Programmable stepped electronic equipment heat dissipation temperature control film

An electronic device, a stepped technology, applied in the field of temperature control films, can solve the problems of material leakage, fast heat conduction, and high heat source temperature, and achieve the effects of ensuring safe use temperature, reducing heat source temperature, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

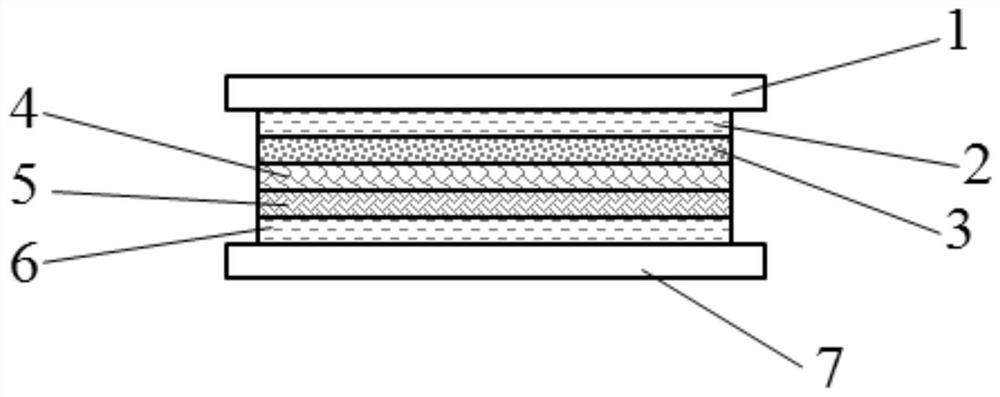

[0023] Such as figure 1 As shown, a programmable stepped heat dissipation and temperature control film for electronic equipment, including an upper release film layer 1, an upper acrylic adhesive layer 2, an elastomer heat-conducting layer 3, and a high phase change The point temperature control layer 4, the low phase transition point temperature control layer 5, the lower acrylic adhesive layer 6 and the lower release film layer 7, the size of the upper release film layer 1 and the lower release film layer 7 are not smaller than the upper acrylic Adhesive layer 2, elastomer heat conduction layer 3, high phase transition point temperature control layer 4, low phase transition point temperature control lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com