Porous high-entropy alloy material and preparation method and application thereof

A high-entropy alloy, pre-pressing technology, used in metal processing equipment, mechanical equipment, shafts and bearings, etc., can solve problems such as large differences in expansion coefficients, stuck, and whistling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a porous high-entropy alloy material, comprising the following steps:

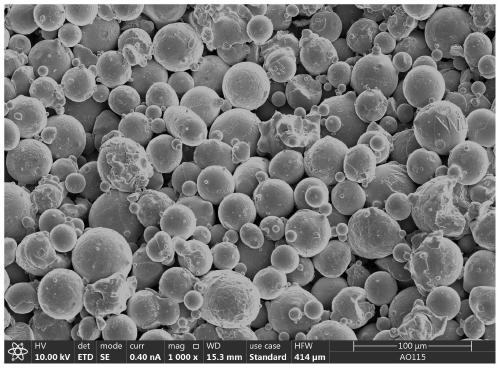

[0022] AlCoCrAgNi high-entropy alloy spherical powder is provided, and the particle size of the AlCoCrAgNi high-entropy alloy spherical powder is 25-380 μm;

[0023] The AlCoCrAgNi high-entropy alloy spherical powder is sequentially pre-pressed and sintered to obtain a porous high-entropy alloy material.

[0024] The invention provides AlCoCrAgNi high-entropy alloy spherical powder, the particle size of the AlCoCrAgNi high-entropy alloy spherical powder is 25-380 μm, preferably 25-38 μm, 38-75 μm, 75-106 μm, 106-150 μm, 150-250 μm or 250-μm- The particle size of the AlCoCrAgNi high-entropy alloy spherical powder is preferably obtained by particle size classification. The particle size range of the AlCoCrAgNi high-entropy alloy spherical powder defined by the invention can ensure uniform pore size of the prepared porous high-entropy alloy material.

[0...

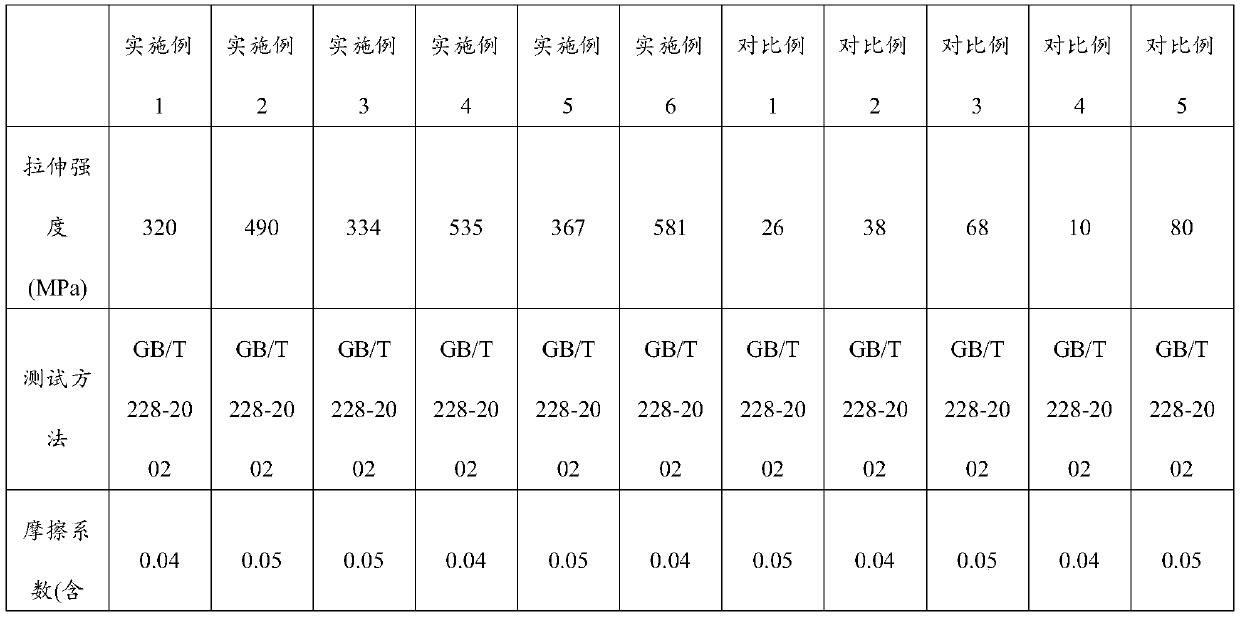

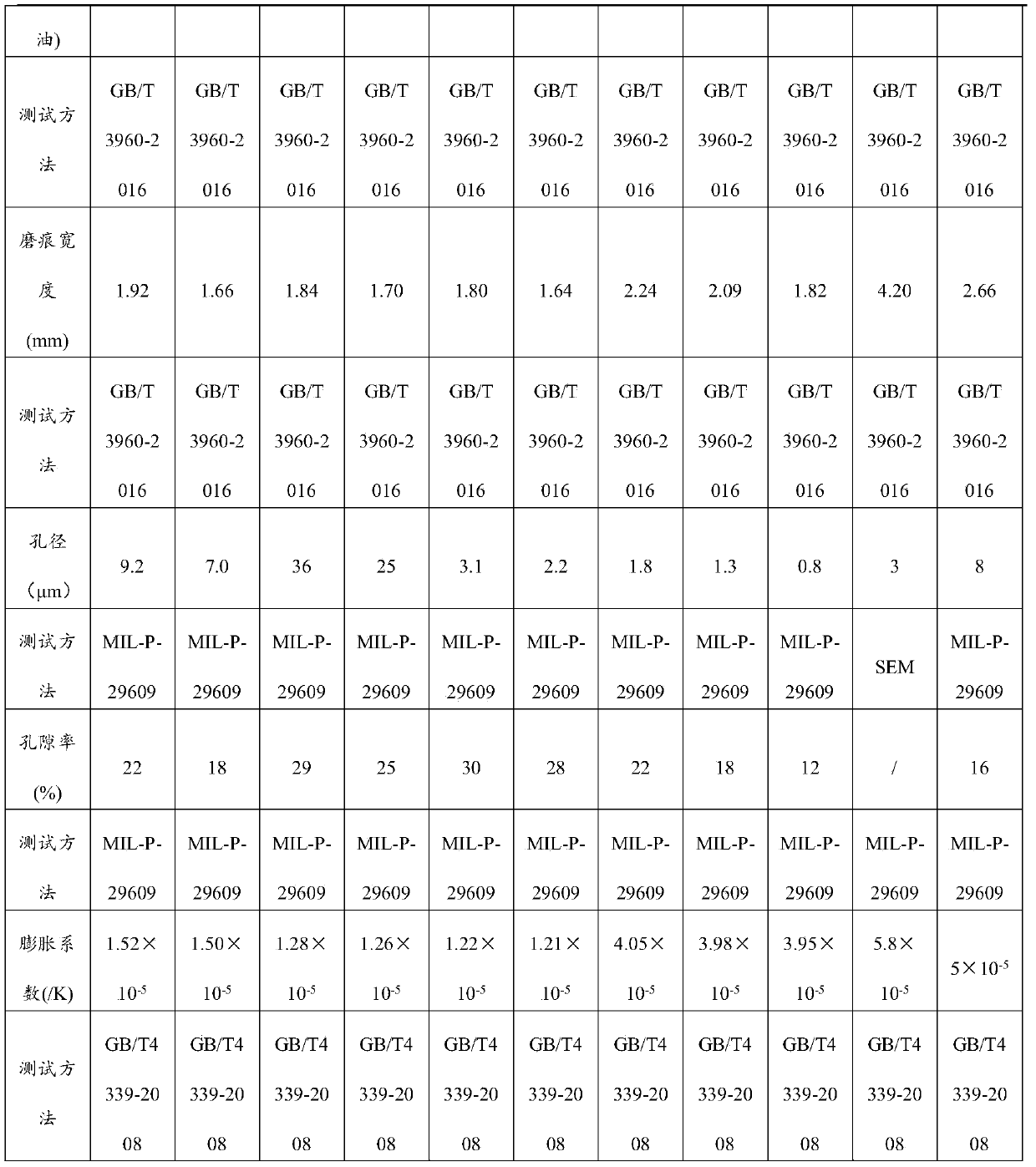

Embodiment 1

[0036] (1) Weigh 54g of Al powder with a particle size of 30-50μm, 118g of Co powder with a particle size of 30-50μm, 104g of Cr powder with a particle size of 30-50μm, 216g of Ag powder with a particle size of 30-50μm and 118g of Ni powder with a particle size of 30-50 μm (the molar ratio is 20:20:20:20:20);

[0037] (2) Obtain high-entropy alloy spherical powder by atomization method;

[0038] (3) Use particle size sieves with a particle size of 25 μm and 106 μm to carry out particle size classification, and take alloy powders with a particle size between 25 μm and 106 μm for use;

[0039] (4) The obtained high-entropy alloy powder is packed into a low-carbon steel ladle, vacuum-packed, and pre-compressed with a cold isostatic press. The pressure of the pre-compressed process is 300 MPa, and the holding time is 30 min;

[0040] (5) Sinter the billets and sheaths obtained after pre-pressing with a hot isostatic press, the sintering pressure is 15MPa, the temperature rises fr...

Embodiment 2

[0045] (1) Weigh 54g of Al powder with a particle size of 30-50μm, 118g of Co powder with a particle size of 30-50μm, 104g of Cr powder with a particle size of 30-50μm, 216g of Ag powder with a particle size of 30-50μm and 118g of Ni powder with a particle size of 30-50 μm (the molar ratio is 20:20:20:20:20);

[0046] (2) Obtain high-entropy alloy spherical powder by atomization method;

[0047] (3) Use particle size sieves with a particle size of 75 μm and 106 μm to carry out particle size classification, and take alloy powders with a particle size between 75 μm and 106 μm for use;

[0048] (4) The obtained high-entropy alloy powder is packed into a low-carbon steel ladle, vacuum-packed, and pre-compressed with a cold isostatic press. The pressure of the pre-compressed process is 300 MPa, and the holding time is 30 min;

[0049] (5) Sinter the billet and sheath obtained after pre-pressing with a hot isostatic press, the sintering pressure is 10MPa, the temperature is raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com