Flash spinning equipment

A flash spinning and equipment technology, applied in the direction of flash spinning, etc., can solve the problems of increasing production risks and safety hazards, many connection and disassembly places, and many leakage places, and achieves simple structure, easy control, Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but the claims of the present invention application are not limited by embodiment.

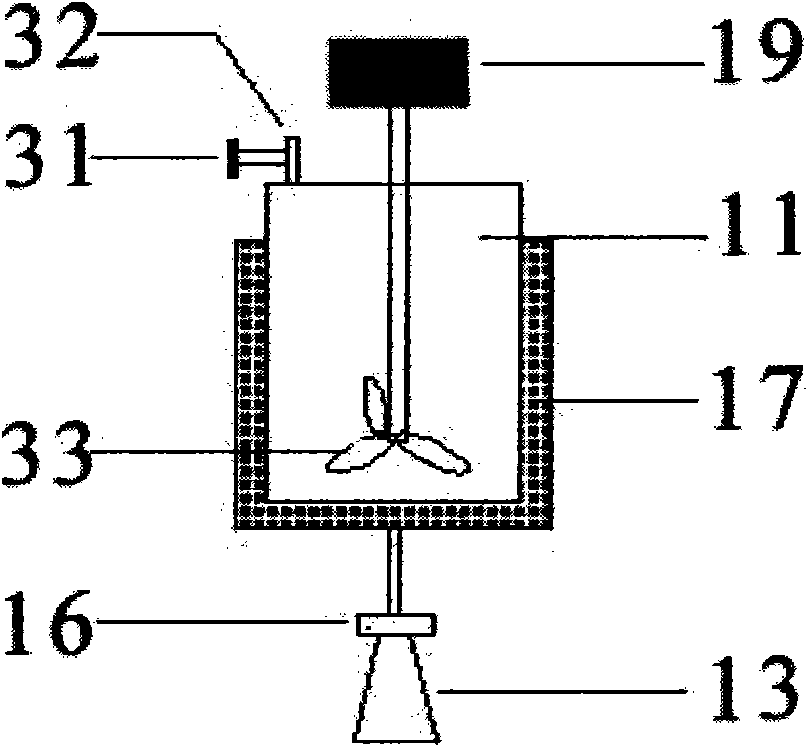

[0012] The flash spinning equipment designed by the present invention (hereinafter referred to as equipment, see image 3 ), mainly comprising an autoclave 11 and a heating jacket 17 thereof, a spinneret 13, a high-voltage electric valve 16, a transmission motor 19 and an agitator 33, and is characterized in that a pressure relief hole 32 is provided on the lid of the autoclave 11, and A pressure relief valve 31 is installed so that the autoclave has the function of a low pressure autoclave or a low pressure chamber at the same time; the bottom of the autoclave 11 is directly connected to the spinneret 13 through a high pressure electric valve 16 . The autoclave heating jacket 17 is wrapped on the outside of the autoclave 11 to provide heating to the autoclave 11; through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com