Aromatic polypropylene fiber and preparation method thereof

A polypropylene fiber and aromatic technology, applied in the field of aromatic polypropylene fiber and its preparation, can solve the problems of complex equipment, high equipment condition requirements, complex processing process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

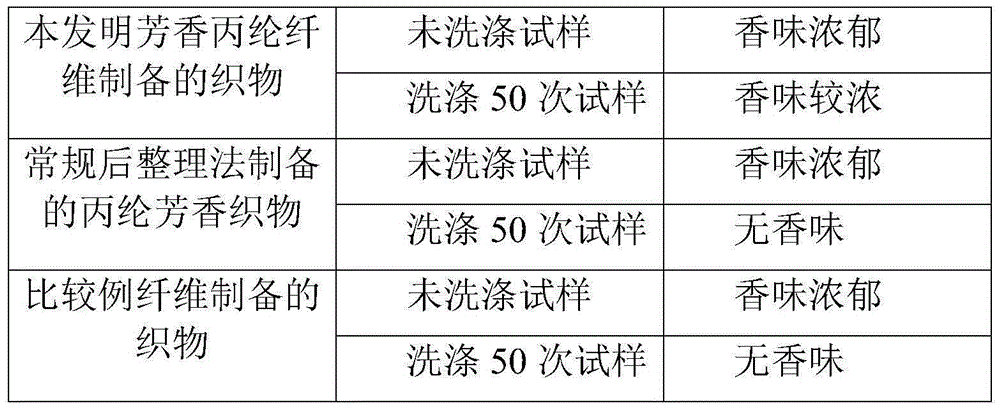

Examples

Embodiment 1

[0036] A kind of aromatic polypropylene fiber is prepared according to the following steps:

[0037] (1) Preparation of pretreated nano-flavor: place the nano-flavor at the bottom of the fluidized bed, send 40-45°C hot air to blow the nano-flavor from the bottom, and the airflow speed is 1m 3 / min, at the same time, use hydroxypropyl-β-cyclodextrin solution as the coating solution for coating treatment, spray the coating solution from the bottom of the fluidized bed, the spray pressure is 0.01Mpa, and the spray speed is 15mL / min, when After the coating solution is completely sprayed, continue to send hot air for 5 minutes to dry the surface of the nano-flavor, stop the hot air, and discharge the material to obtain the required pre-treated nano-flavor, wherein: the mixture of nano-flavor and hydroxypropyl-β-cyclodextrin The mass ratio is 1:0.05; the concentration of the hydroxypropyl-β-cyclodextrin solution is 15%,

[0038] (2) Preparation of aromatic polypropylene masterbatch...

Embodiment 2

[0043] A kind of aromatic polypropylene fiber is prepared according to the following steps:

[0044] (1) Preparation of pre-treated nano-flavor: place the nano-flavor at the bottom of the fluidized bed, send 50-55°C hot air to blow the nano-flavor from the bottom, and the airflow speed is 3m 3 / min, at the same time, use hydroxypropyl-β-cyclodextrin solution as the coating solution for coating treatment, spray the coating solution from the bottom of the fluidized bed, the spray pressure is 0.1Mpa, and the spray speed is 30mL / min, when After the coating solution is completely sprayed, continue to send hot air for 15 minutes to dry the surface of the nano-flavor, stop the hot air, and discharge the material to obtain the required pre-treated nano-flavor, wherein: nano-flavor and hydroxypropyl-β-cyclodextrin The mass ratio is 1:0.1; the concentration of the hydroxypropyl-β-cyclodextrin solution is 25%,

[0045] (2) Preparation of aromatic polypropylene masterbatch:

[0046] (2....

Embodiment 3

[0050] A kind of aromatic polypropylene fiber is prepared according to the following steps:

[0051] (1) Preparation of pre-treated nano-flavor: place the nano-flavor at the bottom of the fluidized bed, send 45-50°C hot air to blow the nano-flavor from the bottom, and the air velocity is 2m 3 / min, at the same time, use hydroxypropyl-β-cyclodextrin solution as the coating solution for coating treatment, spray the coating solution from the bottom of the fluidized bed, the spray pressure is 0.05Mpa, and the spray speed is 20mL / min, when After the coating solution is completely sprayed, continue to send hot air for 12 minutes to dry the surface of the nano-flavor, stop the hot air, and discharge the material to obtain the required pre-treated nano-flavor, wherein: nano-flavor and hydroxypropyl-β-cyclodextrin The mass ratio is 1:0.08; the concentration of the hydroxypropyl-β-cyclodextrin solution is 20%,

[0052] (2) Preparation of aromatic polypropylene masterbatch:

[0053] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com