Patents

Literature

81results about How to "Promotes dynamic recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

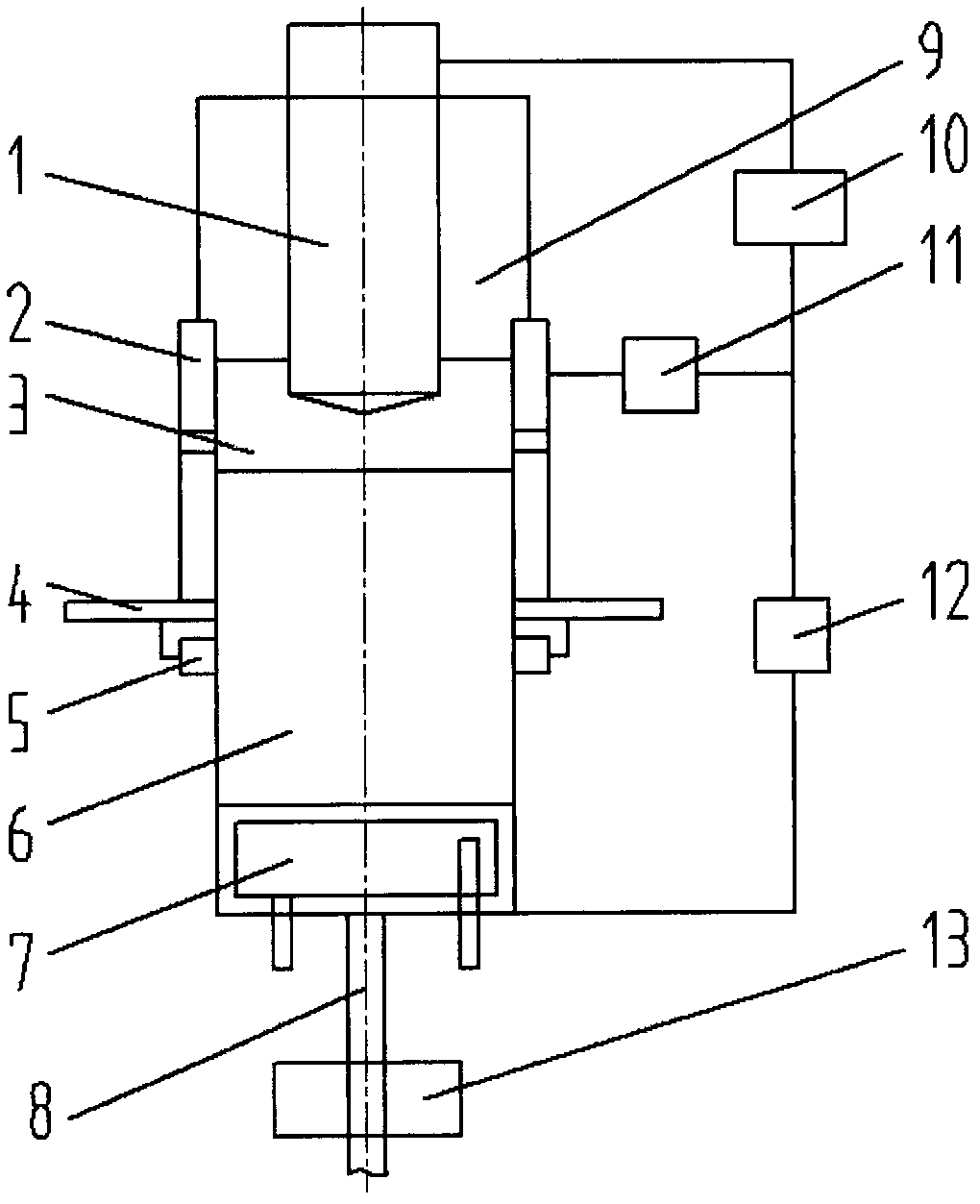

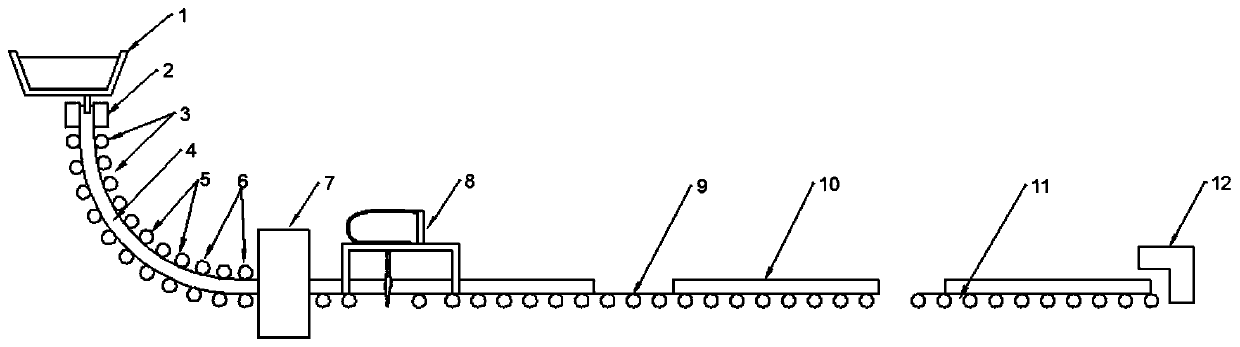

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

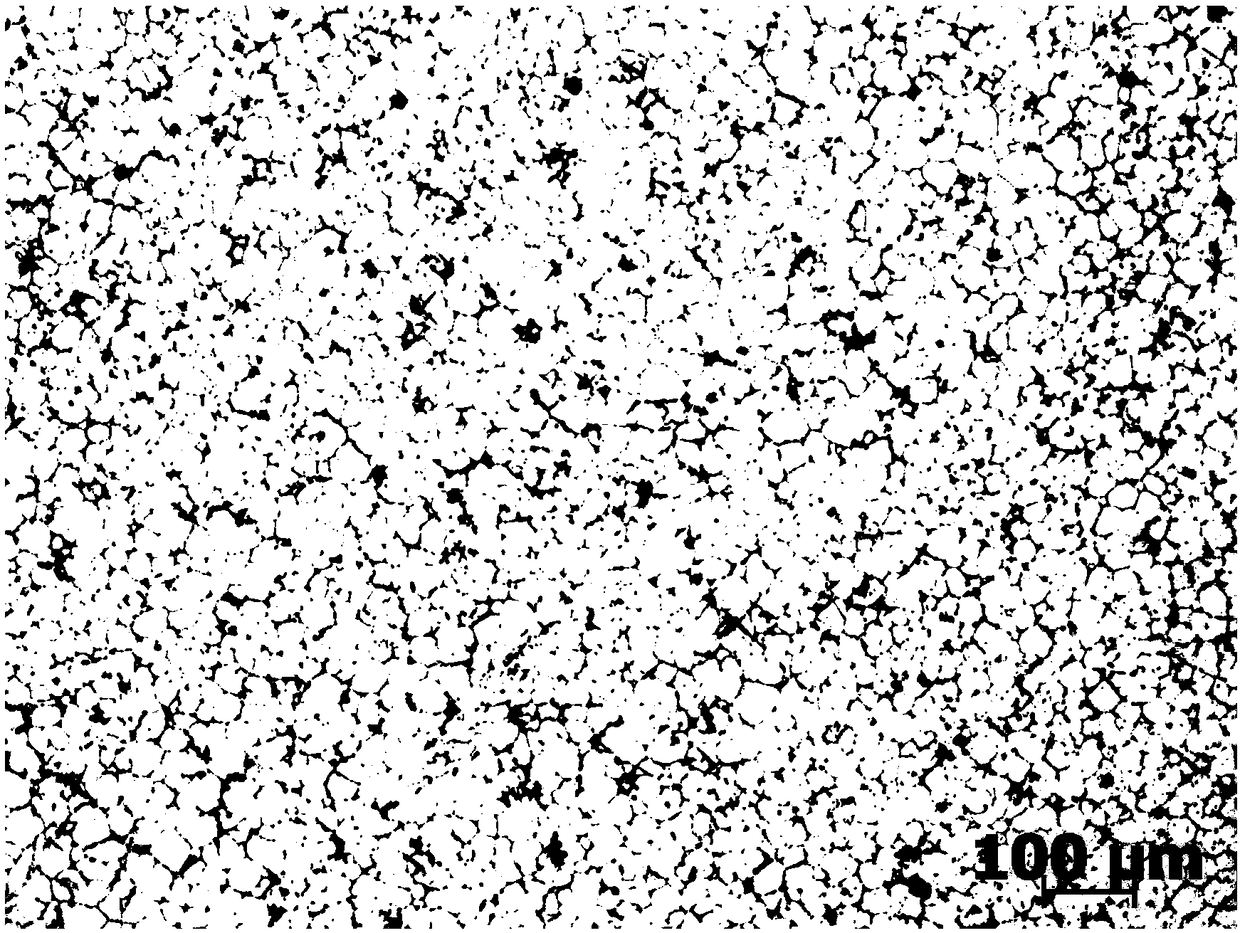

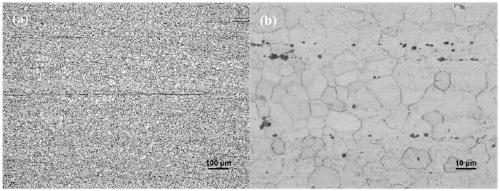

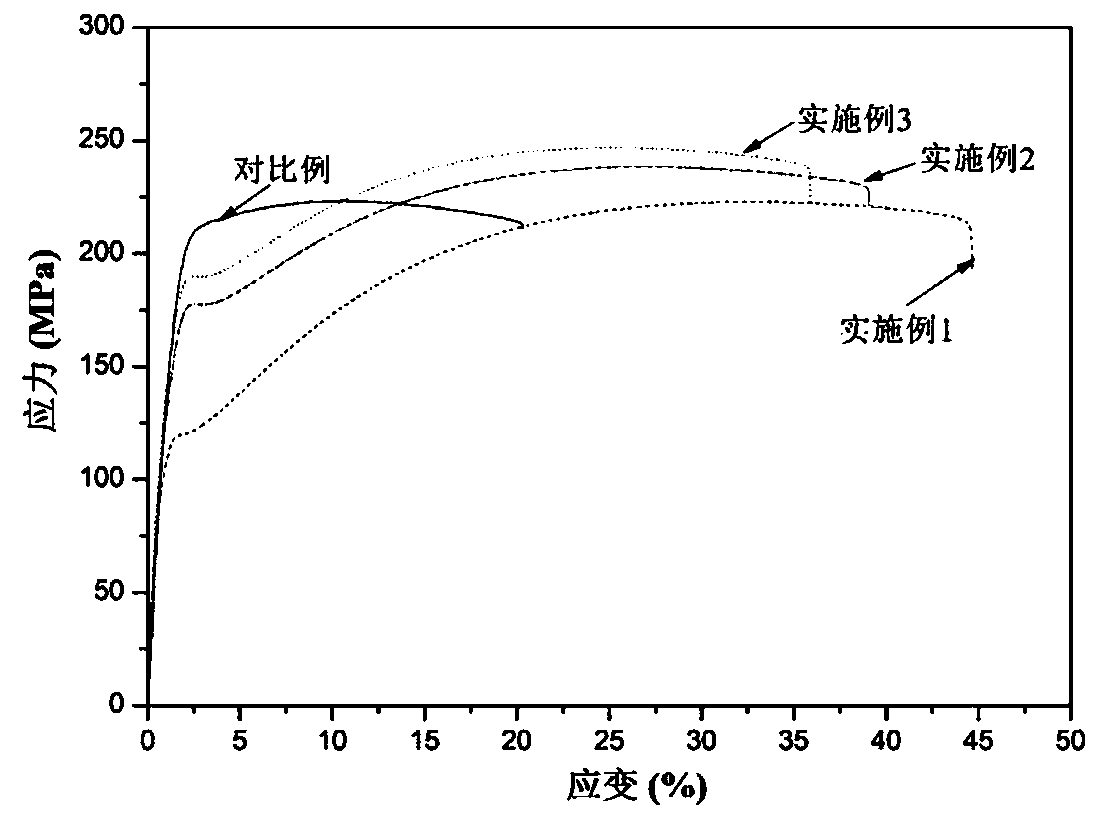

High-performance wrought magnesium alloy material

The invention relates to a high-purity high-performance magnesium alloy material, which consists of the following components in percentage by mass: 6.2 to 6.4 percent of Zn, 0.5 to 0.6 percent of Zr, 0.007 to 0.011 percent of inevitable Fe, Si, Cu, Ni and other impurities, and the balance magnesium. The material is prepared by the following steps: selecting raw magnesium with higher purity as a raw material; melting the raw magnesium by using the semicontinuous casting technology; properly increasing the melt standing time to ensure that compound particles containing Fe, Si and other impurity elements can be sufficiently deposited and a high-purity alloy cast blank can be prepared; and preparing the Mg-Zn-Zr wrought magnesium alloy by adopting the conventional extruding technology. The wrought magnesium alloy can maintain the high strength of traditional commercial ZK60 magnesium alloy to ensure that the plasticity and forming performance of the alloy can be greatly improved and the application potential of the material is sufficiently developed. Furthermore, the technical equipment used in the invention is conventional universal equipment, and the preparation process is simple.

Owner:CHONGQING UNIV

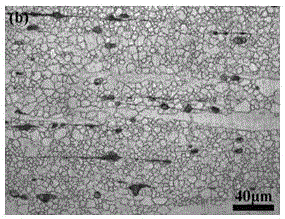

Regulation and preparation method of LPSO phase in Mg-Gd-Er-Zn-Zr alloy

The invention discloses a regulation and preparation method of a LPSO phase in an Mg-Gd-Er-Zn-Zr alloy, and belongs to the technical field of heat treatment. The Mg-Gd-Er-Zn-Zr alloy is heated up to the medium temperature of 300-350 DEG C in a heat treatment furnace; the temperature is kept for 15-60 minutes; the quenching is performed by hot water of 70 DEG C; then, the Mg-Gd-Er-Zn-Zr alloy is heated up to the high temperature of 480-520 DEG C; the temperature is kept for 3-8 hours; the quenching is performed by the hot water of 70 DEG C; and finally, the Mg-Gd-Er-Zn-Zr alloy is heated up to the secondary-high temperature of 400-460 DEG C; the temperature is kept for 12-50 hours; and the quenching is performed by the hot water of 70 DEG C. The method not only can control the volume fraction and one-dimensional dimension of the LPSO phase in the alloy, but also can effectively eliminate the component segregation of the casting alloy. Through the control process, the volume fraction of the LPSO phase is 3.2-45.67%, the range of the one-dimensional dimension is 25-120 microns, the component segregation and thick primary tissues of the casting alloy can be obviously eliminated, and the mechanical performance of the alloy is obviously improved.

Owner:BEIJING UNIV OF TECH

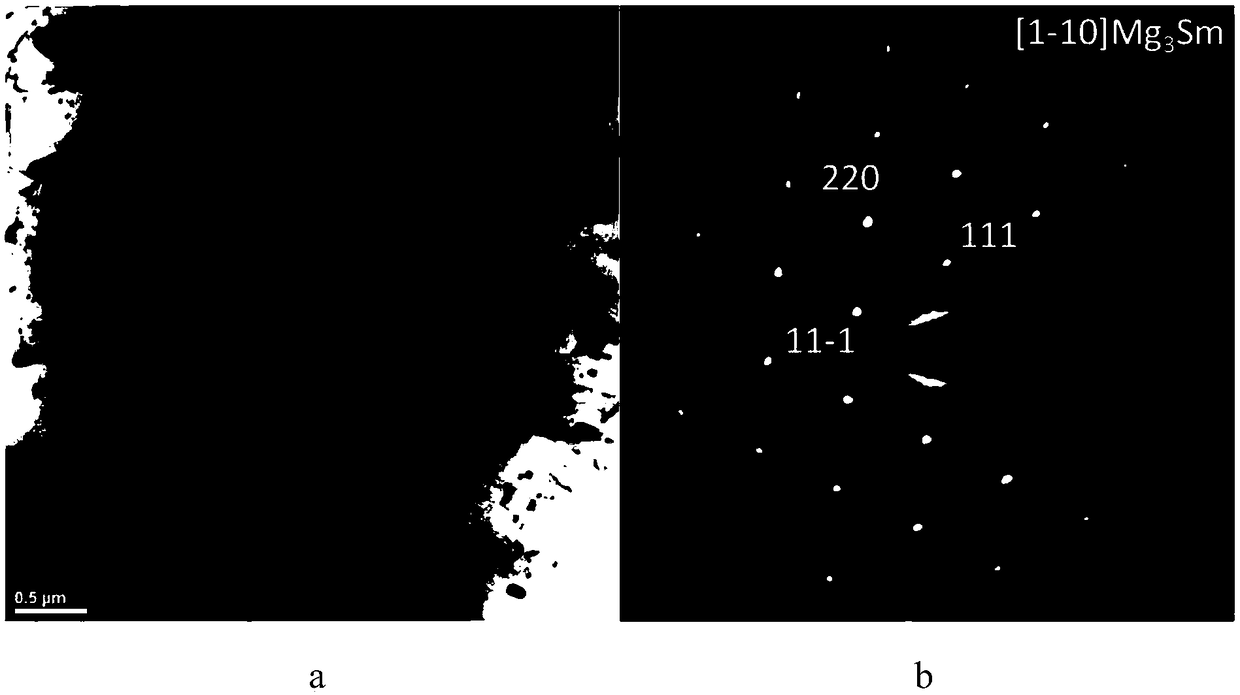

High-strength deformation magnesium alloy containing rare earth samarium, and preparation method thereof

The invention provides a high-strength deformation magnesium alloy containing rare earth samarium, and a preparation method thereof, belongs to the technical field of metal materials, and solves the problem of overhigh rare earth content and poor mechanical property of traditional magnesium alloy. The magnesium alloy disclosed by the invention is prepared from the following ingredients in parts byweight: 1.0-6.6wt% of Sm, 0.5-3.5wt% of Zn, 0.15-1.5wt% of Zr and the balance of Mg. The invention also provides a preparation method for the high-strength deformation magnesium alloy containing rareearth samarium. The high-strength deformation magnesium alloy containing rare earth samarium disclosed by the invention has excellent mechanical property. Mg-3.5Sm-0.6Zn-0.5Zr is taken as an exampleto show that the indoor temperature yield strength and the tensile strength are respectively 415MPa and 423MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

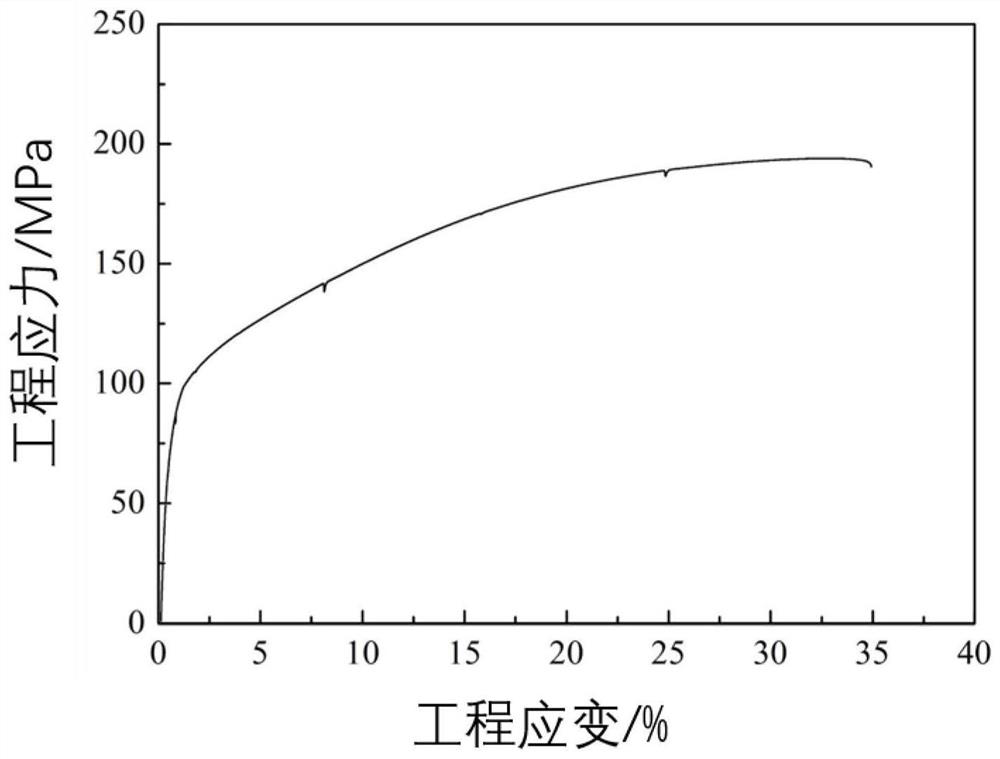

Deformation magnesium alloy with high yield ratio and high-ductility

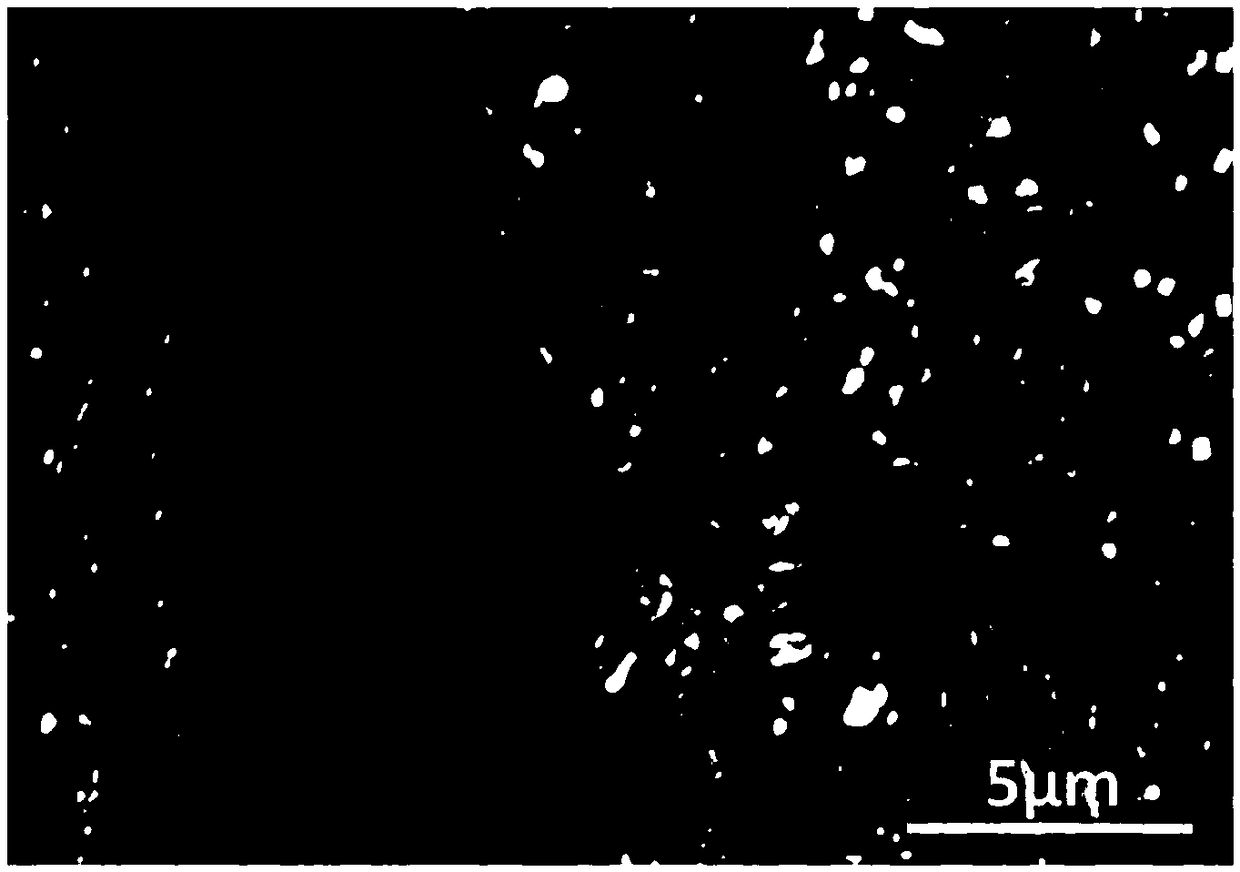

The invention discloses a wrought magnesium alloy with high yield tensile ratio and high plasticity, wherein the percentage by weight of each component of the alloy comprises zinc 1.0%-2.0%, zirconium 0.1%-0.6%, rare earth erbium 0.1%-0.8%, and others are magnesium and unavoidable impurities. Erbium and impurity element, magnesium and oxygen which is rolled alloy liquid in alloy are combined to form small and dispersed precipitation phase which effectively purifies alloy, promotes dynamic recrystallization in the process of thermal deformation, and blocks recrystallized grain to grow. Zinc plays a solution strength effect in alloy. The wrought magnesium alloy of the invention not only has high yield tensile ratio, but also has excellent plasticity, when the yield tensile is not less than traditional commercial wrought magnesium alloy ZK60 with high intensity, the wrought magnesium alloy of the invention greatly improves the plasticity of magnesium alloy, which fully mines application potential of material.

Owner:CHONGQING UNIV

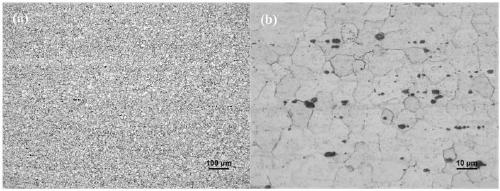

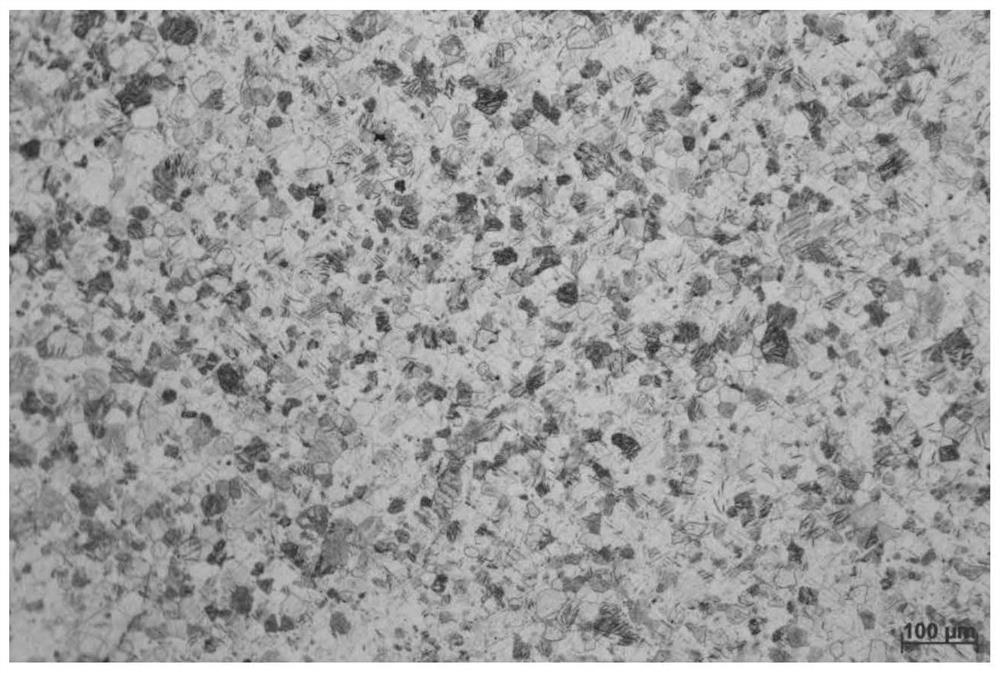

High-plasticity magnesium alloy and preparation method thereof

The invention discloses a high-plasticity magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 3-4% of Zn, 0.1-0.6% of Ca, 0.05-0.8% of Mn, and the balance of Mg and inevitable impurities. Ca and Mn are added in a magnesium zinc alloy to prominently refine alloy grains; in hot extrusion process, the dynamic recrystallization can be promoted to stop growth of recrystallized grains, so that the strength and the plasticity of the alloy are synchronously improved, the base surface texture of the alloy can be prominently weakened, and the plasticity of the alloy is improved; in addition, through separation of a second phase and dispersion and separation of nanoscale Mn particles, the strength of the alloy can be effectively improved; the magnesium alloy is high in plasticity; and the component-optimized alloy can reach the ductility of 25-29.8%, the yield strength of 160-205 MPa and the tensile strength of 270-289 MPa.

Owner:CHONGQING UNIV

Method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance

InactiveCN107119246AImprove mechanical propertiesExcellent thermoforming propertiesCrystal twinningPre deformation

The invention provides a method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance. The method comprises the steps that Mg-Al-Zn magnesium alloy is subjected to pre-deformation treatment at 25 DEG C to 300 DEG C, twin crystal or low-angle crystal boundaries are introduced, and then aging treatment is conducted. According to the deformation heat treatment method, precipitation of a continuous precipitation phase of the Mg-Al-Zn magnesium alloy can be effectively promoted, and alloy tissue with a uniform, small and dispersively distributed precipitation phase is obtained finally; and alloy strength and plasticity are synchronously improved, and thermoforming performance and service performance of the alloy are improved. The method for improving the Mg-Al-Zn magnesium alloy thermoforming and service performance is reasonable in design, simple in equipment requirement, convenient to operate, low in cost and high in efficiency, distribution of the precipitation phase of the Mg-Al-Zn magnesium alloy is reasonably controlled, the thermoforming performance and service performance of the alloy are improved, and the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

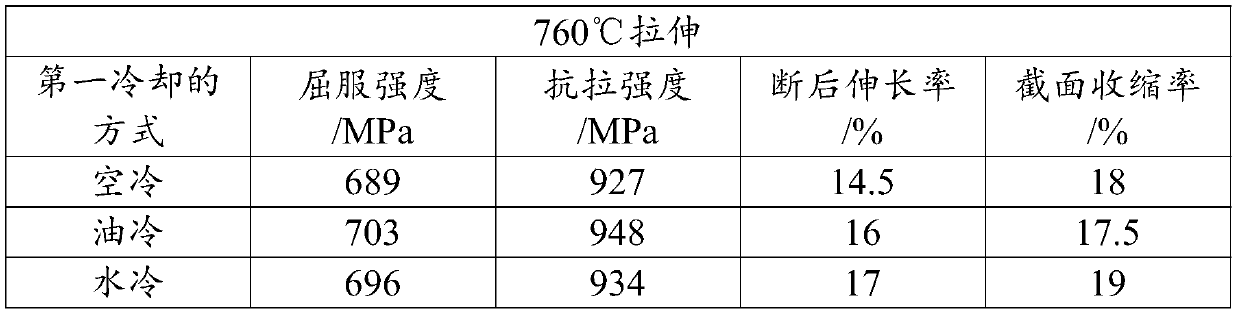

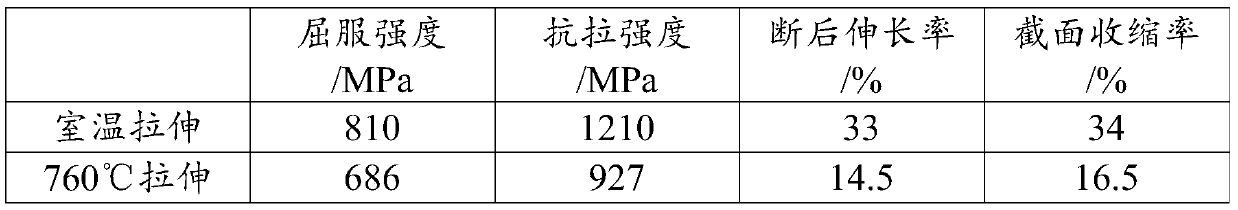

Heat treatment method of GH4780 alloy forging

ActiveCN110484841AHigh strengthImprove plasticityBlade accessoriesStatorsSmelting processUltimate tensile strength

The invention provides a heat treatment method of a GH 4780 alloy forging, and relates to the technical field of alloy manufacturing. The method comprises the following step: carrying out solution heat treatment on the GH 4780 alloy forging, wherein the temperature of the solution heat treatment is 1020-1170 DEG C. The GH 4780 alloy forging subjected to heat treatment not only can effectively eliminate the segregation of alloy elements such as Ti, Al and Cr in the smelting process and eliminate metallurgical defects such as cavities, but also can break columnar crystals and promote dynamic recrystallization, thereby refining the crystal grains and improving the strength and plasticity of the alloy forging.

Owner:BEIJING CISRI GAONA TECH +3

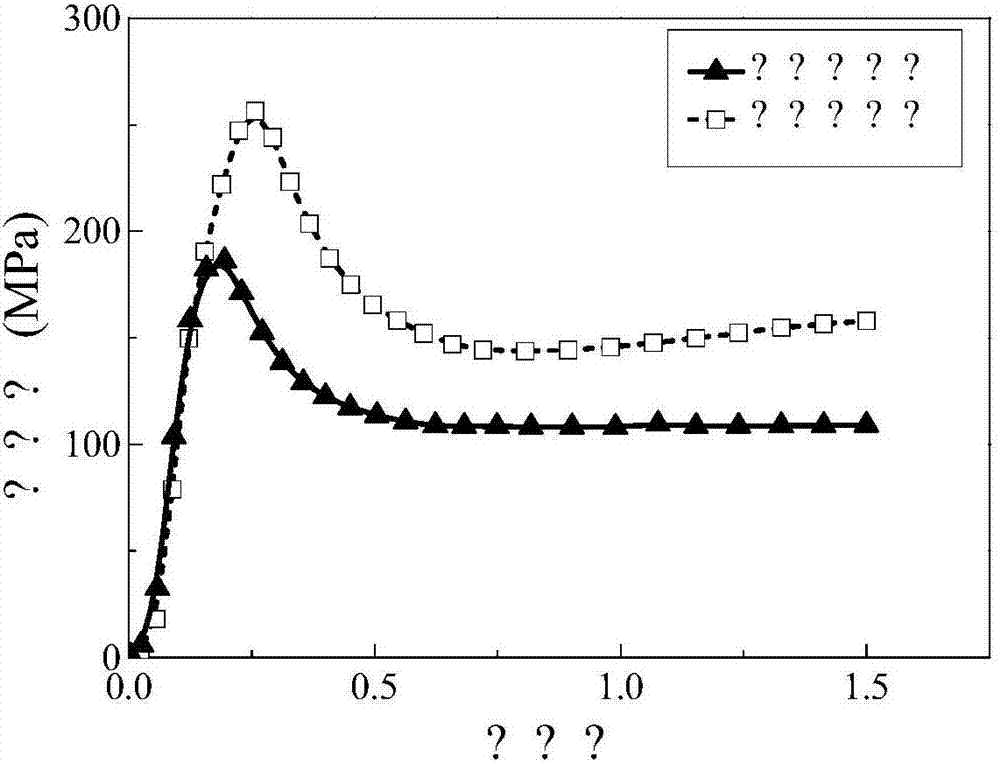

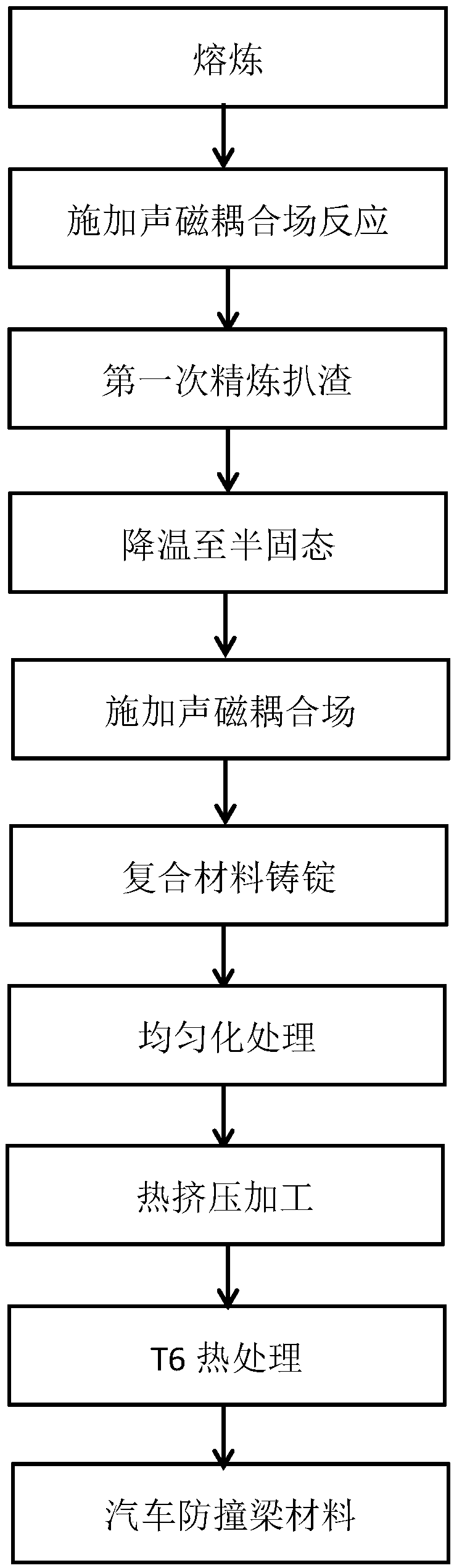

In-situ nanometer reinforced aluminum alloy for lightweight automobile anti-collision beam and preparation method

The invention relates to an aluminum-based composite material, in particular to an in-situ nanometer reinforced aluminum alloy for a lightweight automobile anti-collision beam and a preparation method. Through the in-situ synthesis technology, mixed powder of zirconium carbonate, potassium fluoborate and potassium fluotitanate is adopted as a reactant, an acoustomagnetic coupled field is applied in the reaction process, an acoustomagnetic coupled field is applied in the solidification stage, and an evenly-distributed nanometer wild phase clustered composite material of a fine grain structure is obtained. Then, through the optimized hot extrusion technology and quenching technology, material defects are reduced, sub-grains in the material are promoted to generate dynamic recrystallization,fine recrystallized grains are obtained, the strength, plasticity, impact resistance and corrosion resistance of the material are improved, the collision energy absorption effect of the material is improved to the largest degree, and a qualified aluminum-based composite material profile for the automobile anti-collision beam is obtained.

Owner:JIANGSU UNIV

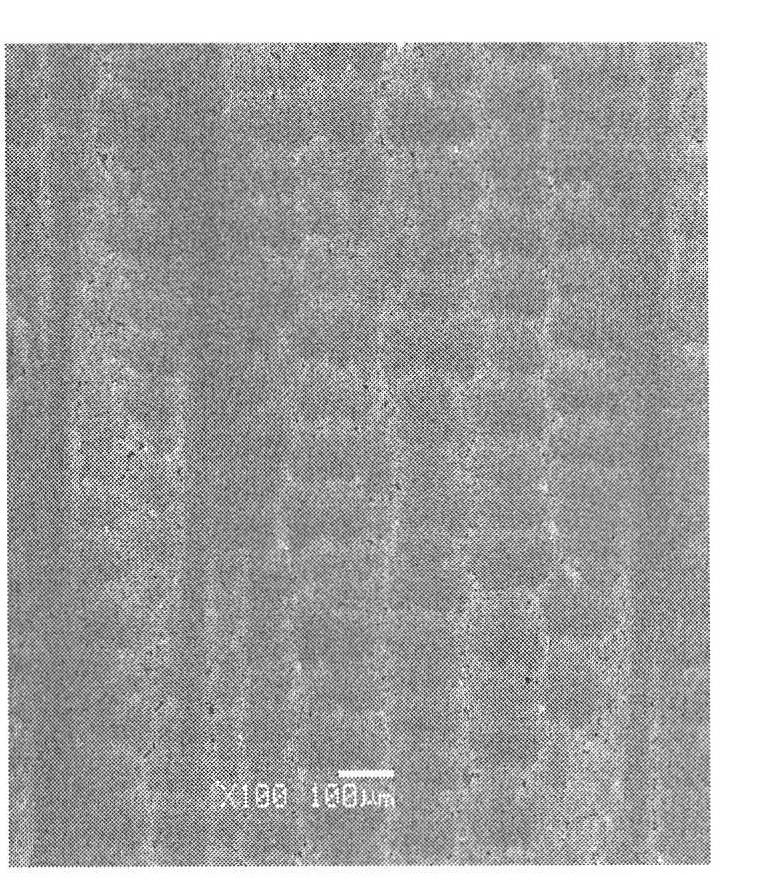

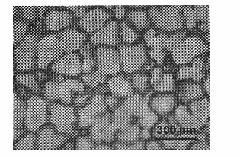

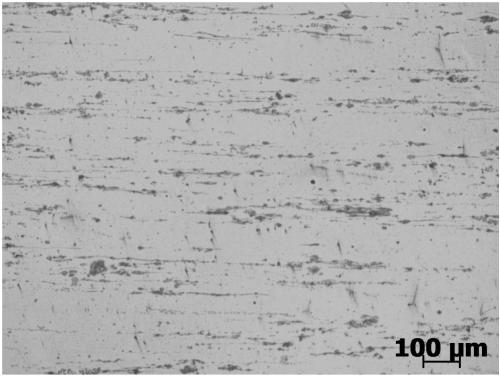

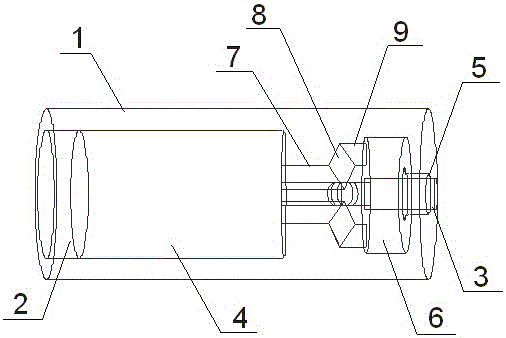

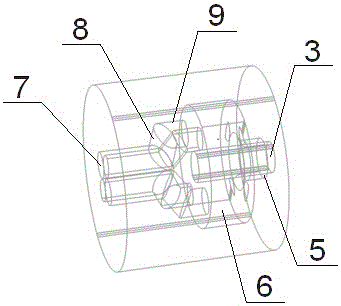

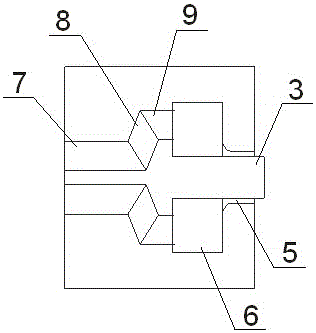

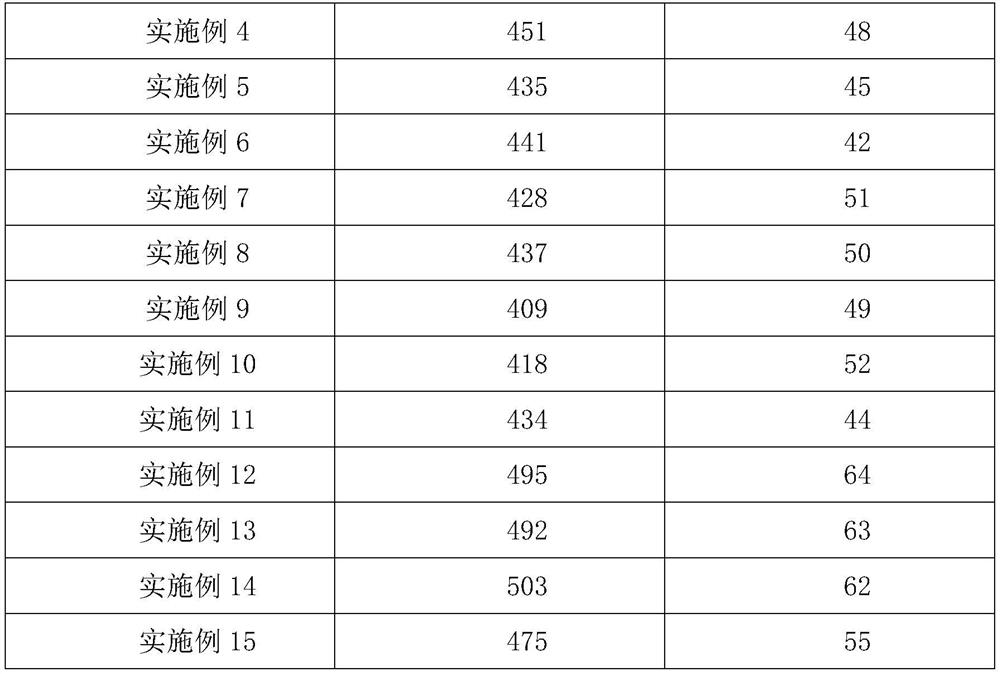

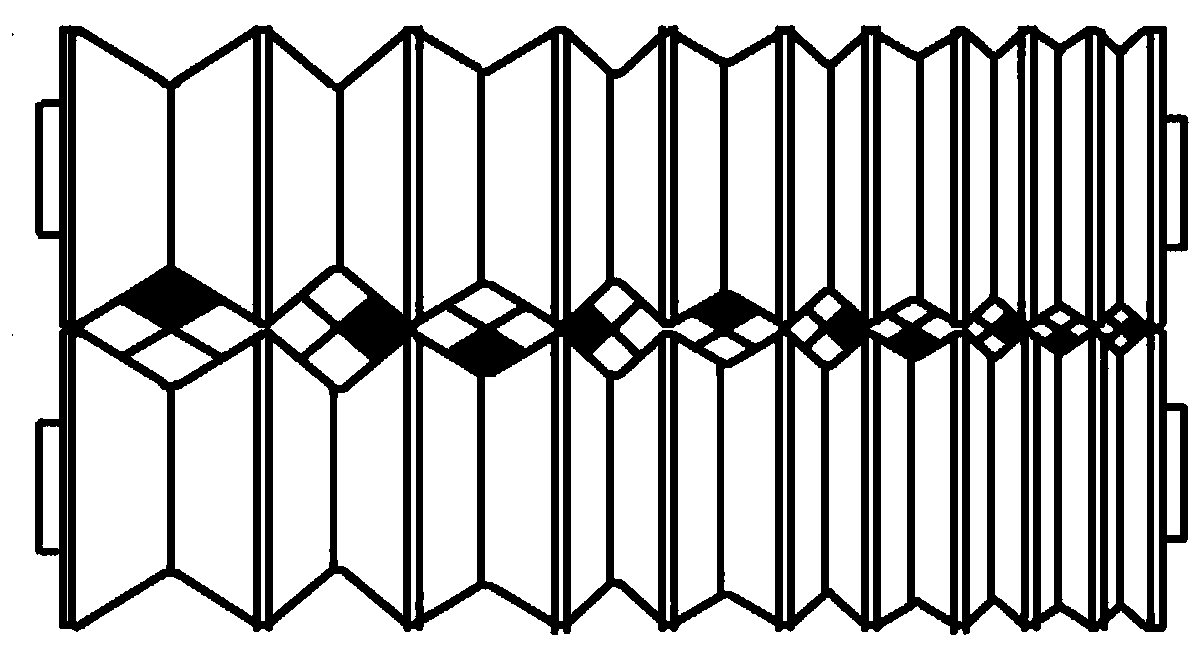

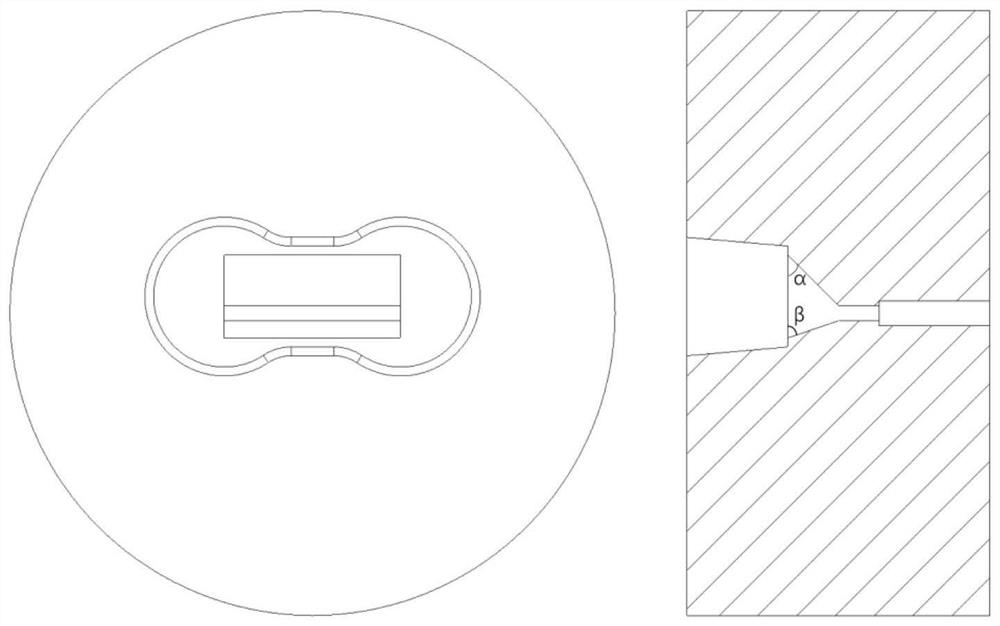

Manufacturing mold and method of high-strength high-toughness fine-grain light alloy tubing

ActiveCN106140852APromotes dynamic recrystallizationDeformation can be controlledExtrusion diesExtrusion containersCushionPlastic property

The invention discloses a manufacturing mold and method of high-strength high-toughness fine-grain light alloy tubing. The manufacturing mold comprises an extrusion container, an extrusion cushion and a forming mandrel. The extrusion container is provided with a feeding section and a discharging section. The extrusion cushion is arranged in the feeding section. A separation section and a welding chamber are arranged between the feeding section and the discharging section. Multiple blank channels are arranged on the separation section. The forming mandrel and the extrusion cylinder are coaxial, and the forming mandrel extends out from the discharging section. The manufacturing method comprises the following steps that firstly, light alloy cylindrical blanks are heated to a temperature being a recrystallization temperature or above; secondly, the heated blanks are placed in the extrusion container; thirdly, an extruding machine is switched on, and the blanks are extruded through the extruding machine; and fourthly, under extrusion of the extruding machine, the tubing is obtained finally. The light alloy material adopted by the manufacturing mold and the method is of a quite fine crystal structure and high in yield stress, and therefore the plasticity, the low-temperature super-plasticity and the high strain rate super-plasticity of the tubing can be greatly improved.

Owner:重庆昱华新材料科技有限公司

High-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy containing gadolinium and yttrium rare earth elements and preparation method thereof

The invention discloses a high-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy containing gadolinium and yttrium rare earth elements and a preparation method thereof, and belongs to the field of wrought magnesium alloy materials. The high-strength Mg-Ca-Mn-Al-Zn series wrought magnesium alloy comprises the following components in percentage by mass: 0.50-2.00% of calcium, 0.10-2.00% of aluminum, 0.10-2.00% of zinc, 0.10-3.00% of manganese, 0.10-3.00% of rare earth (gadolinium or yttrium), and the balance magnesium and inevitable impurities (Si, Ni, Cu and the like). The preparation method of the magnesium alloy comprises the following steps of: firstly, melting a pure magnesium ingot; after fully melting, adding metal calcium, manganese, aluminum, zinc, rare earth (gadolinium or yttrium) and the like; after fully stirring, casting into an ingot; then, homogenizing the ingot; extruding through a reverse extrusion process to obtain a corresponding extruded profile; and preparing the novel wrought magnesium alloy with high strength and high plasticity through smelting, homogenizing and subsequent extrusion (reverse extrusion) processes. The strength and the toughness of the wrought magnesium alloy are enhanced, and the wrought magnesium alloy has better mechanical properties.

Owner:NORTHEASTERN UNIV

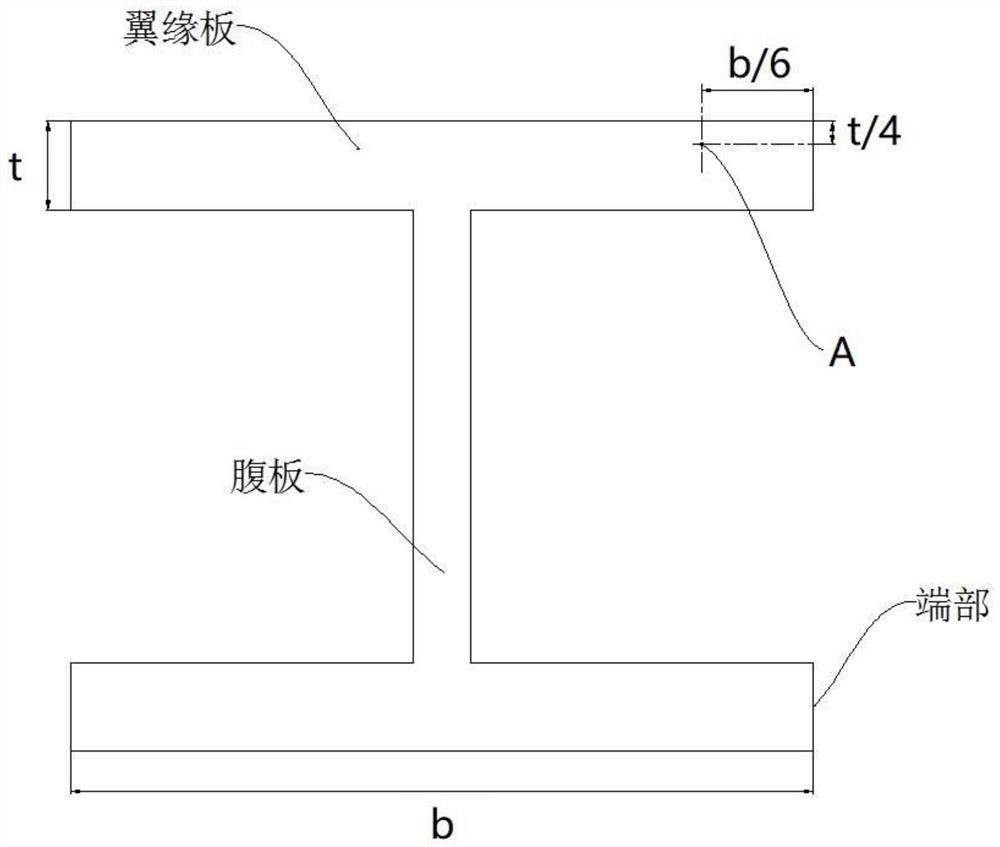

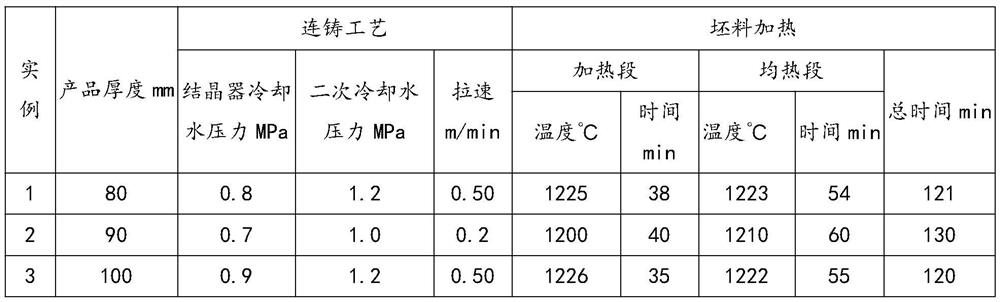

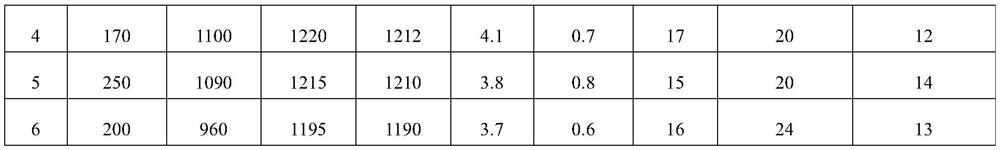

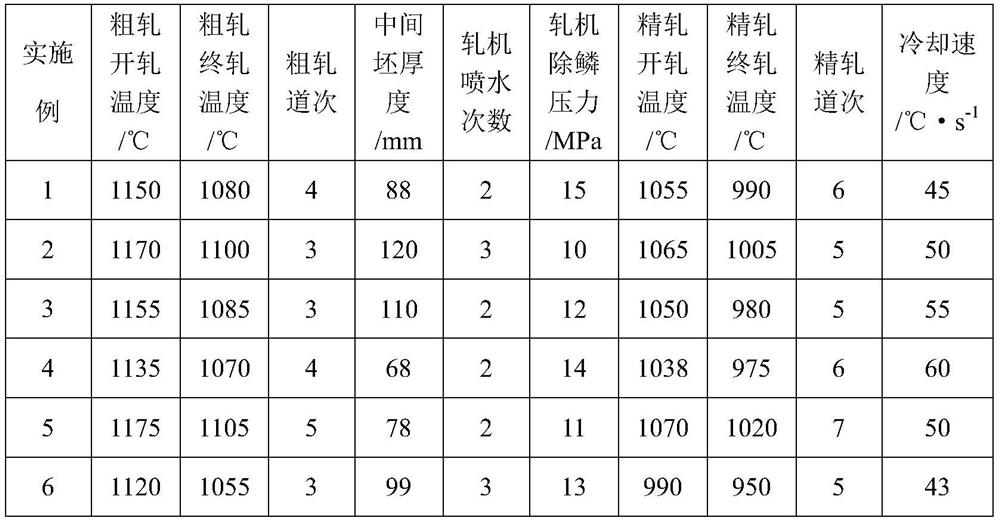

Super-thick Q355-grade hot-rolled H-shaped steel with good low-temperature toughness and production method thereof

ActiveCN112359289AReduce manufacturing costImprove mechanical propertiesTemperature control deviceMetal rolling arrangementsEconomic benefitsToughness

The invention discloses super-thick Q355-grade hot-rolled H-shaped steel with good low-temperature toughness and a production method thereof. The H-shaped steel comprises the following chemical components of, in percentage by mass, 0.12-0.18% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, 0.02-0.06% of Al, 0.02-0.06% of Nb, 0.0040-0.0100% of N, less than or equal to 0.015% of P, less than or equal to 0.005% of S, the balance Fe and inevitable impurities, with flange thickness of 80-150mm, less than or equal to 0.42% of CEV, and less than or equal to 0.25% of Pcm. The invention further provides an Nb and Al microalloying low-cost component design scheme. With reasonable continuous casting process and rolling process, distribution of AlN and NbC in a continuous casting billet and the H-shaped steel is controlled, a beam blank structure is improved, a H-shaped steel structure is refined, the product mechanical performance is good, and the economic benefits are good.

Owner:MAANSHAN IRON & STEEL CO LTD

Low-rare-earth high-strength wrought magnesium alloy containing neodymium and yttrium and preparation method of low-rare-earth high-strength wrought magnesium alloy

InactiveCN112458349ALow costImprove mechanical propertiesFurnace typesHeat treatment furnacesIngotZinc

The invention provides a high-strength wrought magnesium alloy containing rare earth neodymium and yttrium. The alloy comprises the following components in percentages by mass: 5.50-6.50wt.% of Zn, 0.47-0.80wt.% of Zr, 0.45-0.50wt.% of Nd, 0.72-1.00wt.% of Y, less than 0.10wt.% of inevitable impurities and the balance of Mg. A preparation method comprises the following steps: homogenizing a magnesium alloy ingot containing rare earth neodymium and yttrium, and then performing hot extrusion. Crystal grains are remarkably refined, meanwhile, neodymium, yttrium and elements such as magnesium andzinc in the alloy form second phases, and the second phases are re-crushed and distributed into fine dispersed strengthening phases in the hot extrusion process, so that growth of recrystallized crystal grains in the hot deformation process can be effectively hindered, a matrix is strengthened, and good mechanical properties can be obtained; and after hot extrusion, low-temperature aging treatmentis performed, so that the strength can be further improved, and the tensile strength after aging exceeds 400 MPa and is higher than that of most commercial magnesium alloys at present. The alloy is low in cost, a conventional smelting hot extrusion process is adopted, and the alloy has good operability and practicability and is convenient to popularize and apply.

Owner:CHONGQING UNIV

Low-cost high-toughness wrought magnesium alloy capable of being extruded at high speed and preparation method thereof

The invention relates to low-cost high-toughness wrought magnesium alloy capable of being extruded at high speed and a preparation method thereof. The alloy is Mg-Bi-Sn-Al-Ca magnesium alloy and comprises, by mass, 2-45 of Bi, 2-4% of Sn, 1-3% of Al, 0.05-0.5% of Ca and the balance magnesium, wherein the mass ratio of Bi to Sn in the alloy is (0.8-1.2):1. The alloy can be used for high-speed extrusion production at the extrusion speed up to 25 m / min, the production efficiency is improved, and meanwhile, the production cost is reduced. Crystalline grains of a finally extruded product are uniform and fine, a large number of second phases are dispersed in a matrix, the comprehensive mechanical property is good, and the alloy is relatively good in flame retardancy.

Owner:HEBEI UNIV OF TECH

High-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy containing light rare earth element lanthanum and preparation method thereof

The invention discloses a high-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy containing a light rare earth element lanthanum and a preparation method of the high-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy, and belongs to the field of wrought magnesium alloy materials. The high-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy comprises the following components of, in percentage by mass, 0.10to 1.50% of calcium, 0.10 to 1.8% of aluminum, 0.10 to 1.9% of zinc, 0.10 to 4.8% of manganese, 0.20 to 3.00% of lanthanum, and the balance magnesium and unavoidable impurities (Si, Ni, Cu and the like); and the preparation method of the magnesium alloy comprises the following steps that a pure magnesium cast ingot is melt firstly, after fully melting is carried out, metal calcium, manganese, aluminum, zinc, light rare earth lanthanum and the like are added, fully stirring is carried out, casting into a cast ingot is carried out, then homogenizing treatment on the cast ingot is carried out, and extruding through a reverse extrusion process is carried out to obtain a corresponding extruded profile. According to the high-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy containing the light rare earth element lanthanum and the preparation method of the high-strength Mg-Ca-Mn-Al-Zn wrought magnesium alloy, the novel wrought magnesium alloy with high strength and high plasticity is preparedthrough smelting, homogenizing treatment and subsequent extrusion (reverse extrusion) processes, the strength and toughness of the novel wrought magnesium alloy are enhanced, and the novel wrought magnesium alloy has good mechanical properties.

Owner:NORTHEASTERN UNIV

Plastic deformation magnesium alloy and preparation method thereof

InactiveCN109182861AImprove plastic deformation abilityPromote solid solutionRoom temperatureExcessive growth

The invention discloses a plastic deformation magnesium (Mg) alloy and a preparation method thereof. The plastic deformation Mg alloy is a Mg-Al-Bi-Sn-Ca-Y alloy, and consists of, by weight percent, 3.0-6.0% of Al, 1.0-3.0% of Bi, 0.5-2.0% of Sn, 0.02-0.05% of Ca, 0.02-0.05% of Y, and the balance Mg, wherein the total content of the element Ca and the element Y is greater than 0.05% and less than0.1%. The plastic deformation Mg alloy and the preparation method thereof adopt lower extrusion temperature and speed to form a large amount of Mg3Bi2 phases, Mg2Sn phases and Mg17Al12, and inhibit excessive growth of second phases by alloying a trace of the elements Ca and Y at the same time. In addition, the element Bi, the element Sn, a trace of the element Ca and a trace of the element Y are simultaneously dissolved into a matrix to improve the texture characteristics of the deformation alloy so as to develop the high-room-temperature-ductility deformation Mg alloy of which the room temperature elongation can reach upwards of 32%.

Owner:CITIC DICASTAL

High-strength wrought aluminum alloy containing rare earth samarium and preparation method thereof

The invention provides a high-strength wrought aluminum alloy containing rare earth samarium and a preparation method of the high-strength wrought aluminum alloy, and belongs to the technical field ofmetal materials. The problem that an existing aluminum alloy is poor in mechanical property is solved. The aluminum alloy is prepared from the following chemical components of, in percentage by mass,1.5wt.% - 2.5wt.% of Mg, 0.5wt.% - 1.5wt.% of Si, 0.2wt.% - 1.2wt.% of Cu, 0.1wt.% - 0.5wt.% of Sm and the balance Al. The high-strength wrought aluminum alloy containing the rare earth samarium hasexcellent mechanical properties, and by taking Al-2Mg-Si-0.9Cu-0.5Sm as an example, the room-temperature yield strength and the tensile strength of the Al-2Mg-Si-0.9Cu-0.5Sm is 315MPa and 423MPa respectively.

Owner:SHANDONG NANSHAN ALUMINUM

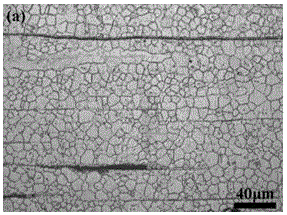

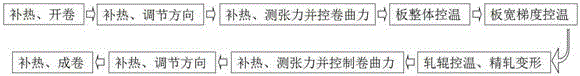

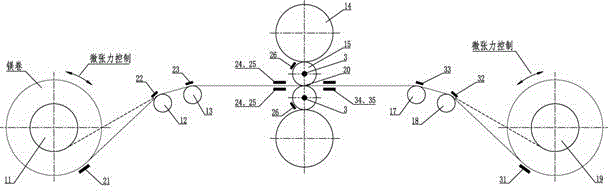

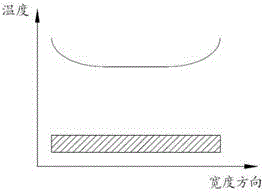

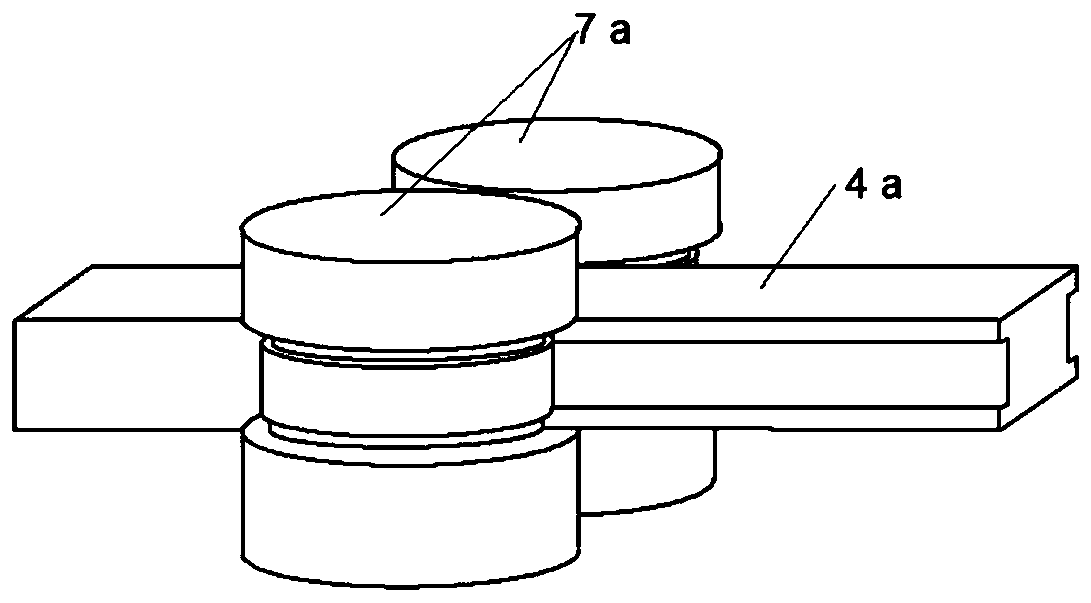

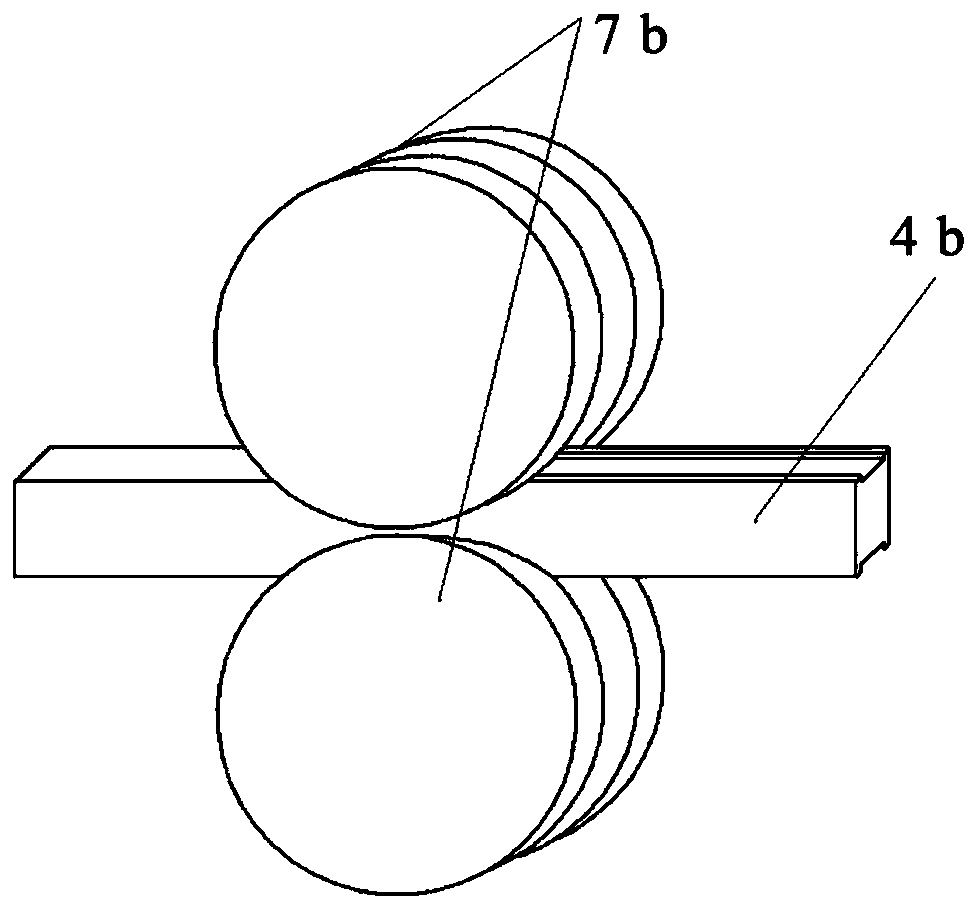

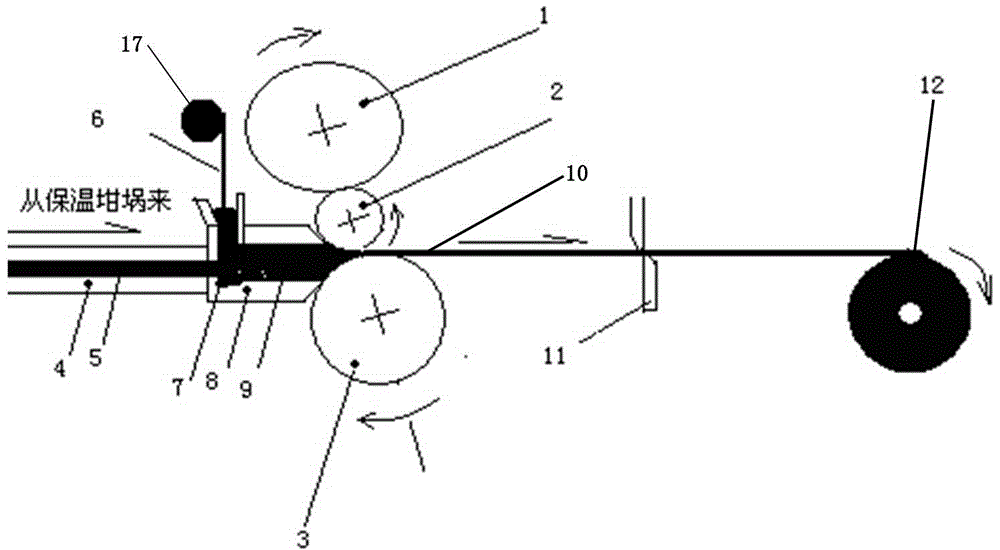

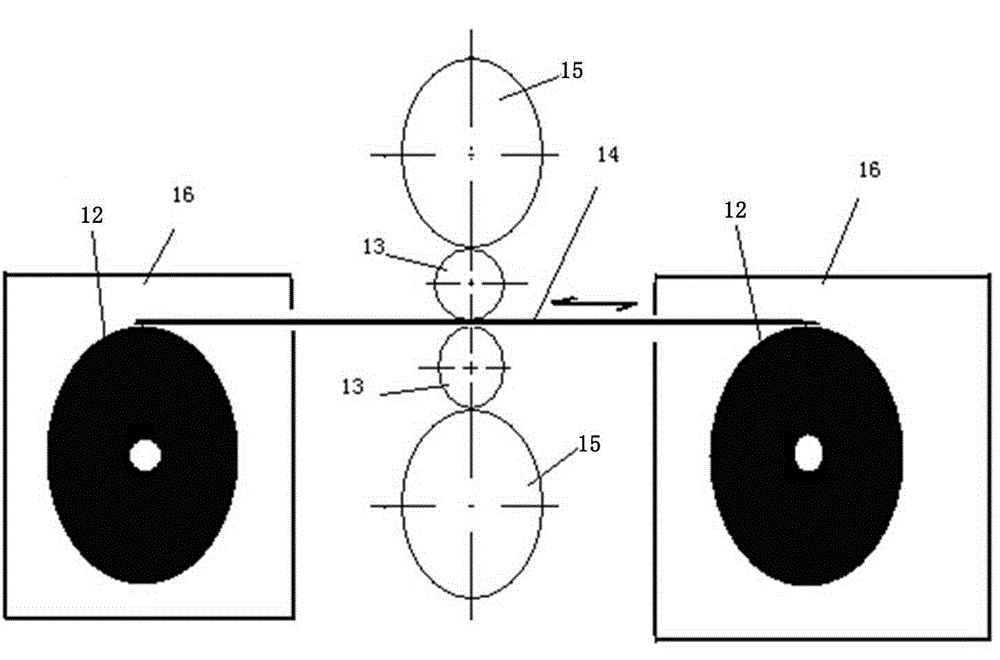

Temperature-controlled rolling technology of magnesium alloy coiled sheet

ActiveCN105834227AAvoid bumpingAvoid featuresTemperature control deviceMetal rolling arrangementsTemperature controlRolling mill

The invention discloses a temperature-controlled rolling technology of magnesium alloy coiled sheets. The steps comprise: (1) performing heating compensation on a magnesium coiled sheet and uncoiling the magnesium coiled sheet; (2) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (3) measuring tension of the sheet and controlling a crimp force value; (4) performing integrated temperature control on a part which is to bite into the sheet; (5) performing gradient temperature control on the width direction of the part which is to bite into the sheet; (6) through a temperature-controlled roll, performing finishing rolling on the sheet and the sheet deforming; (7) measuring tension of the sheet and controlling a crimp force; (8) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (9) performing sheet heating compensation and coiling the sheet in rolls; (10) if the thickness of the magnesium plate coil sheet does not reach the thickness (t0) of a target magnesium plate, reversely repeating the steps (1)-(9) on magnesium coiled sheets on a reversible temperature-controlled rolling mill according to the process steps, performing next temperature-controlled finish rolling processing; (11) if the thickness of the magnesium sheet reaches the thickness (t0) of the target magnesium plate, obtaining the magnesium alloy coiled sheet satisfying the thickness requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

Square bloom continuous casting manufacturing method facilitating elimination of core defects

InactiveCN110508765AReduce riskHigh porosity removal capacityMetal rolling arrangementsPorosityRolling mill

The invention provides a square bloom continuous casting manufacturing method facilitating elimination of core defects and belongs to the field of large-section square bloom production. According to the square bloom continuous casting manufacturing method, the continuous casting blank soft reduction technology and the hot core high-temperature heavy reduction rolling technology are optimized and combined. The core macrosegregation defects are eliminated in the soft reduction process; heavy-reduction rolling mills are directly arranged behind a continuous casting straightening and withdrawing machine, the online opposite reduction rolling process is implemented by making full use of cold outside and hot inside temperature field features of a casting blank under the complete solidification state of the casting blank to eliminate the defects such as core shrinkage cavity porosity.

Owner:NORTHEASTERN UNIV

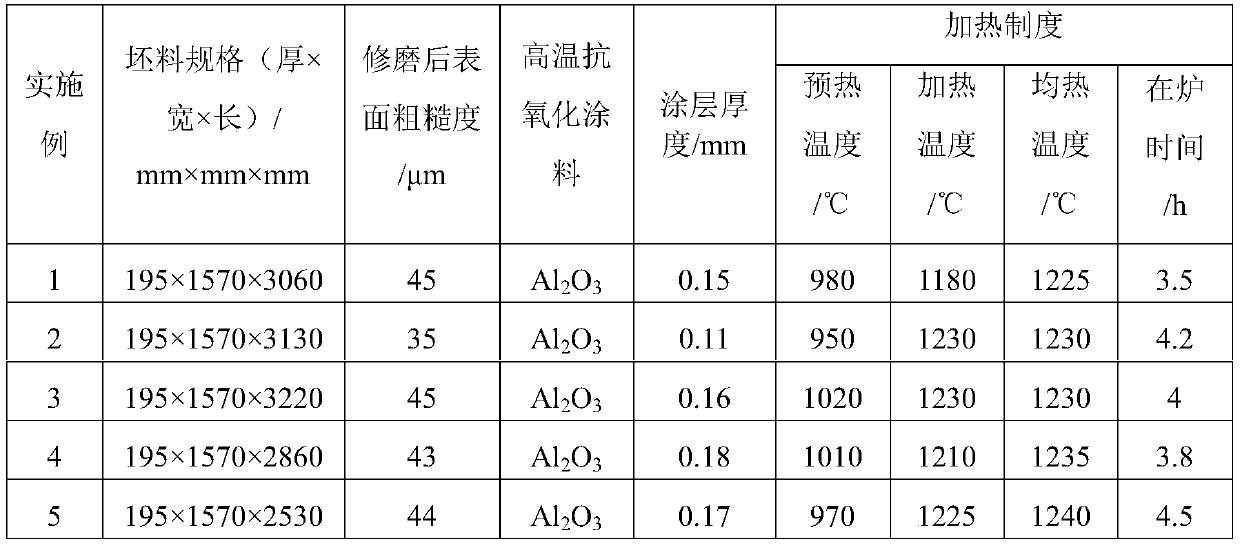

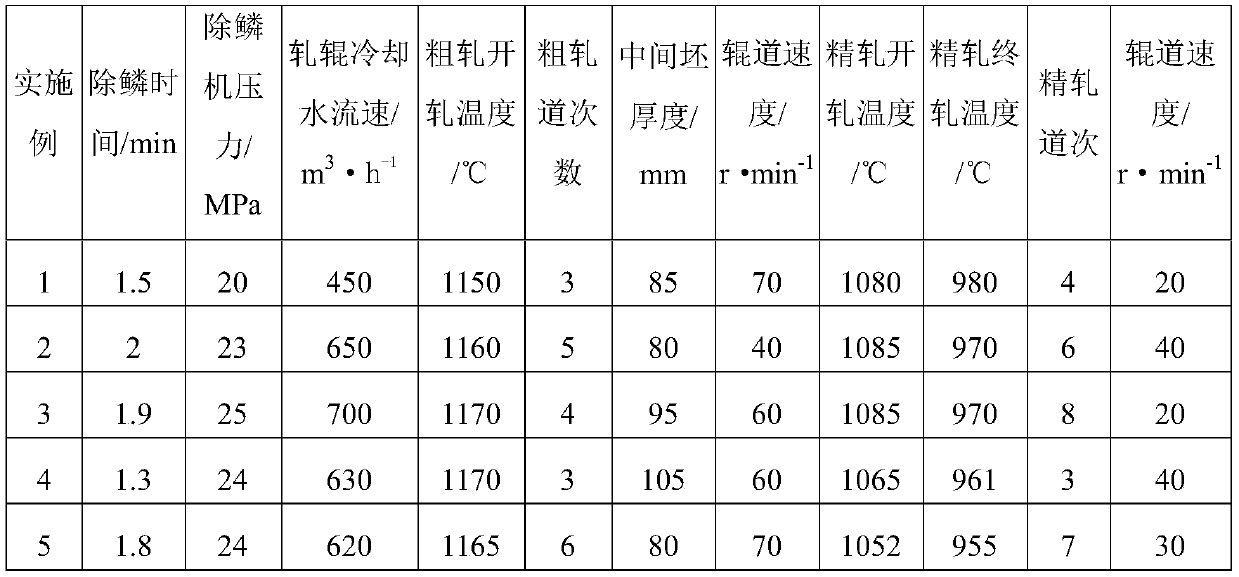

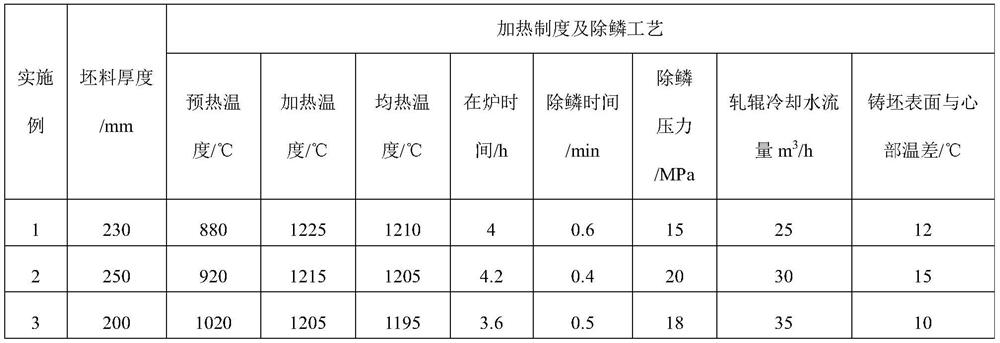

Ultra-wide economical duplex stainless steel medium plate and manufacturing method thereof

ActiveCN110453148AHigh strengthReduces surface scratches and cratersProcess efficiency improvementPapermakingReduction rate

The invention discloses an ultra-wide economical duplex stainless steel medium plate and a manufacturing method thereof. The medium axial crystal proportion of a continuous casting billet is not lowerthan 80%; the surface roughness Ra of the casting billet is smaller than or equal to 50 [mu]m, and high-temperature antioxidant coating is sprayed; the preheating section temperature of the casting billet is 960-1100 DEG C, the heating section temperature is 1150-1230 DEG C, and the soaking section temperature is 1220-1250 DEG C; the rough rolling starting temperature is larger than or equal to 1150 DEG C, the first pass reduction amount is larger than or equal to 25%, the subsequent pass reduction amount is smaller than or equal to 20%, the roller speed is 40-70 r / min, and the thickness of an intermediate blank is 60-120 mm; the finish rolling start temperature is larger than or equal to 1050 DEG C, the finish rolling temperature is larger than or equal to 950 DEG C, the rolling reduction rate is smaller than or equal to 20%, product specifications are 2800-4000 mm wide and 20-60 mm thick, and the surface crack rejection rate is decreased from above 10% to below 1.5%. The product iswidely applied to the engineering fields of nuclear power, oil and gas, shipbuilding, papermaking, seawater desalination and the like.

Owner:ANGANG STEEL CO LTD

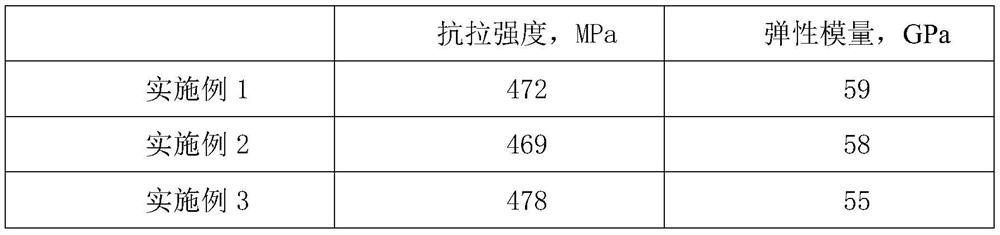

High-strength rare earth wrought magnesium alloy and preparation method thereof

The invention discloses a high-strength rare earth wrought magnesium alloy and a preparation method thereof. The high-strength rare earth wrought magnesium alloy comprises, by mass, 6%-9% of Al, 1.5%-2.5% of Nd, 0.2%-1.5% of Zn, 0.3%-2.0% of Si, 1.2%-2.5% of Zr, 5%-7% of Y, 5%-7% of Gd, 1%-5% of Sm, and the balance Mg and inevitable impurities, wherein (Y+Gd): Sm is equal to 2.8-14; According to the high-strength rare earth wrought magnesium alloy and the preparation method thereof, by adding aluminum, silicon, zinc and various rare earth elements into magnesium alloy raw materials, the tensile strength of the magnesium alloy raw materials is greater than 450 MPa, the elastic modulus of the magnesium alloy raw materials is greater than 55 GPa, the requirements for high strength and high elastic modulus of magnesium alloy in the prior art can be met, and the high-strength rare earth wrought magnesium alloy has the wider application field.

Owner:湖南镁卓新材料科技有限公司

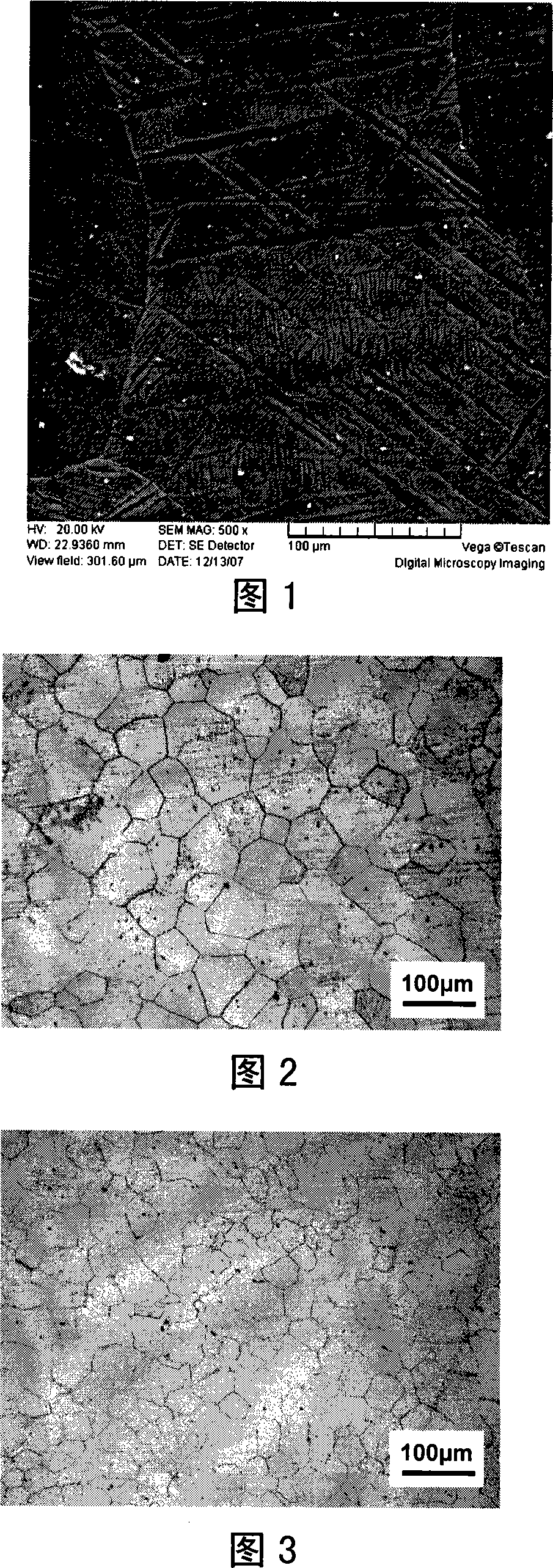

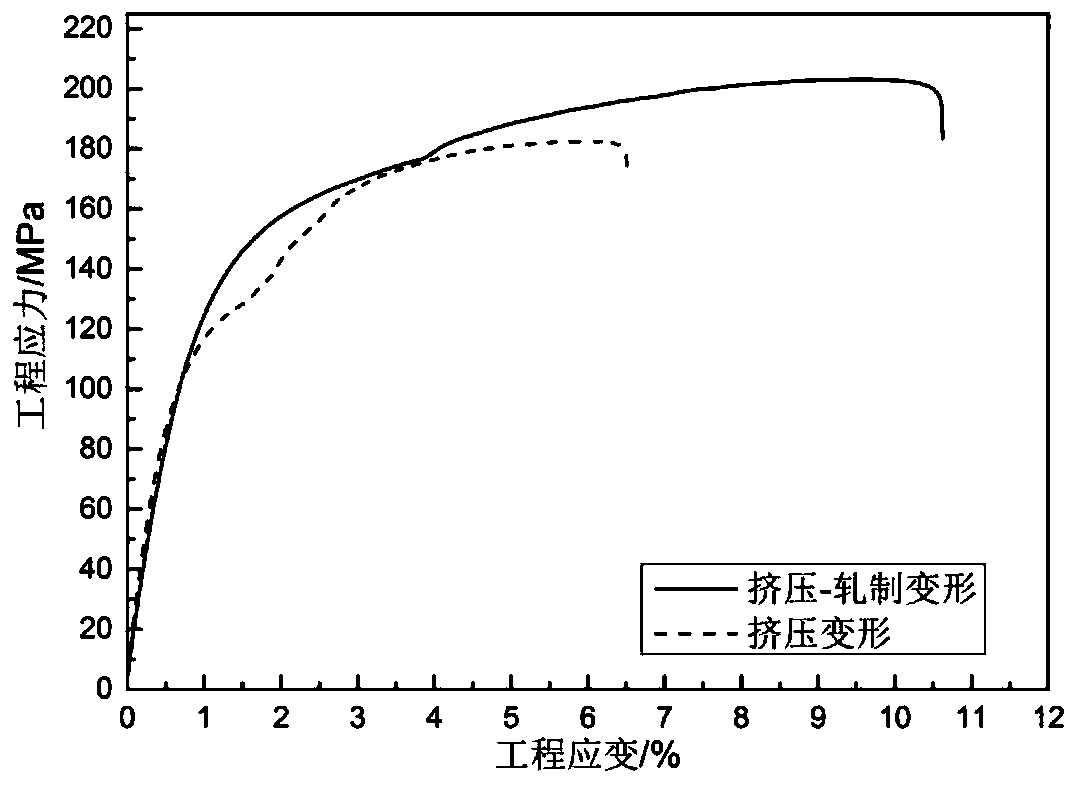

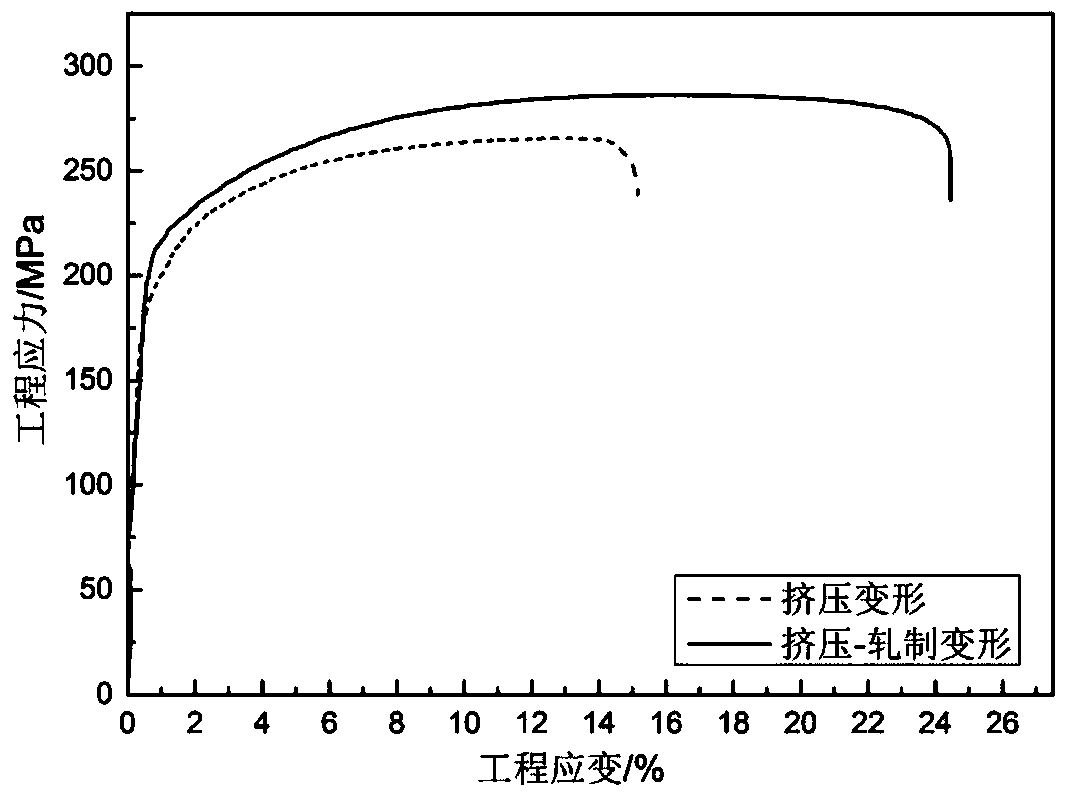

Manufacturing method of magnesium alloy bar

ActiveCN110802125AImprove mechanical propertiesReduce texture strengthRollsMetal rolling arrangementsMetallurgyRolling speed

The invention discloses a manufacturing method of a magnesium alloy bar. The manufacturing method of the magnesium alloy bar comprises the following steps that a raw blank is machined, so that the baris obtained; the bar is extruded; the bar is preheated; and the obtained magnesium alloy bar is subjected to hole pattern rolling operation, the rolling operation is conducted in sequence according to the diamond-square mode, 1-4 passes are conducted through the rolling operation, the rolling speed is 0.1m / s-0.5m / s, the bar is rotated by 90 degrees when each pass is changed in the rolling process, finally the square hole serves as the final rolling pass, the correction is conducted for one time, and therefore the final form of the bar can be guaranteed. By the adoption of the manufacturing method of the magnesium alloy bar, the anisotropy of the bar which is extruded to deform can be remarkably improved, and the toughness of the bar can be further improved.

Owner:HEBEI UNIV OF TECH

Producing method of hot-rolled alloy plate for automobile body

ActiveCN104550231AImprove performanceMeet the requirementsMetal rolling arrangementsAuto industryManufacturing technology

The invention relates to a magnesium alloy plate manufacturing technology. Based on existing mature conventional magnesium alloy which is good in comprehensive performance but cannot completely meet the plate requirement of an automobile body, a micron quasi-crystal intermediate alloy online mixed melting technology, a magnesium alloy plate cast rolling technology and a dynamic recrystallization hot rolling technology are adopted to modify the magnesium alloy and enable the performance of the magnesium alloy to be improved. By means of the producing method, the production cost can be remarkably reduced, the performance of the plate can be improved, and index can be closer to the requirement for sheet metal parts in the automobile industry.

Owner:山西银光华盛镁业股份有限公司

High-Mn Mg-Ca-Mn-Al-Zn series deforming magnesium alloy and preparing method thereof

The invention discloses a high-Mn Mg-Ca-Mn-Al-Zn series deforming magnesium alloy and a preparing method thereof, and belongs to the field of deforming magnesium alloy materials. The high-Mn Mg-Ca-Mn-Al-Zn series deforming magnesium alloy comprises, by mass percent, 0.10 to 0.40% of Ca, 0.30 to 2.50% of Al, 0.30 to 2.50% of Zn, 2.00 to 5.00 of Mn and the balance Mg and other inevitable impurities(Si, Ni, Cu and the like), and the preparing method of the magnesium alloy comprises the steps that a pure magnesium ingot casting is melted, after sufficient melting, calcium, manganese, aluminum, zinc and the like are added, after sufficient stirring, pouring is carried out to form the ingot casting, then, homogenization treatment of the ingot casting is carried out, and through a reverse extrusion process, a corresponding extrusion profile is obtained. Through a smelting, homogenization treatment and subsequent extrusion (reverse extrusion) process, the novel deforming magnesium alloy highin strength and high in plasticity can be prepared, the strength and the plasticity can be reinforced, and the good mechanical property is achieved.

Owner:NORTHEASTERN UNIV

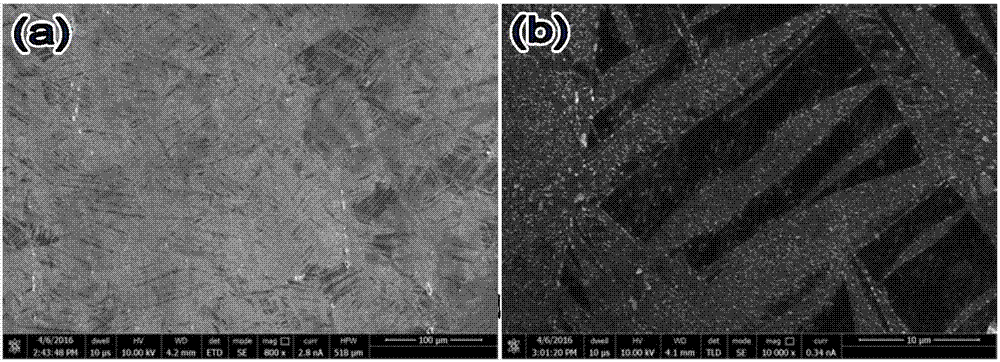

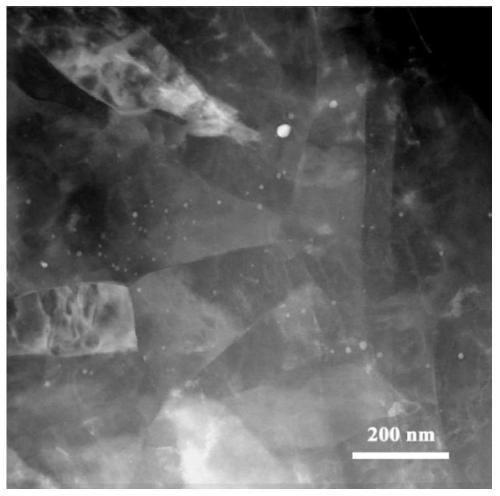

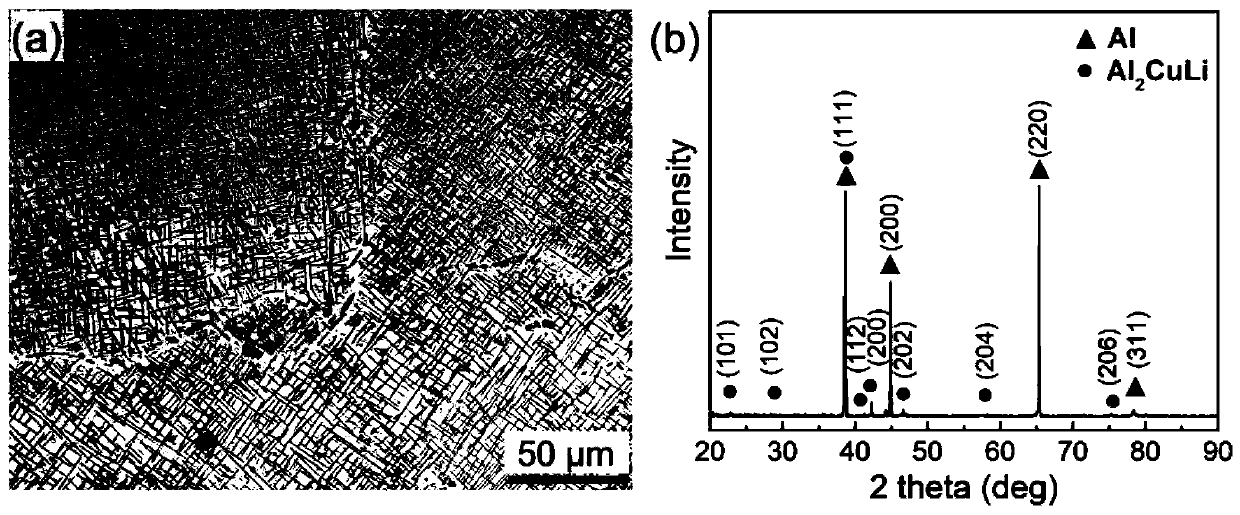

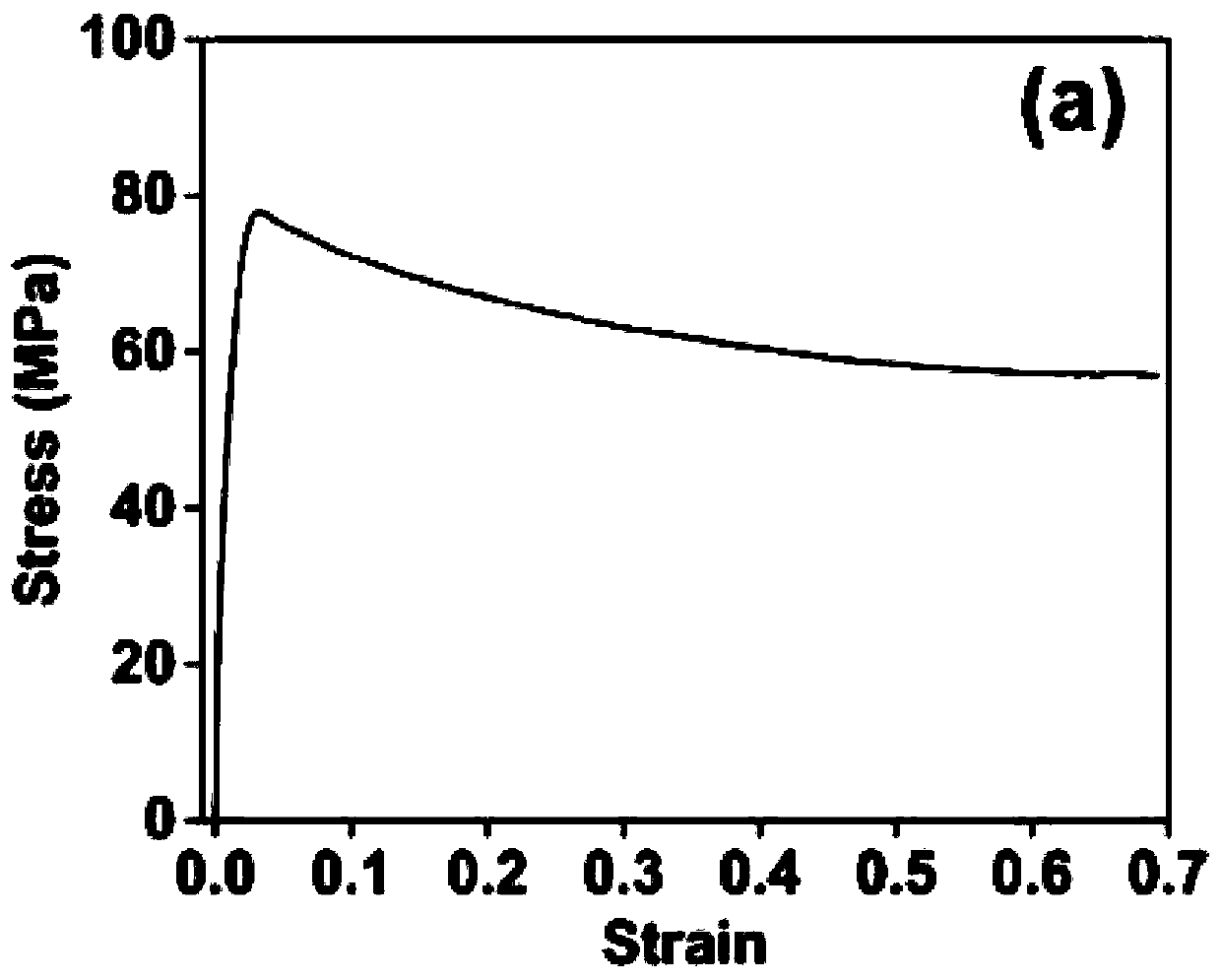

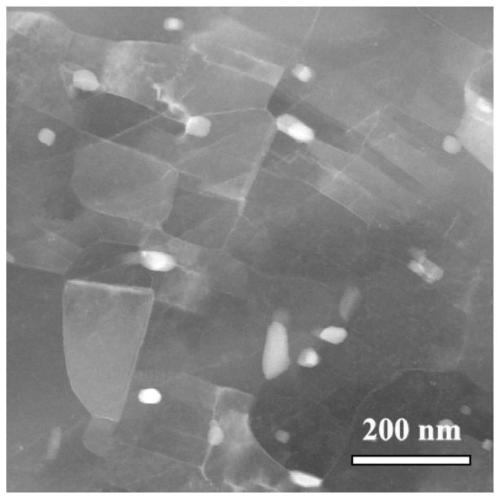

Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation

ActiveCN110541131AImprove the degree of recrystallizationFine grainMicron scaleManufacturing technology

The invention discloses an Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation, and belongs to the technical field of aerospace component manufacturing. Accordingto the process, an Al-Cu-Li alloy can be remarkably promoted to be subject to thermal deformation and recrystallization to obtain an isometric fine crystal structure. The process comprises the following steps of carrying out homogenizing annealing on an alloy ingot to obtain a uniformly-distributed micron-scale T1 phase (Al2CuLi), then performing hot-pressing deformation, and annealing at a hightemperature. According to the process, the high-stability recrystallization structure in the Al-Cu-Li alloy can be obtained controllably, the recrystallization degree is high, the fine crystal effectis obvious, the structure is stable, the alloy texture can be remarkably weakened, the alloy anisotropy is reduced, and therefore the multi-directional bearing performance and the corrosion resistanceof the alloy are improved, the comprehensive service performance of the Al-Cu-Li alloy can be greatly improved, the application range of the Al-Cu-Li alloy in aerospace components can be extended, and the competitiveness of products such as materials / components can be improved

Owner:HARBIN INST OF TECH

Method for controlling grain size of low-carbon austenitic stainless steel extra-thick plate

ActiveCN113560343AHigh strengthReduce surface scratchesTemperature control deviceWork cooling devicesThick plateSS - Stainless steel

The invention relates to a method for controlling the grain size of a low-carbon austenitic stainless steel extra-thick plate. The method comprises the following steps of that 1) a casting blank is heated, specifically, the casting blank with the thickness of 250 mm or below is fed into a stepping heating furnace for heating, after the casting blank is sequentially treated through a preheating zone, a heating zone and a soaking zone, and the casting blank is discharged out of the furnace; after high-pressure water descaling, the temperature difference between the surface of the casting blank and the center of the casting blank is controlled to be 10-15 DEG C; (3) the initial rolling temperature of rough rolling is greater than or equal to 1110 DEG C, and the surface is not descaled in the rough rolling stage; the finish rolling temperature in the rough rolling stage is greater than or equal to 1050 DEG C; after rough rolling is finished, the steel plate passes through 2-3 passes in an idle mode, and descaling water of a rolling mill is sprayed in each pass; the initial rolling temperature of finish rolling is greater than or equal to 980 DEG C, and the finish rolling temperature in the finish rolling stage is greater than or equal to 950 DEG and controlled cooling is carried out, specifically, the hot-rolled steel plate quickly passes through an ultra-fast cooling system after finish rolling. The method has the advantages that the problem that the surface grain size and the center grain size of the steel plate are inconsistent can be solved, and the grain size of the steel plate reaches level 3 or above.

Owner:ANGANG STEEL CO LTD

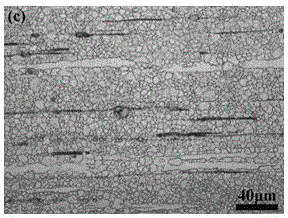

Method for improving forging properties of gamma-TiAl alloy through hydrogenation

InactiveCN104308455AReduce deformation resistanceDoes not increase densitySolid state diffusion coatingHydrogenRoom temperature

The invention discloses a method for improving forging properties of gamma-TiAl alloy through hydrogenation, relates to the method for improving the forging properties of the gamma-TiAl alloy, and aims to improve the hot forming properties of the gamma-TiAl alloy under the conditions that the density of the existing gamma-TiAl alloy is not increased, the creep resistance is not reduced, and the room-temperature ductility is not reduced. The method comprises the following steps: firstly, filling hydrogen to a gamma-TiAl alloy green body; secondly, spraying a high-temperature antioxidant on the surface of the hydrogenated gamma-TiAl alloy billet and preheating; thirdly, forging the hydrogenated gamma-TiAl alloy billet at high temperature, and performing heat insulation to obtain a hydrogenated gamma-TiAl alloy forged piece; fourthly, dehydrogenating the hydrogenated gamma-TiAl alloy forged piece. The method disclosed by the invention is used for improving the forging properties of the gamma-TiAl alloy.

Owner:HARBIN INST OF TECH

Wrought magnesium alloy containing neodymium samarium light rare earth elements and high Mn content and preparation method thereof

InactiveCN111485153AFacilitates the dynamic recrystallization processGuaranteed strength and toughnessRare-earth elementAluminium

The invention discloses a wrought magnesium alloy containing neodymium samarium light rare earth elements and high Mn content and a preparation method of the wrought magnesium alloy, and belongs to the field of wrought magnesium alloy materials. The wrought magnesium alloy comprises the following components of, in percentage by mass, 0.30% to 1.90% of calcium, 0.30% to 1.50% of aluminum; 0.20% to1.70% of zinc; 0.30% to 2.80% of manganese; 0.30% to 3.00% of light rare earth (samarium or neodymium), and the balance of magnesium and inevitable impurities (Si, Ni, Cu and the like); and the preparation method of the magnesium alloy comprises the following steps that a pure magnesium cast ingot is melt firstly, after fully melting is carried out, metal calcium, manganese, light rare earth (samarium or neodymium) and the like are added, after fully stirring is carried out, casting into a cast ingot is carried out, then homogenization treatment on the cast ingot is carried out, and extrudingthrough a backward extrusion process is carried out to obtain a corresponding extruded profile. According to the wrought magnesium alloy containing neodymium samarium light rare earth elements and high Mn content and the preparation method of the wrought magnesium alloy, the novel wrought magnesium alloy with high strength and high plasticity is prepared through smelting, homogenization treatmentand subsequent extrusion (backward extrusion) processes, the strength and toughness of the novel wrought magnesium alloy are enhanced, and the novel wrought magnesium alloy has good mechanical properties.

Owner:NORTHEASTERN UNIV

Ultrahigh-plasticity rare earth wrought magnesium alloy and preparation method of extruded plate thereof

ActiveCN114293079AEasy to startReduce the anisotropy of mechanical propertiesMetal-working apparatusPlastic propertyMagnesium alloy

The invention provides an ultrahigh-plasticity rare earth wrought magnesium alloy and a preparation method of an extruded plate of the ultrahigh-plasticity rare earth wrought magnesium alloy, and belongs to the technical field of magnesium alloy materials and molding.The ultrahigh-plasticity rare earth wrought magnesium alloy comprises, by mass, 0-4% of Gd, 0-4% of Er, 0.1-0.6% of Zr, the balance Mg and 1-4% of total rare earth, the ultrahigh-plasticity rare earth magnesium alloy is prepared by upsetting an ultrahigh-plasticity rare earth magnesium alloy material and carrying out asymmetric extrusion by using an extrusion die. The method has the two advantages that 1, in the aspect of the forming process, a die is used for upsetting, it is guaranteed that different areas of the extruded plate are fully deformed, grains are further refined, and non-uniform extrusion can greatly weaken the defect of a strong base surface texture of the extruded plate under a traditional deformation process; and 2, in the aspect of material design, the ultrahigh-plasticity magnesium alloy plate is obtained through the action of activating a non-crystal face slippage system by rare earth elements, and the percentage elongation after fracture of the plate is larger than or equal to 35%. The wrought magnesium alloy plate disclosed by the invention has the characteristics of ultrahigh plasticity and weak texture at room temperature, can be subjected to large-strain room-temperature forming and processing, and has a wide application prospect.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Method for simultaneously improving low-carbon low-alloy steel strength and plasticity

ActiveCN113322365AReduce replyImprove acceleration performanceProcess efficiency improvementTemperingMetallic materials

The invention relates to a method for simultaneously improving low-carbon low-alloy steel strength and plasticity, and belongs to the technical field of metal materials. According to the method, low-carbon low-alloy steel with both high strength and high plasticity is acquired by subjecting quenched-state low-alloy steel which contains Mo as well as one or more of V, Nb and Ti to tempering treatment, dynamic large deformation and annealing treatment in sequence. Crystalline grains can be further refined through carbides precipitated out of the tempered-state low-carbon low-alloy steel which contains the strong carbide forming elements in the dynamic large deformation process; and in the follow-up annealing process, a large number of fine dispersed carbides are precipitated out, so that the improvement of the steel plasticity can be facilitated when a remarkable second-phase strengthening effect is provided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com