Graphene oxide/nano-copper composite antibacterial agent, antibacterial master batch and preparation methods thereof

A composite antibacterial agent and nano-copper technology, applied in the field of graphene, can solve problems such as difficult industrial application, poor antibacterial effect, complicated preparation process, etc., and achieve the effects of weight reduction, good antibacterial effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

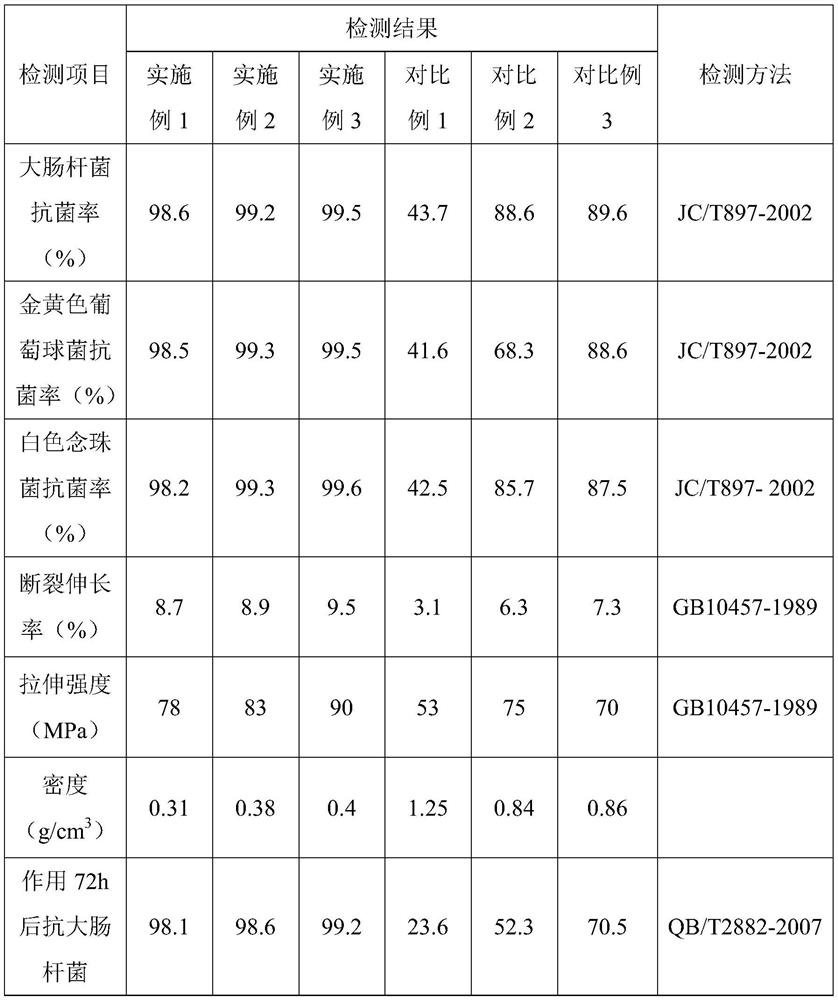

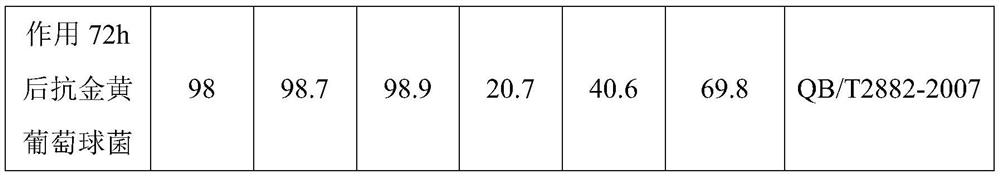

Examples

Embodiment 1

[0039] Embodiment 1 adopts the inventive method to prepare graphene oxide composite polylactic acid antibacterial sheet

[0040] The specific operation steps are as follows:

[0041] 1. Dissolve 60mg copper sulfate in 20ml deionized water to form solution A;

[0042] 2. Heat 5g of polyvinyl alcohol (PVA) at 80°C and stir to dissolve it in 30ml of deionized water to form solution B;

[0043] 3. Stir solution B in a magnetic stirrer, add solution A dropwise while stirring, so that copper ions dissolve in B, PVA plays a protective role, then add 5ml glucose to reduce copper ions into nano-copper particles, stir for 0.5h, Finally, solution C is formed;

[0044] 4. Dissolve 200mg of graphene oxide in 20ml of deionized water, stir ultrasonically to form a stable dispersed suspension, then add solution C to it, then transfer the mixture to a long glass tube, seal it, and freeze it at -20°C After thawing, Cu / GO composites were formed after repeated 3 times;

[0045] 5. Finally, fr...

Embodiment 2

[0049] Embodiment 2 adopts the inventive method to prepare graphene oxide composite polylactic acid antibacterial sheet

[0050] The difference from Example 1 is that the PVA dissolution temperature is 85°C, the freezing and thawing cycles are 4 times in step 4, the freeze-drying time in step 5 is 10h, the concentration of copper sulfate solution is 4mg / ml, and the concentration of PVA solution is 0.18g / ml , the volume ratio of the two is 2.5:3.5; when preparing graphene oxide composite polylactic acid antibacterial masterbatch, the weight ratio of raw materials is 98% polylactic acid masterbatch and 2% graphene oxide composite antibacterial agent.

Embodiment 3

[0051] Embodiment 3 adopts the inventive method to prepare graphene oxide composite polylactic acid antibacterial sheet

[0052] The difference from Example 1 is that the PVA dissolution temperature is 90°C, the freezing and thawing cycle is 5 times in step 4, the freeze-drying time in step 5 is 12h, the concentration of copper sulfate solution is 5mg / ml, and the concentration of PVA solution is 0.32g / ml , the volume ratio of the two is 3:4; when preparing graphene oxide composite polylactic acid antibacterial masterbatch, the weight ratio of raw materials is 97% polylactic acid masterbatch and 3% graphene oxide composite antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com