Three-claw gripping device

A technology of grabbing device and three-jaw chuck, which is applied in the direction of manipulators, collets, manufacturing tools, etc., can solve problems such as complex structure, unreliability, and manufacturing difficulties, and achieve simple manufacturing process, many objects to grab, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

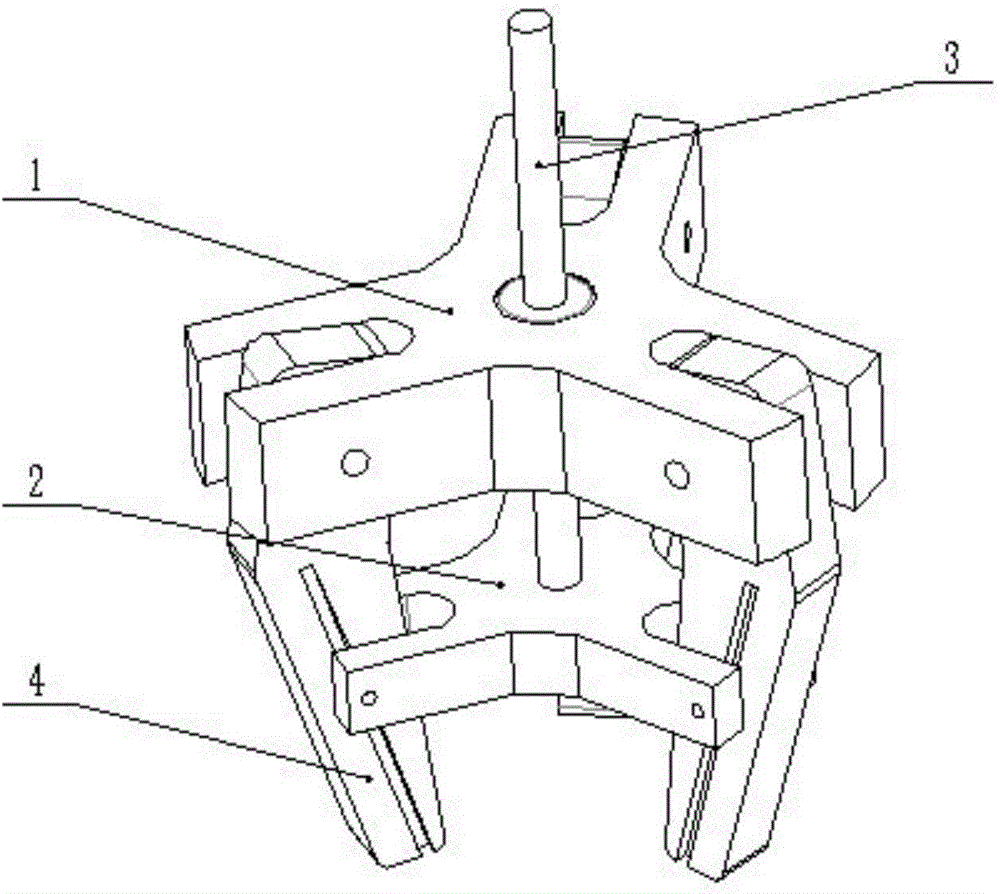

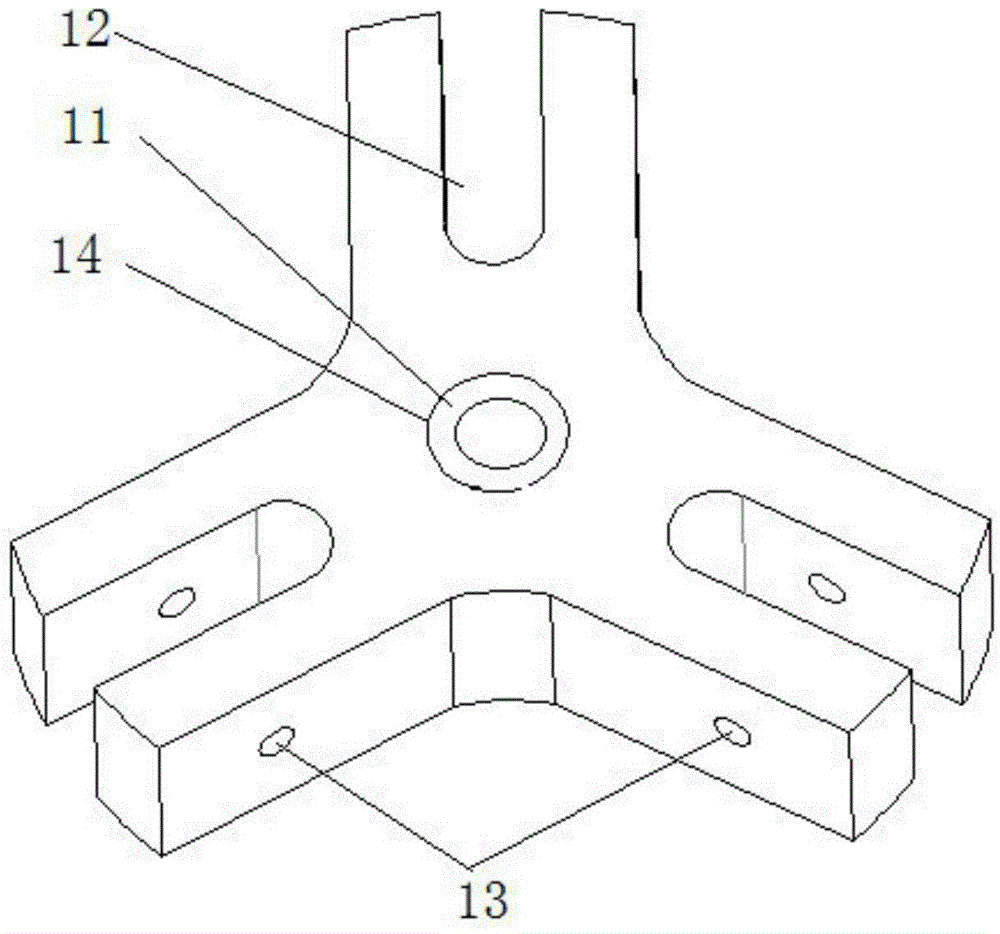

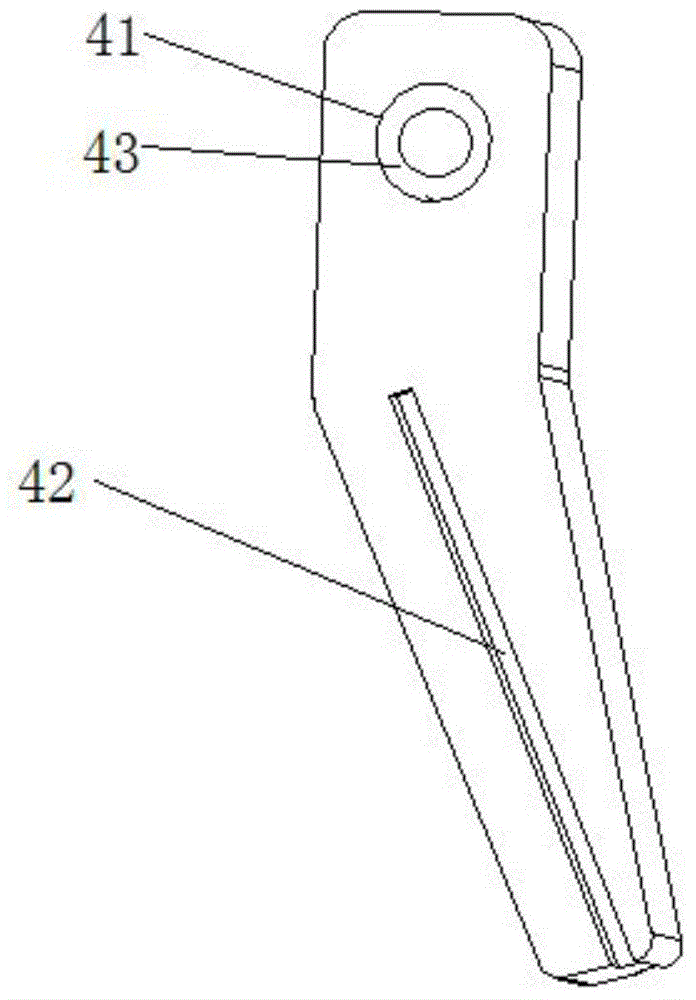

[0023] The three-jaw grasping device of the present embodiment (see Figure 4) includes a three-jaw chuck 1, a three-jaw clip 2, a telescopic rod 3 and three claw fingers 4, the upper part of the telescopic rod 3 is fixed on the three-jaw chuck 1, and the lower part is connected with the three-jaw clip 2; the upper part of the three claw fingers 4 It is fixed in the clamping groove of the three-jaw chuck 1, and the lower part of the three claw fingers 4 is fixed in the clamping groove of the three-jaw clamp 2; the three-jaw chuck is Y-shaped, and has three claws evenly distributed along the circumferential direction. The included angle between two adjacent claws is 120°. The center of the three-jaw chuck 1 is provided with a central through hole 14, and a linear bearing 11 is arranged in the center through hole. On the outer side of each claw of the three-jaw chuck 1 The clamping grooves 12 are all n-type grooves, and both sides of the n-type grooves are provided with threaded...

Embodiment 2

[0026] This embodiment adopts the connection method of Embodiment 1, and the difference is that the clamping groove on the outside of each claw of the three-jaw chuck 1 is a rectangular groove, and the volume of the three-jaw chuck 1 is that of the three-jaw clip 2. 1.5 times of the volume, the clamping groove on the outside of each claw on the three-jaw clamp 2 is also a rectangular groove, and the width of the rectangular groove on the three-jaw clamp 2 is equal to the width of the rectangular groove on the three-jaw chuck 1. The distance from the threaded through hole on the jaw chuck 1 to the central through hole of the three-jaw chuck 1 is 1.2 times the distance from the threaded through hole on both sides of the rectangular groove on the three-jaw clamp 2 to the central through hole of the three-jaw clamp 2. The thickness of 4 matches the width of the rectangular groove of three-jaw chuck 1 and three-jaw clamp 2. A layer of metallic copper is cast on the inner wall of th...

Embodiment 3

[0029] This embodiment adopts the connection method of Embodiment 1, and the difference is that the volume of the three-jaw chuck 1 is twice the volume of the three-jaw chuck 2, and the threaded through hole on the three-jaw chuck 1 is connected to the center of the three-jaw chuck 1. The hole distance is 1.3 times of the distance from the threaded through hole on both sides of the rectangular groove on the three-jaw clip 2 to the center through hole of the three-jaw clip 2. The width of the clamping groove on the three-jaw clip 2 and the three-jaw chuck 1 is different. etc., and the width of the clamping groove of the three-jaw chuck 1 matches the thickness of the upper part of the claw finger 4, the width of the clamping groove of the three-jaw clip 2 matches the thickness of the upper part of the three claw fingers 4, each finger 4 A layer of copper-plated material is provided in the through grooves at the bottom. The external drive mechanism is driven by a crank rocker.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com