Copper-based aerogel enhanced copper alloy and preparation method thereof

An aerogel-enhanced technology, which is applied in the field of copper-based aerogel-enhanced copper alloys and their preparation, can solve the problems of rare research and difficulty in uniform dispersion, and achieve good wear resistance and hinder dislocation movement and grain boundary slip, reducing friction coefficient and wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

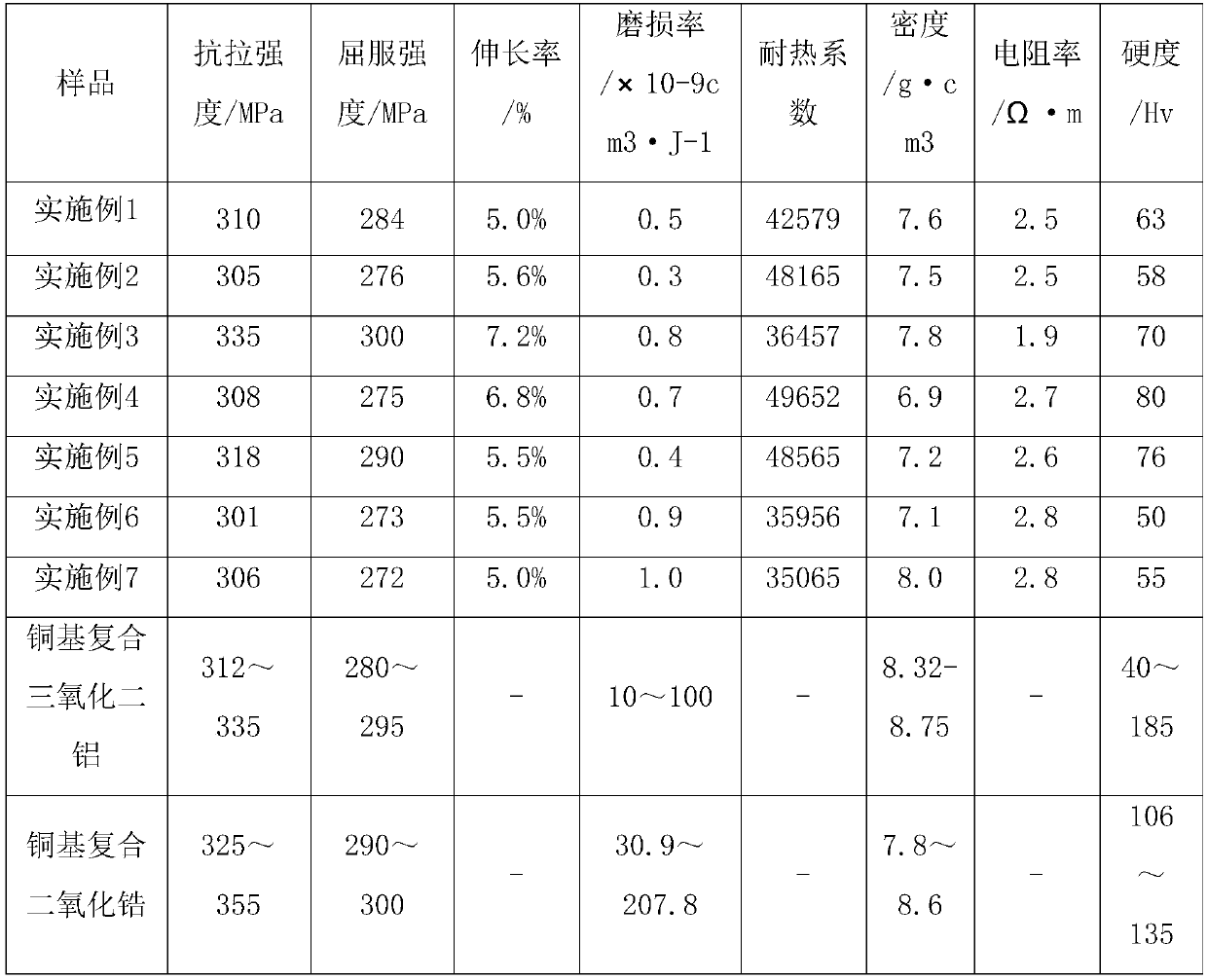

Examples

preparation example Construction

[0026] The preparation method of the copper-based aerogel-enhanced copper alloy of the present invention includes the following steps: batching, high-energy ball milling, mixing, cold pressing, pressure sintering and finished products. The specific process steps include:

[0027] (1) High-energy ball milling: the weighed electrolytic copper powder (average particle size≤74μm, purity≥99.9wt%), nanometer SiO 2 (The average particle size is 20-40nm) is placed in a planetary high-energy ball mill for pre-ball milling for 2 to 4 hours.

[0028] (2) Raw material mixing: copper-nano-SiO after ball milling 2 Mixed powder, atomized zinc powder (average particle size 40-50μm, purity ≥98wt%), micron SiO 2 (The average particle size is 40-50μm, and the moisture content is ≤1wt%) and mixed in a small V-shaped mixer for 3-5h; the quality of the raw materials used in the examples is the same as above.

[0029] (2) Cold forming: the powder is pressed into a density of 4~5g / cm in a steel mold of Ф26m...

Embodiment 1

[0032] The production process method is as follows: batching, ball milling, mixing, cold pressing, pressure sintering and finished products.

[0033] The specific process is: according to the ingredients shown in Table 1: zinc: 5%, aerogel (SiO 2 ): 5%, the balance is copper. Combine copper and nano SiO 2 The mixed powder is ball milled in a high-energy ball mill for 3 hours, and then mixed with other raw materials in a small V-shaped mixer for 3 hours; The powder is pressed into a steel mold with a density of 4g / cm 3 The compact is sintered in a bell furnace at 1.0MPa pressure, the sintering temperature is 980℃, the average heating rate is 6℃ / min, and the reducing protective atmosphere is used during the sintering process. The sintering time is 40min. The furnace is cooled to room temperature in a protective atmosphere to make a finished product. The properties of the finished product are shown in Table 2.

Embodiment 2

[0035] The production process of the copper-based aerogel enhanced copper alloy is as follows: batching, ball milling, mixing, cold pressing, pressure sintering and finished products.

[0036] The specific process is: according to the ingredients shown in Table 1: zinc: 2%, aerogel (SiO 2 ): 3%, the balance is copper. Combine copper and nano SiO 2 The mixed powder is ball milled in a high-energy ball mill for 2 hours, and then mixed with other raw materials in a small V-shaped mixer for 5 hours; The powder is pressed into a steel mold with a density of 4.2g / cm 3 The compact is sintered in a bell furnace at a pressure of 2.5 MPa, the sintering temperature is 900 ℃, the average heating rate is 5 ℃ / min, the hydrogen reducing protective atmosphere is used during the sintering process, and the sintering time is 35 min. Finally, the furnace is cooled to room temperature under a protective atmosphere to make a finished product. The properties of the finished product are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com