Wide temperature window de-nitration catalyst and preparation method and application thereof

A denitration catalyst and wide temperature technology, applied in the field of flue gas denitrification, can solve the problems of catalyst pore blockage, reduced service life, catalyst poisoning, etc., and achieve the effects of easy operation, long service life and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

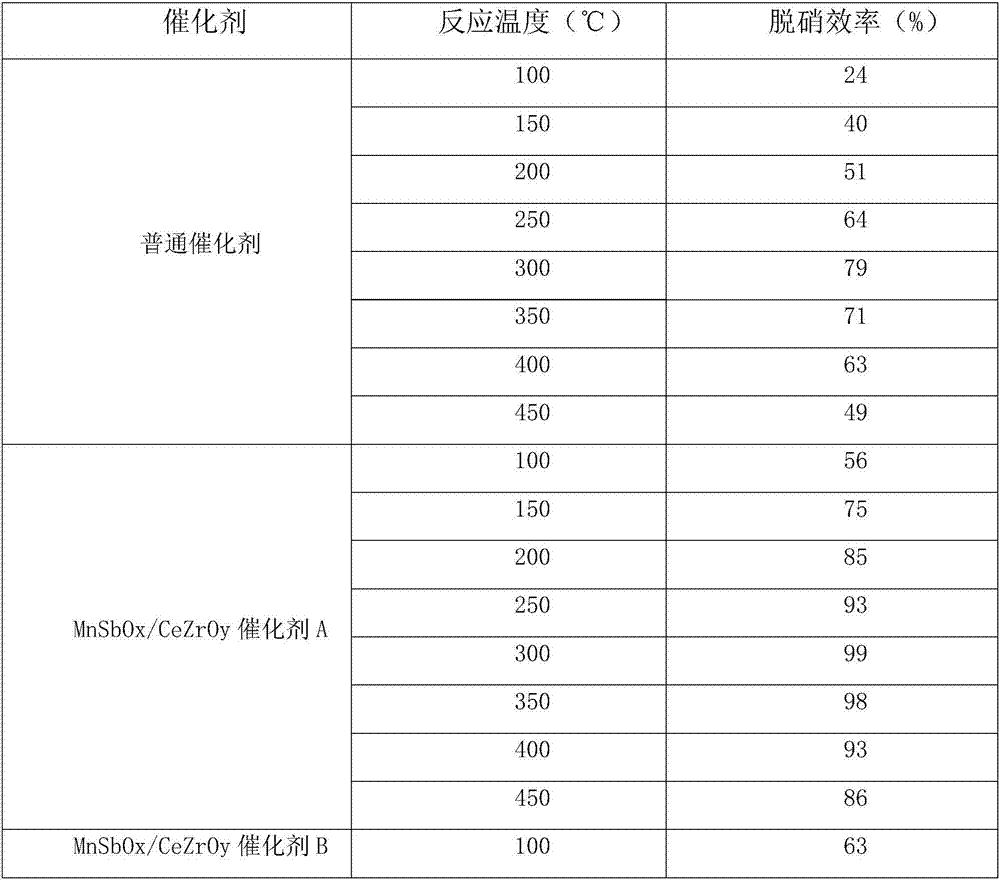

Embodiment 1

[0048] A wide temperature window denitrification MnSbOx / CeZrOy catalyst A is calculated according to the molar ratio of the contained metal elements Mn:Sb:Ce:Zr, wherein Mn:Sb:Ce:Zr is 0.5:0.1:1:2.

[0049] The preparation method of the above-mentioned wide temperature window denitration MnSbOx / CeZrOy catalyst A specifically includes the following steps:

[0050] (1) Dissolve 4.342g soluble cerium salt and 8.5864g soluble zirconium salt in 300ml deionized water, use polytetrafluoroethylene stirring paddle at room temperature, control the stirring rate to be 200rpm and stir to dissolve, then add 3mol / L of After adjusting the pH to 10 with ammonia water, stir for 1 h, filter the obtained precipitate, and rinse the obtained filter cake with deionized water until the pH of the eluate is neutral;

[0051] Described soluble cerium salt is Ce(NO 3 ) 3 ·6H 2 O; soluble zirconium salt is Zr(NO 3 ) 4 ·5H 2 O;

[0052] The amount of soluble cerium salt, soluble zirconium salt and ...

Embodiment 2

[0061] A wide temperature window denitrification MnSbOx / CeZrOy catalyst B is calculated according to the molar ratio of the contained metal elements Mn:Sb:Ce:Zr, wherein Mn:Sb:Ce:Zr is 0.5:0.2:1:2.

[0062] The preparation method of the above wide temperature window denitrification MnSbOx / CeZrOy catalyst B specifically includes the following steps:

[0063] (1) Dissolve 4.342g soluble cerium salt and 8.5864g soluble zirconium salt in 300ml deionized water, use polytetrafluoroethylene stirring paddle at room temperature, control the stirring rate to be 200rpm and stir to dissolve, then add 3mol / L of After adjusting the pH to 10 with ammonia water, stir for 1 h, filter the obtained precipitate, and rinse the obtained filter cake with deionized water until the pH of the eluate is neutral;

[0064] Described soluble cerium salt is Ce(NO 3 ) 3 ·6H 2 O; soluble zirconium salt is Zr(NO 3 ) 4 ·5H 2 O;

[0065] The amount of soluble cerium salt, soluble zirconium salt and deioni...

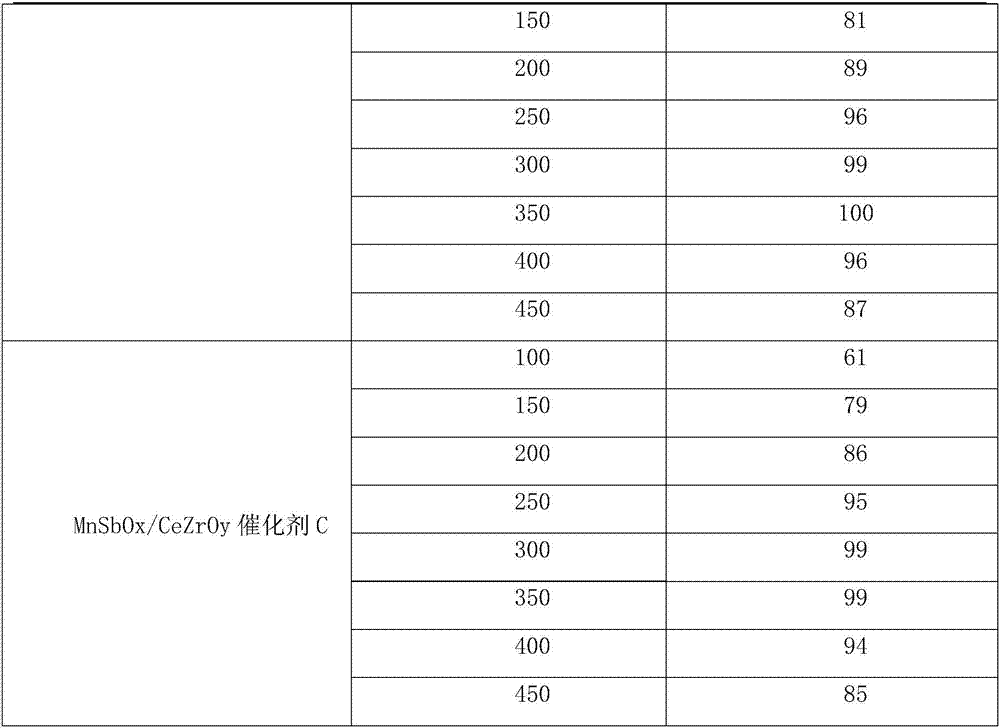

Embodiment 3

[0074] A wide temperature window denitrification MnSbOx / CeZrOy catalyst A is calculated according to the molar ratio of the contained metal elements Mn:Sb:Ce:Zr, wherein Mn:Sb:Ce:Zr is 0.5:0.3:1:2.

[0075] The preparation method of the above wide temperature window denitrification MnSbOx / CeZrOy catalyst C specifically includes the following steps:

[0076] (1) Dissolve 4.342g soluble cerium salt and 8.5864g soluble zirconium salt in 300ml deionized water, use polytetrafluoroethylene stirring paddle at room temperature, control the stirring rate to be 200rpm and stir to dissolve, then add 3mol / L of After adjusting the pH to 10 with ammonia water, stir for 1 h, filter the obtained precipitate, and rinse the obtained filter cake with deionized water until the pH of the eluate is neutral;

[0077] Described soluble cerium salt is Ce(NO 3 ) 3 ·6H 2 O; soluble zirconium salt is Zr(NO 3 ) 4 ·5H 2 O;

[0078] The amount of soluble cerium salt, soluble zirconium salt and deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com