Two-dimensional code marking system

A two-dimensional code and code scanning technology, applied in typewriters, printing devices, printing, etc., can solve the problems of labor cost waste, worker injury, low efficiency, etc., and achieve the effect of improving processing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

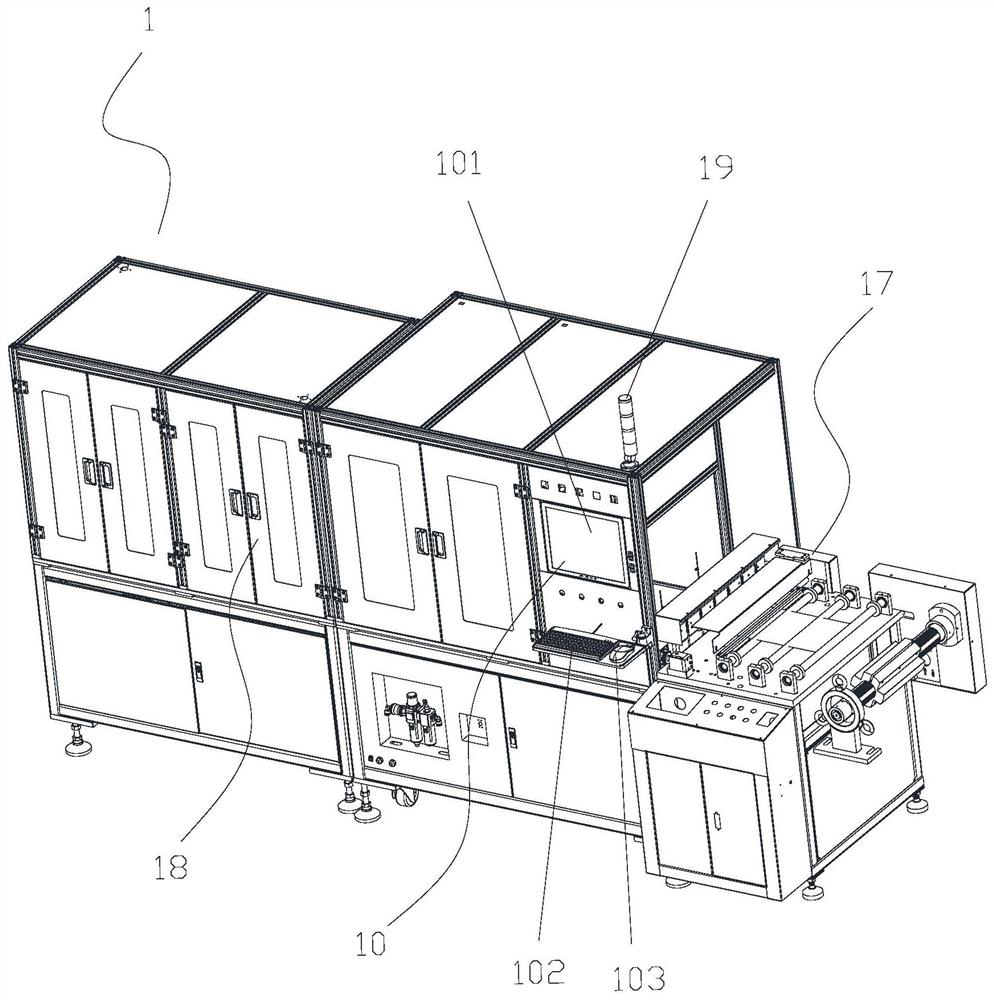

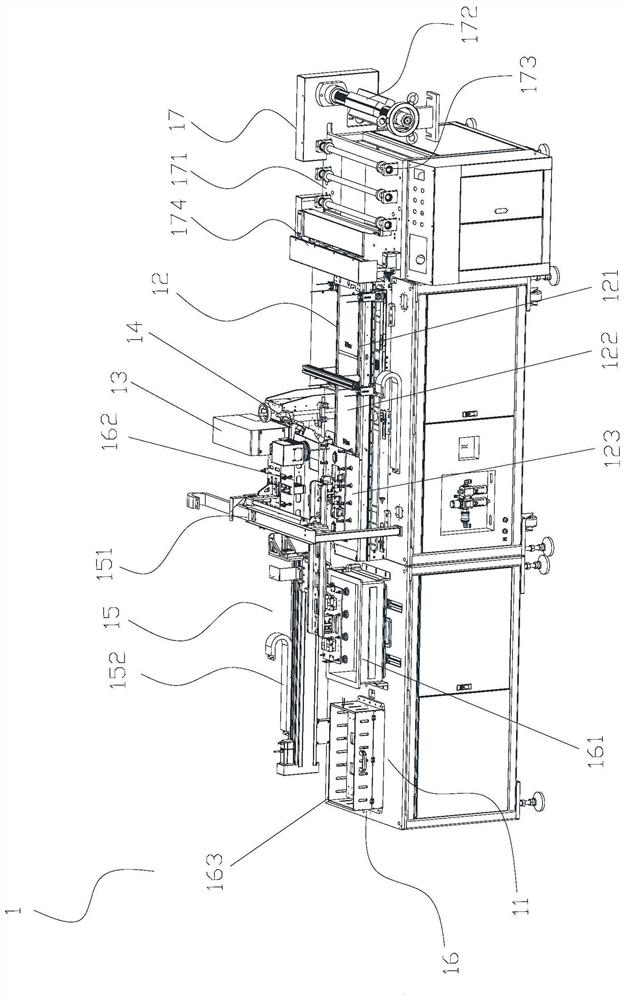

[0041] Example 1 see Figure 1 to Figure 17 , in a two-dimensional code marking system of this embodiment, the two-dimensional code marking system 1 includes a control device, a workbench 11 and a product delivery unit 12, a laser marking unit 13, a code scanning unit The detection unit 14 , the conveying unit 15 and the magazine 16 , the product conveying unit 12 , the laser coding unit 13 , the code scanning detection unit 14 and the conveying unit 15 are electrically connected to the control device 10 .

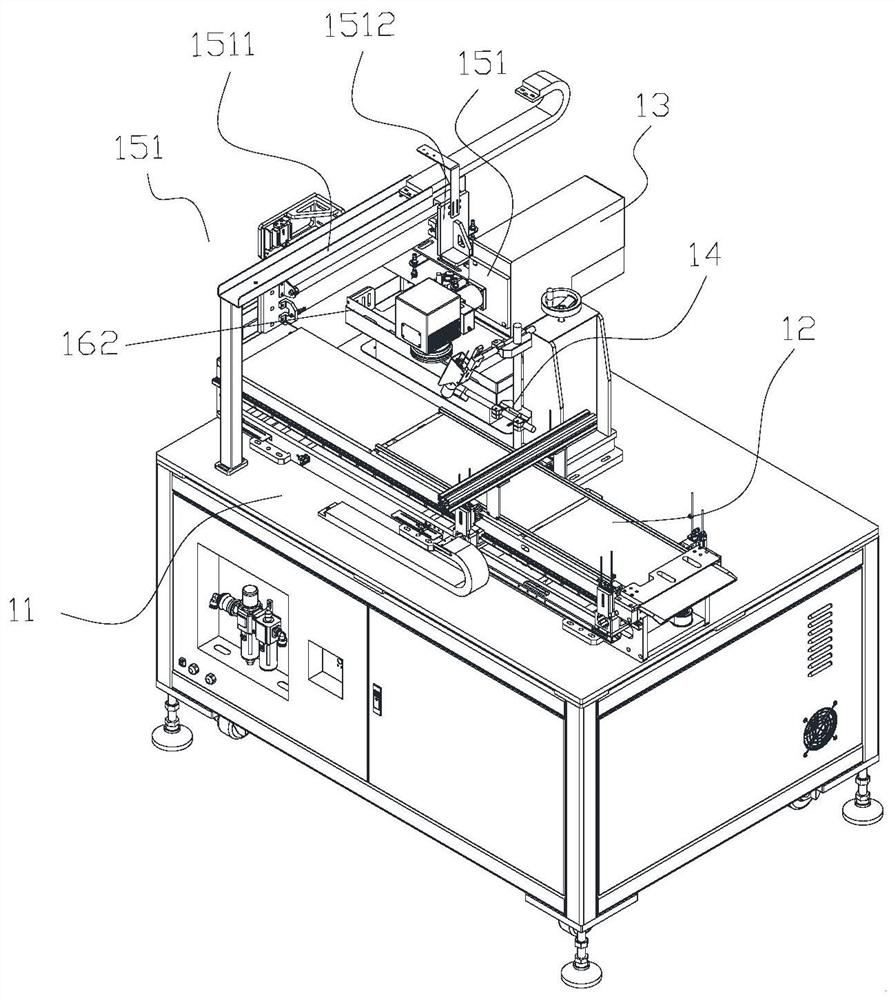

[0042] See figure 2 and Figure 5 , the product conveying unit 12 includes a linear track 121 , and a detection station 122 and a handling station 123 are arranged on the linear track 121 .

[0043] See Figure 5 to Figure 7 , both sides of the linear track 121 are respectively provided with slide rail mechanisms 125, and the slide rail mechanisms 125 on both sides are respectively provided with clamping jaw assemblies 126 for moving products. The gripper assembly inc...

Embodiment 2

[0073] See Figure 18 , in a two-dimensional code marking system of this embodiment, the two-dimensional code marking system 2 includes a control device, a workbench 21 and a product delivery unit 22 located on the workbench 21, a laser marking unit 23, a code scanning unit The detection unit 24, the conveying unit 25 and the material box, the product conveying unit 22, the laser coding unit 23, the code scanning detection unit 24 and the conveying unit 25 are electrically connected to the control device.

[0074] Please continue to see Figure 18 , the product conveying unit 22 includes a linear track 221 , and a detection station 222 and a handling station 223 are arranged on the linear track 221 .

[0075] Please continue to see Figure 18 , the material box 26 is arranged on the side of the handling unit 25, including an OK material box 261 for placing qualified products and an NG material box 262 for placing unqualified products. Preferably, a slide rail is provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com