High-strength deformation magnesium alloy containing rare earth samarium, and preparation method thereof

A technology for deforming magnesium alloys and magnesium alloys, which is applied in the field of metal materials and can solve problems such as poor mechanical properties and excessive rare earth content in magnesium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

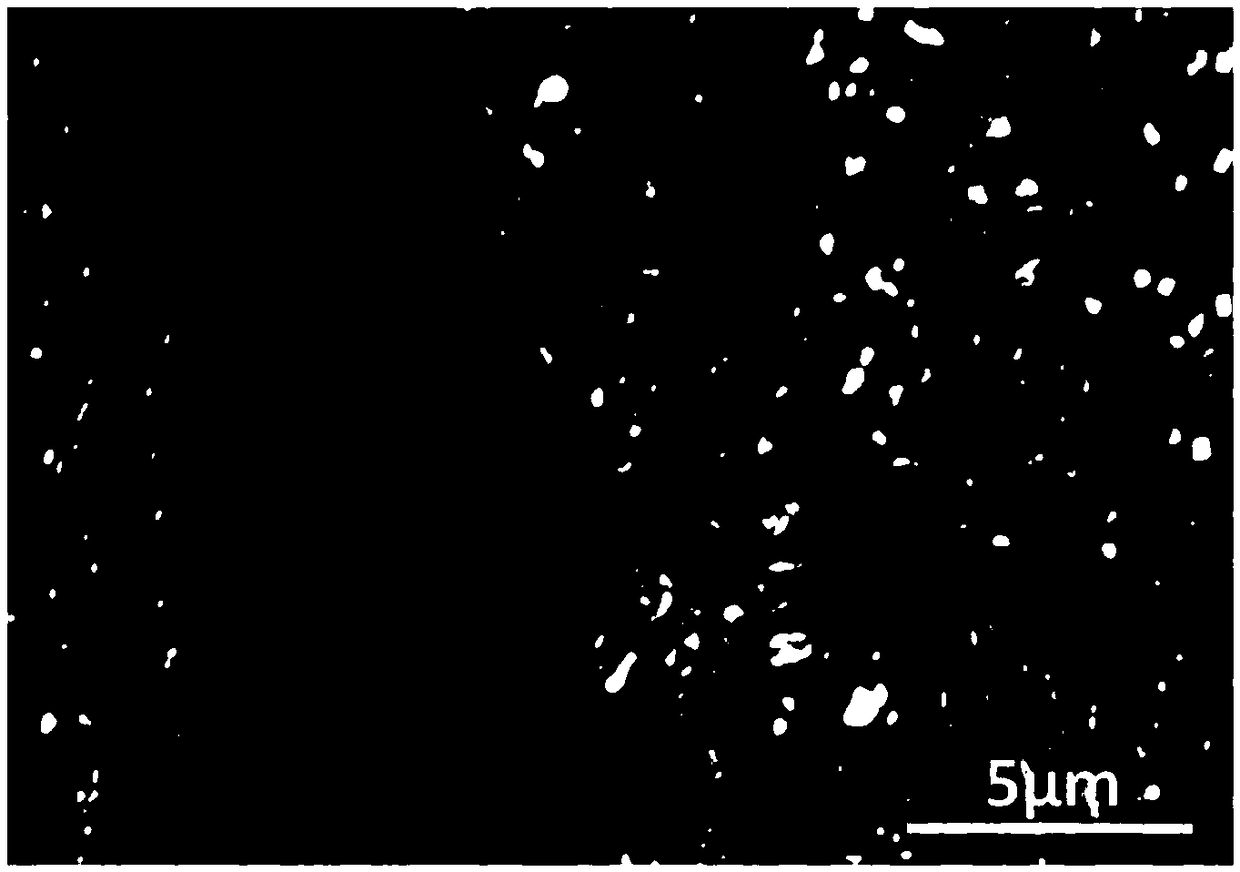

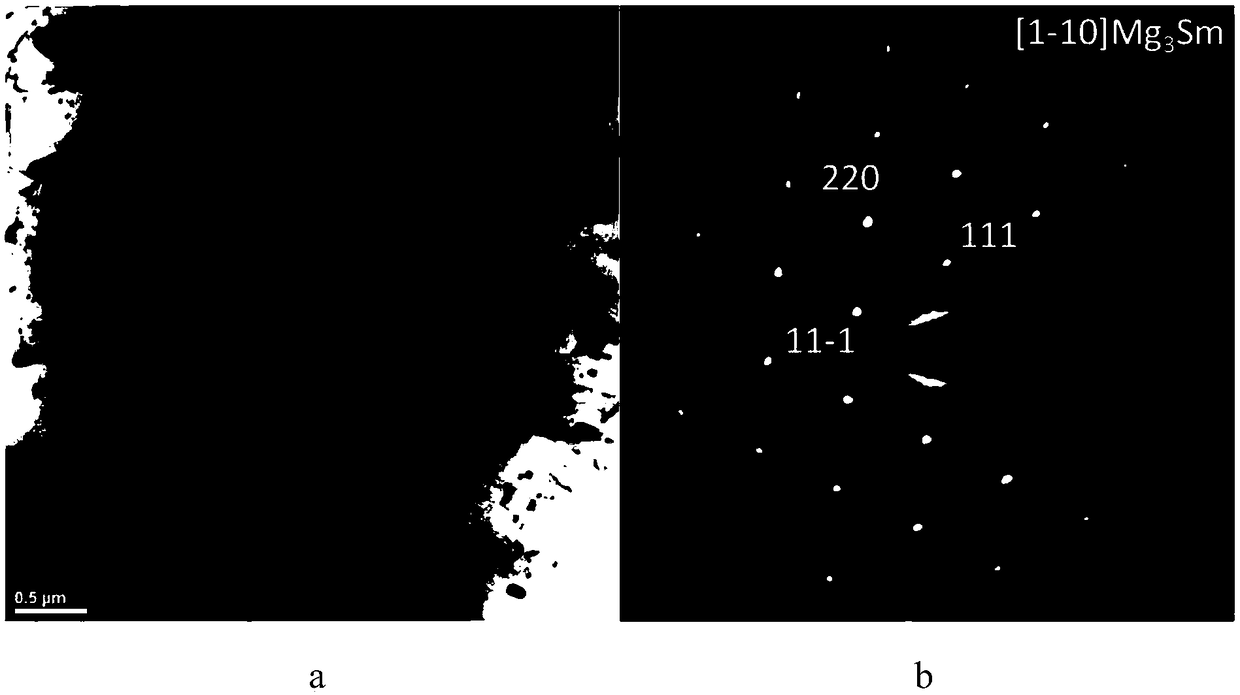

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of high-strength wrought magnesium alloy containing rare earth samarium. The magnesium alloy uses pure Mg ingot, pure Zn ingot, Mg-Zr master alloy and Mg-Sm master alloy as raw materials for smelting and casting, homogenization treatment, heating Prepared by extrusion and aging treatment, including the following steps:

[0036] (1) Preparation of magnesium alloy ingots: mixing pure Mg ingots, pure Zn ingots, raw materials of Zr elements, and raw materials of Sm elements, and casting them into magnesium alloy ingots;

[0037] (2) Preparation of extrusion billet: homogenize the above-mentioned magnesium alloy ingot at 500-530° C. for 6-14 hours, and process it into an extrusion billet;

[0038] (3) Preparation of extrusion profiles: preheat the above-mentioned extrusion billet and extrusion die in a resistance furnace at 300-400°C for 1.5-3.5h, and preheat the extruder at 300-400°C for 1-2h, and the extrusion ratio ...

Embodiment 1

[0049] The high-strength wrought magnesium alloy of this embodiment is composed of the following components by mass percentage: 3.5% Sm, 0.6% Zn, 0.5% Zr, and the balance is Mg and unavoidable impurities.

[0050] The preparation of the high-strength wrought magnesium alloy of this embodiment comprises the following steps:

[0051] (1) Preparation of magnesium alloy ingot: pure Mg ingot, pure Zn ingot, Mg-Zr (Zr is 20wt.%) master alloy, Mg-Sm (Sm is 25wt.%) master alloy batching according to the above-mentioned mass percentage, then Drying is carried out, the drying temperature is 280°C, and the drying time is 1.5h.

[0052] During the preparation process, the melt has been in CO 2 and SF 6 Under the protection of mixed gas, CO 2 with SF 6 The ratio is 99:1, put the dried pure Mg ingot into the crucible and heat up with the furnace until it is completely melted, and the temperature is controlled at 730°C to obtain a magnesium melt;

[0053] Add the dried Mg-Sm master allo...

Embodiment 2

[0063] The difference between Example 2 and Example 1 is that the extrusion billet and extrusion die are preheated in a resistance furnace at 380°C for 2 hours, the extruder is preheated at 380°C for 2 hours, the extrusion ratio is 20:1, and the extrusion speed 1.0m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com