Method for separating and recovering lithium from waste lithium ion battery

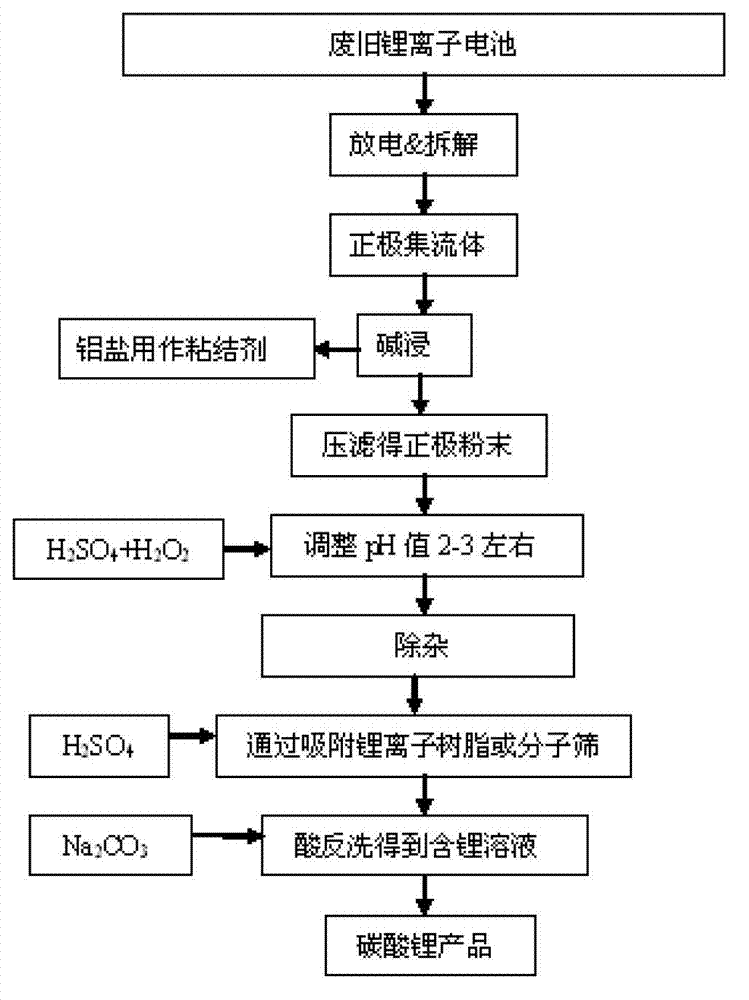

A lithium ion battery, separation and recovery technology, which is applied in the field of lithium ion recovery from waste lithium ion batteries, can solve the problems of low purity, lag in research and development, and low recovery rate of lithium ion products, and achieves a simple recovery method and low cost. Low, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Disassemble the waste lithium-ion battery after discharging, take the positive electrode current collector of the battery, add excess sodium hydroxide to the positive electrode current collector of the battery for alkaline leaching, dissolve the aluminum metal in the positive electrode current collector, and filter the alkaline leaching solution to obtain positive electrode powder , the positive electrode powder is leached with sulfuric acid and hydrogen peroxide, the pH value is adjusted to 2-3, filtered to obtain the filtrate, and the Fe in the filtrate 2+ oxidized to Fe by the oxidizing agent 3+ , then add calcium carbonate to adjust the pH value of the solution to 3.5-6.0, so that the iron precipitates, after filtering, adjust the pH value of the filtrate to 8, filter to remove impurities and precipitates, and obtain a recovery solution containing lithium ions; The recovered liquid is adjusted to a pH of 4, and the strongly acidic ion exchange resin G-26 is used to ...

Embodiment 2

[0029] Disassemble the waste lithium-ion battery after discharging, take the positive electrode current collector of the battery, add excess potassium hydroxide to the positive electrode current collector of the battery for alkaline leaching, dissolve the aluminum metal in the positive electrode current collector, and filter the alkaline leaching solution to obtain positive electrode powder , the positive electrode powder is leached with sulfuric acid and hydrogen peroxide, the pH value is adjusted to 2-3, filtered to obtain the filtrate, and the Fe in the filtrate 2+ oxidized to Fe by the oxidizing agent 3+ , then add calcium carbonate or magnesium oxide to adjust the pH value of the solution to 5.0, so that the iron precipitates, and after filtering, adjust the pH value of the filtrate to 9, filter to remove impurities and precipitates, and obtain a recovery solution containing lithium ions; Adjust the pH of the recovery solution to 6, use strong acidic ion exchange resin AM...

Embodiment 3

[0031] Disassemble the waste lithium-ion battery after discharging, take the positive electrode current collector of the battery, add excess potassium hydroxide to the positive electrode current collector of the battery for alkaline leaching, dissolve the aluminum metal in the positive electrode current collector, and filter the alkaline leaching solution to obtain positive electrode powder , the positive electrode powder is leached with sulfuric acid and hydrogen peroxide, the pH value is adjusted to 2-3, filtered to obtain the filtrate, and the Fe in the filtrate 2+ oxidized to Fe by the oxidizing agent 3+ , then add calcium carbonate or magnesium oxide to adjust the pH value of the solution to 3.5-6.0, so that iron precipitates, after filtering, adjust the pH value of the filtrate to be greater than or equal to 8, filter to remove impurities and precipitates, and obtain a recovery solution containing lithium ions The recovery solution containing lithium ions is adjusted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com