Flexible tubular large-aperture membrane filtration device and cleaning method thereof

A tubular membrane, large pore size technology, used in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of reducing the service life of the membrane, incomplete cleaning, and inability to effectively remove substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

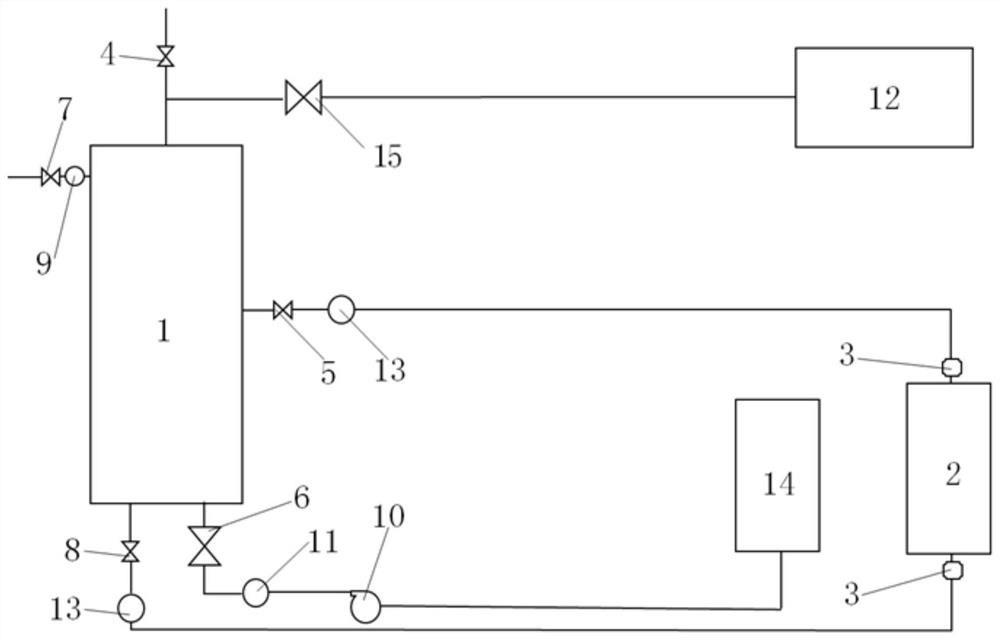

[0042] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0043] Such as figure 1As shown, a flexible tubular large-aperture membrane filtration device includes a membrane filtration device 1, the diameter of the tubular membrane in the membrane filtration device 1 is not less than 5 mm, the aperture of the tubular membrane is 6-200 μm, and the tubular membrane adopts uniform Made of plasma membrane, there is no filter layer and support layer in the traditional membrane filtration device, the forward and reverse cleaning and filtration effects are the same, the tubular membrane 1 is flexible enough for physical deformation; the membrane filtration device 1 is set to communicate with its interior The top emptying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com