Patents

Literature

72results about How to "Hinder dislocation movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-plasticity and low-anisotropism deformed magnesium alloy plate and preparation method thereof

ActiveCN108796327AImprove mechanical propertiesEasy rolling deformationAnisotropic deformationMetallic materials

The invention relates to the technical field of light metal materials, in particular to a high-plasticity and low-anisotropism deformed magnesium alloy plate and a preparation method thereof. The high-plasticity and low-anisotropism deformed magnesium alloy plate is composed of the following components of, by mass, 3.0-5.0% of Al, 0.3-0.6% of Mn, 0.1-0.9% of Y, 0.1-0.8% of Ca, 0.1-0.5% of Zn, andthe balance Mg and unavoidable impurities, wherein the content of the impurities is smaller than or equal to 0.3%. The prepared magnesium alloy plate has the high plasticity and low anisotropism at the room temperature, the basal texture strength is obviously weakened, and the comprehensive mechanical property is good.

Owner:ZHENGZHOU UNIV

Corrosion-resistant welding rod and its preparing method

InactiveCN101148008AWill not cause short supplyAvoid corrosionLiquid surface applicatorsWelding/cutting media/materialsNiobiumBoron carbide

The present invention belongs to the field of welding material technology, and is especially one kind of anticorrosive welding rod. The welding rod includes one core wire and one welding rod coating comprising tungsten carbide 2-10 wt%, boron carbide or boron nitride 2-8 wt%, nickel powder 2-10 wt%, copper 0.30-0.85 wt%, RE elements 0.2-4.60 wt%, Mn-N alloy and / or V-N alloy in any ratio 0.20-2.80 wt%, ferromolybdenum 0.6-3.2 wt%, marble 25-38 wt%, titanium white powder 2-8 wt%, fluorite 1-6 wt%, low carbon ferromanganese 3-8 wt%, ferrovanadium 0.35-4 wt%, ferroniobium or ferrotitanium 0.35-4 wt%, and low carbon ferrochrome for the rest. The welding rod has high corrosion resistance, high wear resistance, good welding performance and other advantages.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

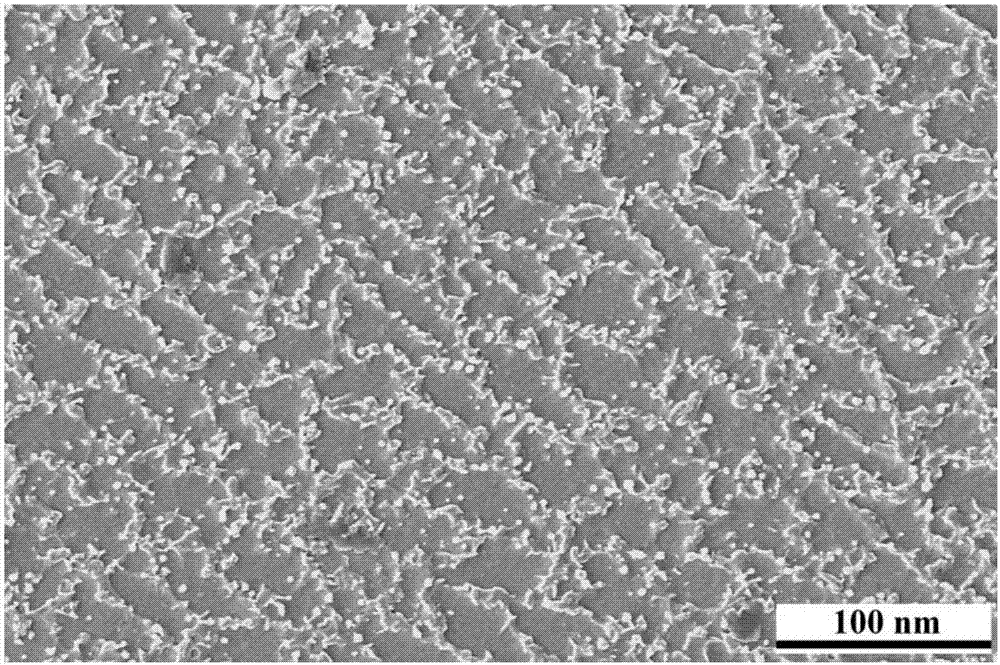

Preparation method for regenerating dental prosthetic material and acidic amino acid-induced demineralized dental enamel outer enamel prism thereof in situ

ActiveCN104000736AArranged in orderClosely arrangedImpression capsDentistry preparationsBiological activationTwo step

The invention discloses a method for regenerating a dental prosthetic material and an acidic amino acid-induced demineralized dental enamel outer enamel prism thereof in situ, and belongs to the technical field of in-situ regeneration of dental enamel outer enamel prisms. The preparation method is as follows: firstly, carrying out surface calcium activation onto a dental enamel surface, i.e., grafting calcium ions; then, forming calcium carbonate stable calcium ions step by step; finally, taking calcium carbonate stable calcium ions as foundation forms to synthesize hydroxyapatite crystals. Amino acid participates in the whole process, concentration of the amino acid added in a two-step process is consistent. The hydroxyapatite crystals deposited on the surface of the demineralized dental enamel are orderly and compact in sequence, and uniform in crystal morphology, so that obvious continued growth tendency of an artificial layer can be seen. The preparation method disclosed by the invention lowers protein extracting cost and harsh restrictions on an application environment, and is wide in prospect. The material prepared by the method disclosed by the invention can be applied to cosmetic dental for filling demineralization gaps, also can be used for repairing early-stage enamel demineralization, and can be used as a combined material for bottom pulp capping pit and fissure sealing, and the like.

Owner:JILIN UNIV

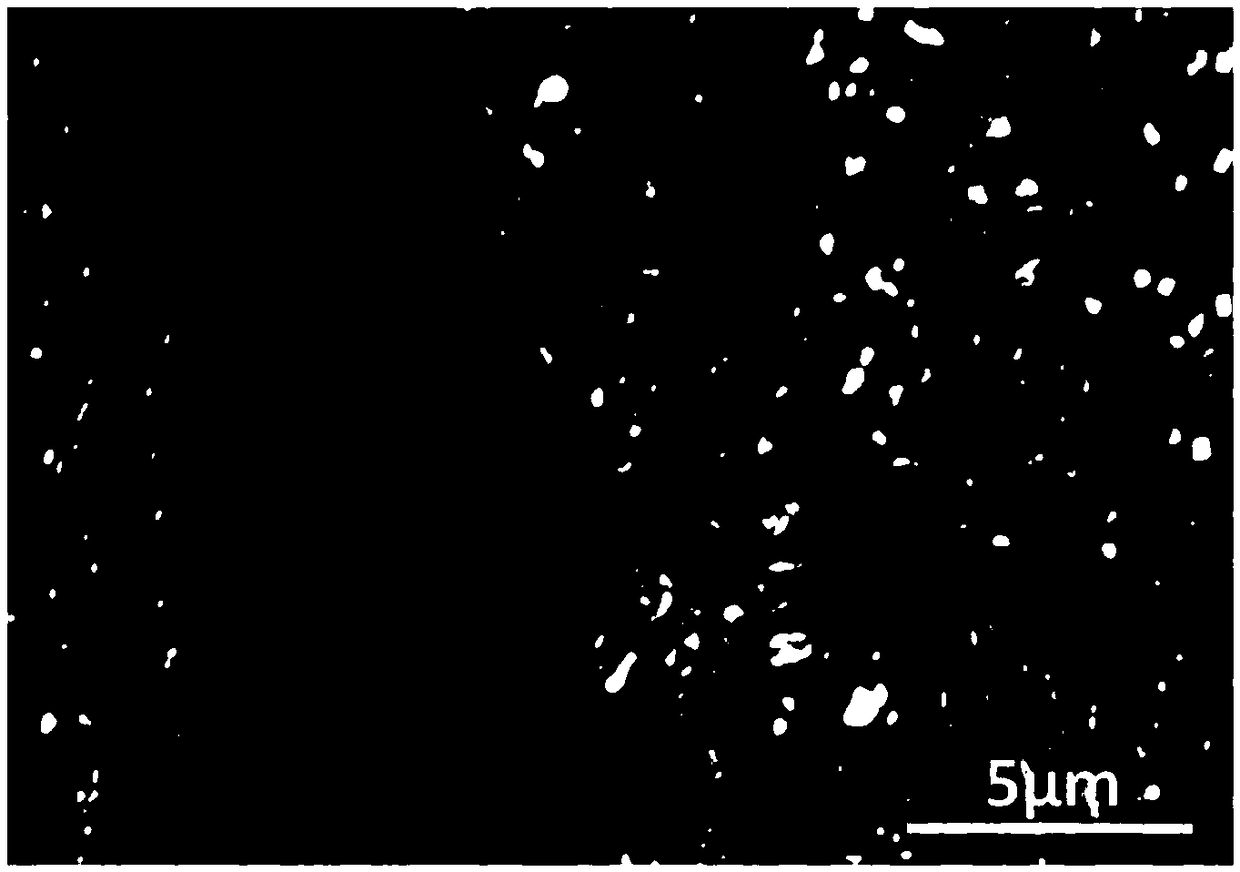

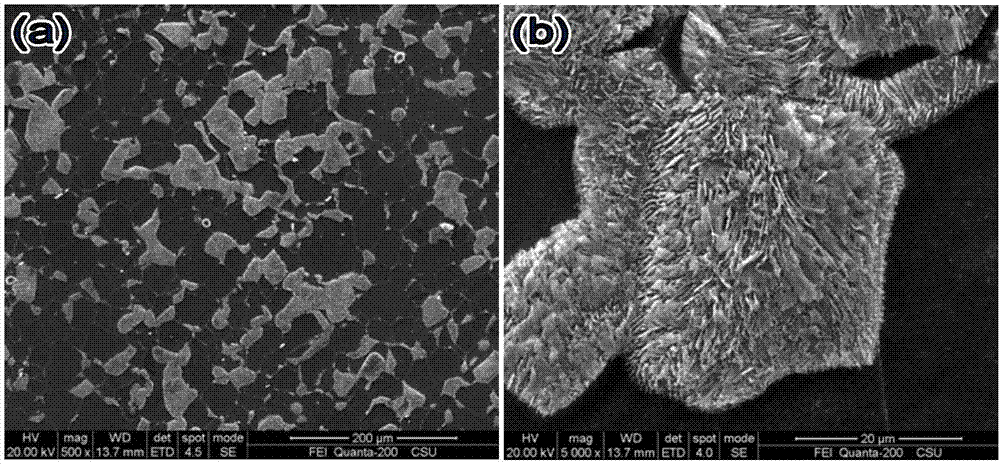

High-strength and high-toughness cast magnesium alloy and preparation method thereof

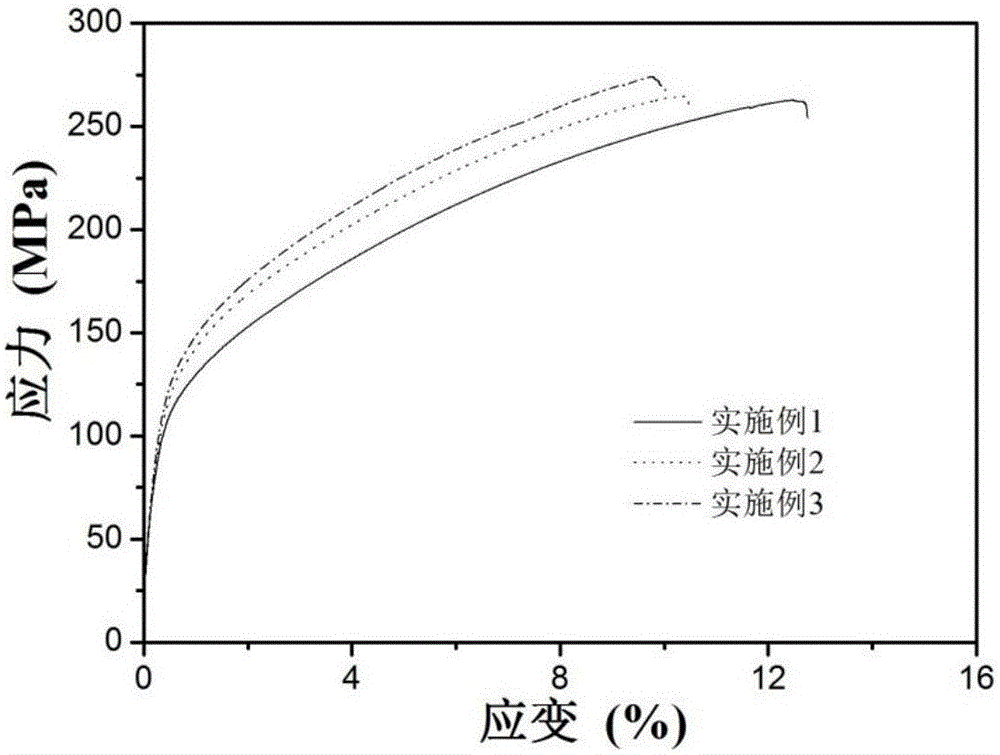

The invention discloses high-strength and high-toughness cast magnesium alloy. The high-strength and high-toughness cast magnesium alloy is Mg-Bi-Ca-Zn alloy and composed of, by weight, 3.0-8.0% of Bi, 0.1-1.2% of Ca, 0.1-2.0% of Zn and the balance Mg. According to the invention, Bi serves as the main alloy element, lots of Mg3Bi2 phases are formed through the simple alloying way, few Ca elements and Zn elements are adopted for improving the strength of the alloy, the Ca elements effectively improve the morphology and distribution of the Mg3Bi2 phases so as to improve the plasticity of the alloy, and therefore the high-strength and high-toughness cast magnesium alloy can be developed for the Mg-Bi alloy series. The cast magnesium alloy is high in strength and plasticity, the tensile strength of the alloy with the components optimized reaches about 270 MPa, the yield strength of the alloy reaches about 145 MPa, and the ductility of the alloy reaches about 10%. Thus, the strength can be as high as that of rare earth magnesium alloy, and the ductility is high.

Owner:山东汇达蠕墨装备有限公司

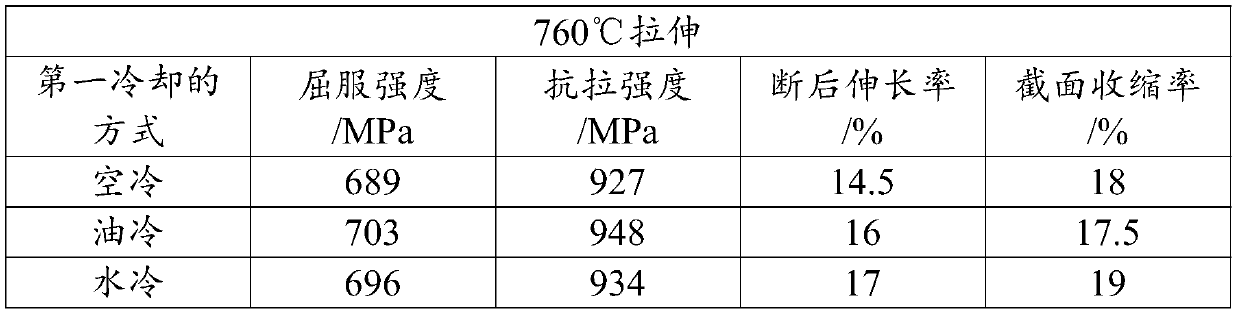

Heat treatment method of GH4780 alloy forging

ActiveCN110484841AHigh strengthImprove plasticityBlade accessoriesStatorsSmelting processUltimate tensile strength

The invention provides a heat treatment method of a GH 4780 alloy forging, and relates to the technical field of alloy manufacturing. The method comprises the following step: carrying out solution heat treatment on the GH 4780 alloy forging, wherein the temperature of the solution heat treatment is 1020-1170 DEG C. The GH 4780 alloy forging subjected to heat treatment not only can effectively eliminate the segregation of alloy elements such as Ti, Al and Cr in the smelting process and eliminate metallurgical defects such as cavities, but also can break columnar crystals and promote dynamic recrystallization, thereby refining the crystal grains and improving the strength and plasticity of the alloy forging.

Owner:BEIJING CISRI GAONA TECH +3

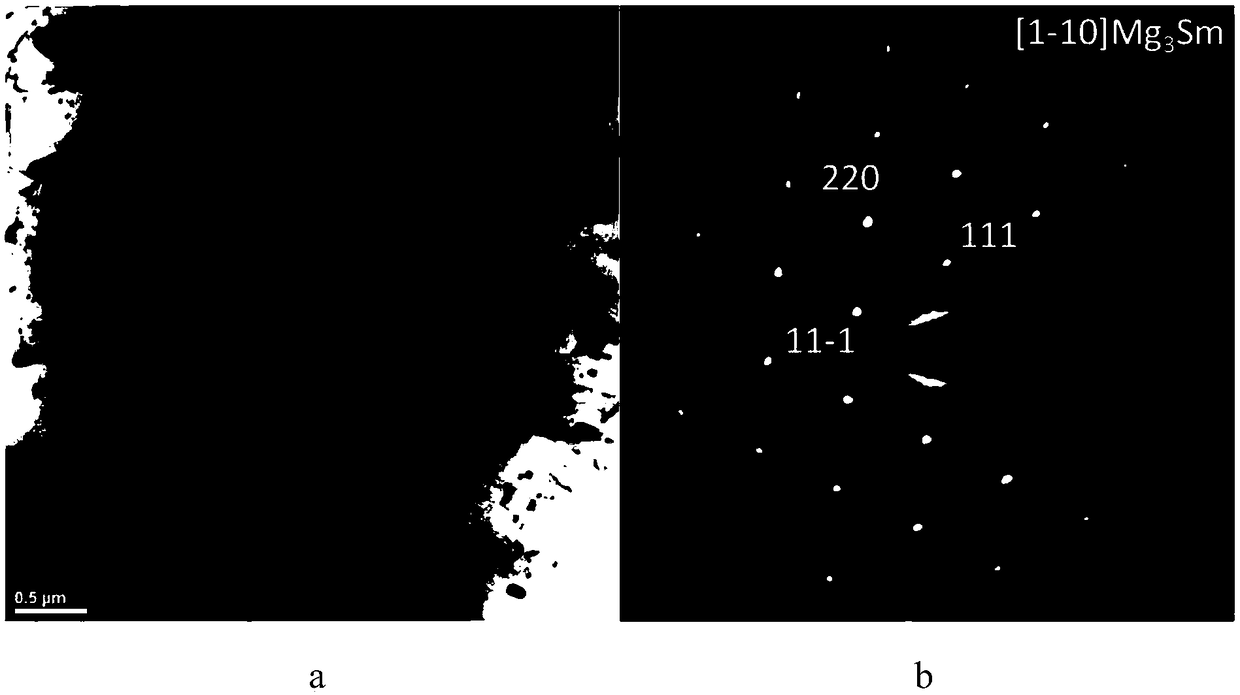

High-strength deformation magnesium alloy containing rare earth samarium, and preparation method thereof

The invention provides a high-strength deformation magnesium alloy containing rare earth samarium, and a preparation method thereof, belongs to the technical field of metal materials, and solves the problem of overhigh rare earth content and poor mechanical property of traditional magnesium alloy. The magnesium alloy disclosed by the invention is prepared from the following ingredients in parts byweight: 1.0-6.6wt% of Sm, 0.5-3.5wt% of Zn, 0.15-1.5wt% of Zr and the balance of Mg. The invention also provides a preparation method for the high-strength deformation magnesium alloy containing rareearth samarium. The high-strength deformation magnesium alloy containing rare earth samarium disclosed by the invention has excellent mechanical property. Mg-3.5Sm-0.6Zn-0.5Zr is taken as an exampleto show that the indoor temperature yield strength and the tensile strength are respectively 415MPa and 423MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

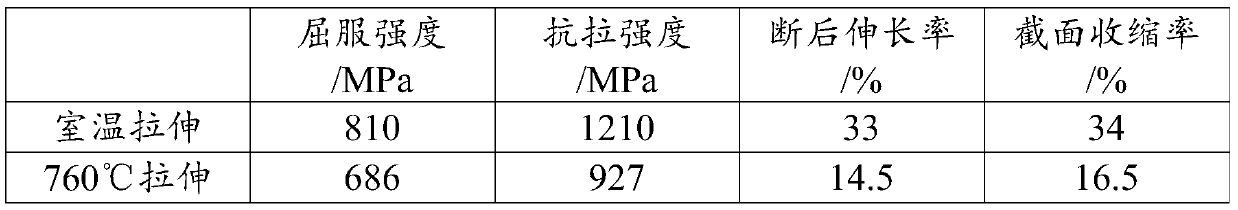

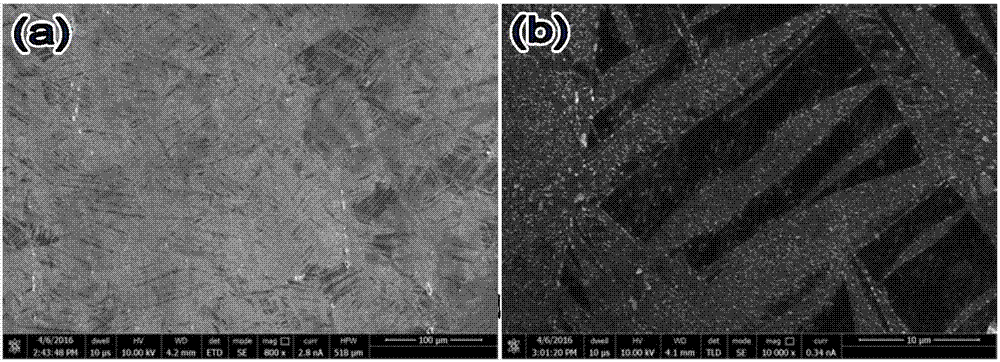

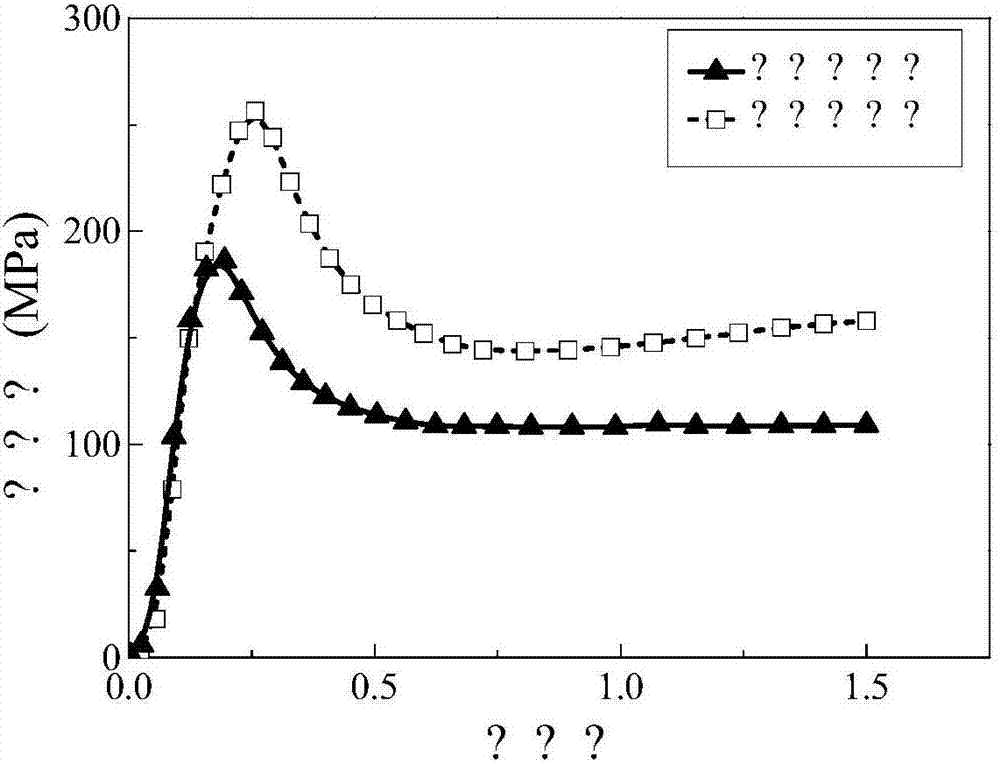

Method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance

InactiveCN107119246AImprove mechanical propertiesExcellent thermoforming propertiesCrystal twinningPre deformation

The invention provides a method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance. The method comprises the steps that Mg-Al-Zn magnesium alloy is subjected to pre-deformation treatment at 25 DEG C to 300 DEG C, twin crystal or low-angle crystal boundaries are introduced, and then aging treatment is conducted. According to the deformation heat treatment method, precipitation of a continuous precipitation phase of the Mg-Al-Zn magnesium alloy can be effectively promoted, and alloy tissue with a uniform, small and dispersively distributed precipitation phase is obtained finally; and alloy strength and plasticity are synchronously improved, and thermoforming performance and service performance of the alloy are improved. The method for improving the Mg-Al-Zn magnesium alloy thermoforming and service performance is reasonable in design, simple in equipment requirement, convenient to operate, low in cost and high in efficiency, distribution of the precipitation phase of the Mg-Al-Zn magnesium alloy is reasonably controlled, the thermoforming performance and service performance of the alloy are improved, and the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

Cu-Ni-Co-Fe-Si-Zr-Zn copper alloy material and preparation method thereof

ActiveCN110951990AEasy to spreadPromote precipitationMetal rolling arrangementsSolution treatmentUltimate tensile strength

The invention discloses a Cu-Ni-Co-Fe-Si-Zr-Zn copper alloy material and a preparation method thereof. The copper alloy material is prepared from, by weight, 2.0%-3.0% of Ni, 0.3%-0.8% of Co, 0.3%-0.8% of Fe, 0.5%-1.1% of Si, 0.1%-0.2% of Zr, 0.1% 0.3% of Zn and the balance Cu. The preparation method of the copper alloy material comprises the following steps of alloy casting, homogenization treatment, hot rolling, solid solution treatment, deep cold rolling and pulse magnetic field aging treatment. The copper alloy material has the advantages of high yield strength, high tensile strength and conductivity, high elongation at break, and good comprehensive mechanical property and conductive performance. In addition, no toxic element is contained in the composition of the copper alloy material, the sources of raw materials are rich, the preparation process does not generate toxic compounds, and the harm to human bodies and the environment is small.

Owner:FUZHOU UNIV +2

Manufacturing process for high-temperature-resistant aluminium-based composite material board

The invention discloses a manufacturing process for a high-temperature-resistant aluminium-based composite material board. The manufacturing process comprises the following steps of (1) melting industrial pure aluminium ingot in a crucible, mixing KBF4 and K2TiF6 in certain proportion, and adding a mixture into aluminium melt, performing mechanical stirring to generate TiB2 particles in situ, removing slag, adding alloy elements, and refining; (2) conducting homogenizing annealing on a refined aluminium-based composite material casting blank for 2-30 hours at a temperature of 460-520 DEG C, uniformly keeping inner and outer temperatures of the annealed aluminium-based composite material casting blank to be 360-460 DEG C, and performing hot-rolling by 3-10 passes to obtain a board; and (3)performing solid-solution treatment for 1-5 hours on the board at a temperature of 460-470 DEG C, performing water-quenching, performing ageing thermal treatment for 12-48 hours at a temperature of 120-140 DEG C, and cooling to the room temperature to obtain the final board finished product. The prepared aluminium-based composite material board has the good high-temperature mechanical property.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

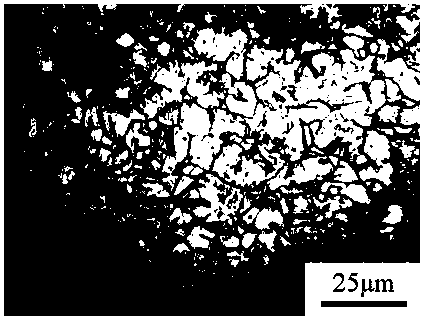

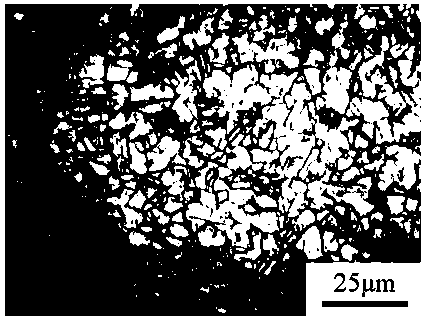

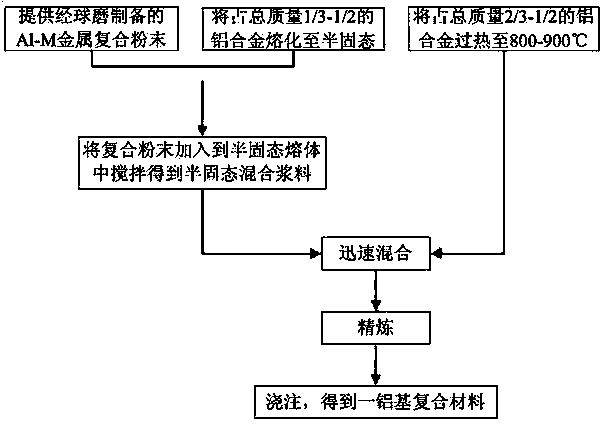

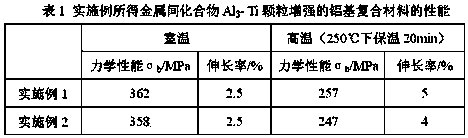

Preparation method of intermetallic compound Al3-M particle reinforced aluminum matrix composite

The invention relates to a preparation method of an intermetallic compound Al3-M particle reinforced aluminum matrix composite and belongs to the technical field of aluminum matrix composite preparation and metal smelting. The invention aims at providing the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite, and provides the intermetallic compound Al3-M particle reinforced aluminum matrix composite prepared by the method at the same time. The invention adopts the technical scheme that the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite well solves the problem of no infiltration between an intermetallic compound reinforced particle and molten metal by a stepped method of firstly increasing the magnesium concentration in aluminum melt and adding the intermetallic compound particle.

Owner:ZHONGBEI UNIV

High-strength titanium alloy and preparation method thereof

ActiveCN108913948AImprove mechanical propertiesHigh specific strengthSolution treatmentRoom temperature

The invention provides a high-strength titanium alloy and a preparation method thereof. The high-strength titanium alloy comprises, by mass, 4.5%-5.5% of Al, 3.5%-4.5% of Mo, 3.5%-4.5% of Cr, 1.5%-2.5% of Sn, 10%-50% of Zr and the balance Ti. According to the high-strength titanium alloy and the preparation method thereof, the content of all the elements is strictly controlled, and the mechanicalproperty of the titanium alloy is improved; the Cr element is added, therefore, a beta phase is stabilized, and the room-temperature strength of a titanium alloy matrix can be significantly improved;the Al element greatly improves the stability of an alpha phase and increases the beta-alpha conversion temperature, the uniform and fine alpha phase can be conveniently obtained after quenching in the solution treatment process, and the specific strength of the titanium alloy can be significantly improved; and in addition, lattice distortion can be caused due to addition of the Zr element, the defects can cause nucleation point increasing and nucleation density increasing in the nucleation process, the grain refinement effect is achieved, and then fine crystal strengthening is achieved.

Owner:YANSHAN UNIV

Rare-earth alloy and preparation method thereof

The invention provides a rare-earth alloy. Elements Mg and Si co-fine a strengthening phase Mg2Si in an ageing thermal treatment process, so that dislocation motion is effectively inhibited and the effect of strengthening a base body is achieved; Al-Ti-B and rare-earth elements are added to form a heterogeneous nucleation core with relatively low mismatching degree with an alpha-Al substrate lattice for performing grain reinforcement on the aluminum alloy, and impurities in the aluminum alloy are purified; elements Cr and Mn are added to inhibit growth advantages in single direction of a needle-like Fe phase, so that the needle-like Fe phase changed into a Chinese character shaped or granular Fe-containing phase; elements Sr and Ca are introduced to introduce eutectic silicon to form high-density twin crystal, so that optimization of the morphology of eutectic silicon is realized. Elements mutually act, so that a base phase alpha-Al, eutectic silicon and a Fe phase of the alloy have excellent microscopic morphology, and thus, the purposes of strengthening the alloy, refining the crystal grains and optimizing the structure morphology are achieved, and a rate of elongation of the alloy is remarkably increased.

Owner:BAODING CITY LIZHONG WHEEL MFG

High-strength wrought aluminum alloy containing rare earth samarium and preparation method thereof

The invention provides a high-strength wrought aluminum alloy containing rare earth samarium and a preparation method of the high-strength wrought aluminum alloy, and belongs to the technical field ofmetal materials. The problem that an existing aluminum alloy is poor in mechanical property is solved. The aluminum alloy is prepared from the following chemical components of, in percentage by mass,1.5wt.% - 2.5wt.% of Mg, 0.5wt.% - 1.5wt.% of Si, 0.2wt.% - 1.2wt.% of Cu, 0.1wt.% - 0.5wt.% of Sm and the balance Al. The high-strength wrought aluminum alloy containing the rare earth samarium hasexcellent mechanical properties, and by taking Al-2Mg-Si-0.9Cu-0.5Sm as an example, the room-temperature yield strength and the tensile strength of the Al-2Mg-Si-0.9Cu-0.5Sm is 315MPa and 423MPa respectively.

Owner:SHANDONG NANSHAN ALUMINUM

Low-density high-strength magnesium lithium alloy and preparing method thereof

The invention provides a low-density high-strength magnesium-lithium alloy and a preparation method thereof. The components and mass percentages of the magnesium-lithium alloy are: 11-15% Li, 0.5-4% Al, 0.05-0.5% Zr, 0.2~1.2%La, 0.1~0.6%Ce, the total amount of impurity elements Fe, Ni, Cu, Si≤0.2%, and the balance is Mg. The preparation method of the magnesium-lithium alloy involved in the present invention includes vacuum induction melting and plastic deformation treatment. The magnesium-lithium alloy processed by means of alloying, crystal grain refinement and deformation treatment in the present invention has high strength and plasticity under the premise of ensuring low density, and at the same time has excellent machining performance.

Owner:江苏立美航材科技有限公司

Novel non-rare earth cast magnesium alloy and preparation method thereof

ActiveCN105154733AImprove mechanical propertiesImprove performanceRare earthUltimate tensile strength

The invention provides a novel non-rare earth cast magnesium alloy. The alloy is an Mg-Bi-Zr-Zn alloy and comprises the following components by weight percent: 0.5-8wt% of Bi, 0.35-1.0wt% of Zr, 0.1-2.0wt% of Zn and the balance of Mg. The novel non-rare earth cast magnesium alloy has the beneficial effects that the obvious grain refinement effect of the element Zr in an Mg-Bi alloy series is found on the basis of Mg-Bi, thus improving the strength and plasticity of the alloy; the strength of the alloy is improved in an auxiliary manner by using a small quantity of the element zinc, thus developing the high-strength cast magnesium alloy from the alloy series; the yield strength is 140-155MPa; the tensile strength is 245-285MPa; and the elongation is about 6.5%.

Owner:HEBEI UNIV OF TECH

High-performance arc spraying Zn-Al powder core wire and preparation method thereof

InactiveCN102839344AImprove mechanical propertiesHinder dislocation movementMolten spray coatingOceanic climateCorrosion

The invention discloses a high-performance arc spraying Zn-Al powder core wire and a preparation method thereof, belonging to the technical field of metal surface protection. The wire is mainly composed of an outer cladding and a powder core, wherein the outer cladding is a Zn-Al alloy strip; the powder core is mainly composed of the following components in percentage by weight: 60-70% of nano Al2O3 powder, 10-20% of nano TiO2 powder and the balance of nano Y2O3 powder; and the nano powder core accounts for 5-20% of the total weight of the wire. The novel Zn-Al nano powder core wire can be prepared into a Zn-Al nano composite coating through an arc spraying method; and the ocean climate corrosion resistance and the hardness of the coating are far higher than those of the common arc spraying Zn-Al coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dual-phase in-situ nano-enhanced ti-based composite material and preparing method thereof

ActiveCN108004426AImprove organizationHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesManufacturing technology

The invention discloses a dual-phase in-situ nano-enhanced ti-based composite material and a preparing method thereof. The preparing method is based on titanium / aluminum and titanium / silicon in-situ reaction characteristics, a laser selective fusion manufacturing technology is used, through the high energy laser beam high temperature inducing effect, titanium / aluminum and titanium / silicon chemicalaction is promoted, and in-situ reaction of Ti3Al and Ti5Si3 nano-enhanced phases is achieved; through technological condition optimization, the flow characteristic of the microcell molten bath nano-enhanced phases is regulated and controlled, homodisperse of the nano-enhanced phases in a titanium alloy base is promoted, and the Ti3Al and Ti5Si3 dual-phase nano ceramic in-situ scattered reinforced titanium matrix composite material is further obtained. According to the preparation method, the process method is simple, the cost is low, the good ceramic / titanium alloy metallurgical bonding interface is better formed, and the wettability of the ceramic / titanium alloy interface is obviously strengthened; and meanwhile, the dual nano-enhanced phases evenly dispersed into the titanium alloy base can effectively improve the comprehensive performance of the ti-based composite material.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

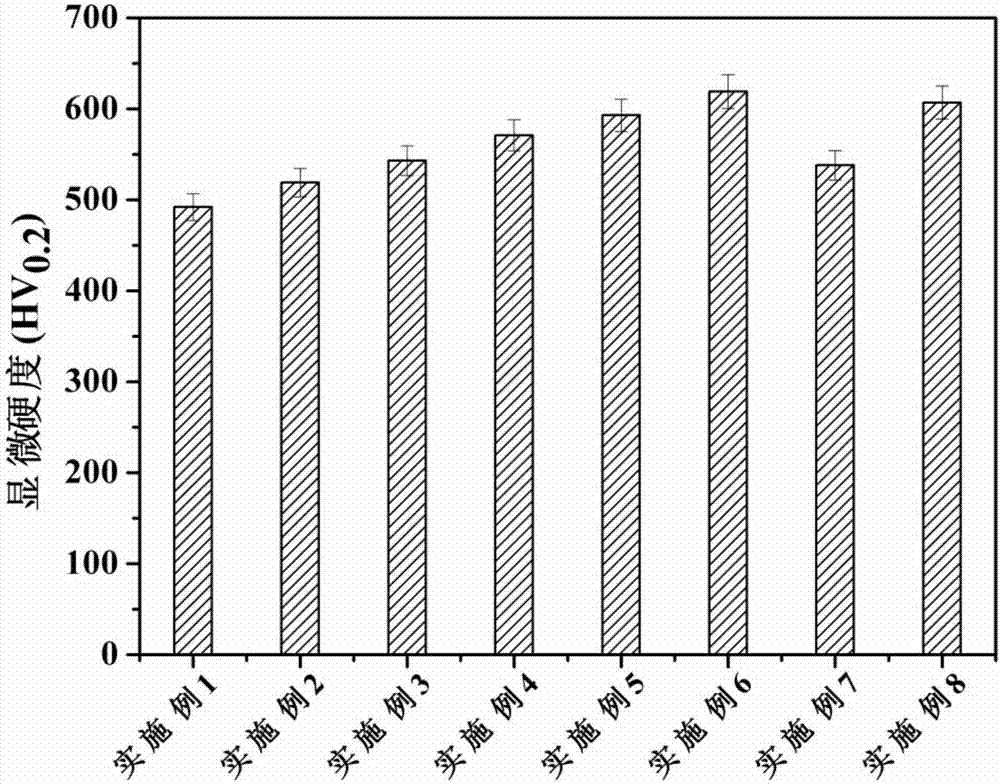

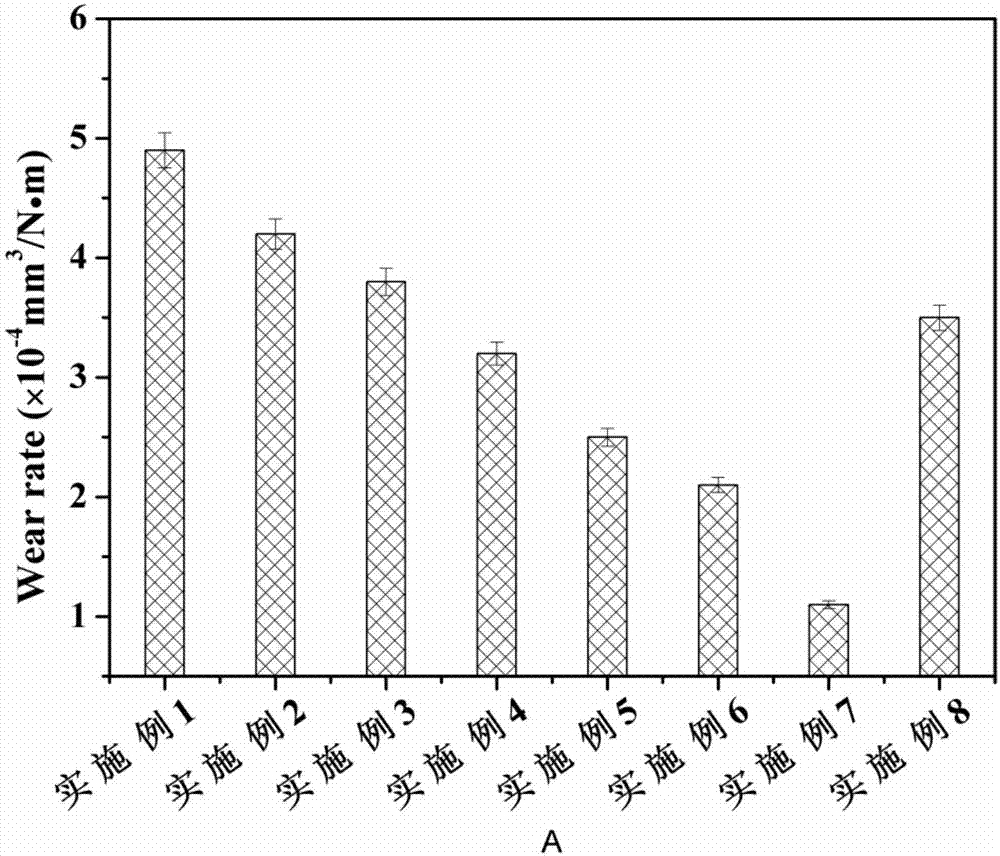

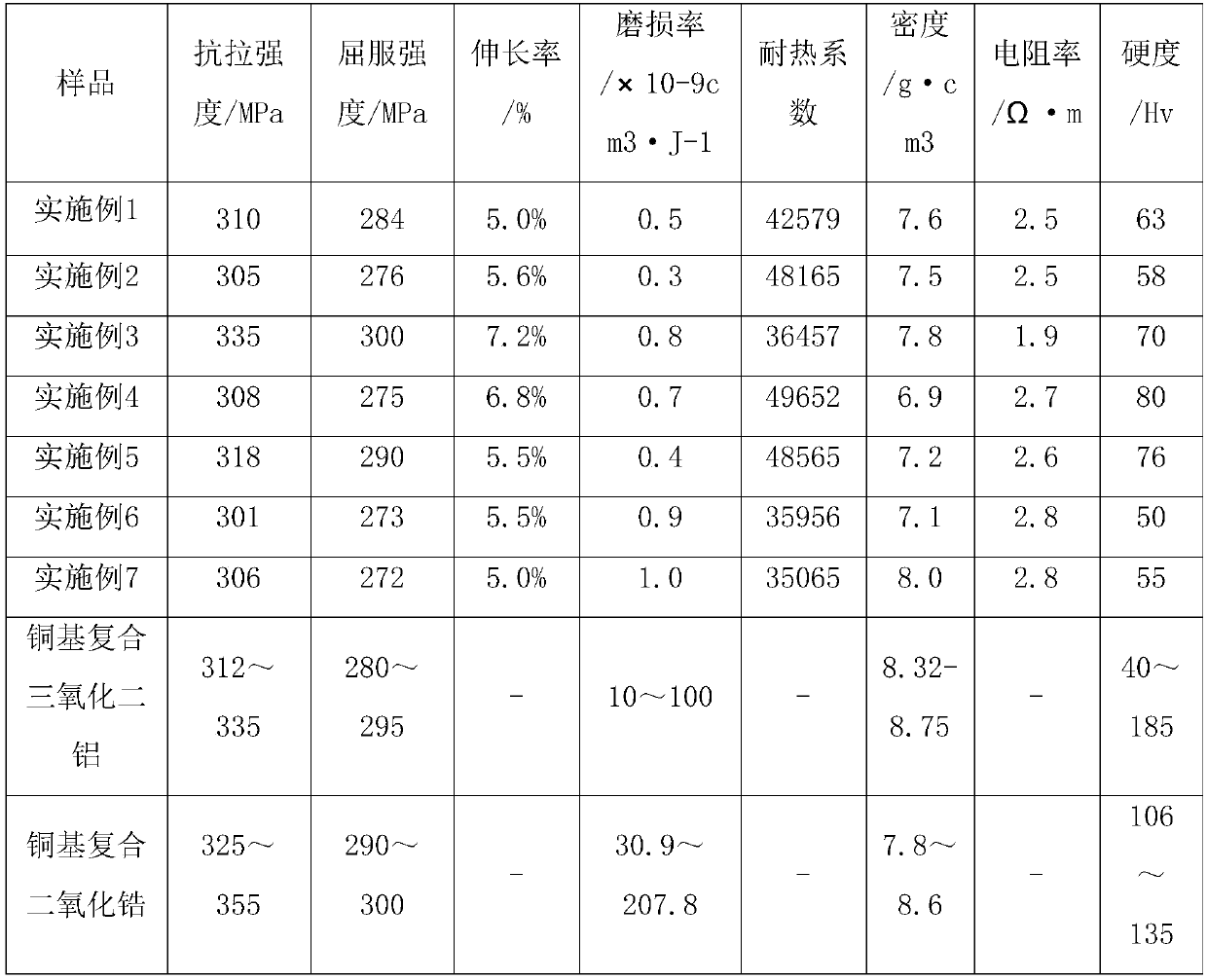

Copper-based aerogel enhanced copper alloy and preparation method thereof

InactiveCN109593987ATensile mechanical properties are equivalent toImprove thermal conductivityWear resistantMetallic materials

The invention discloses a copper-based aerogel enhanced copper alloy and a preparation method thereof, and belongs to the technical field of metal materials and preparation thereof. The copper-based aerogel reinforced copper alloy comprises, by mass, 0.5%-10% of zinc, 2%-8% of silicon dioxide and the balance copper. The preparation method comprises the following steps of burdening, ball milling, material mixing, cold pressing forming, pressure sintering and finished products. According to the copper-based aerogel enhanced copper alloy, the tensile strength of the prepared copper-based composite material is higher than 300 MPa, the yield strength is equivalent to that of a common copper-based aluminum oxide composite material, the wear rate is lower than 1*10<-9>cm<3>.J<-1>, the heat resistance coefficient is higher than 35000, and the heat resistance and the wear resistance can be better than those of the copper-based aluminum oxide composite material, so that the wear-resistant part made of the material can meet the requirements of long-term normal operation of products or equipment under the condition of high temperature.

Owner:BEIJING HONGWEINAJIN SCIENTIFIC & TECHNOLOGICAL CO LTD

Preparation method of high-temperature-softening-resistant, high-strength and high-conductivity copper-based composite material molded part

ActiveCN114293051AEvenly distributedRaise the high temperature softening temperatureMaterial nanotechnologyTungsten/molybdenum carbideCarbonizationMolybdenum carbide

The invention relates to the field of powder metallurgy, in particular to a preparation method of a high-temperature-softening-resistant high-strength high-conductivity copper-based composite material molded part, which comprises the steps of precursor powder preparation, nano molybdenum carbide-copper composite powder preparation, green body forming and combined densification. Nano molybdenum carbide particle reinforced copper-based composite powder is prepared through a co-precipitation-co-reduction-selective carbonization process, a composite material blank is prepared through a cold isostatic pressing forming process, and a copper-based composite material forming part with high strength, high conductivity, high wear resistance and high softening temperature is obtained after high-temperature sintering and deformation machining combined densification. The nanoscale molybdenum carbide particles in the copper-based composite material are stable at high temperature, can hinder dislocation movement at room temperature and high temperature, are remarkable in dispersion strengthening effect, have small influences on the electric conduction and heat conduction performance of the material and are excellent in comprehensive performance, and the copper-based composite material has important application prospects in the fields of heat dissipation grooves, electric resistance welding electrodes, nuclear reactor high-temperature-resistant high-heat-conduction components and the like.

Owner:北京科大京都高新技术有限公司

Method for increasing copper tensile strength

The invention provides a method for increasing copper tensile strength. The method comprises the step of performing torsion and plastic deformation on copper. According to the method disclosed by the invention, the copper is performed with the torsion and plastic deformation, so that the copper tensile strength can be increased by forming high-density nanoscale laminated dislocation interface structures in a graded distribution manner inside the copper; in addition, the shear rate, the deformation temperature and the deformation amount of the torsion treatment can be limited, the spaces among the laminated dislocation interfaces can be further fined, and the copper tensile strength can be increased.

Owner:SOUTHWEST UNIVERSITY

Aluminum alloy mixed powder, and method and product for improving density of aluminum alloy product

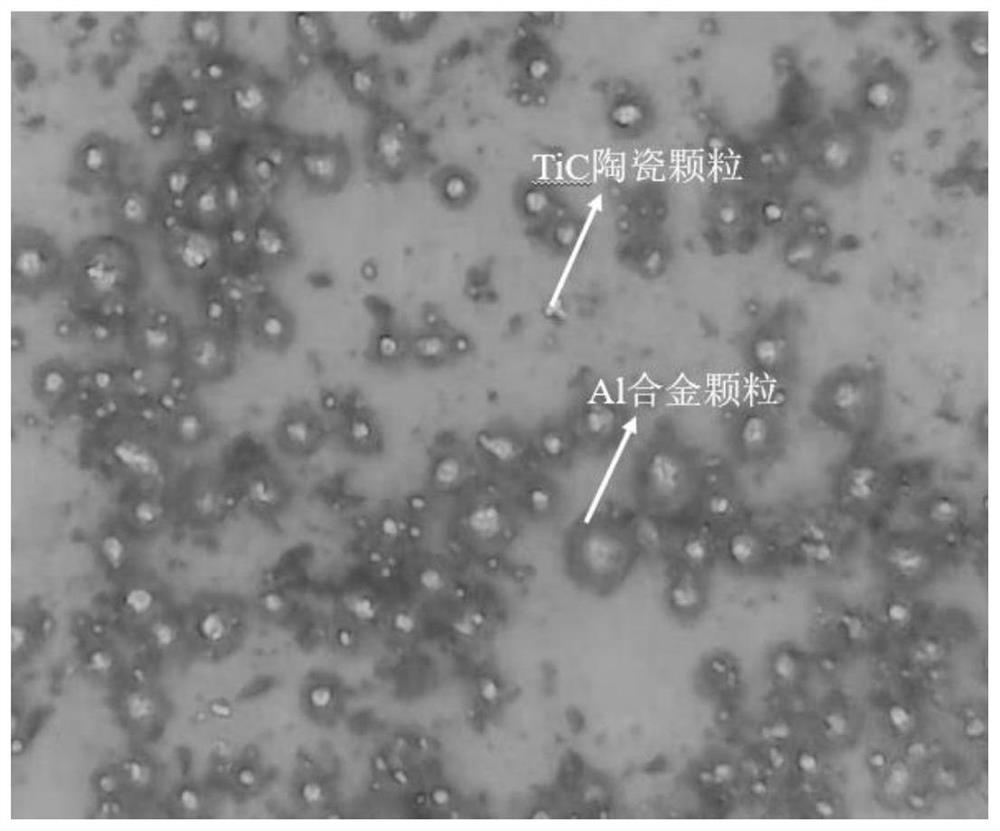

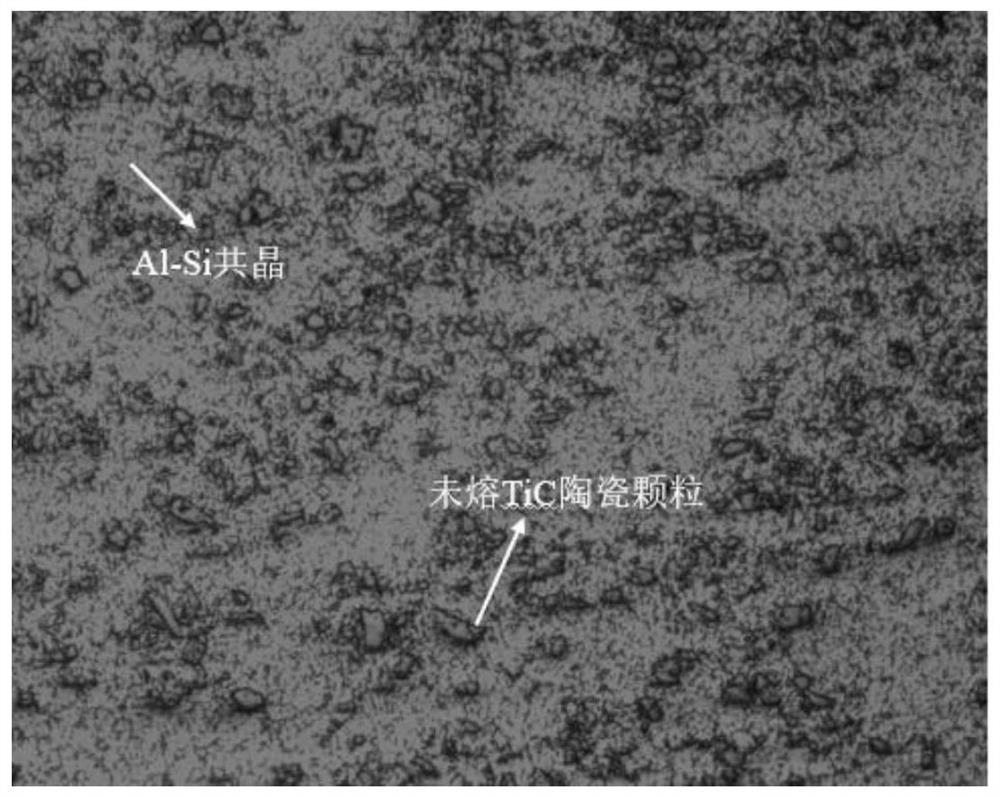

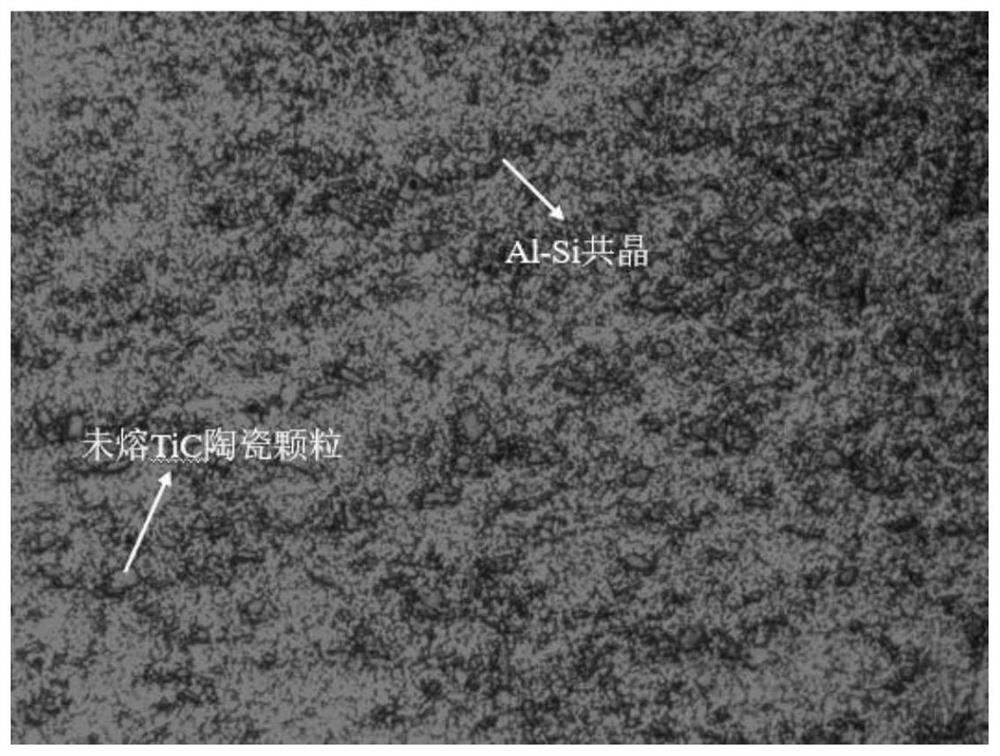

PendingCN112708805AHigh strengthImprove mechanical propertiesAdditive manufacturing apparatusCarbideLaser additive manufacturing

The invention belongs to the related technical field of laser additive manufacturing, and discloses aluminum alloy mixed powder, and a method and product for improving the density of an aluminum alloy product. The mixed powder comprises aluminum alloy powder and transition element carbide ceramic powder, wherein the aluminum alloy powder serves as matrix powder, and the mass fraction of the transition element carbide ceramic powder in the mixed powder does not exceed 10%. The mixed powder is used for laser additive manufacturing; when the mixed powder is molten by laser, the aluminum alloy powder and the transition element carbide ceramic powder are metallurgically bonded, and due to the difference of melting points, the aluminum alloy powder is molten while the transition element carbide ceramic powder is not molten; and thus, the transition element carbide ceramic powder forms similar pinning in the aluminum alloy powder, and strengthening of the aluminum alloy matrix powder is achieved. By means of the mixed powder, the mechanical property of the aluminum alloy product is improved, pores are reduced, and the density is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for preparing Al-Mg3Sb2 composite coating on surface of magnesium alloy

InactiveCN105908118ASimple methodSuitable for mass productionMolten spray coatingAl powderHeat stability

The invention discloses a method for preparing an Al-Mg3Sb2 composite coating on the surface of magnesium alloy. After being mixed, Mg powder and Sb powder are ball-milled in a ball milling machine, so that Mg chemically reacts with Sb to form an Mg3Sb2 intermetallic compound, Mg3Sb2 powder and granulated Al powder are thermally sprayed to the surface of a magnesium alloy workpiece subjected to sandblasting treatment, and the Al-Mg3Sb2 composite coating is obtained; after the Al-Mg3Sb2 composite coating is heated, the coating is hot-pressed on a press machine. The Mg powder and the Sb powder have a solid-phase reaction in the ball milling process to generate the Mg3Sb2 intermetallic compound, Mg3Sb2 melting point is high, heat stability is good, dislocation movement can be effectively hindered, a substrate and a grain boundary are remarkably reinforced, and high-temperature mechanical properties and creep resistance of the workpiece are improved. Pores and layered structures in the thermally sprayed Al-Mg3Sb2 composite coating disappear in the hot press process because the composite coating plastically deforms and is compacted, compactness of the coating is remarkably improved, and the high-temperature mechanical properties and creep resistance are given full play to.

Owner:HUBEI UNIV OF TECH

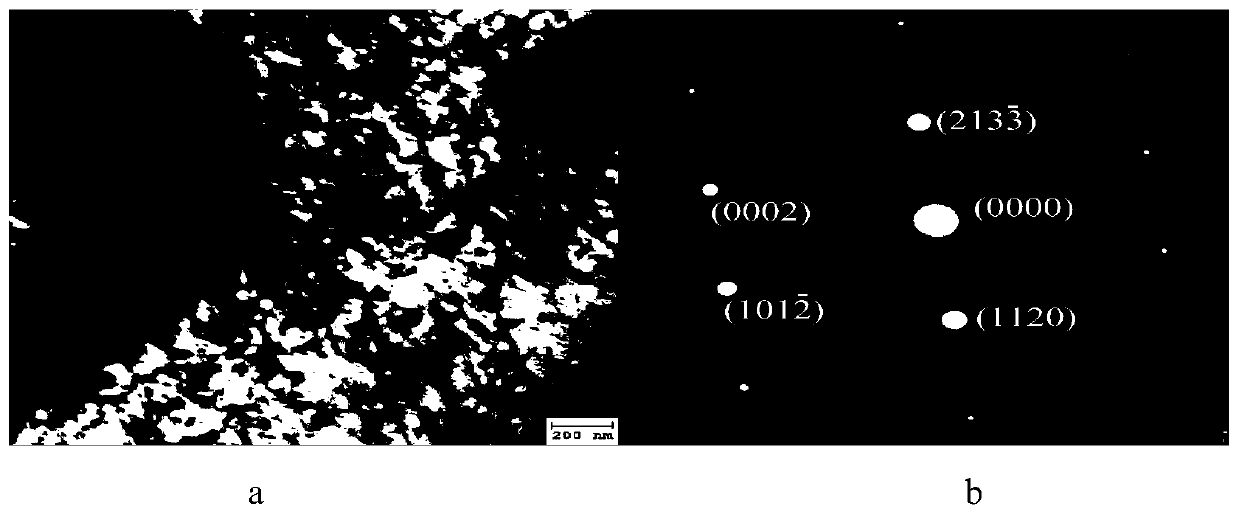

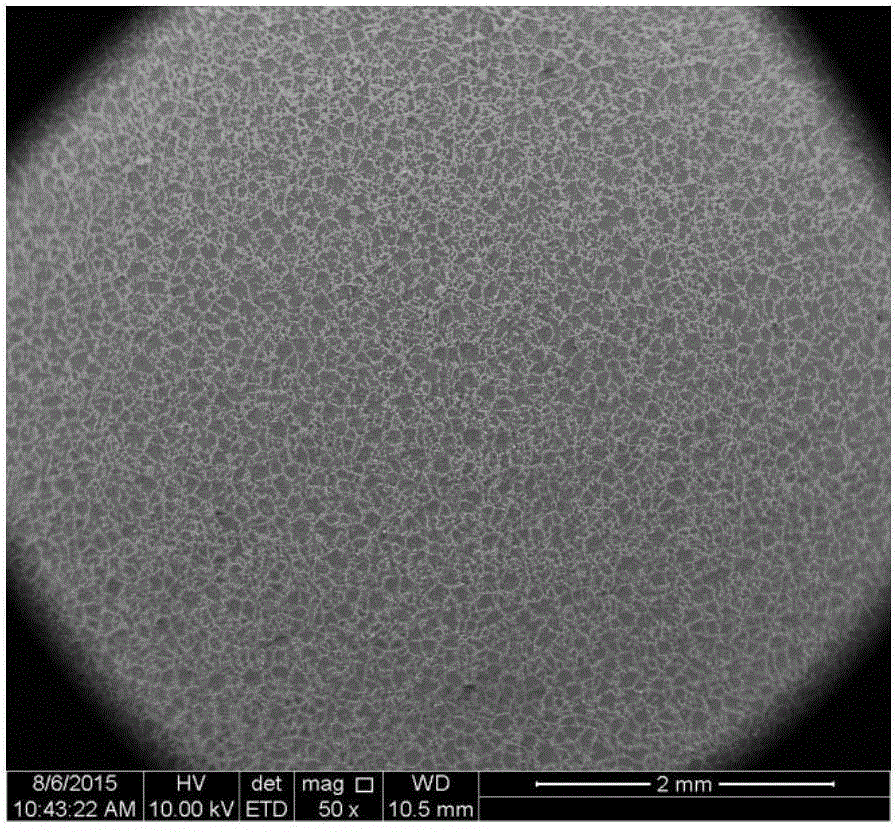

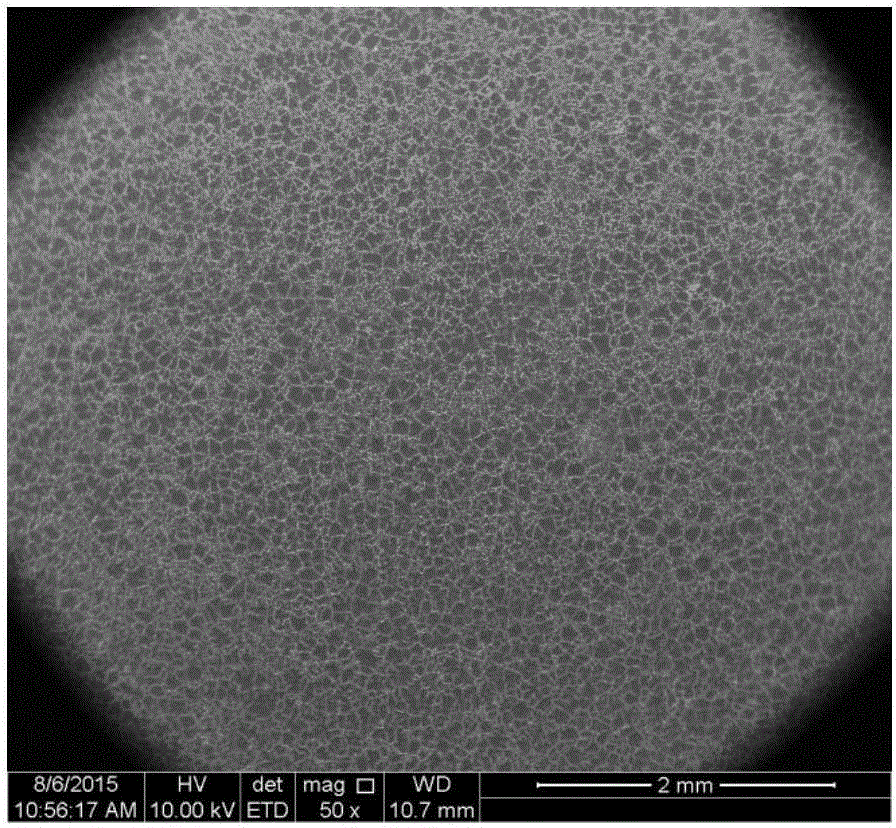

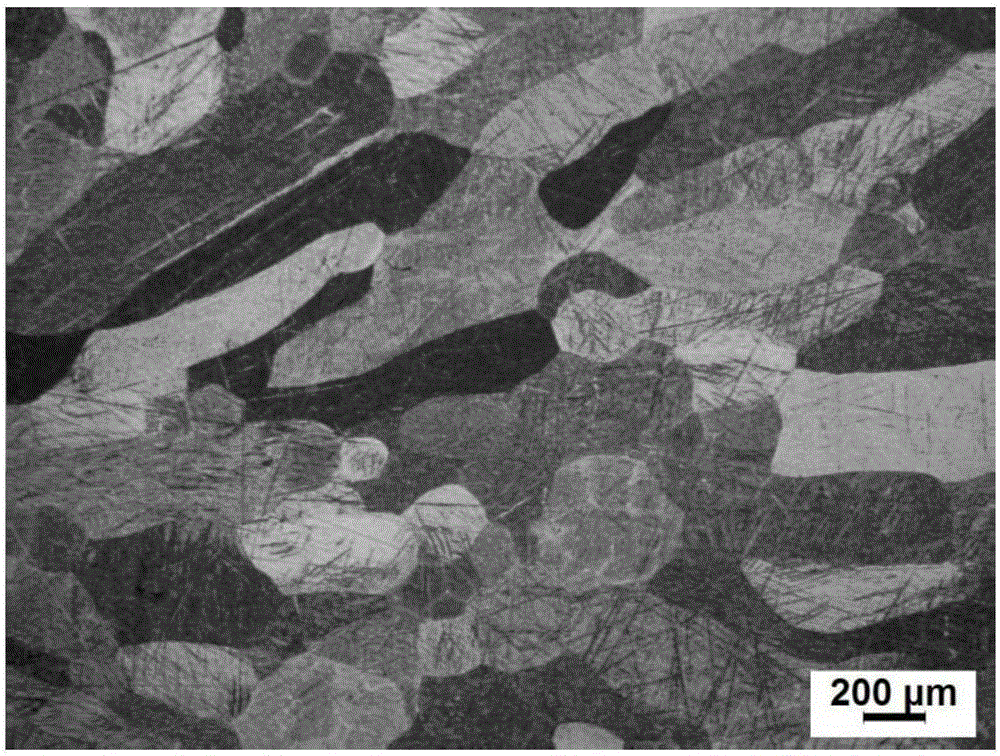

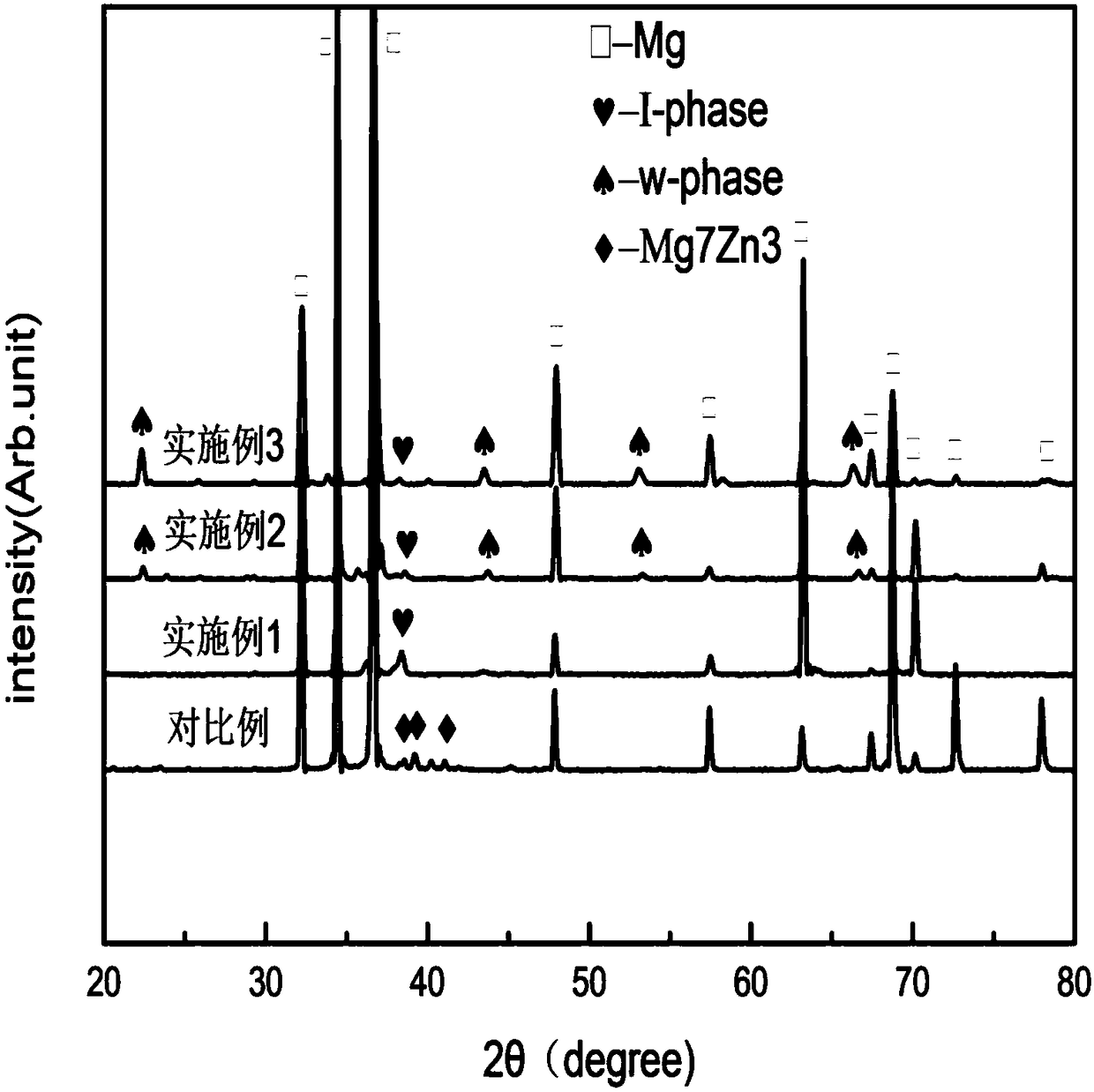

Magnesium-zinc-manganese-gadolinium magnesium alloy with high strength and high plasticity as well as preparation method thereof

The invention relates to a magnesium-zinc-manganese-gadolinium magnesium alloy with high strength and high plasticity as well as a preparation method thereof, and belongs to the technical field of production of magnesium alloys. The magnesium alloy is prepared from the following components in percentage by mass: 5.0 percent to 7.0 percent of Zn, 0.5 percent to 1.5 percent of Mn, 1.0 percent to 8.0percent of Gd, less than or equal to 0.15 percent of inevitable impurities and the balance of magnesium. The magnesium alloy has the advantages of higher strength and higher plasticity; the tensile strength of the magnesium alloy is 316MPa to 373MPa, the yield strength is 234MPa to 333MPa, and an elongation ratio is 11.8 percent to 18 percent. The magnesium alloy is formed through smelting processing and plastic processing; a preparation process is simple, and smelting is carried out by adopting a conventional cast ingot preparation means; and therefore, the magnesium alloy has an industrialuse valve, limitations of a complicated preparation process and harsh preparation conditions of a high-performance magnesium alloy are removed, and the high-performance magnesium alloy can be directlyproduced under existing industrial conditions.

Owner:CHONGQING UNIV

High-strength cast magnesium alloy and preparation method thereof

ActiveCN105112751AGood aging precipitation strengthening effectImprove mechanical propertiesUltimate tensile strengthAluminium element

The invention relates to a high-strength cast magnesium alloy. The high-strength cast magnesium alloy is an Mg-Bi-Al-Zn-Sr alloy and comprises components in percentage by weight as follows: 3wt%-8.0wt% of Bi, 0.5wt%-4.0wt% of Al, 0.1wt%-1.0wt% of Zn, 0.05wt%-0.15wt% of Sr and the balance of Mg. The Bi element is used as a main alloy element, a large quantity of Mg3Bi2 phases are formed through simple alloying means, a small quantity of aluminum and zinc elements are used for improving the strength of the alloy, so that the high-strength cast magnesium alloy is developed from the alloy series, and the alloy has the tensile strength of 276-296 MPa, the yield strength of 155-170 MPa and the elongation of 5.3%-7.3% and has mechanical properties comparable with those of rear earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

High-strength anti-fatigue aluminum alloy and preparation method thereof

The invention discloses a high-strength anti-fatigue aluminum alloy and a preparation method thereof. The alloy is prepared from, by mass percent, 3.6%-4.1% of Cu, 0.6%-1.1% of Mg, 0.57%-0.69% of Mn,0.35%-0.72% of Ti+La, 0.15%-0.31% of Ni, 0.41%-0.53% of Fe, 0.11%-0.27% of Si, 0.04%-0.13% of Zr, 0.12%-0.26% of Ce, 0.1%-0.18% of W, 0.12%-0.19% of Y, 0.32%-0.46% of Ge, 0.03%-0.12% of Sn, 0.16%-0.29% of Pr+Nd+Er, 0.05%-0.09% of V and the balance Al. The preparation of the aluminum alloy is simple in process, and the obtained aluminum alloy is high in strength, good in toughness and excellent inheat stability and fatigue resistance.

Owner:黄山市龙跃铜业有限公司

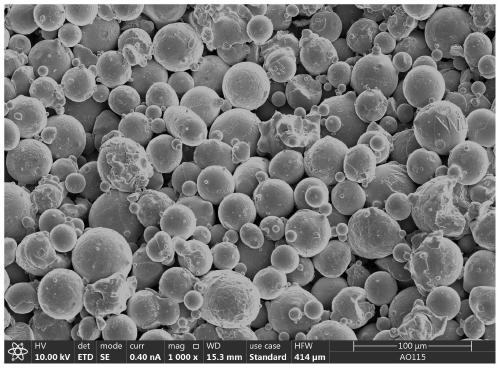

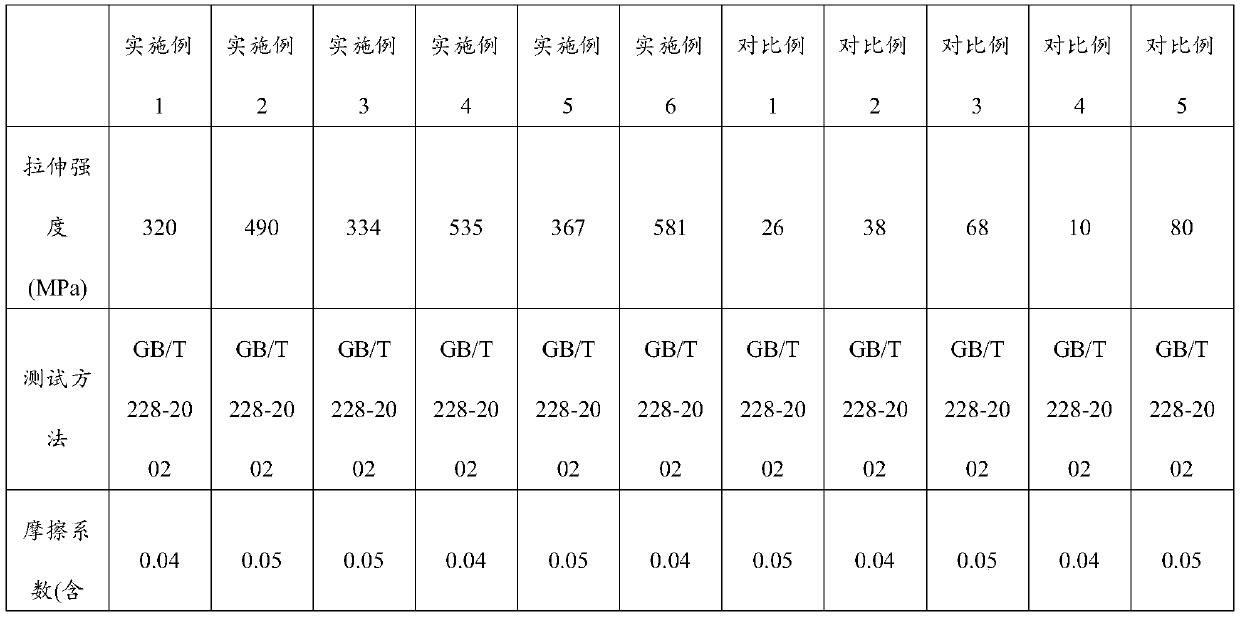

Porous high-entropy alloy material and preparation method and application thereof

ActiveCN111085685AHigh tensile strengthHigh porosityTransportation and packagingMetal-working apparatusHigh entropy alloysRolling-element bearing

The invention provides a porous high-entropy alloy material and a preparation method and application thereof, and belongs to the technical field of high-entropy alloy preparation. The provided preparation method comprises the following steps that AlCoCrAgNi high-entropy alloy spherical powder is provided, and the particle size of the AlCoCrAgNi high-entropy alloy spherical powder is 25-380 microns; and the AlCoCrAgNi high-entropy alloy spherical powder is sequentially subjected to pre-pressing treatment and sintering to obtain the porous high-entropy alloy material. The prepared porous high-entropy alloy material has the advantages of being high in tensile strength, high in porosity, low in friction coefficient, and good in matching performance between the expansion coefficient and a bearing; and meanwhile, the prepared porous high-entropy alloy material, as a bearing retainer, can be used for a heavy machinery rolling bearing, and solve the problems that in the prior art, an oil bearing retainer is low in bearing capacity, and poor in the matching performance between the expansion coefficient and a steel bearing.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Improved low-silver Sn-Ag-Au solder for microelectronic packaging and preparation method thereof

InactiveCN110102931AHinder dislocation movementImprove the mechanical properties at room temperatureWelding/cutting media/materialsMetal working apparatusDislocationRare-earth element

The invention discloses improved low-silver Sn-Ag-Au solder for microelectronic packaging and a preparation method thereof. The solder comprises the following components of, by mass of 0.3%-1.0% of Ag, 0.5%-1.0% of Cu, 0.05%-0.5% of Nb and 97.5%-99.07% of Sn. The solder alloy has the advantage that the Nb element is added in trace on the premise of maintaining the good anti-drop performance of thelower-silver Sn-Ag-Cu solder alloy, so that dislocation movement is hindered, the normal temperature mechanical property of the solder is improved, and the creep resistance is greatly improved; an Zrelement is added, so that the synergistic effect of the Zr element and the Nb element can be achieved, further dispersed distribution of the Nb is promoted, meanwhile, the alloy structure is refined,and the strength and the hardness of the solder are improved; and the liquidity of liquid solder can be improved by addition of a rare earth element Yb, the wettability can be improved, and the creepresistance of brazing filler metal can be improved.

Owner:SOUTH CHINA UNIV OF TECH

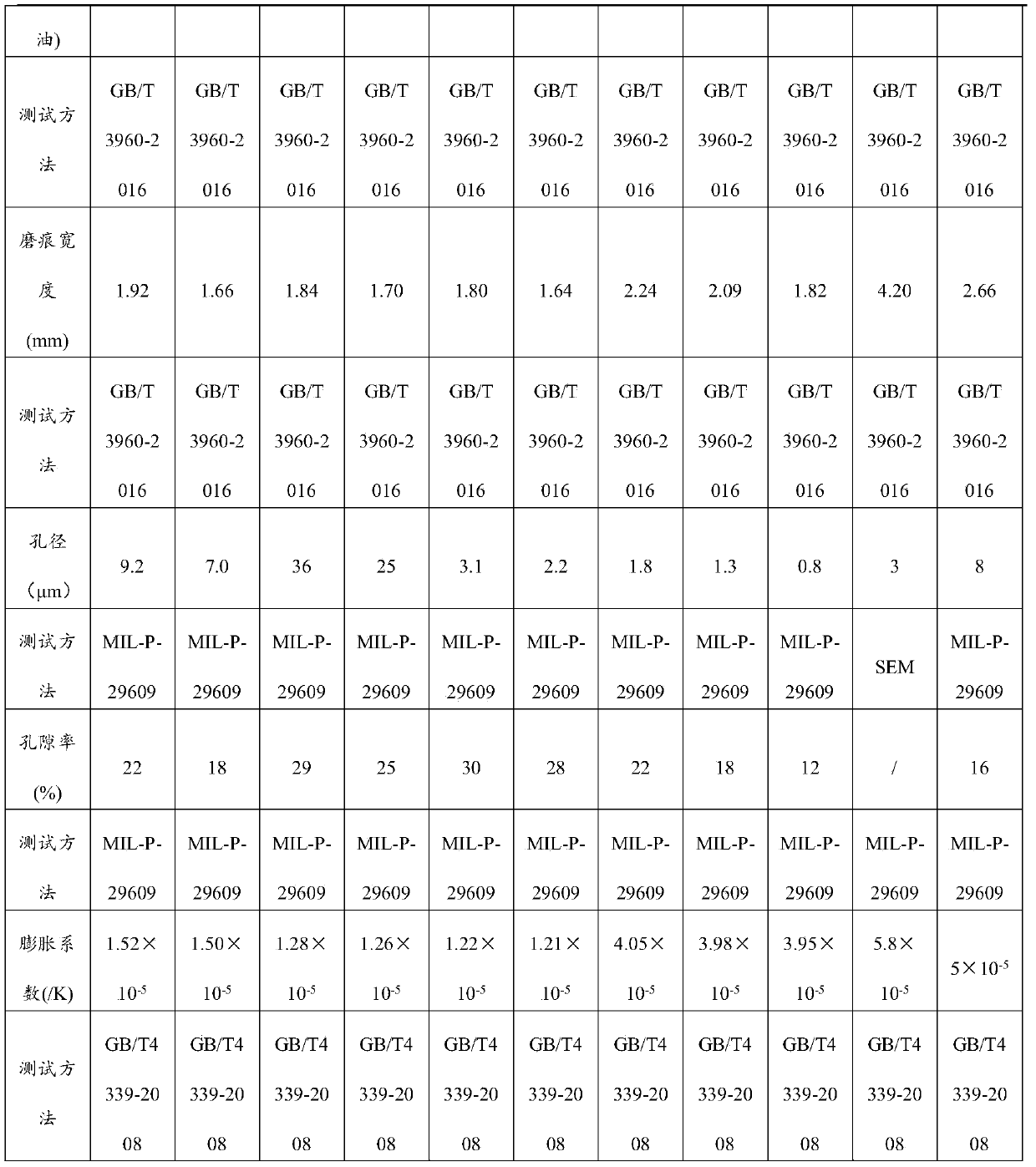

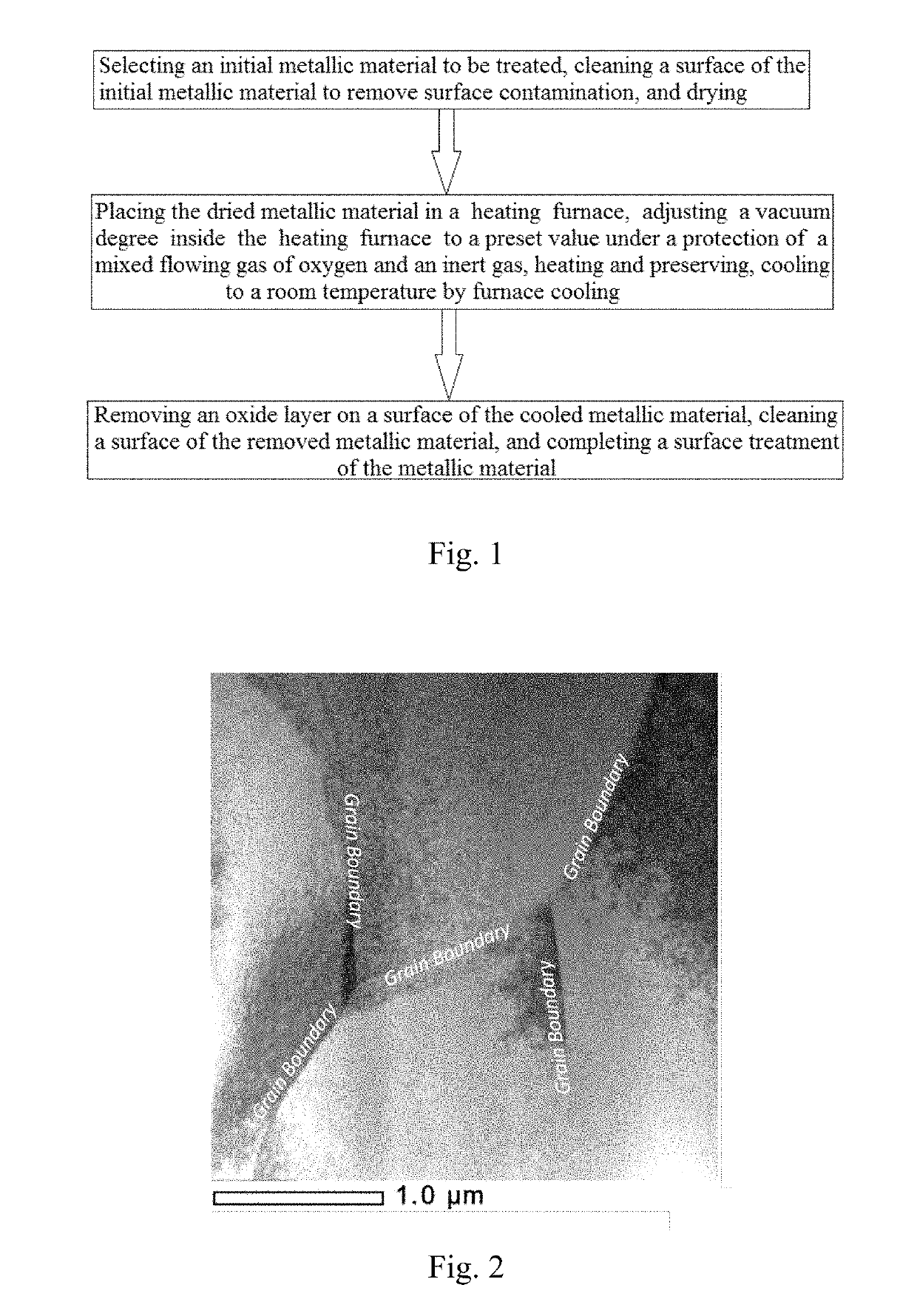

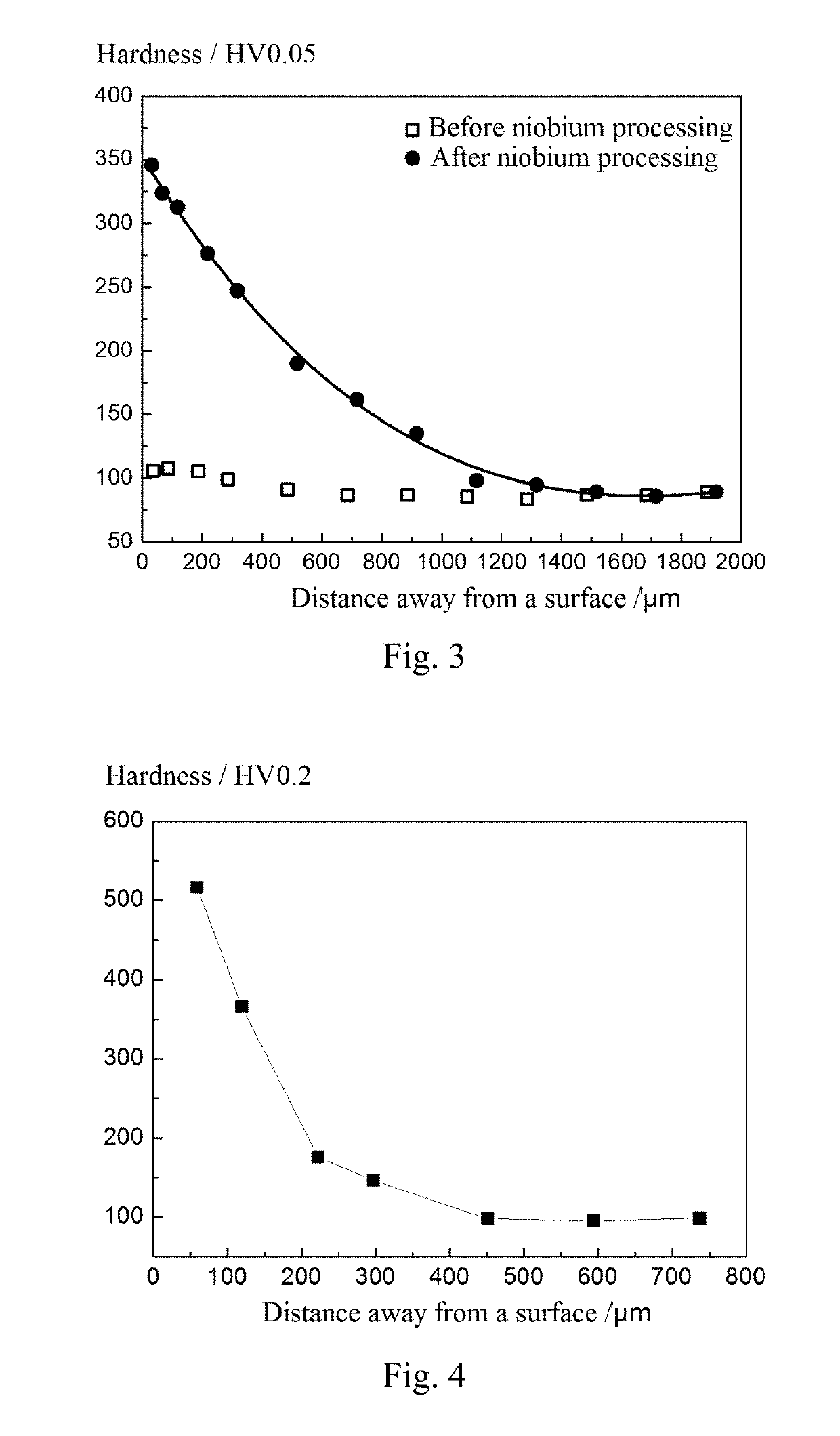

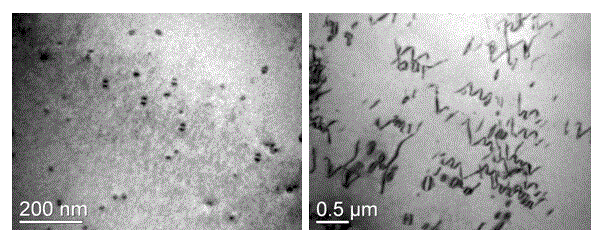

Surface treatment method of metallic materials

ActiveUS20190323102A1High surface hardnessReduce processing costsSolid state diffusion coatingFurnace typesMetallic materialsOxygen

A surface treatment method of metallic materials provided by the present invention includes steps of: (S1) cleaning a surface of an initial metallic material to be treated, and then drying; and (S2) placing the dried metallic material in a heating furnace, adjusting a vacuum degree inside the heating furnace to a preset value under the protection of a mixed flowing gas of oxygen and an inert gas, heating and preserving, cooling to room temperature by furnace cooling, and completing the surface treatment of the metallic material to be treated, wherein the heating temperature is larger than the destruction temperature of the native oxide at the surface of the initial metallic material. The present invention is able to increase the surface hardness of the metallic material within a large depth, and has the advantages of low processing cost, high efficiency, good controllability, convenient operation and low surface contamination for the workpiece.

Owner:XI AN JIAOTONG UNIV

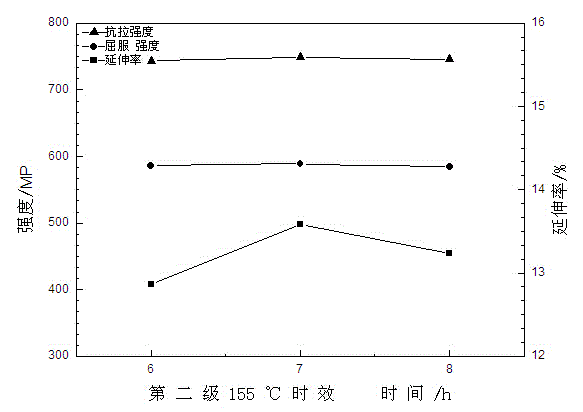

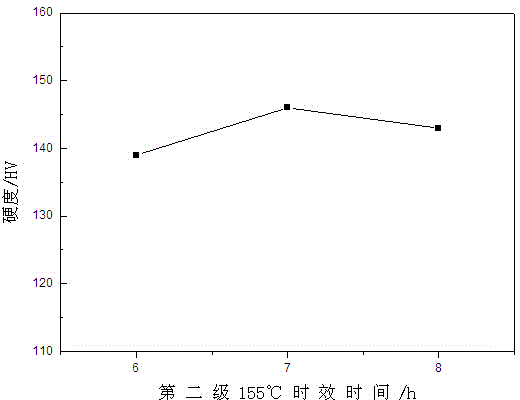

Aging heat treatment method for high-zinc aluminum alloy containing scandium

The invention belongs to the technical field of heat treatment of aluminum alloys, and specifically relates to an aging heat treatment method for a high-zinc aluminum alloy containing scandium. The method comprises the following steps: firstly, preserving heat for the high-zinc aluminum alloy containing scandium for 3.5-4.5h at the temperature of 455-465 DEG C, then, 10s later after heat preservation, transferring the high-zinc aluminum alloy containing scandium into water at room temperature for quenching for 5min, and further carrying out two-stage aging heat treatment: preserving heat for 5.5-6.5h at 100-120 DEG C, then, heating up to 155-175 DEG C in furnace and preserving heat for 6-8h, finally cooling to room temperature, and thereby obtaining the high-zinc aluminum alloy containing scandium subjected to aging heat treatment. With the method provided by the invention, hardness, tensile strength, yield strength and elongation of alloy are all improved remarkably, and application range of the high-zinc aluminum alloy containing scandium in the industrial circle is extended.

Owner:NORTHEASTERN UNIV

Nitrogen-vanadium-titanium-niobium rare earth microalloyed high-strength deep-drawing cold-rolled steel plate and production method thereof

The invention discloses a nitrogen-vanadium-titanium-niobium rare earth microalloyed high-strength deep-drawing cold-rolled steel plate and a production method thereof. According to the invention, microalloyed elements are fully utilized to be combined with residual interstitial atoms carbon and nitrogen in steel and added trace nitrogen atoms to generate different types of carbonitrides; the solid solubility of free interstitial atoms carbon and nitrogen in the steel is reduced to the minimum, a very small amount of solid solution rare earth elements is guaranteed, formation of {111} / / ND texture is promoted, and the r value and the n value of the cold-rolled steel sheet are greatly increased; under the action of factors such as temperature, deformation and cooling rate, the sizes and distribution of different types of carbonitride precipitates are controlled, thicker micron-sized precipitates are beneficial to formation of {111} / / ND textures, and dispersed and uniformly distributed nanoscale vanadium carbonitride, titanium carbonitride, niobium carbonitride and rare earth carbonitride hinder dislocation movement, so that the strength of the steel is improved; and under the condition of ensuring proper coarsening of the crystal grains, formation of cake-shaped crystal grains is promoted, and the deep drawing performance is greatly improved.

Owner:长沙东鑫环保材料有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com