Aging heat treatment method for high-zinc aluminum alloy containing scandium

An aging heat treatment, scandium-aluminum alloy technology, applied in the field of aluminum alloy heat treatment, can solve the problems of increasing difficulty of alloy formability, lack of theoretical basis and data accumulation, insufficient performance and heat treatment technology and system, etc. The effect of increasing the proportion, elongation, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

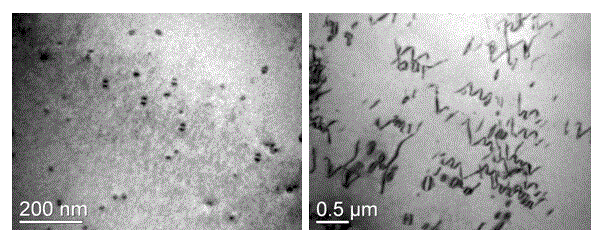

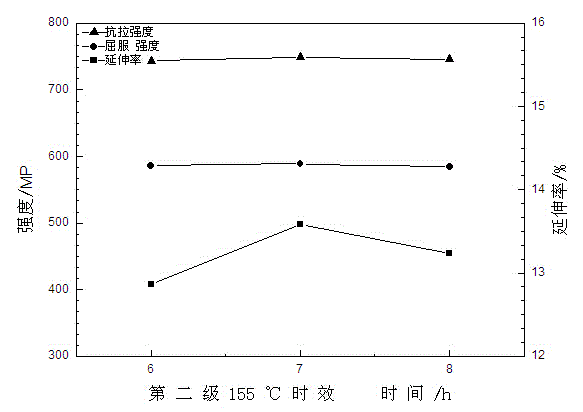

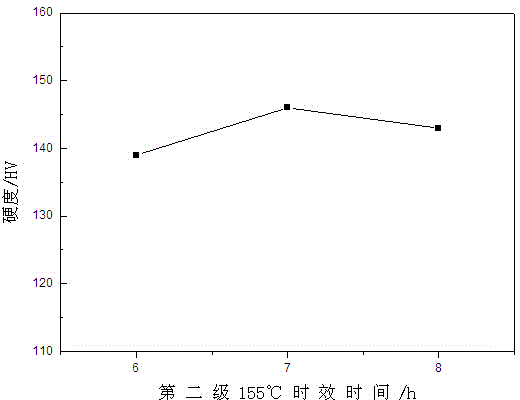

[0026] First, heat the high-zinc-scandium-containing aluminum alloy at 455°C for 4.5 hours, then transfer the high-zinc-scandium-containing aluminum alloy to room temperature water for 5 minutes 10 seconds after the heat preservation, and then perform a double-stage aging heat treatment: heat preservation at 100°C After 6 hours, the furnace was heated to 155°C within 2 hours and kept for 6 hours, and finally cooled to room temperature. The transmission electron microscope image of the high-zinc and scandium-containing aluminum alloy after aging heat treatment is as follows figure 1 shown, from figure 1 It can be seen that a large amount of fine Al particles dispersed in the aluminum alloy matrix after aging heat treatment 3 (Sc,Zr) particles, the mechanical properties curve is as follows figure 2 As shown, the hardness as image 3 As shown, its tensile strength is 750MPa, yield strength is 580MPa, elongation is 13.0%, and hardness is 140Hv.

Embodiment 2

[0028] First, heat the high-zinc-scandium-containing aluminum alloy at 460°C for 4 hours, then transfer the high-zinc-scandium-containing aluminum alloy to room temperature water for 5 minutes 10 seconds after the heat preservation, and then perform a double-stage aging heat treatment: heat preservation at 100°C for 5.5 After h, the temperature is raised to 155°C within 2 hours and kept for 7 hours with the furnace, and finally cooled to room temperature. The mechanical property curve of the high-zinc and scandium-containing aluminum alloy after aging heat treatment is as follows figure 2 As shown, the hardness as image 3 As shown, its tensile strength is 750MPa, yield strength is 580MPa, elongation is 13.6%, and hardness is 145Hv.

Embodiment 3

[0030] First, heat the high-zinc and scandium-containing aluminum alloy at 465°C for 3.5 hours, then transfer the high-zinc and scandium-containing aluminum alloy to room temperature water for 5 minutes after the heat preservation is over for 10 seconds, and then perform a double-stage aging heat treatment: heat preservation at 100°C After 6.5 hours, the furnace was heated to 155°C within 2 hours and kept for 8 hours, and finally cooled to room temperature. The mechanical property curve of the high-zinc and scandium-containing aluminum alloy after aging heat treatment is as follows: figure 2 As shown, the hardness as image 3 As shown, its tensile strength is 750MPa, yield strength is 580MPa, elongation is 13.2%, and hardness is 142Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com