Method for obtaining GH4169 alloy ultra-fine grain forging

A GH4169, ultra-fine grain technology, applied in the field of forging, can solve the problems of reduced mechanical properties and performance, coarse grain and mixed grain, and the degree of recrystallization is very different, and achieves the effect of fine and uniform forging structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

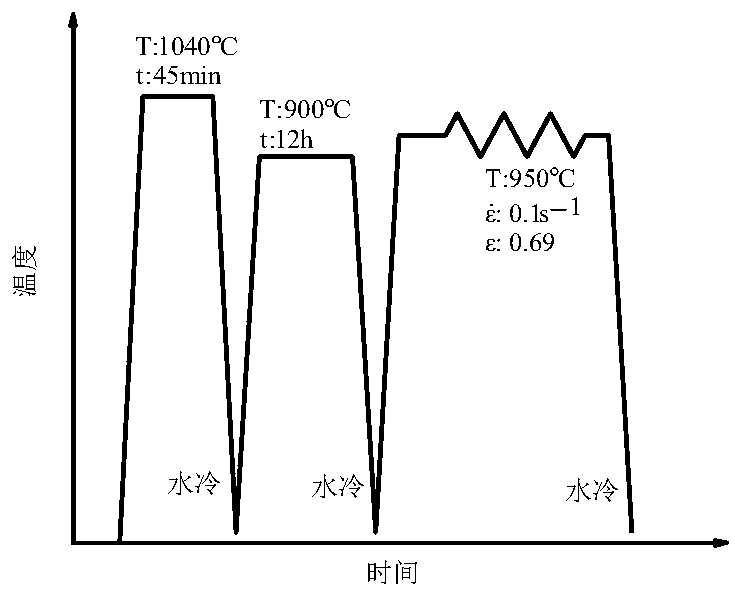

[0022] Step 1: The GH4169 alloy forging billet is subjected to solution treatment and aging treatment successively, the solution temperature is 1040±5°C, the solution time is 45min, the aging temperature is 900±5°C, and the aging time is 12h. Water quenching is carried out on the forged billet after solid solution and aging treatment respectively;

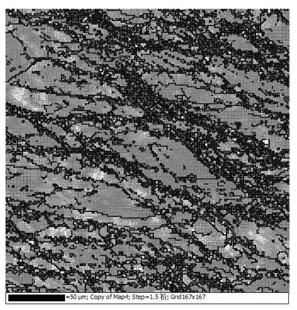

[0023] Step 2: Heat the GH4169 alloy forging billet processed in step 1 to the deformation temperature and hold it for 5 minutes, then perform upsetting thermal deformation, the deformation temperature is 950±5°C, and the strain rate is 0.1s -1 , the amount of deformation is 50% (equivalent to 0.69), and the forging is water quenched immediately after the deformation. The processing route of GH4169 alloy forging blank through steps 1 and 2 is as follows figure 1 As shown, the deformed structure after forging is as follows figure 2 shown;

[0024] Step 3: Perform delta phase aging treatment on the forging obtained in step 2, the...

Embodiment 2

[0028] Step 1: The GH4169 alloy forging billet is subjected to solution treatment and aging treatment successively, the solution temperature is 1040±5°C, the solution time is 45min, the aging temperature is 900±5°C, and the aging time is 12h. Water quenching is carried out on the forged billet after solid solution and aging treatment respectively;

[0029] Step 2: Heat the GH4169 alloy forging billet processed in step 1 to the deformation temperature and hold it for 5 minutes, then perform upsetting thermal deformation, the deformation temperature is 950°C, and the strain rate is 0.1s -1 , the amount of deformation is 50% (equivalent to 0.69), and the forging is water quenched immediately after the deformation;

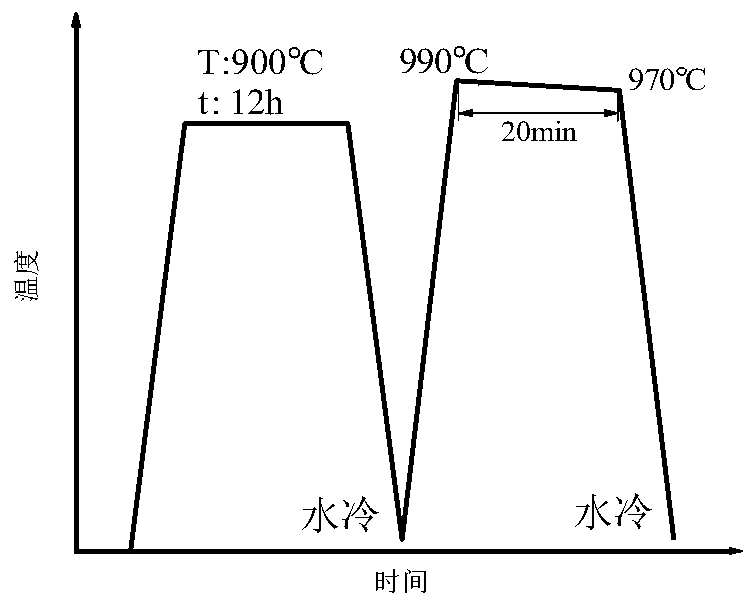

[0030] Step 3: Perform aging treatment on the forging obtained in step 2, the aging temperature is 900±5°C, the aging time is 12h, and then water quenching;

[0031] Step 4: Perform continuous cooling annealing on the GH4169 forging obtained in step 3. The initial an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com