Method for judging running states of magnetic suspension cooling water units in freezing station control systems

A technology for chillers and control systems, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of inability to confirm the full-load use current of magnetic levitation centrifugal units and different operating states, and achieve obvious energy-saving effect and increase load capacity. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

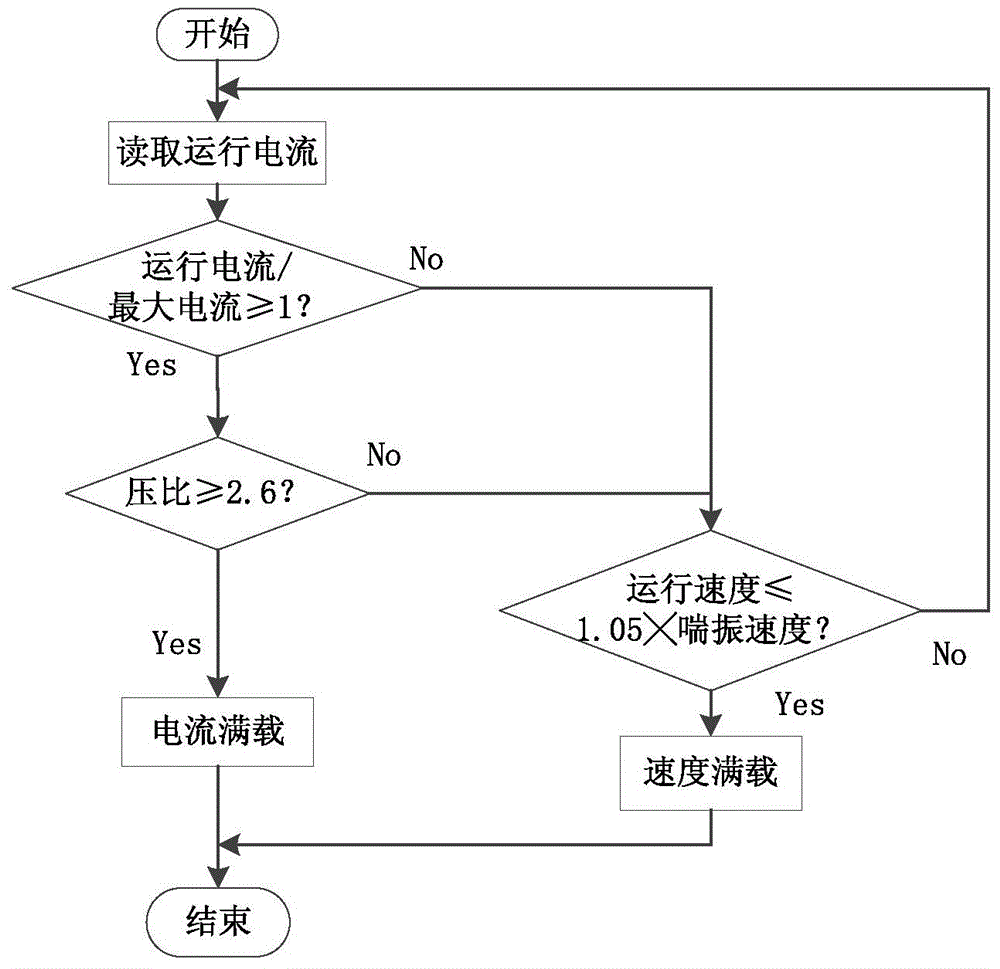

[0019] A method for judging the operating state of a maglev chiller in a control system of a freezing station, the specific steps are as follows:

[0020] 1) Use a current transformer to read the operating current of the maglev chiller;

[0021] 2) After comparing the operating current with the maximum current of the control system of the refrigeration station, the state of the maglev chiller is judged, and thus the full load state of the compressor in the maglev chiller is judged.

[0022] In step 1), when the ratio of the operating current to the maximum current is greater than or equal to 1, continue to judge whether the ratio of the total pressure at the outlet of the compressor to the total pressure at the inlet is greater than or equal to 2.6. When the ratio of the running current to the full load current is less than 1, continue to judge whether the running speed of the compressor is less than or equal to 1.05 times the speed at the time of surge.

[0023] In the step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com