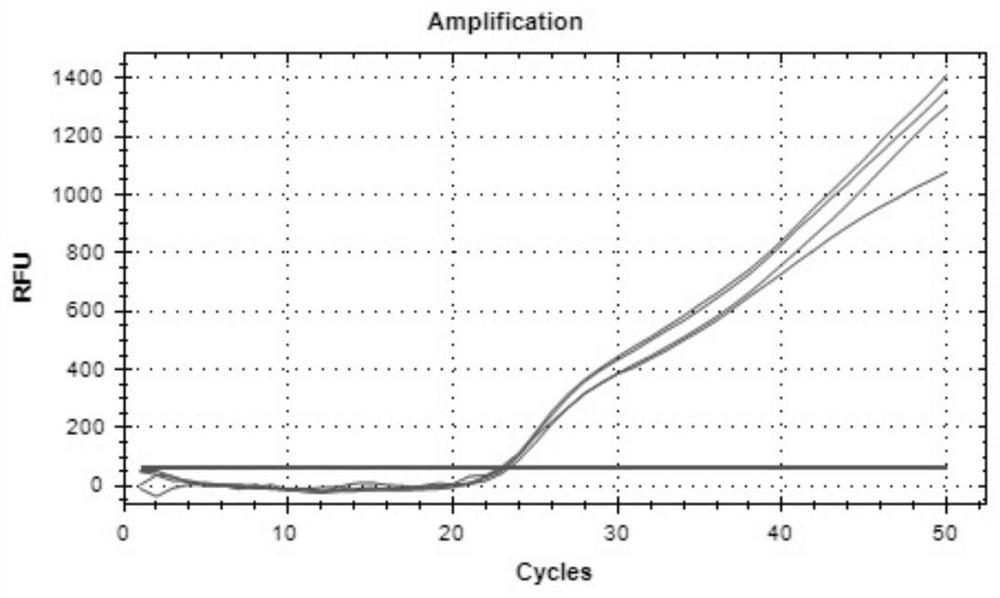

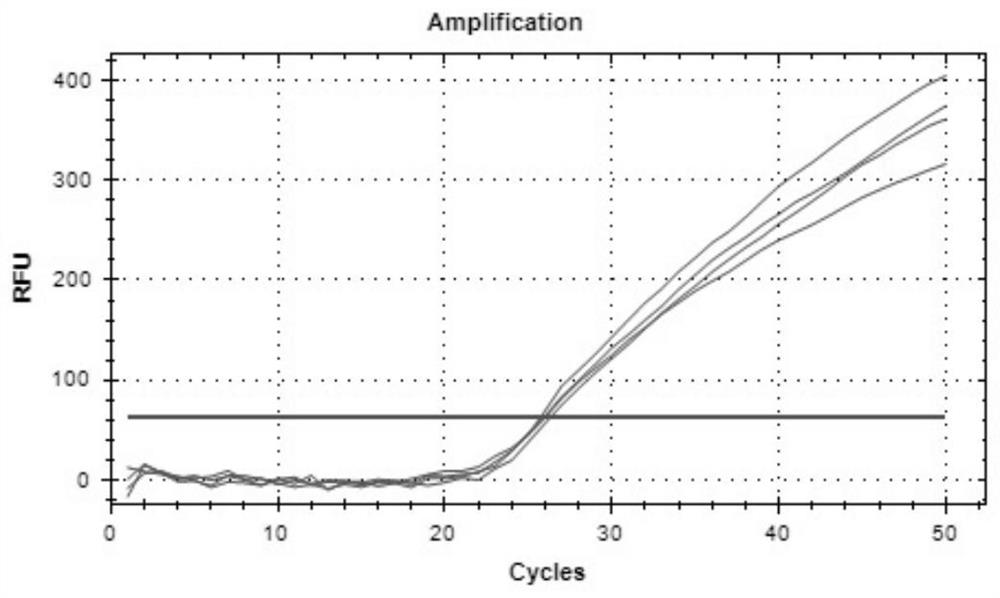

LNA-Taqman-multiplex fluorescence PCR technology and application thereof in rapid detection of candida

ActiveCN112680541AQuick checkReal-time identificationMicrobiological testing/measurementMicroorganism based processesMultiplexMicrobiology

The invention relates to the technical field of biotechnology, in particular to LNA-Taqman-multiplex fluorescence PCR and application thereof in candida detection. According to the present invention, the system of specific amplification primer and LNA-Taqman probe can be used for rapid amplification detection of common candida in female genital tract, and compared with the traditional detection method, the detection efficiency, the sensitivity, the specificity and the multiple detection rate are improved.

Owner:中迅优检生物科技(江苏)有限公司

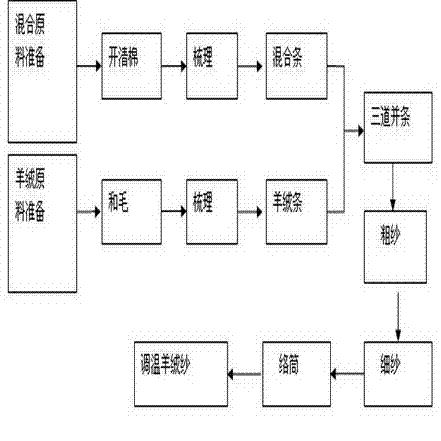

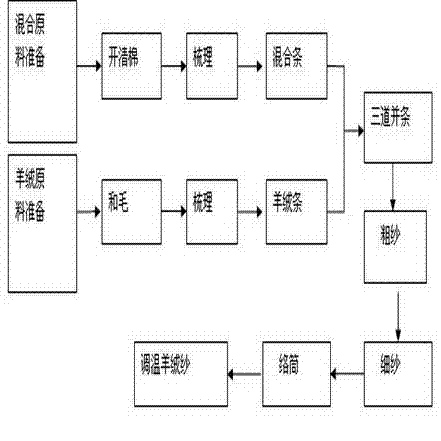

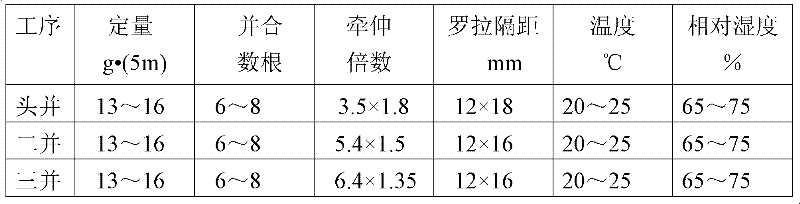

Thermoregulation cashmere yarn and production method thereof

The invention discloses a thermoregulation cashmere yarn and a production method thereof. The thermoregulation cashmere yarn is characterized in that the fineness is 33.3-100tex, the thermoregulation cashmere yarn is formed by blending the following components according to mass ratio: 30-60% of thermoregulation fiber, 30-60% of cashmere fiber and 10-30% of third fiber; the thermoregulation fiber is rayon-based thermal-storage thermoregulation fiber, the fineness is 1.7-2.2dtex, and the length is 38-42nm; for the cashmere fiber, the fineness is 14-16mum, and the length is 36-44mm; and the third fiber is modal fiber, polyster fiber or milk protein fiber, the fineness is 1.7-2.2dtex, and the length is 38-42mm. The production method is suitable for the thermoregulation cashmere yarn, and comprises the following steps: respectively producing the thermoregulation fiber, third fiber mixed strips and cashmere strips, then drawing and doubling the mixed strips and the cashmere strips according to design, then roving, finely spinning and spooling the mixed strips and the cashmere strips in sequence, and finally obtaining the thermoregulation cashmere yarn.

Owner:内蒙古焱太经贸有限责任公司 +1

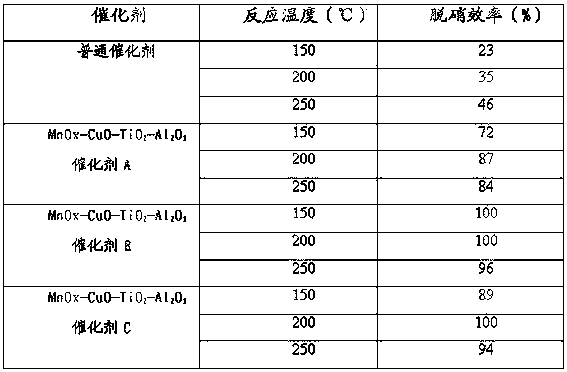

Low-temperature denitration MnOx-CuO-TiO2-Al2O3 catalyst as well as preparation method and application thereof

InactiveCN103566948AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a low-temperature denitration MnOx-CuO-TiO2-Al2O3 catalyst as well as a preparation method and application thereof. The low-temperature denitration MnOx-CuO-TiO2-Al2O3 catalyst is composed of a carrier and an active ingredient, wherein the carrier is TiO2 and Al2O3; the active ingredient is MnOx and CuO; in the low-temperature denitration MnOx-CuO-TiO2-Al2O3 catalyst, in terms of a molar ratio of metal elements Mn, Ti, Al and Cu, Cu: Ti: Al: Mn is (0.2-0.4):1:1:(0.4-1.2). The preparation method of the catalyst comprises the following step of: preparing the MnOx-CuO-TiO2-Al2O3 catalyst by using titanium sulfate, aluminum nitrate, manganese nitrate and copper nitrate as precursors through a coprecipitation method. The low-temperature denitration MnOx-CuO-TiO2-Al2O3 catalyst disclosed by the invention is low in preparation cost, convenient for industrial popularization and has better denitration effect in a flue gas of 150 DEG C-250 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

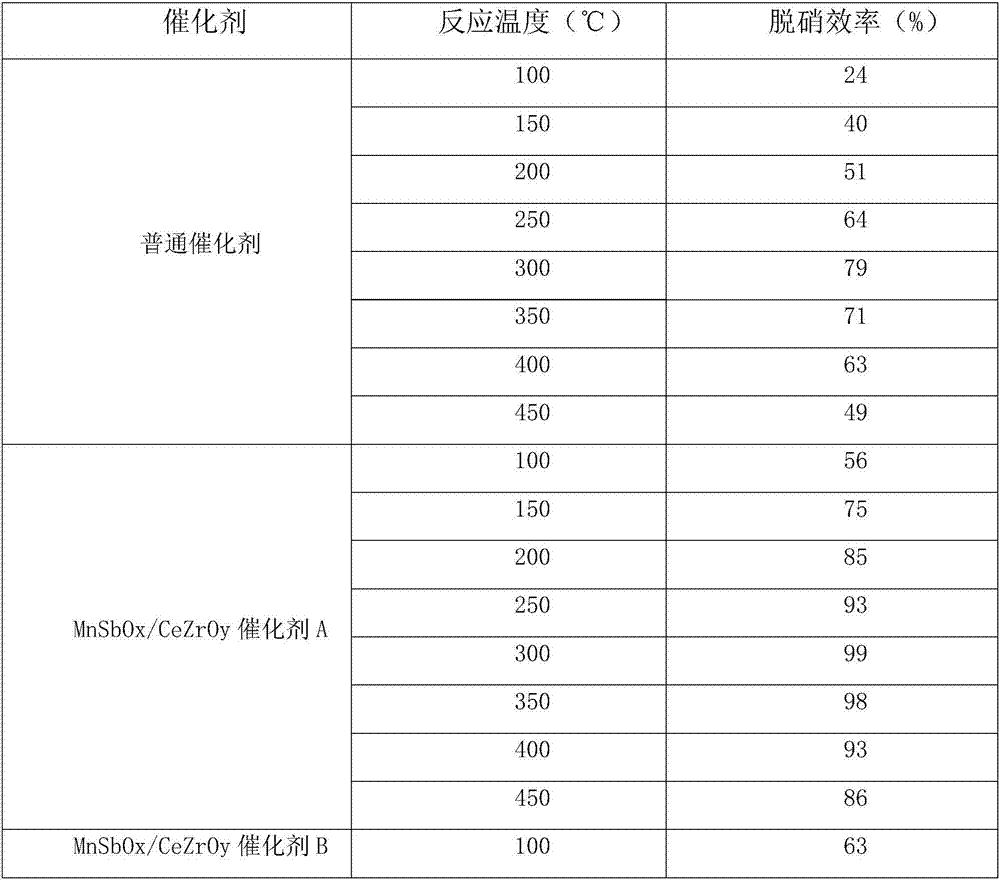

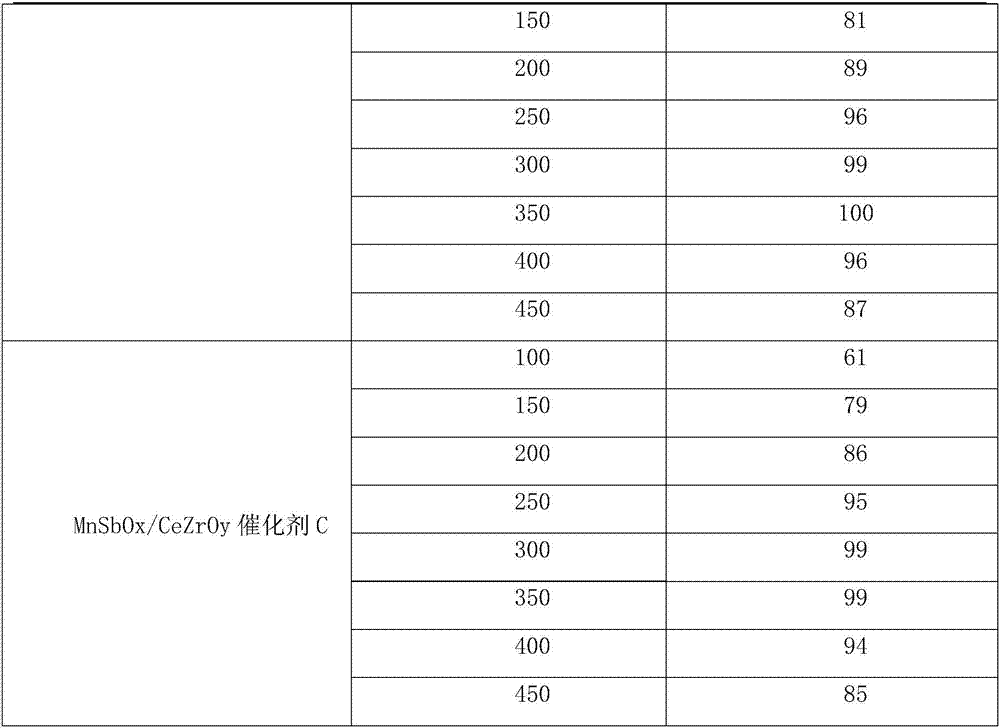

Wide temperature window de-nitration catalyst and preparation method and application thereof

InactiveCN107469811AHigh activityImprove operating economyGas treatmentHeterogenous catalyst chemical elementsMANGANESE ACETATENitration

The invention discloses a wide temperature window de-nitration catalyst and a preparation method and application thereof. In present SCR method de-nitration technology, hole blockage of the catalyst is easily caused due to the fact that smoke is free of desulfuration or dust collection. The wide temperature window de-nitration catalyst disclosed by the invention is MnSbOx / CeZrOy, and consists of two parts which are a carrier and an active ingredient, the carrier is a CeO2 and ZrO2 composite oxide, and the active ingredient is an MnOx and Sb2O5 composite oxide; and the wide temperature window de-nitration catalyst is calculated in terms of molar ratio of metal elements such as Mn, Sb, Ce and Zr, wherein the ratio of Mn, Sb, Ce to Zr is 0.5: (0.1 to 0.3): 1: 2. The preparation method comprises the following steps: taking manganese acetate, antimony acetate, zirconium nitrate and cerous nitrate as precursors, and using a coprecipitation method and an impregnation method to prepare the catalyst. The preparation cost is low, and the catalyst has relatively high de-nitration effect in smoke with the temperature of 150 to 400 DEG C.

Owner:浙江浙能富兴燃料有限公司 +1

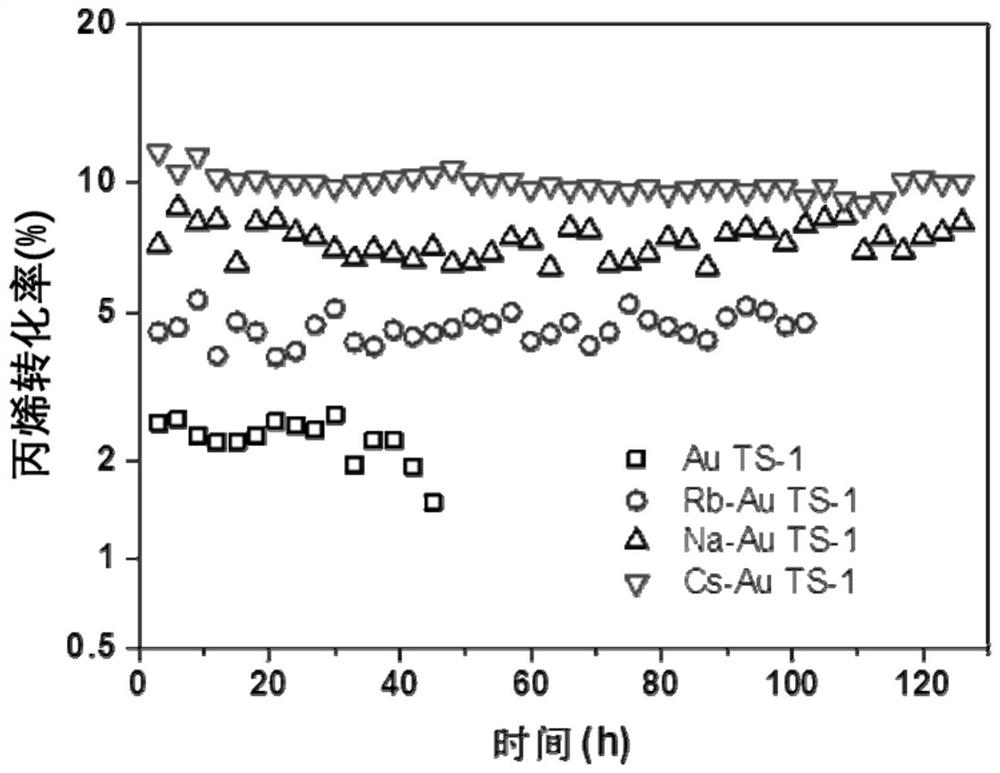

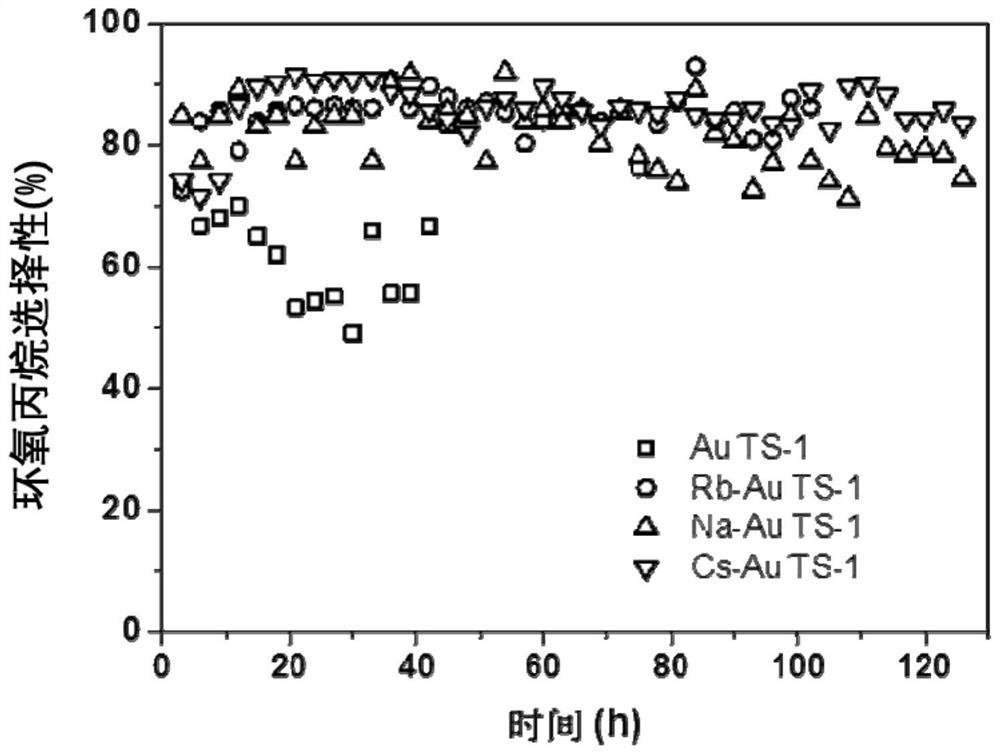

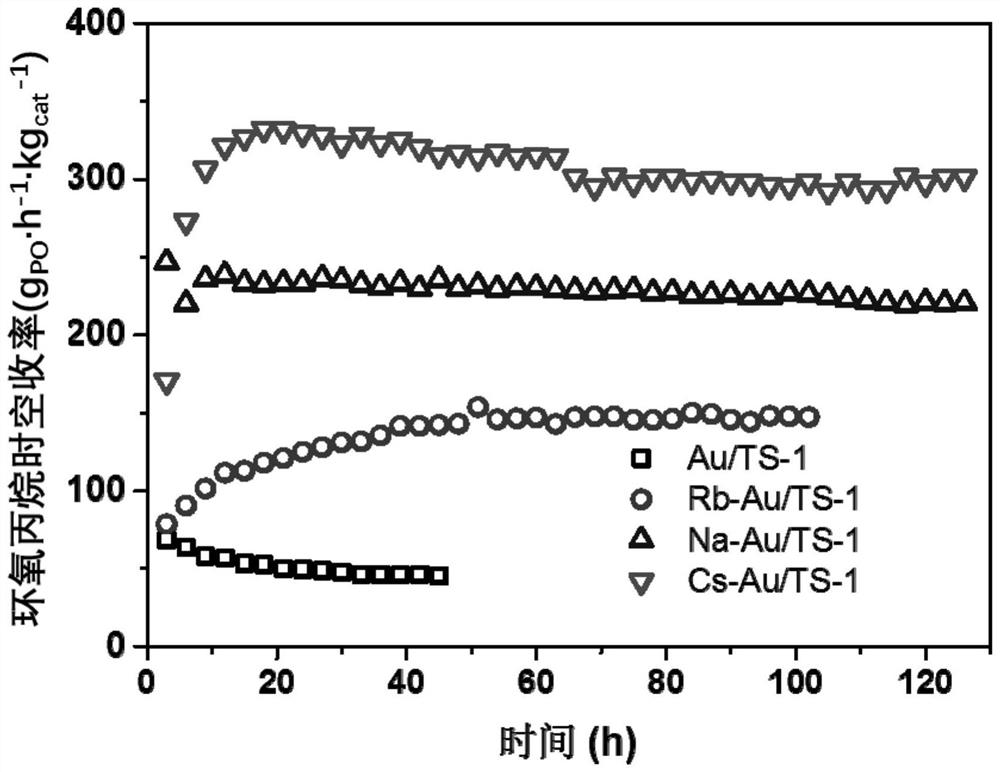

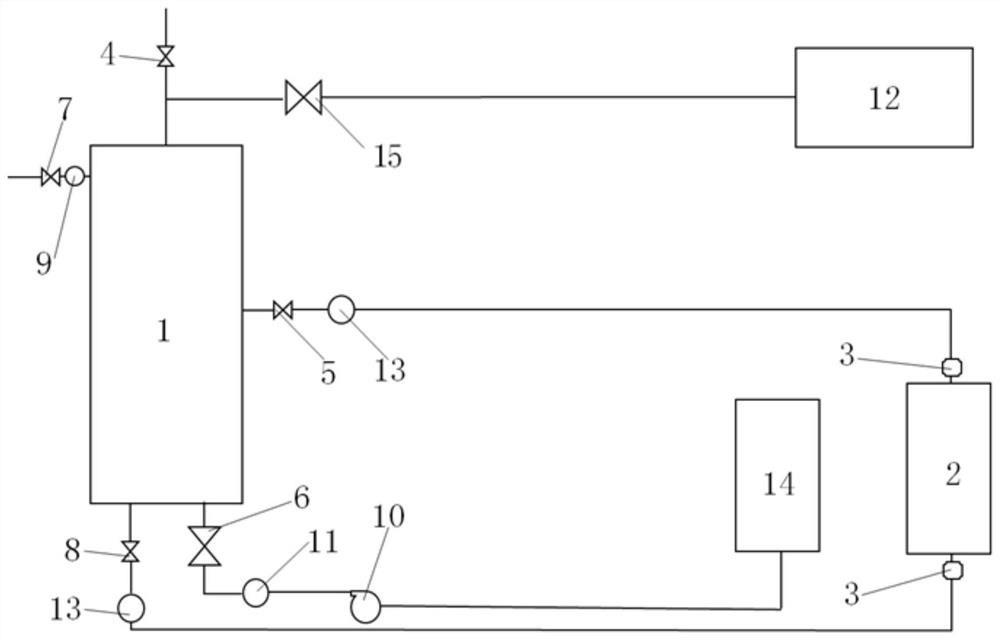

Modification method of Au/TS-1 catalyst

PendingCN111822044AImprove stabilityExtend your lifeOrganic chemistryMolecular sieve catalystsPtru catalystPhysical chemistry

The invention relates to the field of chemical catalysis, in particular to a modification method of a selective oxidation catalyst. The modification method comprises the following steps: (1) loading an active component Au on a carrier TS-1 to prepare an Au / TS-1 catalyst; (2) impregnating the Au / TS-1 catalyst with a solution of alkali metal carbonate X2CO3, and then drying to obtain a modified catalyst X2CO3-Au / TS-1, wherein the molar ratio of the X2CO3 to the active component Au loaded on the Au / TS-1 catalyst ranges from 20: 1 to 1: 5; and (3) carrying out activation treatment on the modifiedcatalyst X2CO3-Au / TS-1 before the reaction. According to the present invention, the method for modifying Au / TS-1 through alkali carbonate impregnation is adopted, and the prepared X2CO3-Au / TS-1 catalyst has characteristics of high catalytic performance and long service life; and the preparation method has good repeatability.

Owner:CHENGDU ZHONGKE CATALYSIS TECH CO LTD

High-resilience ultraviolet light and moisture dual-curing hot melt adhesive and preparation method thereof

PendingCN113337220AIncrease elasticityImprove flexibilityOrganic non-macromolecular adhesiveBonding strengthPhoto irradiation

The invention discloses a high-resilience ultraviolet light and moisture dual-curing hot melt adhesive and a preparation method thereof. The hot melt adhesive comprises hydroxyl-terminated rubber, polyester polyol, polyether polyol, a hydroxyl-free or amino-free UV active monomer, polyisocyanate, trifunctional micromolecular polyol, a photoinitiator, a defoaming agent, an adhesion promoter and a catalyst. The elasticity and flexibility of a hot melt adhesive product are improved by adding the hydroxyl-terminated rubber; the hydroxyl-free or amino-free UV active monomer does not participate in polymerization reaction in the early stage, so that the final product becomes viscoelastic after being irradiated by UV light, and the cleaning of excessive glue is reduced; the polyisocyanate is added in batches, so that the molecular weight of the polymer can be increased, the initial bonding strength is quickly improved within the same curing time, the positioning time is shortened, and the production efficiency is improved; the initial adhesion after dispensing is improved, the buffer resistance of large screen frame adhesion is improved, the reworkability of screen frame adhesion is achieved, and the hot melt adhesive can replace traditional screen sealing adhesive tapes, and realizes narrow frame dispensing.

Owner:SUZHOU ENBRIGHTECH

Enzyme preparation for low antigen protein fermented soybean meal and application thereof

PendingCN110878292AEfficient degradationImprove digestibilityFood processingAnimal feeding stuffBiotechnologyPectinase

The invention relates to the technical field of enzymes, in particular to an enzyme preparation for low antigen protein fermented soybean meal and application thereof. The enzyme preparation consistsof alkaline protease, neutral protease, phytase, galactosidase and pectinase. The enzyme preparation can be matched with microbial inoculums for fermented soybean meal production, can efficiently degrade anti-nutritional components such as antigen protein, has high protein digestibility, increases the nutritional value of a feed, and is suitable for industrial production.

Owner:JINANBESTZYME BIO ENG CO LTD

Preparation method of modified carbon fiber reinforced nylon particle

InactiveCN111574731AEvenly distributedGood mechanical propertiesFire retardantHyperbranched polymers

The invention provides a preparation method of a modified carbon fiber reinforced nylon composite material. According to the method, nylon, a hyperbranched polymer, modified carbon fiber, a coupling agent, a flame retardant, an antioxidant and a lubricant are used as raw materials to nylon particles by a simple and convenient method. The composite material particles have high tensile strength, bending strength and impact resistance.

Owner:苏州君彰新材料科技有限公司

Flexible tubular large-aperture membrane filtration device and cleaning method thereof

The invention discloses a flexible tubular large-aperture membrane filtration device and a cleaning method thereof. According to the invention, the diameter of a tubular membrane in the membrane filtration device is not less than 5 mm; the aperture of the tubular membrane is 6-200 [mu]m; the tubular membrane is made of a homogeneous membrane, so forward and reverse cleaning and filtering effects are the same; the tubular membrane has sufficient flexibility for physical deformation; and gas in a gas source can enter the membrane filtration device through an opened water production side gas inlet valve and an opened water inlet side bottom gas inlet valve respectively and then is discharged through a water production side gas outlet valve, and no gas seal is formed under the condition of weak pressure regardless of hydrophilic, hydrophobic or humid conditions. Traditional water cleaning is replaced by gas cleaning in the invention, cleaning is completed by means of gas such as air, dirt and the like which are hidden on the inner wall of the membrane filtration device and are difficult to clean are effectively removed, cleaning is more thorough, and water consumption is reduced; the filtering effect is not affected by water flux, so yield is high; cleaning does not depend on chemical reagents, so reagent residues do not exist, and use safety is high; and the cleaning method is simple, efficient, energy-saving and consumption-reducing.

Owner:迈海(苏州)环保科技有限公司

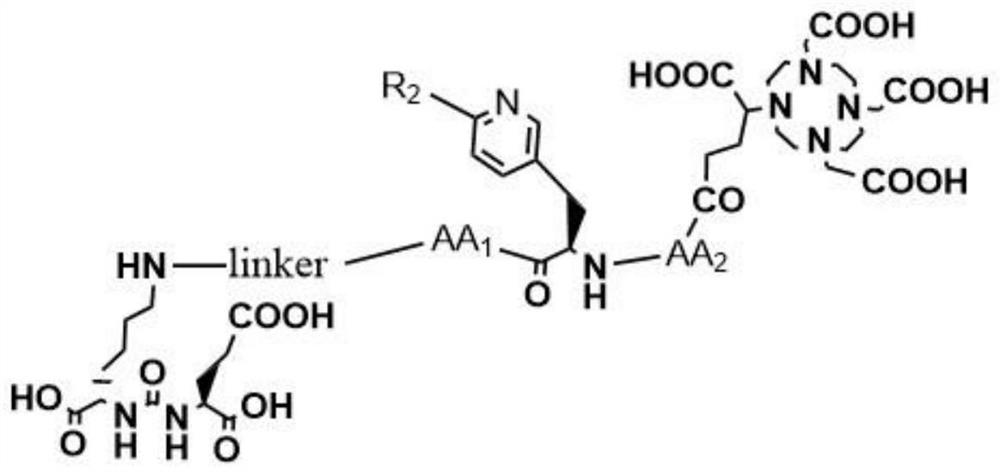

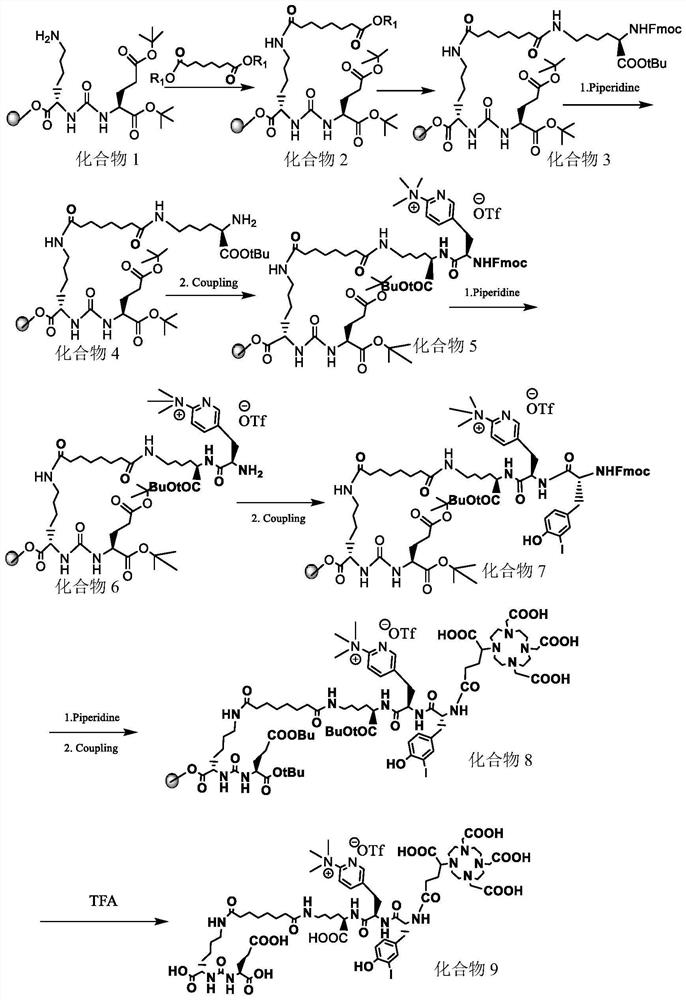

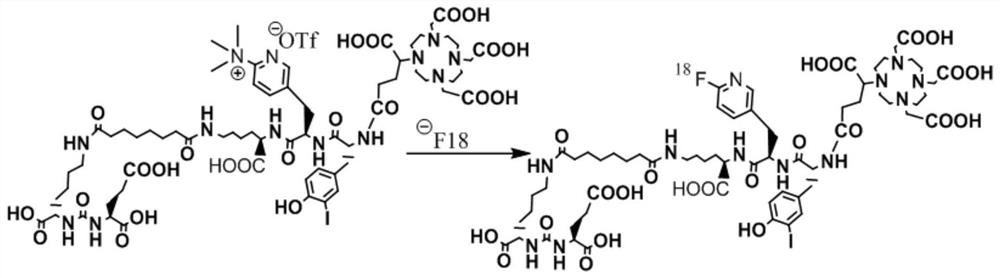

Synthesis method of three-function diagnosis and treatment integrated prodrug for prostate cancer and product thereof

PendingCN113354707AVersatileHigh selectivityPeptide preparation methodsPeptides with abnormal peptide linkChemical compoundProstate cancer

The invention discloses a synthesis method of a three-function diagnosis and treatment integrated prodrug for prostate cancer and a product thereof. A compound 1 is used as a raw material, and the compound 1 and three different amino acids are used to gradually synthesize the three-function diagnosis and treatment integrated prodrug, so that the prodrug can obtain the ability to mark three radionuclides of 18F, 68Ga and 177Lu. The invention realizes that the marking rate of 18F reaches 40%, and the marking rate of 68Ga and 177Lu reaches 90% or more, and can be combined with other targeting molecules other than PSMA to design more bifunctional or trifunctional diagnostic drugs, the structure will greatly open the PSMA structure drug market, provide more, more flexible, more functional radionuclide marker options for such type of drugs, and have a great promotion effect on the diagnosis and treatment of prostate cancer, which is suitable for industrial popularization and use.

Owner:SUZHOU SITRI ISOTOPE TECH RES INSITITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com