Patents

Literature

87 results about "Aluminium element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

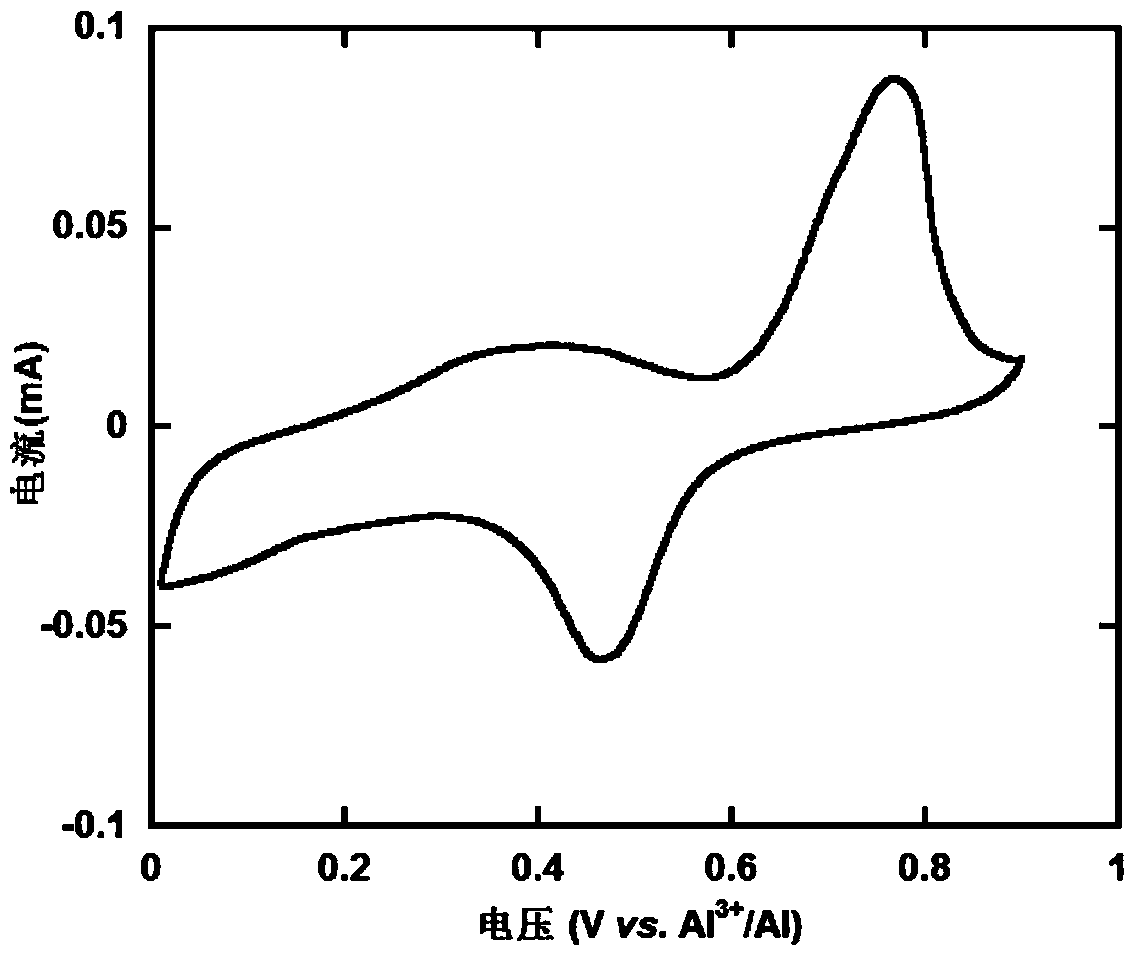

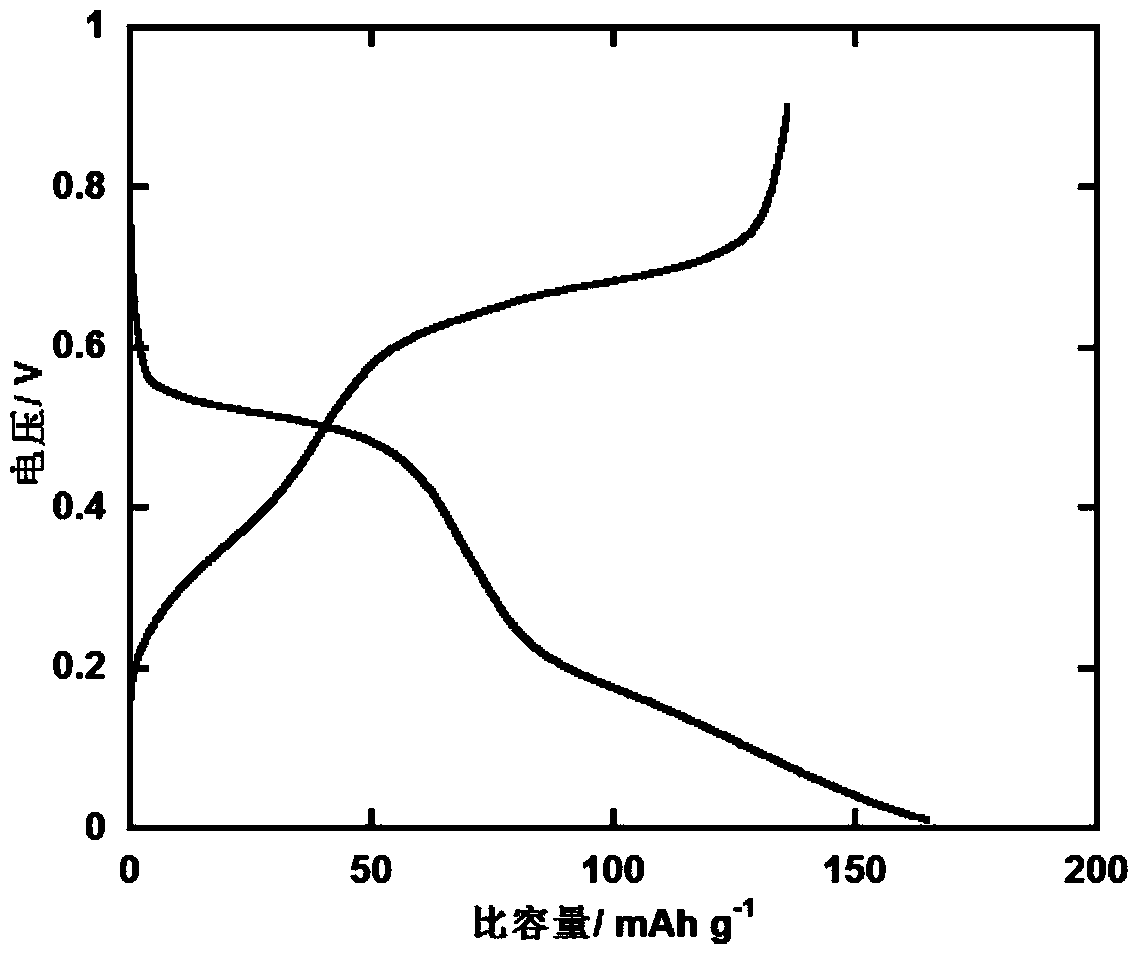

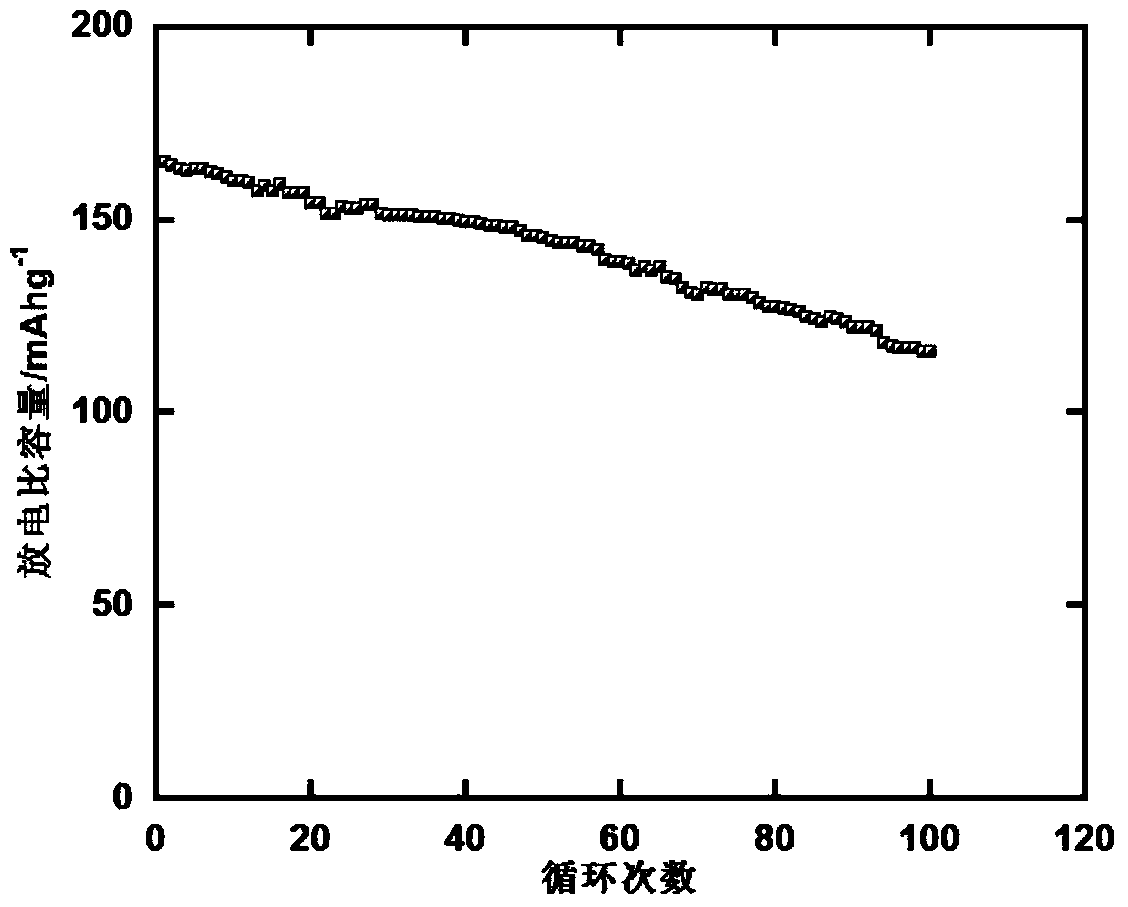

Aluminium ion battery and preparation method thereof

InactiveCN103825045AImprove securityImprove insulation performanceCell electrodesFinal product manufactureAluminum IonAluminium-ion battery

The invention relates to an aluminium ion battery and a preparation method thereof and belongs to the field of aluminium ion batteries and preparation thereof. The aluminium ion battery comprises a positive electrode, a negative electrode and an aluminium ion electrolyte, wherein the positive electrode is made of transition metal oxide; the negative electrode is made of high purity aluminium; the battery comprises a diaphragm material when the aluminium ion electrolyte is in a liquid state. Since abundant aluminium elements are stored, the cost for the ion battery is greatly reduced; the safety performance is improved; the transition metal oxide is applicable to hypervalent ion batteries due to relative stability under the variable valence states and different valence states. The ion liquid serves as the electrolyte for the hypervalent ion battery, so that aluminium ion is high in conductivity, good in heat stability, broad in electrochemical window and high in chemical stability and almost incapable of reacting with the positive electrode materials, the negative electrode materials, a current collector, a binder and a diaphragm in a battery system and capable of maintaining the liquid state in a board temperature range. The aluminium ion battery can be applied to various fields, such as electronic industries, communication industries and electric vehicles and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing ternary positive electrode material precursor by virtue of waste batteries

ActiveCN104659438AAchieve recyclingAvoid pollutionReclaiming serviceable partsWaste accumulators reclaimingPhysical chemistryManganese

The invention discloses a method for preparing a ternary positive electrode material precursor by virtue of waste batteries. The method comprises the steps of detaching waste batteries, roasting the detached waste batteries and carrying out sulfuric acid dissolving to obtain a waste battery positive electrode material, then separating and removing metal impurities in the waste battery positive electrode material by virtue of an extraction method to obtain a sulfate solution, supplementing manganese or aluminum to prepare a mixed solution for preparing the ternary positive electrode material precursor, then sequentially adding ammonia water and a sodium hydroxide solution, reacting to generate ternary positive electrode material precursor precipitates, and finally washing and drying to obtain the ternary positive electrode material precursor. According to the method, the cyclic utilization of resources of nickel and cobalt in waste batteries is realized, and the environmental pollution caused by heavy metals is avoided; furthermore, a nickel-cobalt-aluminum precursor and a nickel-cobalt-manganese precursor are produced from the recycled waste batteries, so that the requirements on primary mineral resources are lowered, and the purchase costs of nickel and cobalt are lowered; the method adopts a simple technological process and is applicable to industrial large-scale production.

Owner:广东芳源新材料集团股份有限公司

Catalyst for preparing isophorone by acetone condensation method

InactiveCN101698147AImprove conversion rateHigh selectivityOrganic compound preparationCatalyst activation/preparationCeriumLanthanum

The invention provides a catalyst for preparing isophorone by acetone condensation method. The catalyst is sinter formed by the step that magnesium oxide or nitrate, calcium oxide or nitrate, barium oxide or nitrate, zirconium oxide or nitrate, rare earth metal oxide or nitrate and aluminium oxide are mixed and then sintered at 400-600 DEG C for 4-6 hours. The sinter contains 25.4-46.4% of aluminium element, 3-18% of magnesium element, 1.4-7.1% of calcium element, 0.8-4.2% of barium element, 0.7-1.5% of zirconium element and 0.5-6% of rare earth metal element; wherein the rare earth metal is one or two of lanthanum, cerium and yttrium. The catalyst is used for catalyzing acetone condensation reaction, can effectively improve acetone conversion and selectivity of isophorone and causes the acetone conversion and selectivity of isophorone to respectively reach more than 86% and 65%.

Owner:GUANGZHOU UNIVERSITY

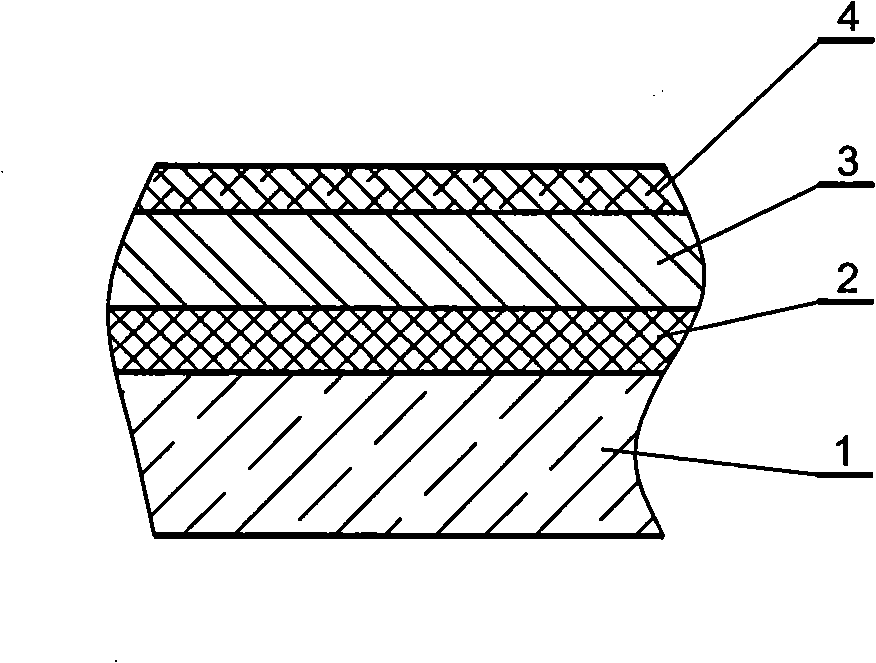

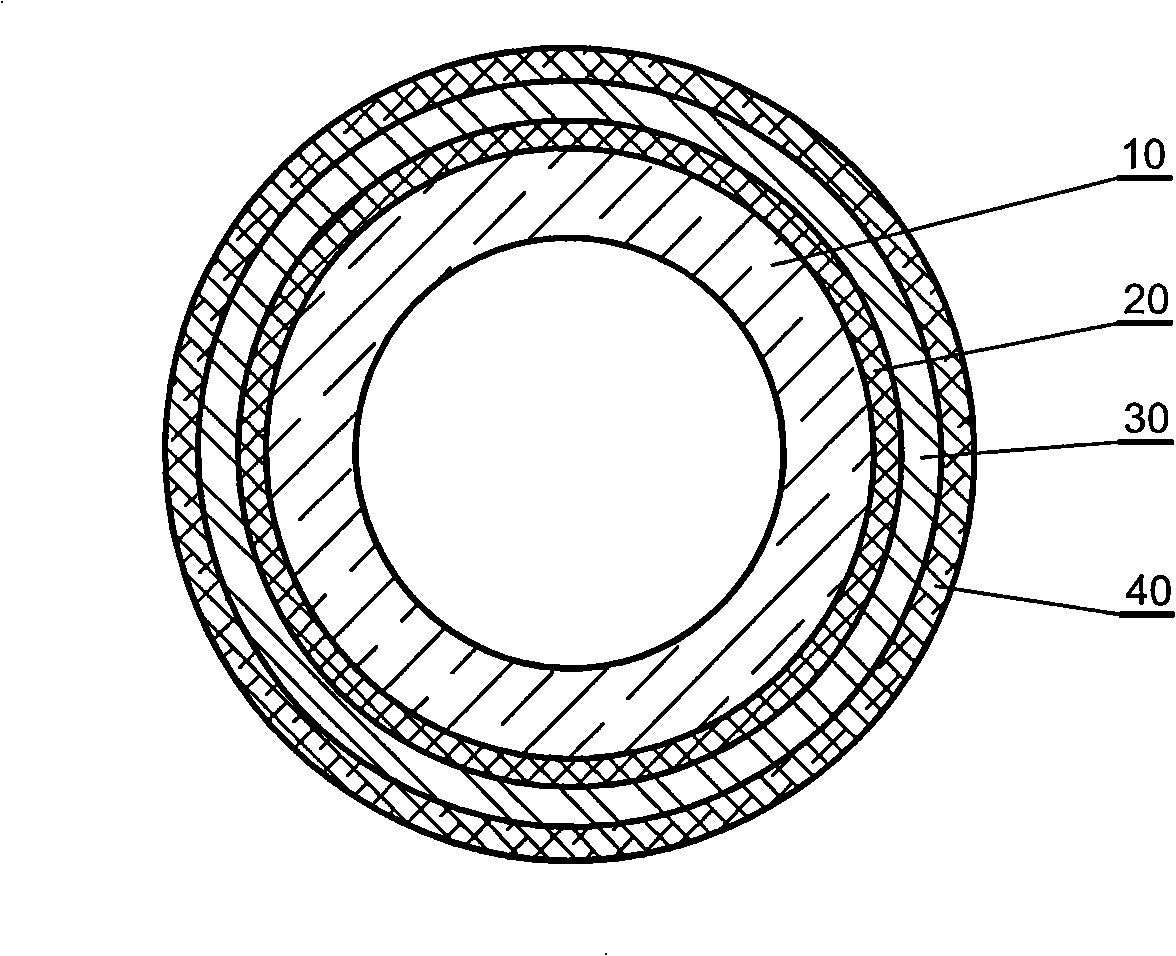

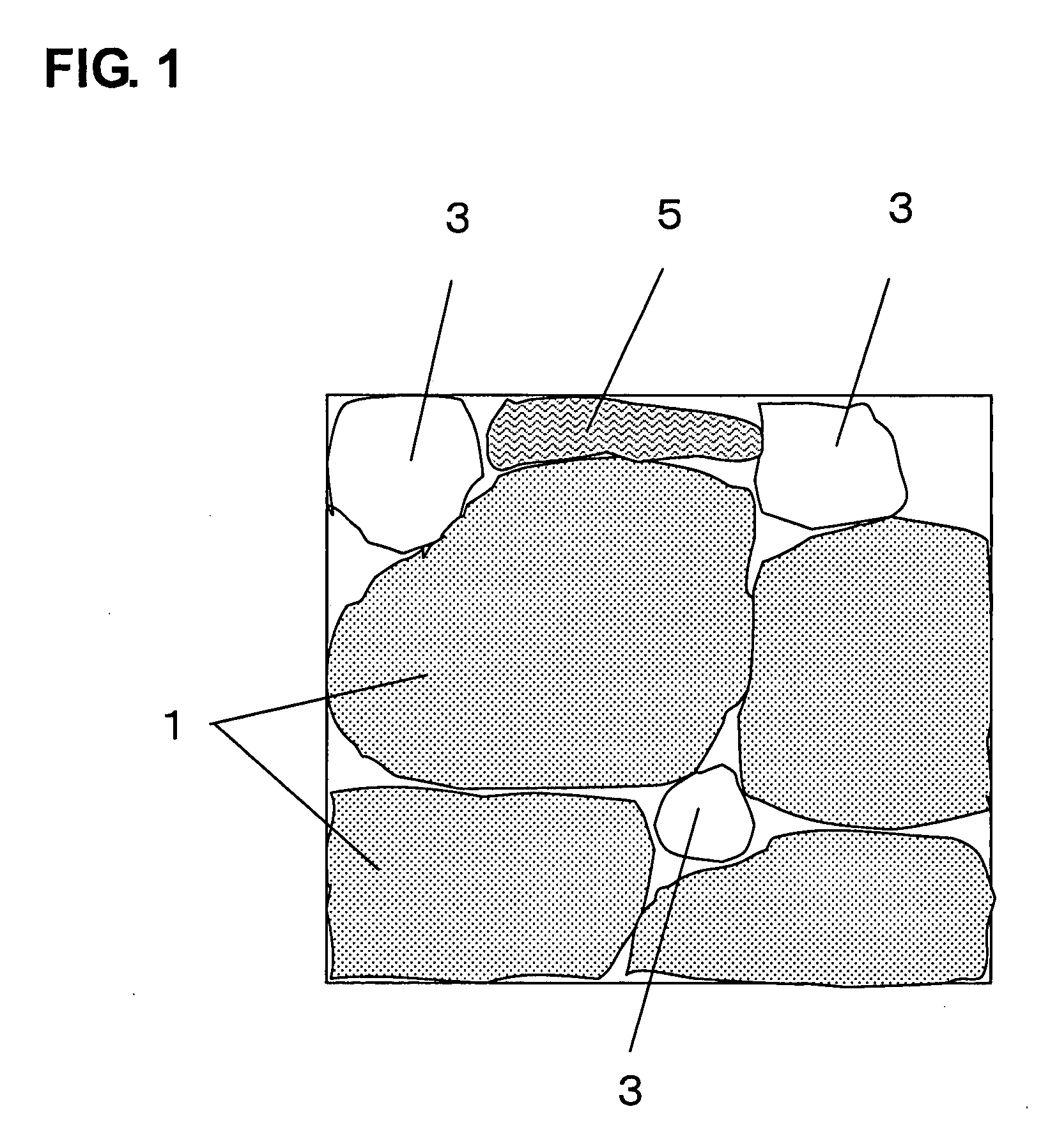

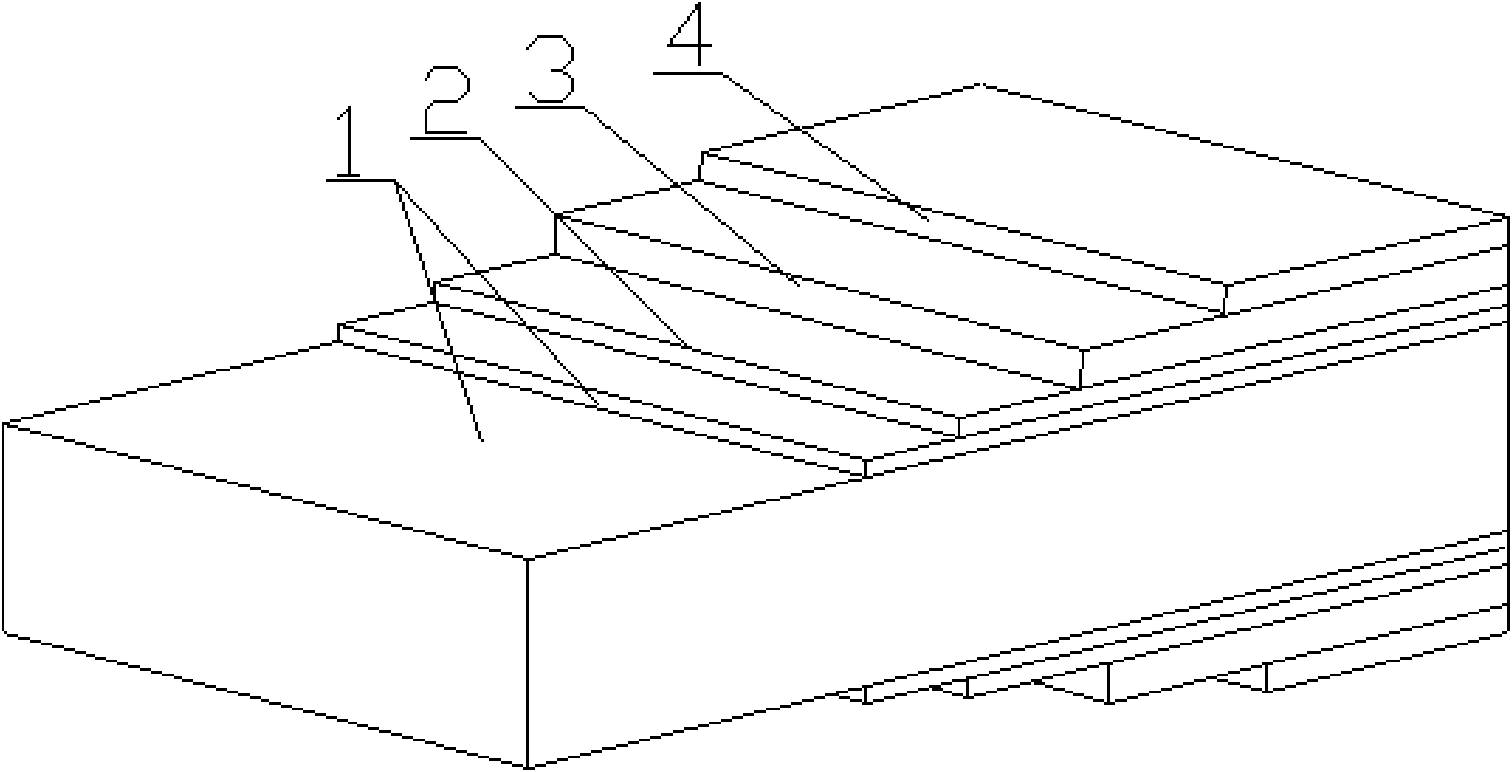

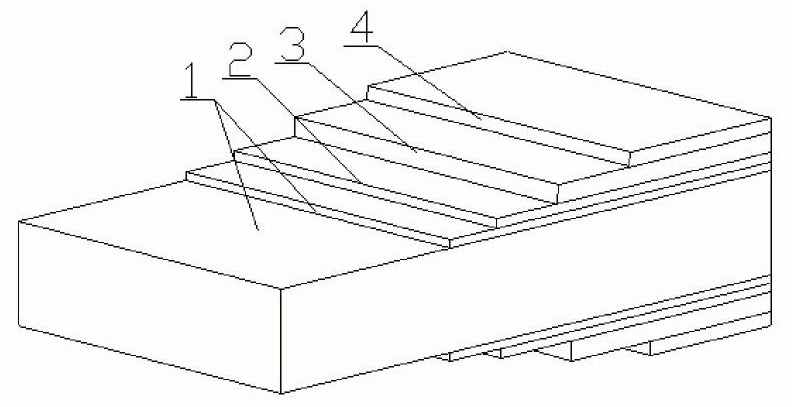

Electrode Material and Method for Producing Same

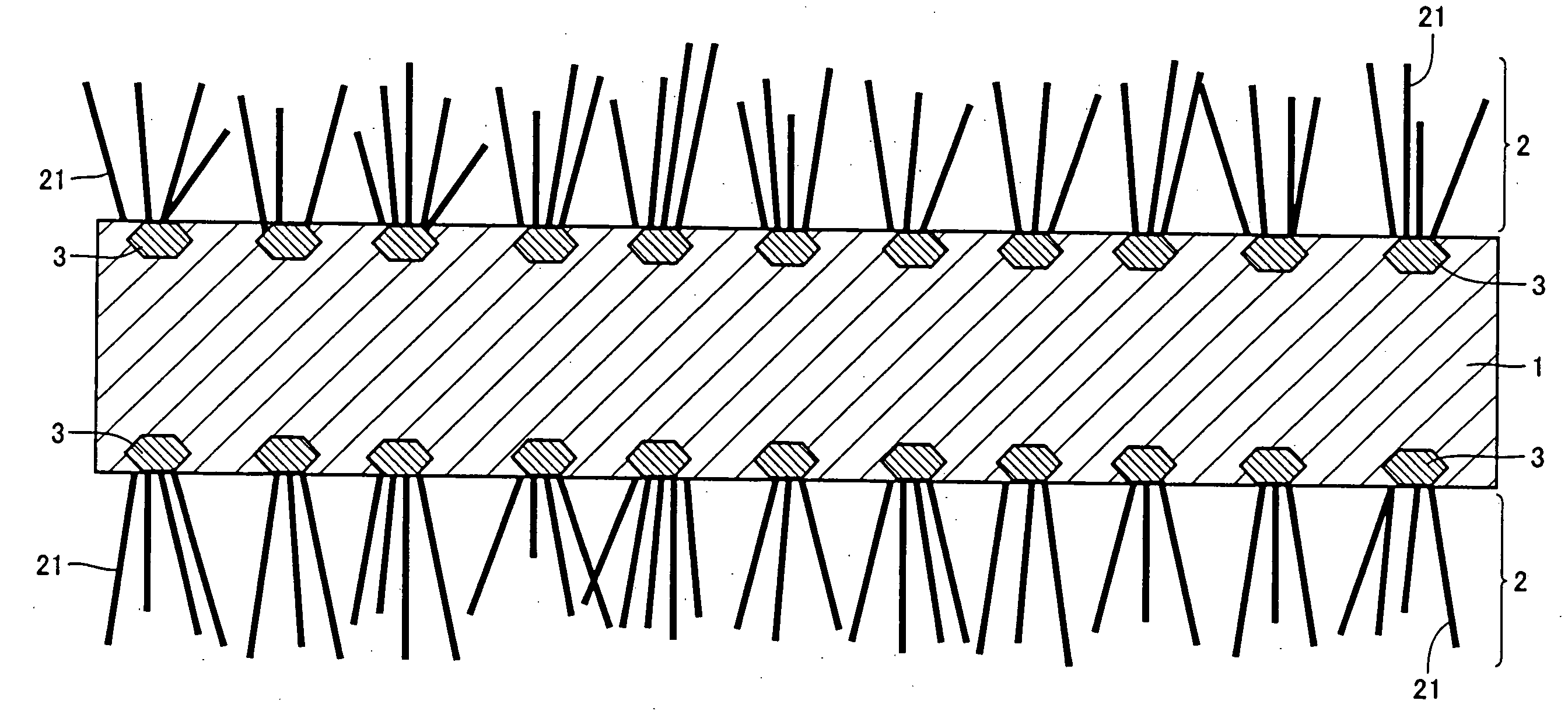

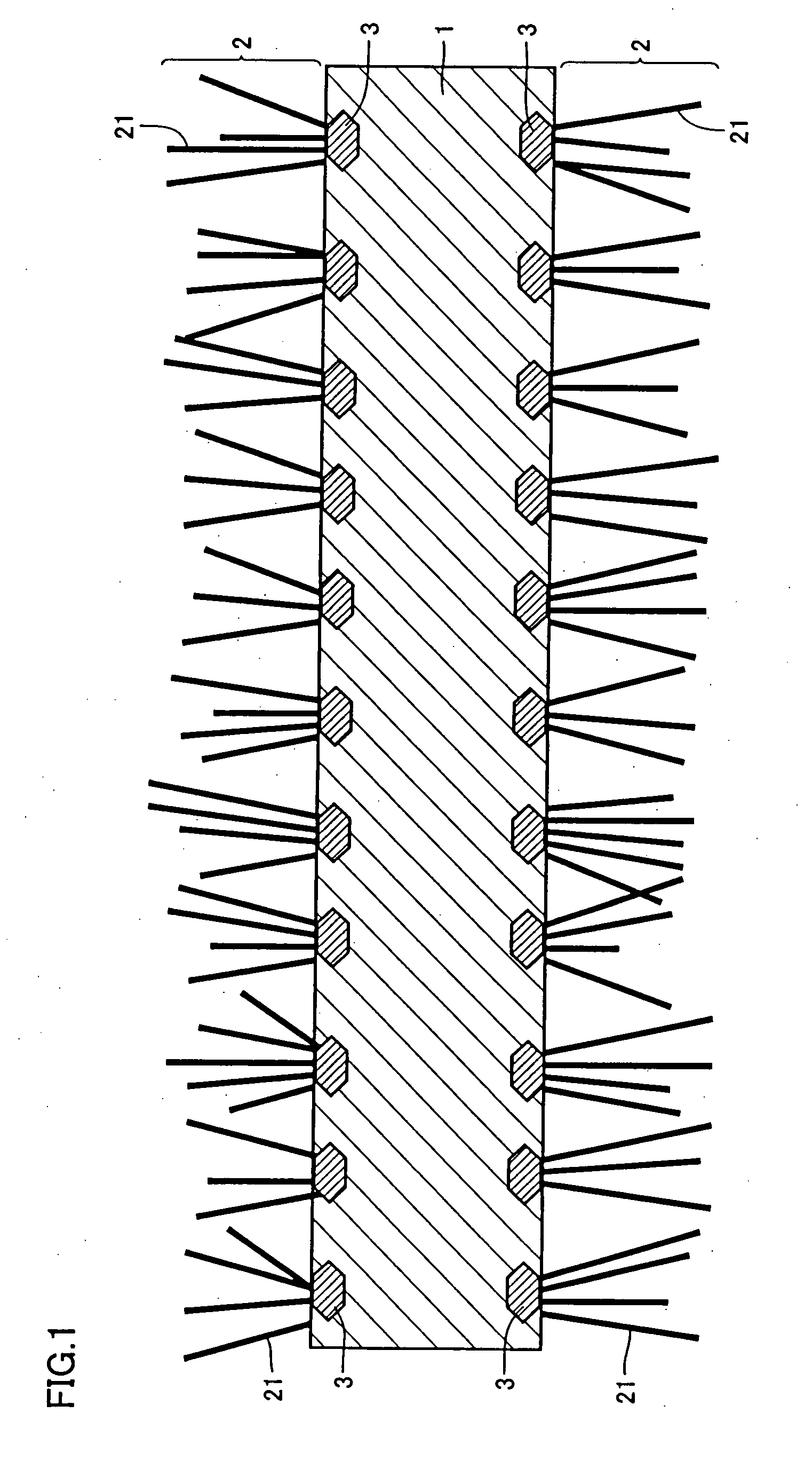

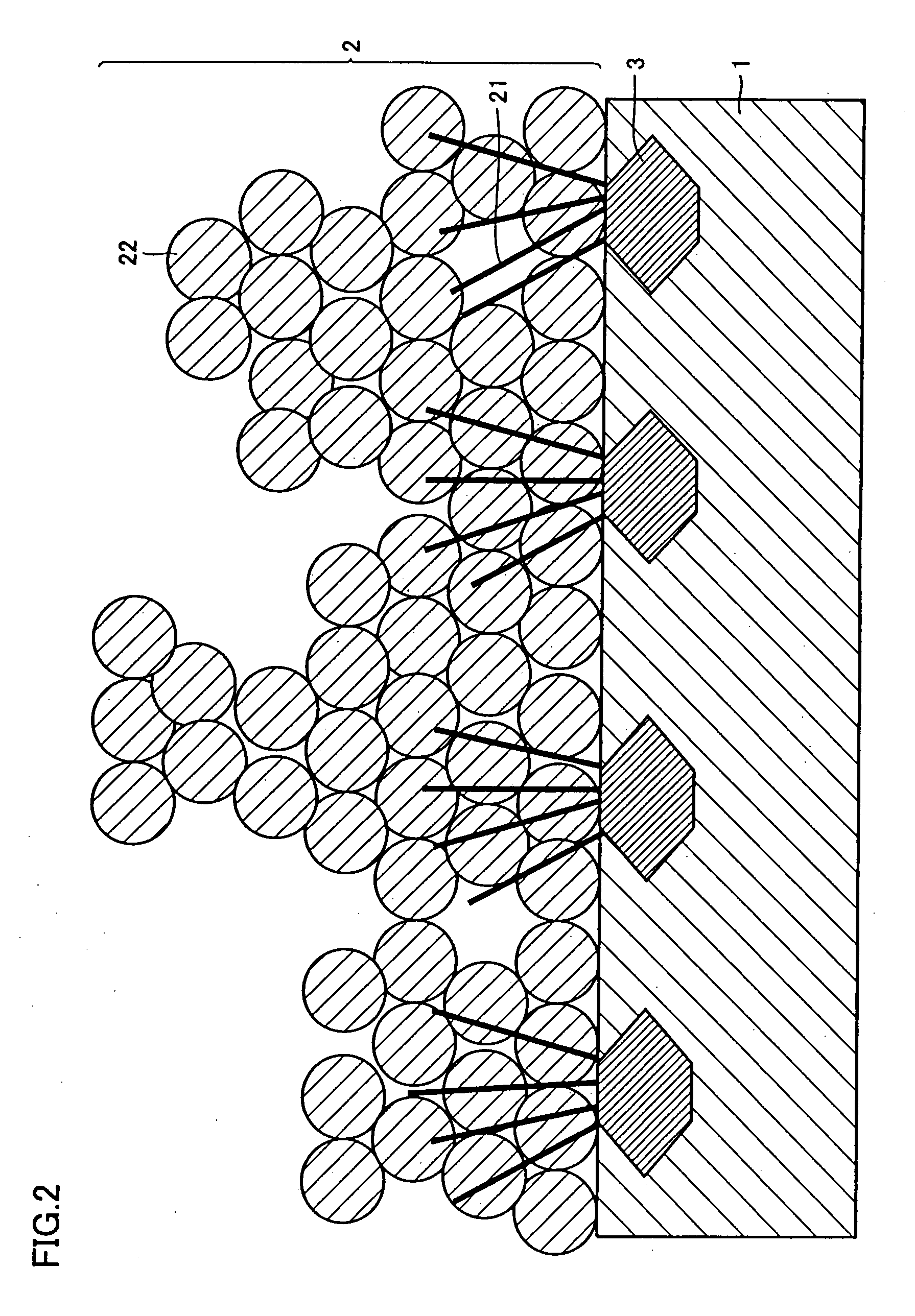

ActiveUS20080130202A1Improve adhesionIncrease capacityHybrid capacitor electrodesLiquid electrolytic capacitorsConductive materialsHydrocarbon

Provided are an electrode material which can secure both high electrical capacity and high stability with time and can be improved in the adhesion of a conductive material and a method for producing the electrode material. The electrode material comprises an aluminum foil (1) and a carbon-containing layer (2) formed on the surface of the aluminum foil (1). An interposition layer (3) containing an aluminum element and a carbon element is formed between the aluminum foil (1) and the carbon-containing layer (2). The method for producing the electrode material comprises the steps of disposing an aluminum foil in a space containing a hydrocarbon-containing material and heating this aluminum foil.

Owner:TOYO ALUMINIUM KK

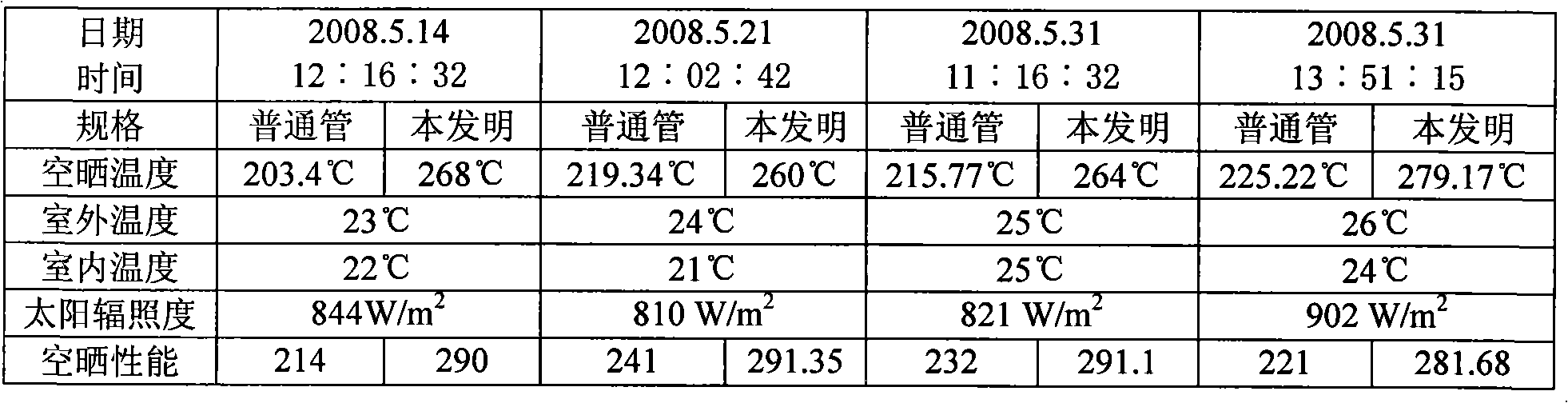

Solar spectrum selective absorption film and preparation method thereof

InactiveCN101344334APromote absorptionImprove high temperature resistanceSolar heating energySolar heat devicesSilicon alloyAbsorption rate

The invention relates to a solar spectrum selective absorbing film and a preparation method thereof, the solar spectrum selective absorbing film comprises a film coated substrate, an infrared reflection layer, an absorption layer and an antireflection layer are sequentially covered on the surface of the substrate from interior to exterior; the infrared reflection layer is a sputtering deposition layer containing titanium element plus aluminium element plus silicon element, the absorption layer is the sputtering deposition layer containing aluminum nitrogen cluster plus titanium nitrogen cluster plus silicon nitrogen cluster plus aluminum titanium silicon cluster; the antireflection layer is the sputtering deposition layer containing aluminum nitrogen cluster plus titanium nitrogen cluster plus silicon nitrogen cluster; the solar spectrum selective absorbing film and the preparation method of the invention adopt the sputtering technology of the titanium silicon alloy target and the aluminium alloy target; the full color absorption rate Alpha to solar spectrum of a solar energy heat collecting tube adopting the invention is not less than 94 percent, the total emissivity Epsilon is not more than 4.5 percent, and the air drying performance of the solar energy heat collecting tube can be improved 21.33 percent. The solar spectrum selective absorbing film can be used under the temperature of higher than 400 DEG C all year around.

Owner:范天方

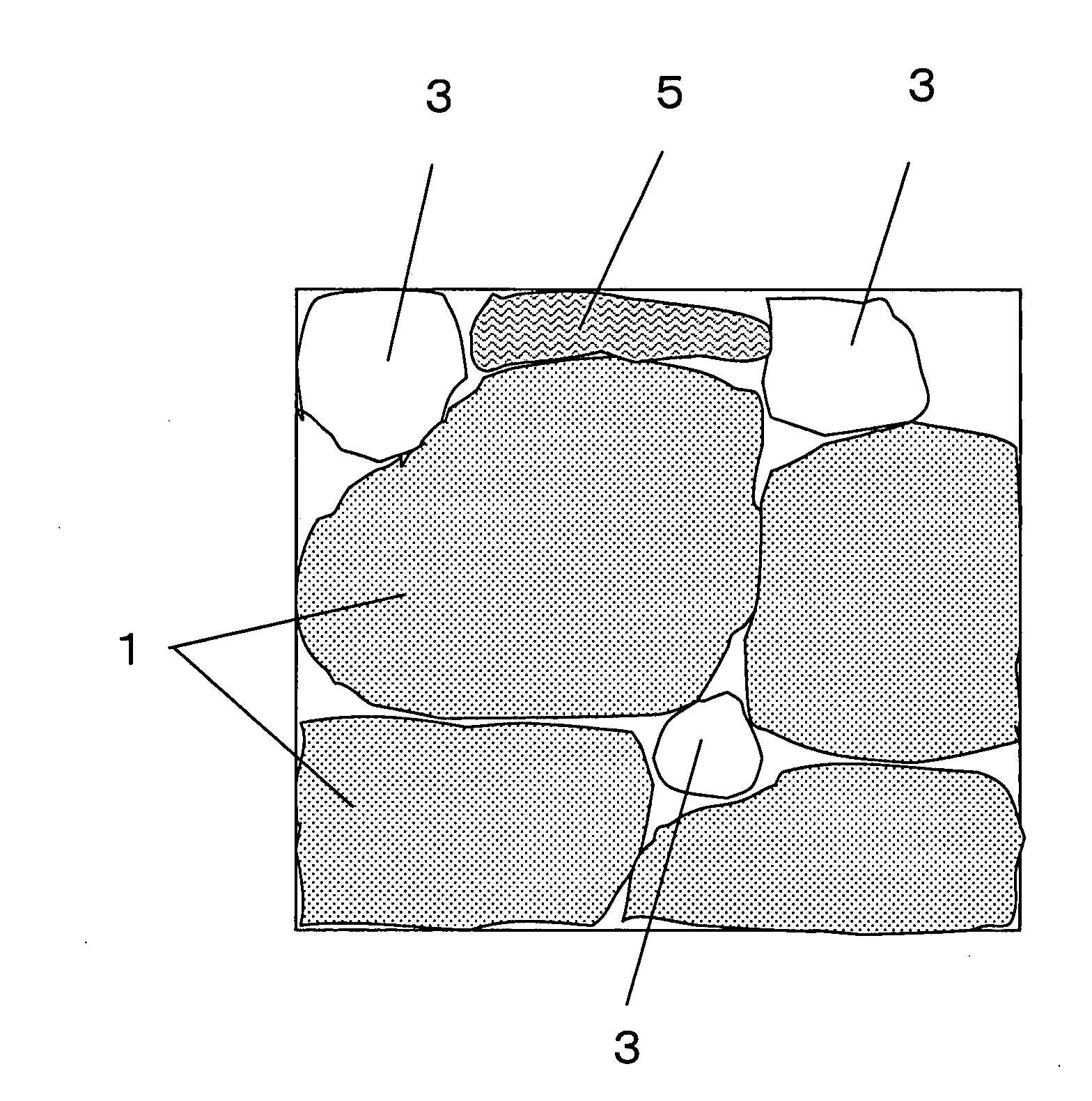

Composite Ceramic and Method for Making the Same

InactiveUS20080118722A1Improve toughnessLow mechanical strengthLayered productsThin material handlingAlkaline earth metalComposite ceramic

A composite ceramic of the present invention includes granular alumina particles (A) having an aspect ratio of 3 or less, granular zirconia particles (B) having an aspect ratio of 3 or less, and a columnar crystal (C) having an aspect ratio of 3 or more, the columnar crystal including a complex metal oxide containing an alkaline-earth metal element and aluminum element. The composite ceramic has high flexural strength, toughness, and hardness, and achieves excellent hot-water resistance and high flexural strength after hydrothermal degradation resistance test.

Owner:KYOCERA CORP

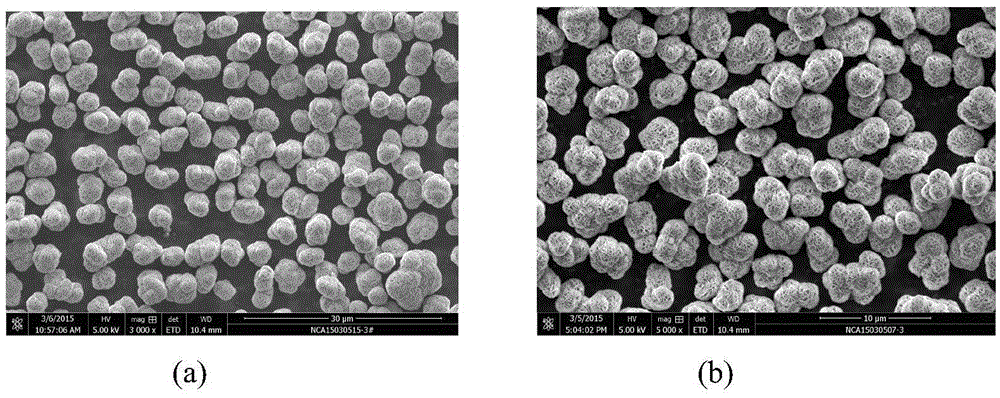

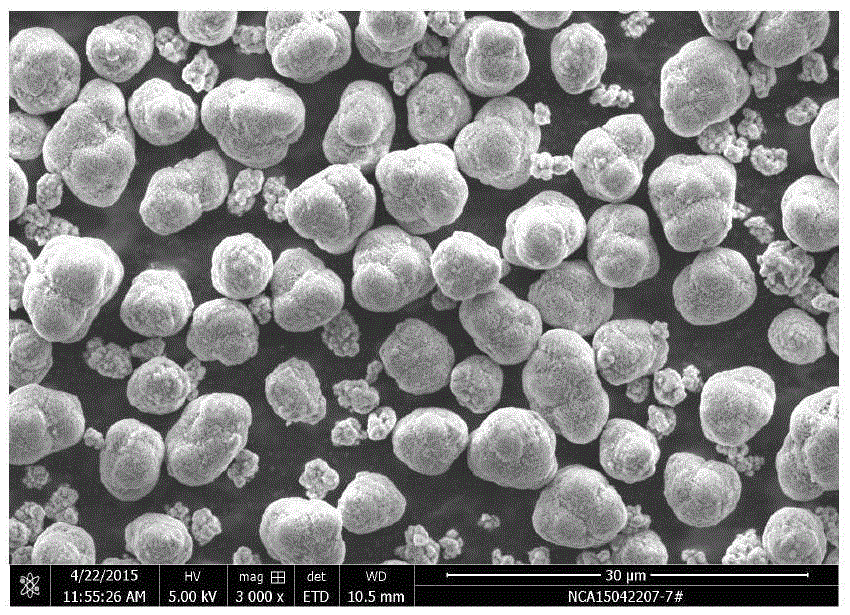

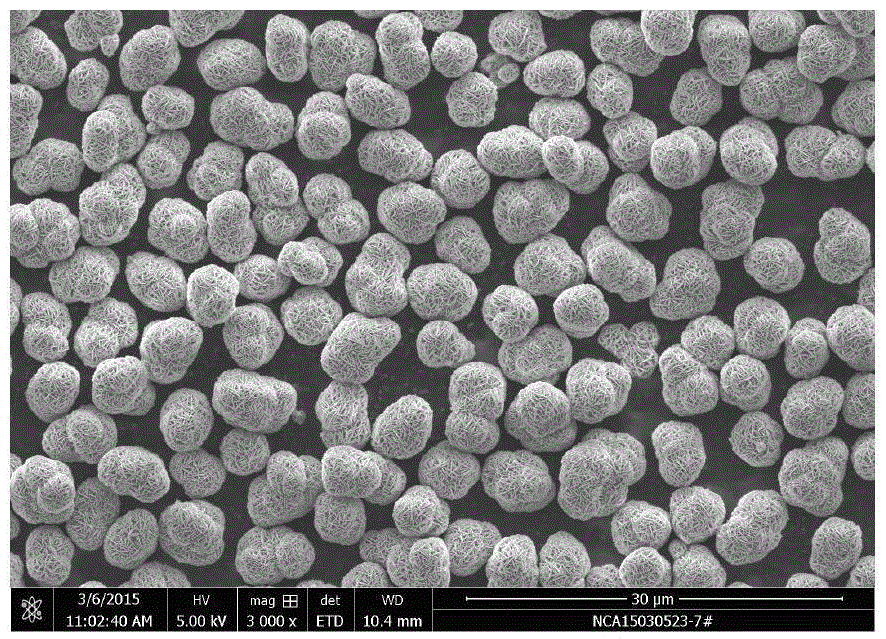

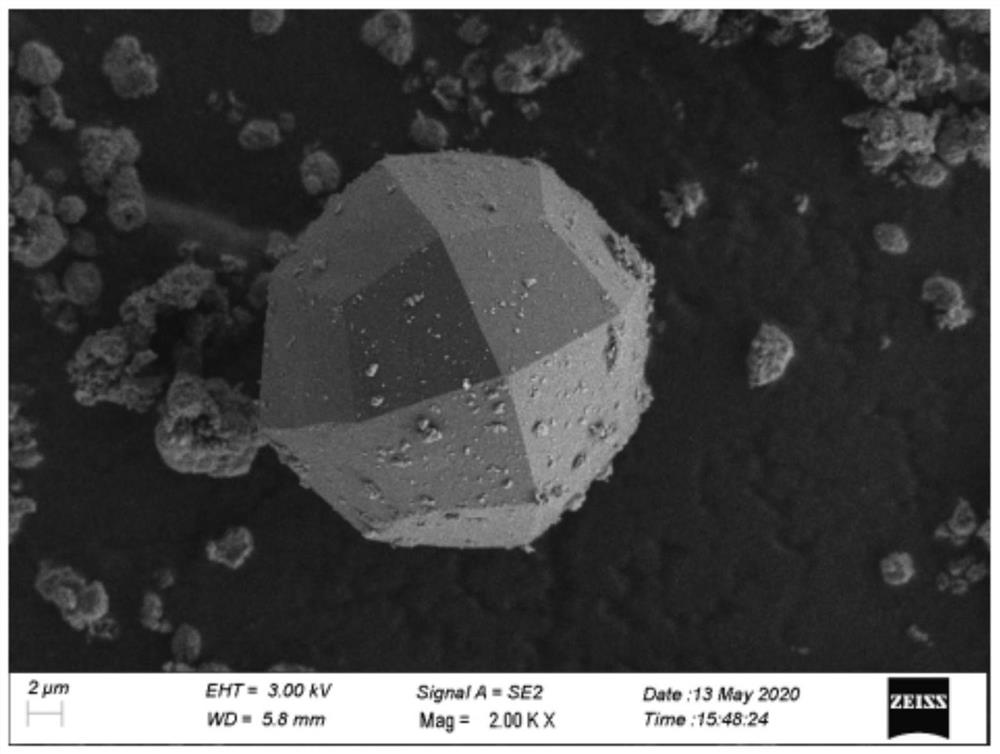

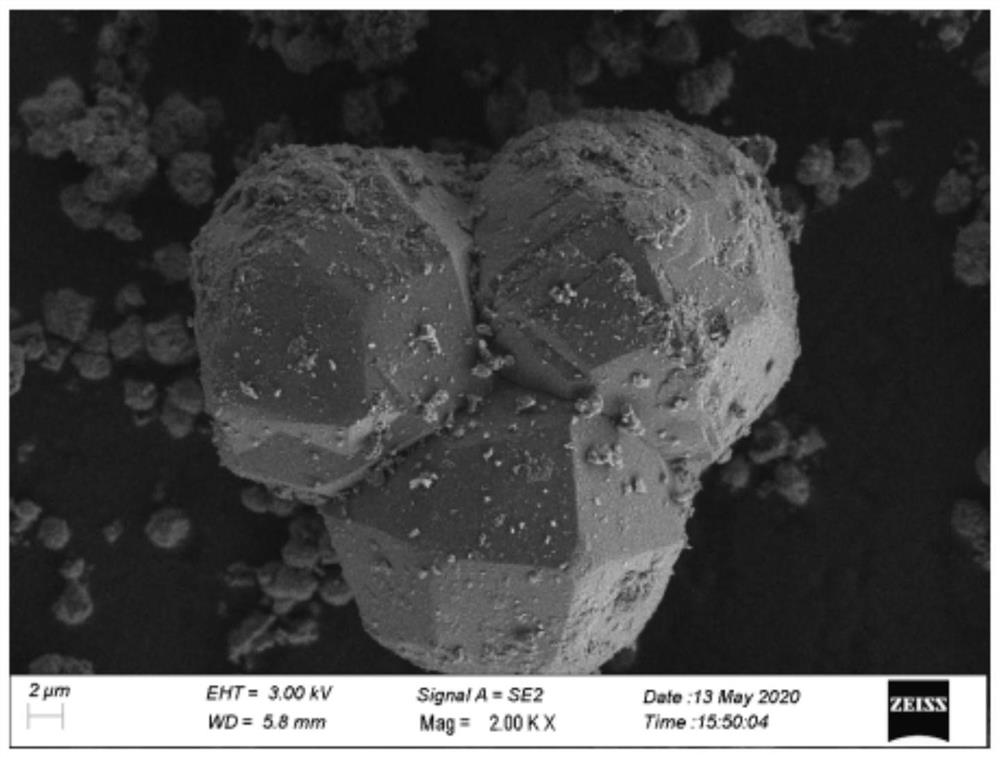

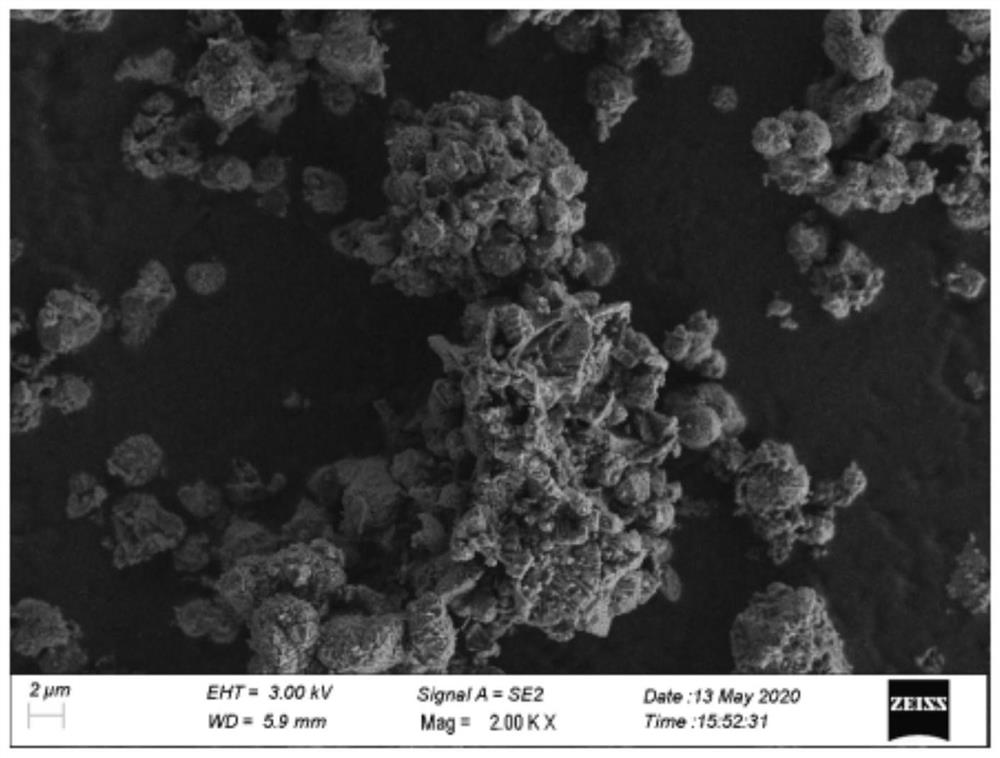

Nickel-cobalt-aluminium oxide precursor, nickel-cobalt-aluminium oxide and preparation method therefor

ActiveCN105552363AGood sphericityHomogeneous adsorption reactionCell electrodesCobaltMaterials science

The invention provides a preparation method for a nickel-cobalt-aluminium oxide precursor. A dry nickel-cobalt hydroxide with a large specific surface area and relatively high degree of sphericity is obtained through a coprecipitation method; a melted organic aluminium source is mixed with the dry nickel-cobalt hydroxide to enable the aluminium element to be fully and uniformly adsorbed on the porous structure of the nickel-cobalt hydroxide under vacuum negative pressure for realizing uniform distribution of the aluminium element in the nickel-cobalt hydroxide; and the nickel-cobalt-aluminium oxide precursor with high degree of sphericity and high tap density is obtained by drying. The preparation method is simple in process and high in degree of controllability; the problems of uneven distribution of nickel, cobalt and aluminium elements and low degree of sphericity of the nickel-cobalt-aluminium material caused by incomplete precipitation of aluminium ions in the preparation of the nickel-cobalt-aluminium oxide precursor material in the prior art are solved; and the invention also provides the nickel-cobalt-aluminium oxide precursor prepared by the preparation method, and a nickel-cobalt-aluminium oxide and a preparation method therefor.

Owner:JINGMEN GEM NEW MATERIAL

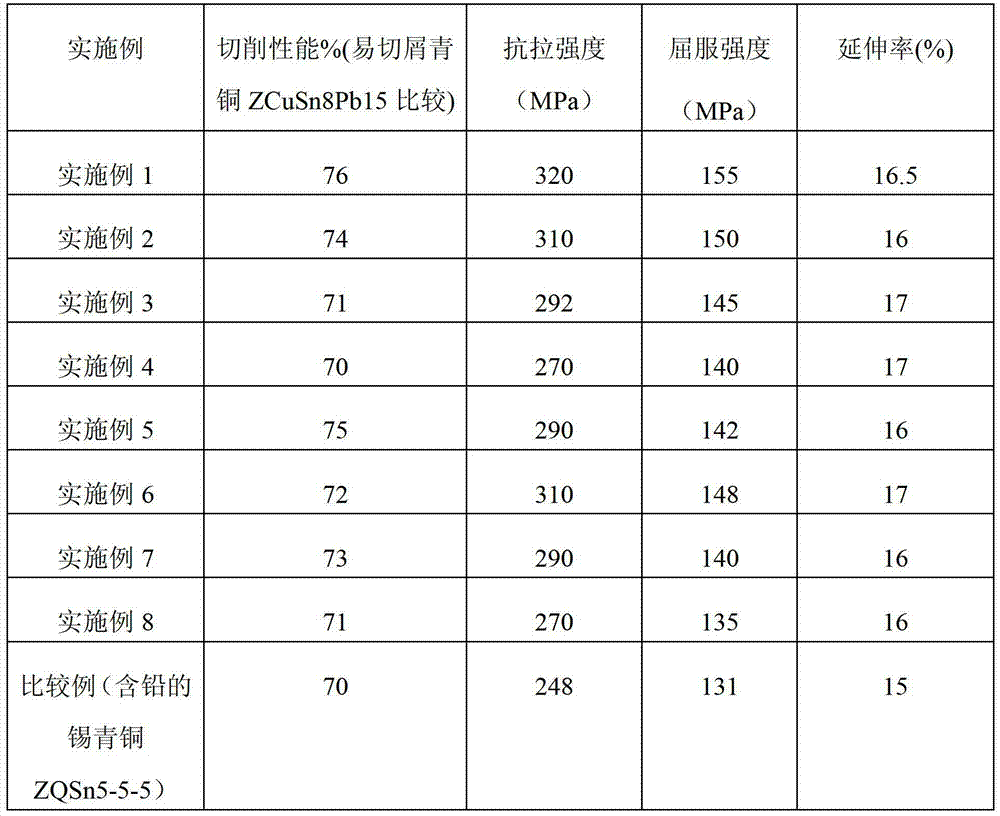

New environment-friendly lead-free silicon-containing alloy material and preparation method thereof

The invention discloses a new environment-friendly lead-free silicon-containing alloy material. The new environment-friendly lead-free silicon-containing alloy material comprises the following components in percentage by weight: 6-8 percent of zinc, 6-8 percent of tin, 1-3 percent of silicon and the balance of copper. By the new material, the traditional lead element is replaced by a silicon element; under the condition that cost is not increased, the chip cutting performance of the existing tin bronze is preserved, and the environment protection performance of the alloy is improved; and phosphorus and aluminium elements are properly added, based on the advantages, the mechanical performance of the alloy also can be greatly improved, such as tensile strength, yield strength and elongation rate, and the new material has a wide application prospect.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

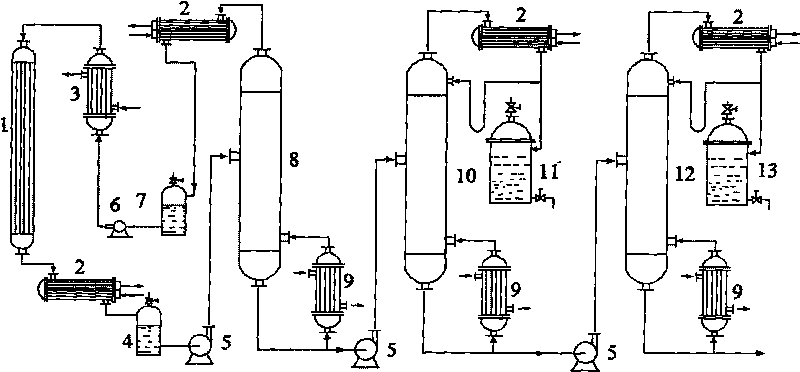

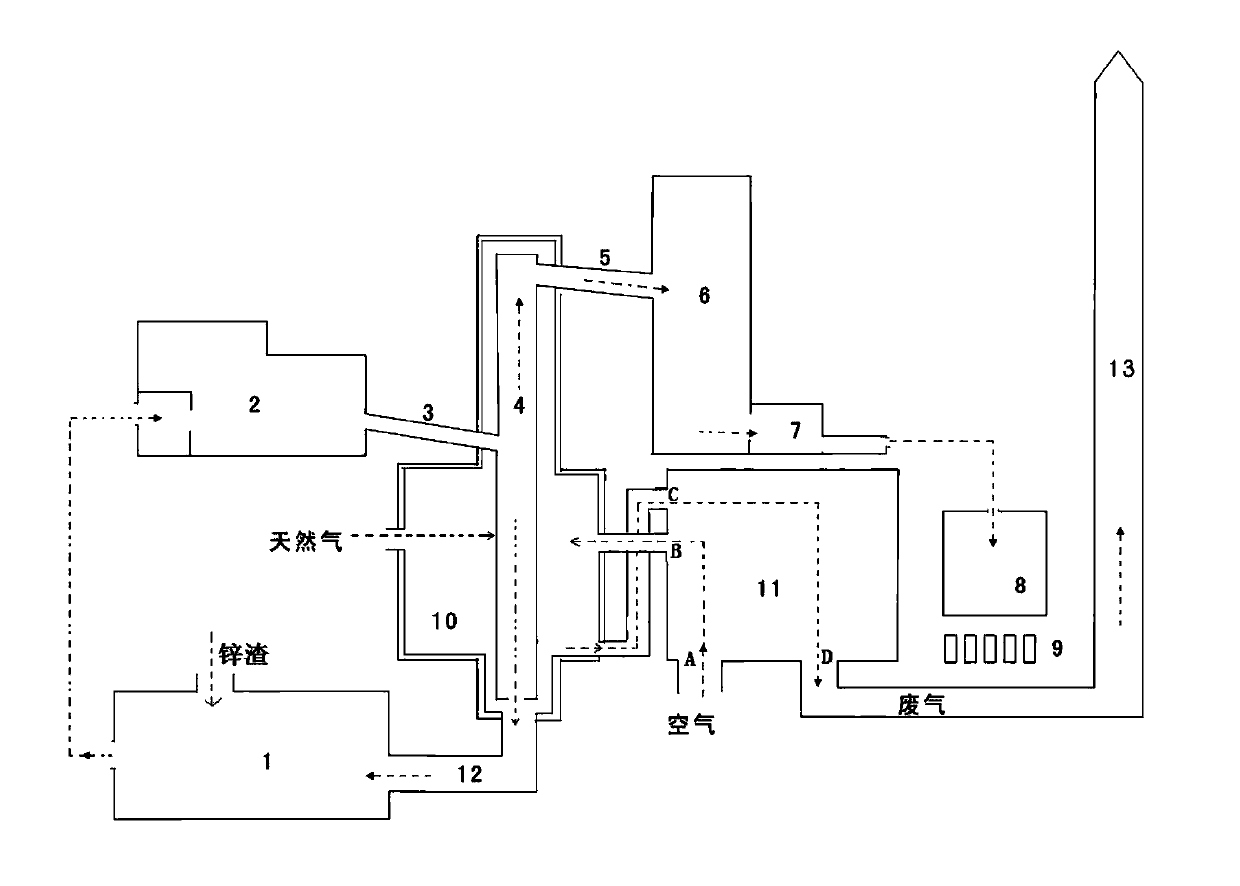

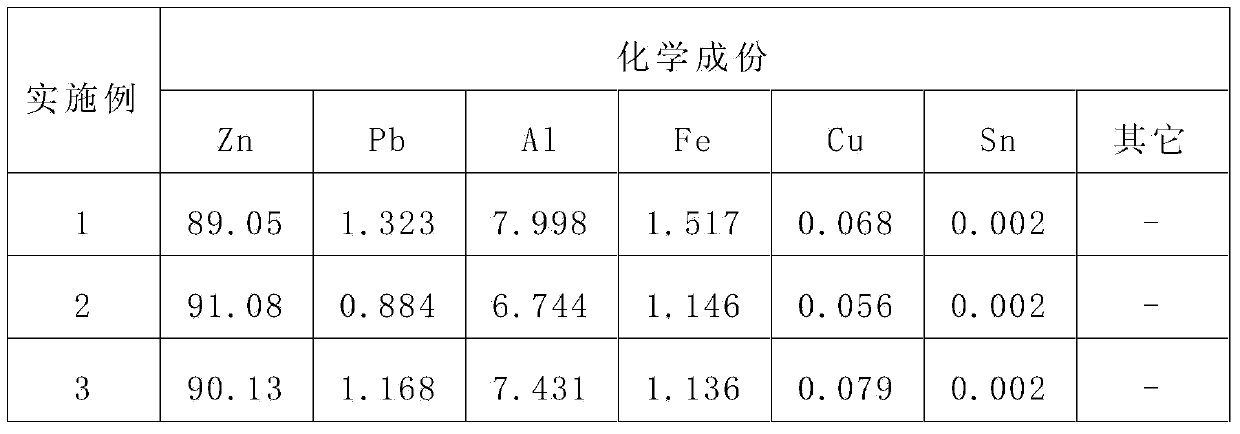

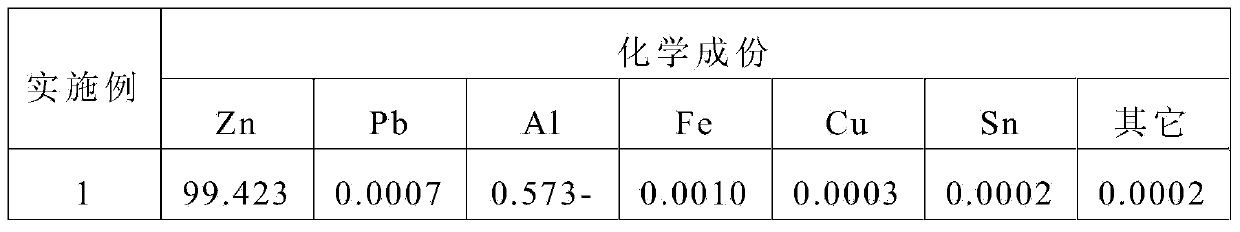

Method and device for producing zinc alloy used for hot dipping by using zinc slag

ActiveCN103602828AReduce consumptionExtended service lifeHot-dipping/immersion processesProcess efficiency improvementSlagZinc alloys

The invention discloses a method and a device for producing a zinc alloy used for hot dipping by using zinc slag. The method comprises the following steps of 1) adding materials for a first time and removing slag for the first time; 2) keeping warm and removing residues; 3) rectifying and heat-exchanging; 4) condensing; 5) re-adding the materials for circulation; 6) preparing the alloy: adding aluminium element in condensed No. 0 zinc liquid according to requirements, and mixing uniformly to cast a alloy ingot. The invention also provides a device for producing the zinc alloy used for hot dipping by using the zinc slag. The method is reasonable in process arrangement and low in production cost, greatly reduces in energy consumption, reduces potential risks, can control the whole production process, and realizes cyclic utilization of resources.

Owner:武汉扬光实业有限公司资源循环科技分公司

Degradable airway stent and application thereof

InactiveCN101785879AStrong anti-infection effectAvoid cloggingStentsSurgeryRare-earth elementIrritation

The invention discloses a degradable airway stent and application thereof. The degradable airway stent contains 80 percent to 99.5 percent of magnesium element in percentage by weight and at least one of aluminium element, manganese element, zinc element, zirconium element, rare earth element, lithium element, calcium element or silver element. The degradable airway stent can be quickly degraded, thus meeting the requirement of the airway on the degradation rate of the stent, and moreover, because the magnesium alloy stent has excellent biocompatibility, the degradable airway stent has less irritation on tissues and high anti-infection capability. Because the surface of the magnesium alloy stent is processed or coated with degradable material and therapeutic medicine, fibrous tissues cannot grow inwards to form granulation tissues, or tumor cells can be prevented from proliferating to block the airway. In addition, the magnesium alloy stent is porously processed, so that the degradation rate of the magnesium alloy stent can be increased. Consequently, the degradable airway stent can be widely applied in airways.

Owner:GUANGDONG GENERAL HOSPITAL

Vacuum distillation method for separating aluminium element from mixed metals in worn-out printing circuit board

InactiveCN1760383ANo pollution in the processReduce pollutionEvaporationProcess efficiency improvementPrinted circuit boardPollution

A process for separating the Pb from the metallic mixture generated by breaking the used or rejected PCBs by vacuum distillation method includes such steps as heating in vacuum furnace, evaporating Pb at 700-800 deg.C and condensing the Pb vapor at 330-360 deg.C. Its advantages are high effect and no pollution.

Owner:SHANGHAI JIAO TONG UNIV

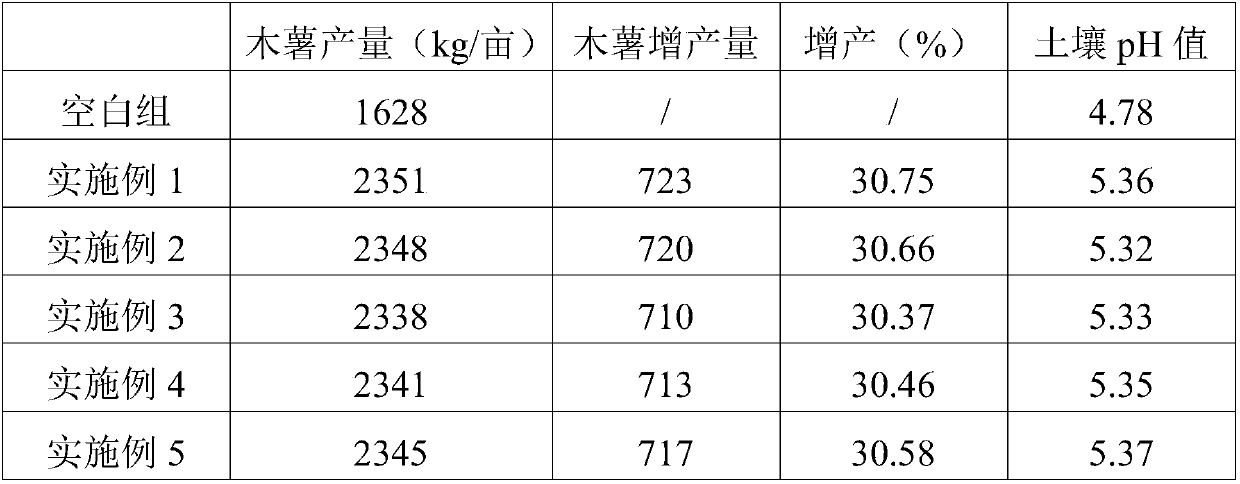

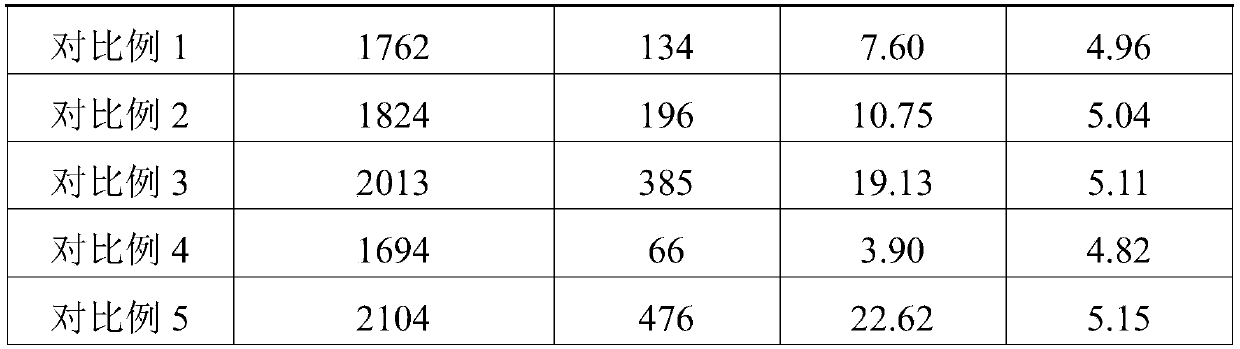

Acid soil conditioner

InactiveCN109097064AAvoid influenceReduce acidityCalcareous fertilisersAgriculture tools and machinesRed mudMicrobial agent

The invention belongs to the technical field of soil conditioning, and specifically relates to an acid soil conditioner. The acid soil conditioner comprises the following raw materials in parts by weight: 50-75 parts of dealumination red mud powder, 15-30 parts of phosphogypsum, 5-10 parts of plant ash, 5-10 parts of a calcium magnesium phosphate fertilizer, 0.5-1 part of a compound microbial agent and 10-25 parts of a cementing material. The acid soil conditioner provided by the invention has the advantages that acid soil can be conditioned in a targeted manner, in particular, a defect that nutrient elements cannot be fixed and retained in the acid soil due to eluviation can be eliminated, aluminium elements in the acid soil can be effectively fixed, and influences of aluminum toxicity onthe soil can be avoided; and meanwhile, sorely lacked potassium, magnesium and calcium in the soil are supplemented, hydrogen and aluminium are adsorbed and cured, the acidic degree of the soil is effectively reduced, soil microcirculation is reconstructed, and yield increasing and income increasing of crops are guaranteed.

Owner:肇庆中奥检测咨询有限公司

Manufacturing method for biomedical titanium alloy TC4ELI rod/wire material

The invention belongs to the technical field of biomedical metallic materials and specifically relates to a manufacturing method for a biomedical titanium alloy TC4ELI rod / wire material. The manufacturing method for the biomedical titanium alloy TC4ELI rod / wire material specifically comprises the following steps: smelting vanadium-aluminum immediate alloy, produced by using an aluminothermic process, and realuminization in a vacuum state at a time; adding a trace amount of strengthening elements of tin and zirconium and a trace amount of refined grain element rare earth in the vacuum smeltingprocess to prepare a new component immediate alloy; mixing the new component immediate alloy and titanium sponge to form a TC4ELI titanium alloy cast ingot; and finally, preparing the TC4ELI titaniumalloy rod / wire material. The manufacturing method for the biomedical titanium alloy TC4ELI rod / wire material, provided by the invention, has the advantages that the process is stable, regional segregation caused by supplementing the elementary aluminium element to the smelted cast ingot is avoided, and the uniformity of trace elements is guaranteed.

Owner:常州博康特材科技有限公司

Low-cost high-plastic-deformation magnesium alloy

The invention discloses a low-cost high-plastic-deformation magnesium alloy. The magnesium alloy comprises the following components in percentage by mass: 0.5-4.0% of Mn, 0.1-0.5% of Al and the balance of magnesium and inevitable impurities. In an Mg-Al-Mn ternary system, elements manganese and aluminum define an aluminum-manganese phase, and a rich manganese element defines an elemental manganesephase. In a preparation process, an extrusion process at a relatively low temperature is adopted to prepare a high-plasticity magnesium alloy material which is suitable for 3C product shells, bearingstructures for leisure goods as well as aerospace parts and the like; and the material is simple in preparation process, is low in cost, and has a very good industrialized prospect.

Owner:CHONGQING UNIV

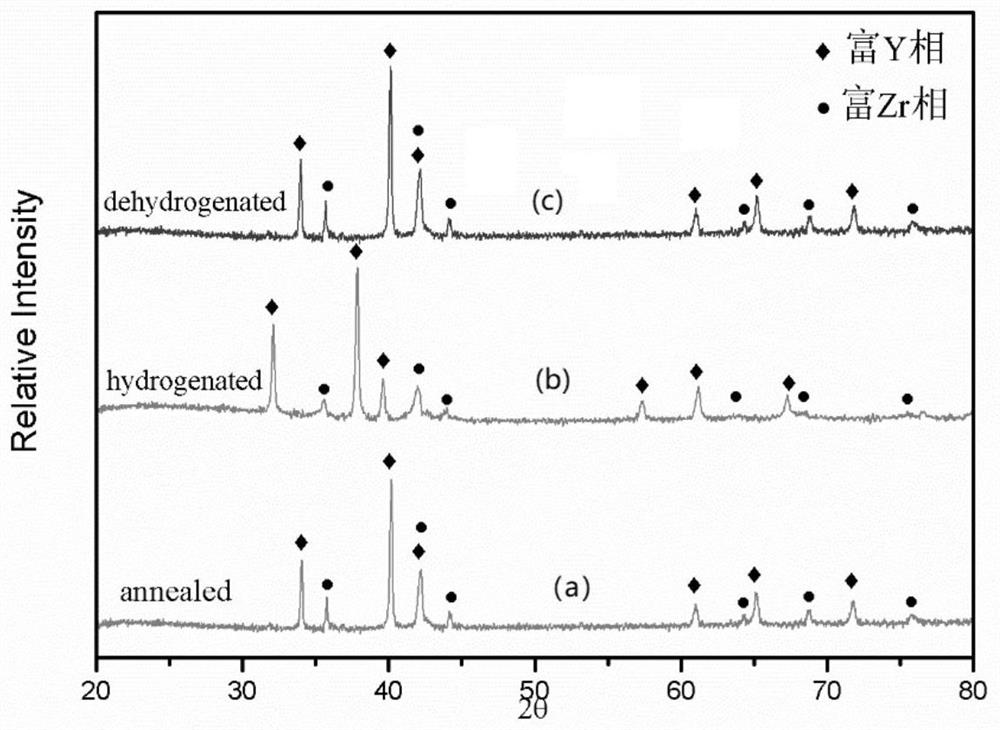

Yttrium-zirconium-iron-aluminum alloy material, preparation method and application

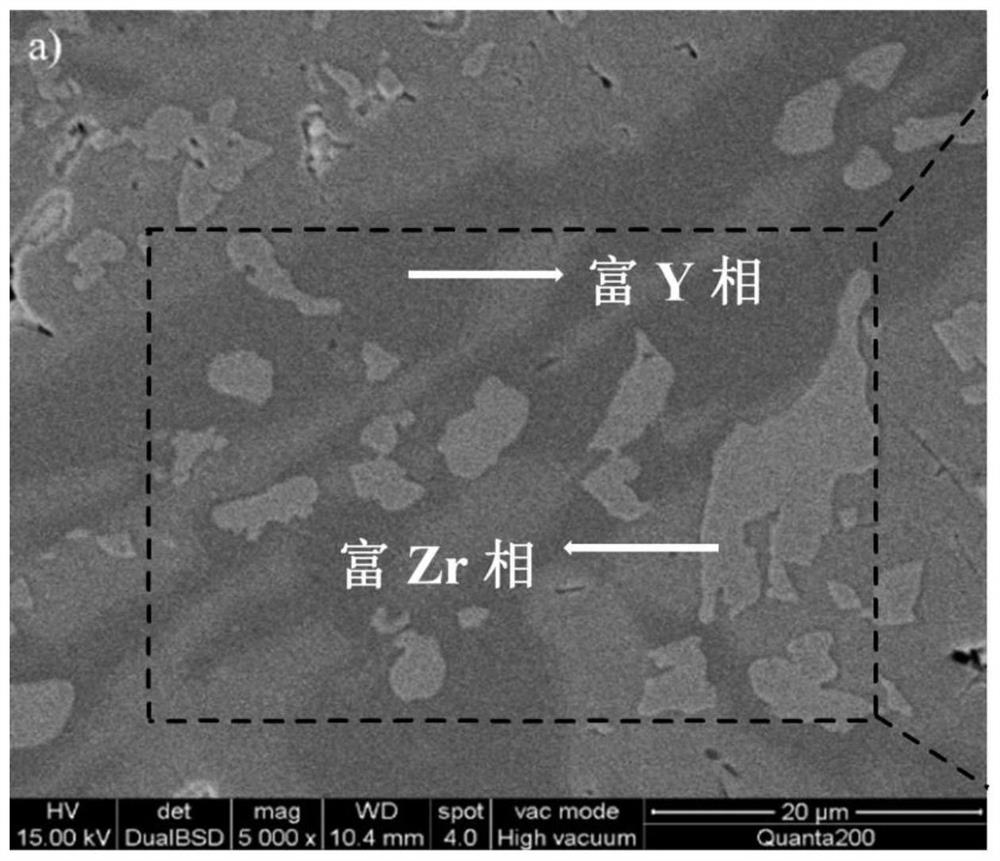

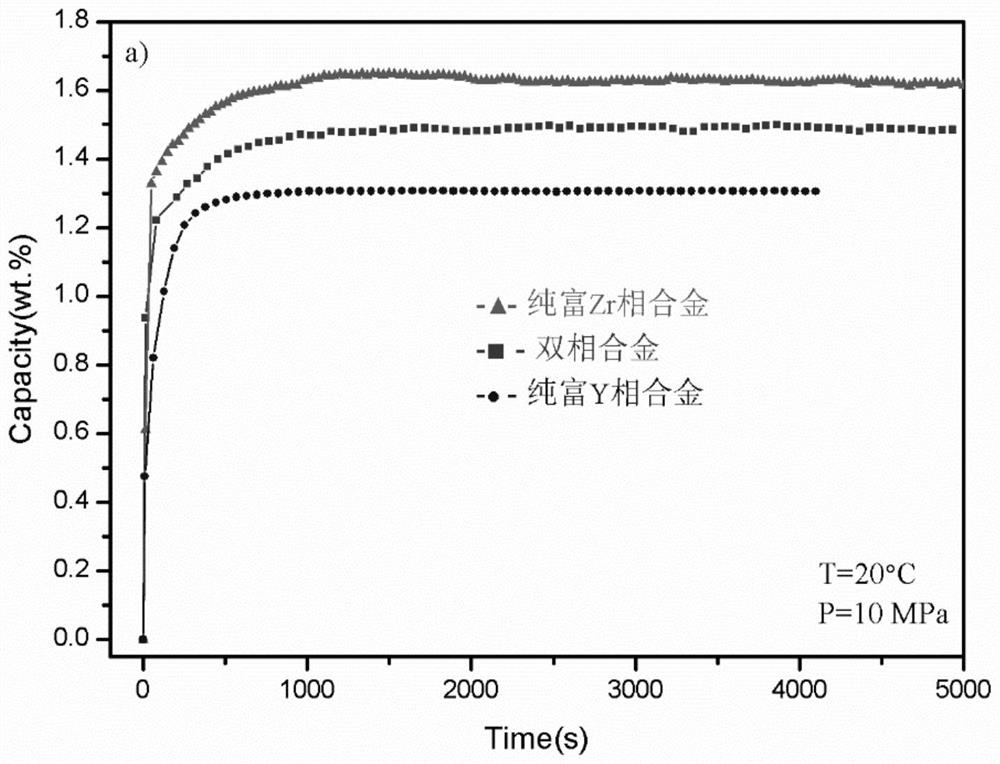

InactiveCN112899548ALow hydrogen absorption and desorption temperatureHigh reversible hydrogen storage capacityHydrogenCell electrodesIngotYttrium

The invention relates to the field of hydrogen storage alloy materials, in particular to an yttrium-zirconium-iron-aluminum alloy material. The chemical general formula of which is Y < 1-x > Zr < x > Fe < 2-y > Al < y >, wherein, 0.25 < x < 0.45, and 0.1 < Y < 0.4. The invention further discloses a preparation method of the yttrium-zirconium-iron-aluminum alloy material. The preparation method comprises the following steps of weighing metal block materials of yttrium, zirconium, iron and aluminum according to the mass ratio of the chemical general formula, mixing, smelting at the temperature of higher than 1600 DEG C, and cooling to obtain an alloy ingot; and placing the obtained alloy cast ingot in an annealing container to be subjected to annealing treatment, and after cooling, crushing the alloy cast ingot into a powder state to obtain the yttrium-zirconium-iron-aluminum alloy material. According to the alloy material, iron and yttrium are partially replaced with the aluminum element with the large atomic radius and the zirconium element with the small atomic radius correspondingly, the prepared yttrium-zirconium-iron-aluminum alloy is of a zirconium-rich phase and yttrium-rich phase double-phase structure, the alloy achieves reversible hydrogen absorption and desorption of the yttrium-rich phase at the room temperature, and the hydrogen storage capacity is obviously improved compared with that of a single yttrium-rich phase.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing crystals of aluminate of at least one metal and/or one metalloid and/or one lanthanide, and applications of same

PendingCN109803926ALow costNo pollution in the processCalcium aluminatesMangesium aluminatesAluminateLiquid medium

To this end, the present invention concerns a method for manufacturing crystals of aluminates of one or more element(s) other than aluminium (Al), referred to as 'A', chosen separately from a metal, ametalloid or a lanthanide, said method comprising at least the following steps: placing starting reagents, comprising at least one aluminium element source and a source of said element(s) A that hasa degree of oxidation of between 1 and 6, in suspension in a liquid medium, so as to form a suspension referred to as the 'starting suspension', milling said starting suspension at an ambient temperature of less than or equal to 50 DEG C, in a three-dimensional liquid medium ball mill for a holding time of less than or equal to 5 minutes; recovering, at the outlet of said three-dimensional ball mill, a suspension referred to as the 'end suspension' comprising said starting reagents in activated form or crystals of aluminate of said element(s) A generally in hydrated form; if required, calcination of said end suspension when it comprises said starting reagents in activated form, so as to obtain generally non-hydrated crystals of aluminate of said element(s) A.

Owner:依瑟尔锌有限公司

High-aluminium alloy and its prepn process

The present invention relates to a high-aluminium alloy and its preparation process, belonging to intermediate alloy scope for deoxidizing molten steel and compounding aluminium element in steel making process. This kind of aluminium alloy with specific weight between that of aluminium and iron is prepared to replace pure aluminium in deoxidizing molten steel and compounding aluminium element. The present invention has stable yield, low total aluminium consumption and saving in resource.

Owner:SHANGHAI ZHENGLI FERRO ALLOY

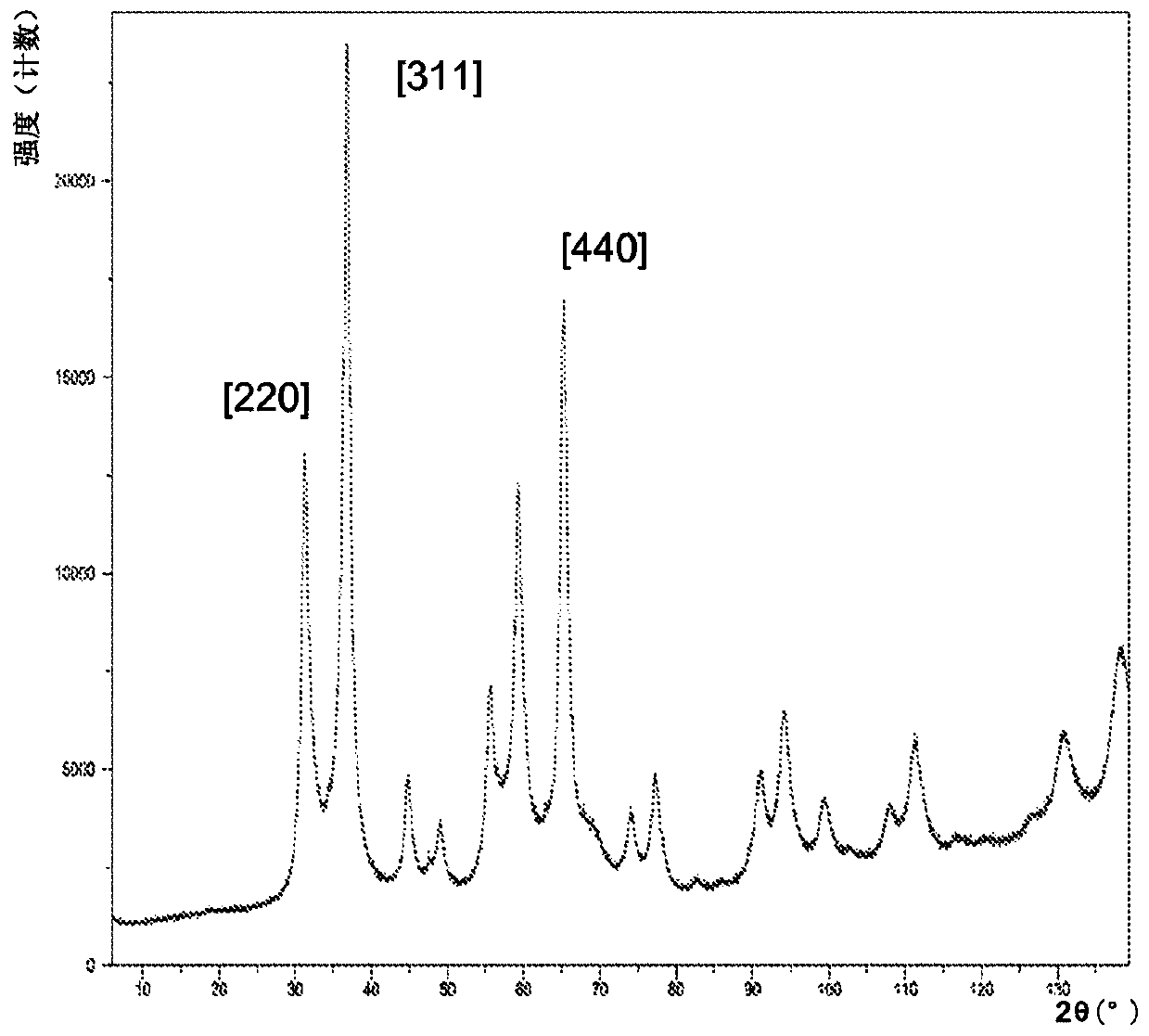

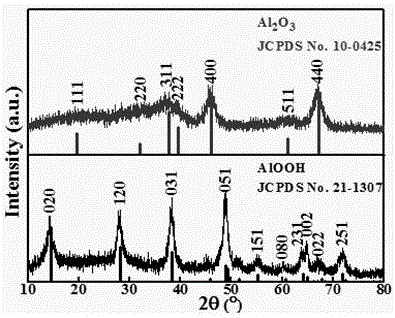

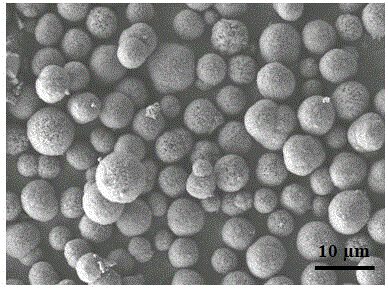

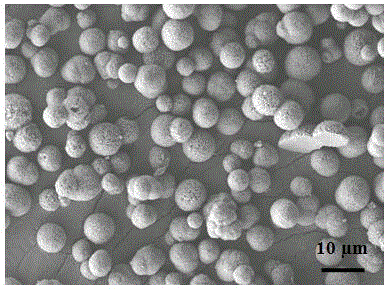

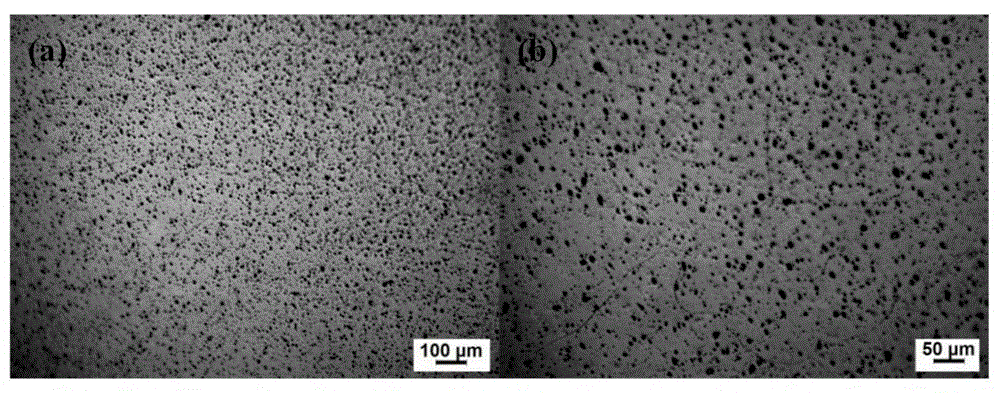

Hydrothermal-thermal conversion method for preparing active boehmite and alumina porous microsphere with red mud as raw material

ActiveCN106830024AHigh crystallinityPure compositionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesRed mudMaterials science

The invention relates to a hydrothermal-thermal conversion method for preparing active boehmite and alumina porous microsphere with red mud as a raw material. The aluminium element extracted from red mud is used as a basic aluminium source and undergoes hydrothermal treatment at 120-210 DEG C in the presence of a proper amount of urea for 1.0-12.0 h so as to prepare AlOOH porous microspheres (diameter is 2.0-10.0 microns and pore diameter is 2-80 nm); and through medium temperature roasting, Al2O3 porous microspheres with morphology maintained greatly are obtained (diameter is 1.5-8.5 microns and pore diameter is 4-120 nm). By using aluminium in waste red mud as the raw material, the AlOOH / Al2O3 porous microsphere structure which has excellent properties and has a wide application prospect in fields of water treatment, industrial catalysis and the like is synthesized by the method. The raw materials are cheap and easily available; equipment is simple; the technological condition is mild; and the method is environment-friendly and is easy for enlarge production.

Owner:QUFU NORMAL UNIV

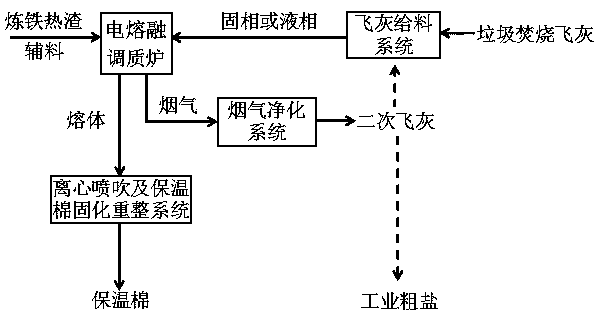

Thermal-insulation cotton prepared from iron making hot slag and waste incineration fly ash, and preparation method thereof

The invention belongs to the technical field of thermal insulation cotton, and more specifically relates to a thermal-insulation cotton prepared from iron making hot slag and waste incineration fly ash, and a preparation method thereof. The thermal-insulation cotton comprises iron making hot slag, waste incineration fly ash, and an auxiliary material at a mass ratio of 1:0.1-0.3:0.01-0.02. The preparation method comprises following steps: 1, iron making hot slag is introduced into an electric melting tempering furnace, and waste incineration fly ash and the auxiliary material are added for high temperature melting mixing; 2, an obtained melt is subjected to centrifugation blowing, and swing hammer cotton spreading to obtain a cotton plate, and the cotton plate is subjected to curing and reforming so as to obtain the thermal-insulation cotton. According to the preparation method, the thermal-insulation cotton is prepared using the heat energy in iron making hot slag, so that iron making hot slag waste energy high efficiency utilization is realized; high temperature treatment is adopted to realize decomposition of dioxin in waste incineration fly ash, separation of a part of heavy metal chlorides and enrichment in secondary fly ash; silicate co-molten substances are formed by a small amount of heavy metal elements left in the melt and other substances, and stabilization is realized; and calcium, silicon, oxygen, and aluminium elements in waste incineration fly ash can be used in thermal insulation cotton preparation.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

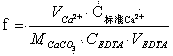

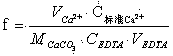

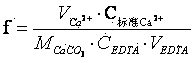

Method for detecting contents of main metal elements in silicate materials

ActiveCN104020163AEasy to detectEasy to operateMaterial analysis by observing effect on chemical indicatorSlagPozzolana

The invention discloses a method for detecting trace elements in silicate materials, which is simple and is strong in operability. The detection method comprises the steps of: (1) preparing a sample to be detected; (2) determining EDTA influence factors; and (3) determining the contents of metal elements such as iron, magnesium, calcium or aluminium. The detection method provided by the invention comprises the step of detecting an iron element, a magnesium element, calcium element and an aluminium element. The detection method disclosed by the invention has the advantages that fast and simple detection for trace metal elements such as iron, magnesium, calcium and aluminium in primary coal ash, blast-furnace slag, volcanic ash and the like, less detection devices are used and the cost is low.

Owner:NANJING TRANSCENDENT NEW MATERIALS TECH CO LTD

Molecular sieve and preparation method thereof

ActiveCN111762794AIncrease the areaLarge pore volumeMolecular sieve catalystsExhaust apparatusRare-earth elementMolecular sieve

Owner:BAOTOU RES INST OF RARE EARTHS +1

High-strength cast magnesium alloy and preparation method thereof

ActiveCN105112751AGood aging precipitation strengthening effectImprove mechanical propertiesUltimate tensile strengthAluminium element

The invention relates to a high-strength cast magnesium alloy. The high-strength cast magnesium alloy is an Mg-Bi-Al-Zn-Sr alloy and comprises components in percentage by weight as follows: 3wt%-8.0wt% of Bi, 0.5wt%-4.0wt% of Al, 0.1wt%-1.0wt% of Zn, 0.05wt%-0.15wt% of Sr and the balance of Mg. The Bi element is used as a main alloy element, a large quantity of Mg3Bi2 phases are formed through simple alloying means, a small quantity of aluminum and zinc elements are used for improving the strength of the alloy, so that the high-strength cast magnesium alloy is developed from the alloy series, and the alloy has the tensile strength of 276-296 MPa, the yield strength of 155-170 MPa and the elongation of 5.3%-7.3% and has mechanical properties comparable with those of rear earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

Method for separating iron element, magnesium element and aluminium element from calcium-removed calcium carbide slag

ActiveCN109694956AEmission reductionEfficient extractionProcess efficiency improvementAluminum IonAluminium hydroxide

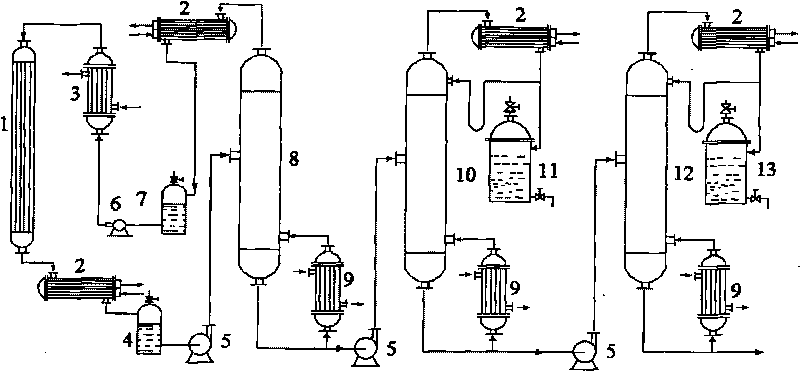

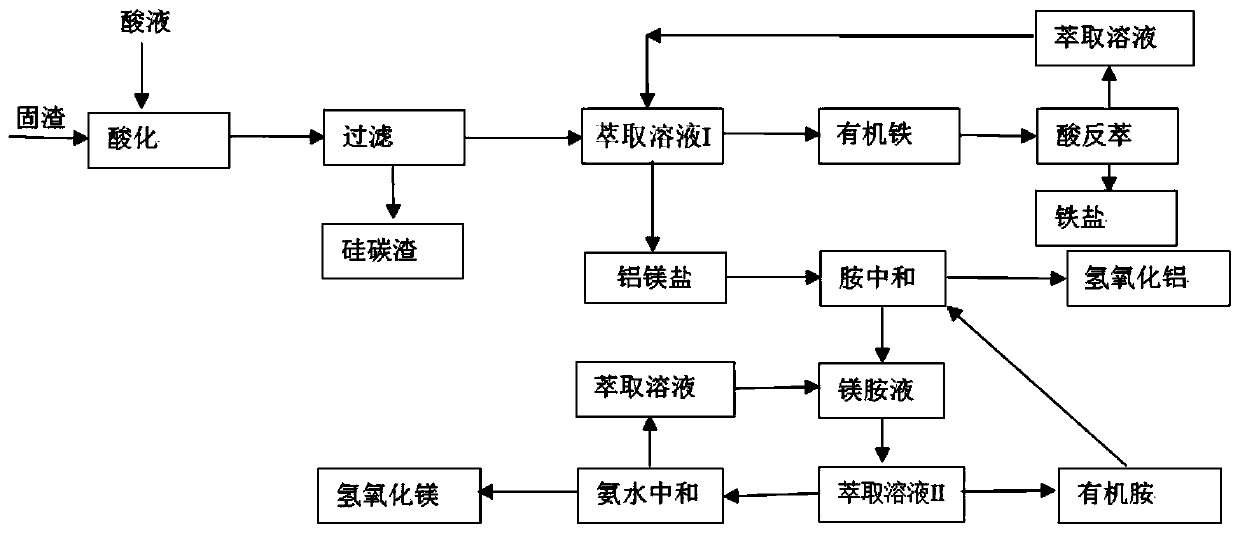

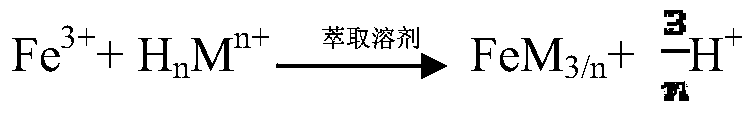

The invention discloses a method for separating an iron element, a magnesium element and an aluminium element from calcium-removed calcium carbide slag. The method for separating the iron element, themagnesium element and the aluminium element from the calcium-removed calcium carbide slag includes the following steps that 1, the calcium-removed calcium carbide slag is acidized with acid, solid substances are filtered out, and then a mixed salt solution containing iron, aluminium and magnesium is obtained; 2, an extraction solution I is added, the ph is adjusted to be smaller than 2.0, an aqueous phase salt solution containing iron organic phase and magnesium aluminium is obtained after stirring and separation; 3, organic amine or an organic amine solution is added dropwise, precipitationof aluminium hydroxide is filtered after precipitation of aluminum ions is completed, and the aqueous phase salt solution containing magnesium is obtained; 4, an extraction solution II containing organic amine is added, and the aqueous solution containing magnesium organic phase and the organic amine is obtained after stirring and separation; and the aqueous solution containing the organic amine is applied in the step 3; and 5, organic phase containing iron and dilute sulfuric acid were stripped countercurrent, and an extractant in the organic phase containing iron is regenerated and applied to the extraction solution I in the step 2. The method for separating the iron element, the magnesium element and the aluminium element from the calcium-removed calcium carbide slag is environmentally-friendly, and the treatment cost is low.

Owner:辽宁赛菲化学有限公司

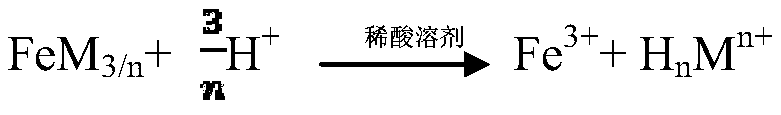

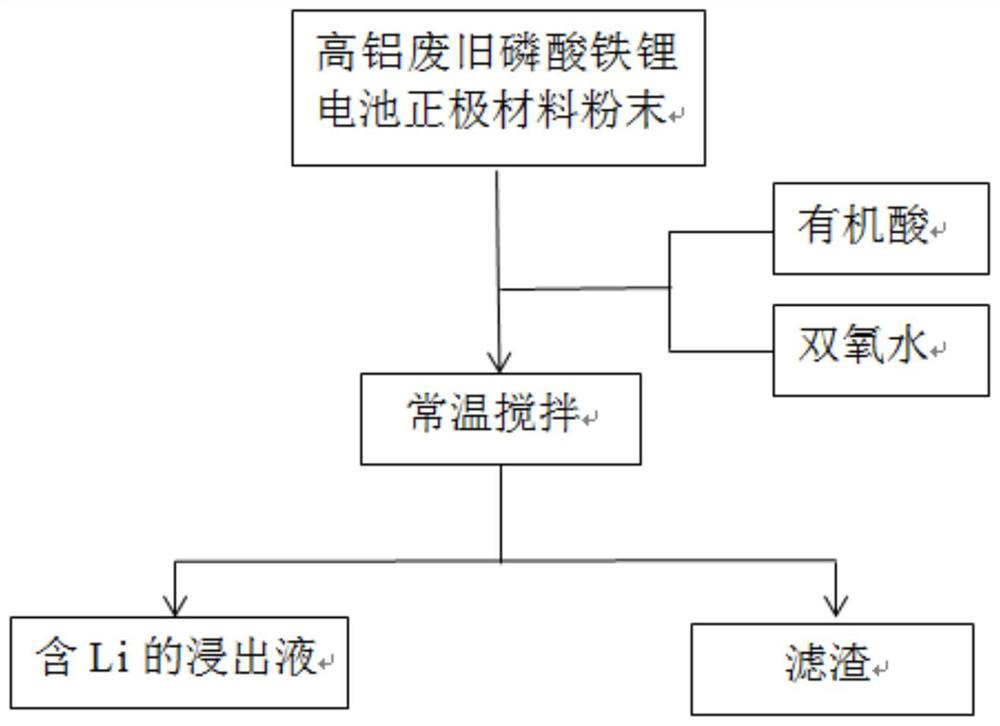

Method for efficiently leaching lithium from high-aluminum waste lithium iron phosphate battery positive electrode material

PendingCN114525407AReduce pollutionImprove leaching rateSecondary cellsBattery recyclingOrganic acidLithium iron phosphate

The invention discloses a method for efficiently leaching lithium from a high-aluminum waste lithium iron phosphate battery positive electrode material, which comprises the following steps: (1) taking the high-aluminum waste lithium iron phosphate battery positive electrode material, taking organic acid as a leaching agent, and taking hydrogen peroxide as a reducing agent; (2) stirring and reacting the system in the step (1) at normal temperature to obtain a reaction solution; and (3) filtering the reaction liquid obtained in the step (2) to obtain filtrate containing lithium, phosphorus, iron and aluminum elements. The pH range of the used organic acid is 1.5-4, the lithium ions are selectively leached at the room temperature, and the leaching rate of other impurity ions is low; under the condition that the leaching rates of lithium ions are roughly the same, compared with the prior art, the consumption of organic acid is less; and the leaching rate is 90% or above at the normal temperature, heating is not needed, the energy consumption needed by the reaction is greatly reduced, and the industrial production cost is low. The method is simple in process, low in cost and easier for industrial production.

Owner:GREEN IND INNOVATION RES INST OF ANHUI UNIV

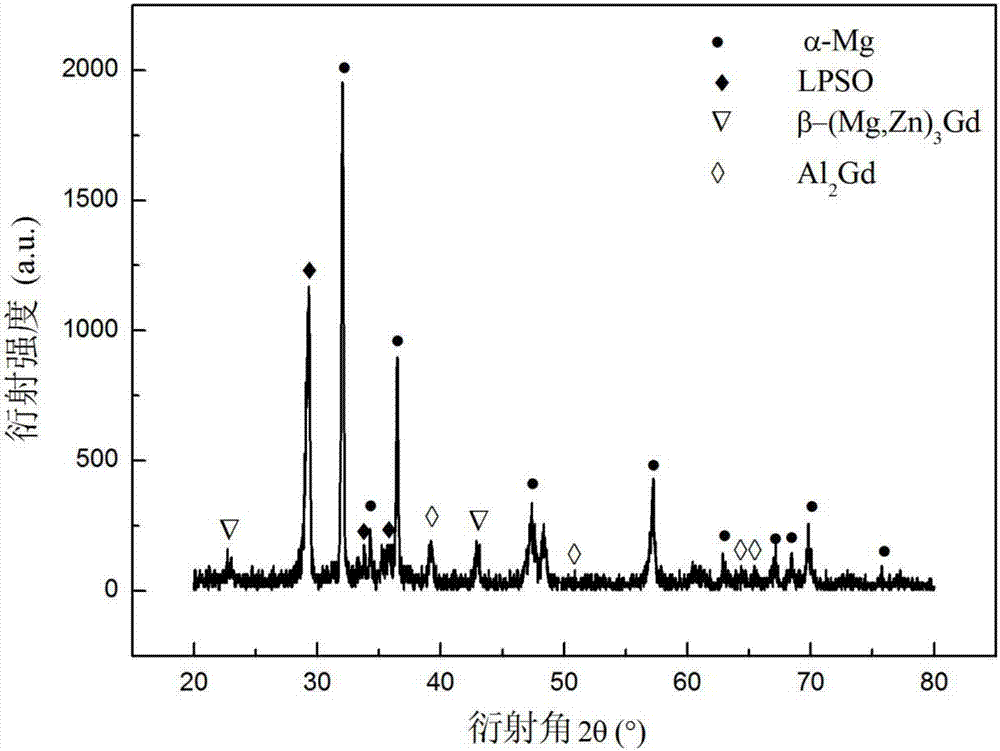

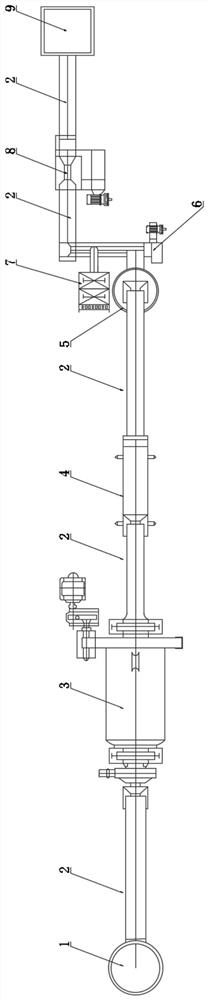

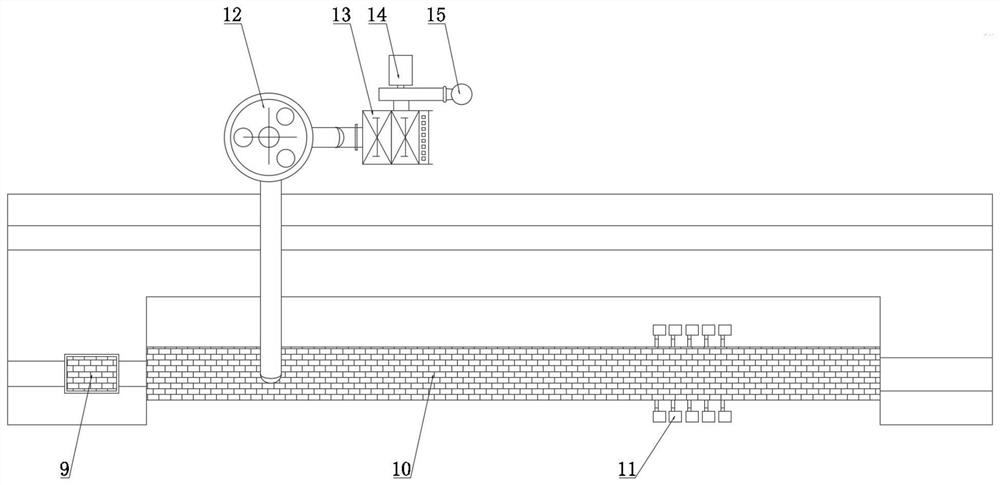

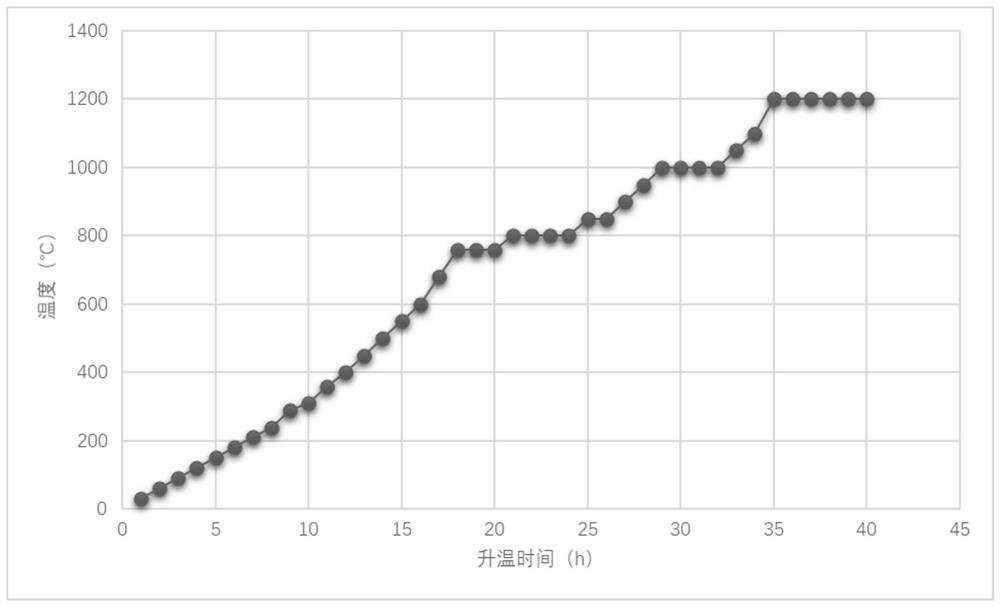

Preparation method of long-period stacking order (LPSO) structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate

The invention relates to a preparation method of a long-period stacking order (LPSO) structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate. The preparation method is aimed at the problem that an LPSO structural phase is hard to form in a cast magnesium gadolinium zinc alloy. The preparation method comprises the steps that calcium and aluminium elements are doped in the magnesium gadolinium zinc alloy, vacuum melting, argon bottom blowing protection and casting ingot forming are adopted, forming of the LPSO structural phase is induced, and a cast LPSO structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy ingot is prepared; and an LPSO structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate enhanced product is prepared through vacuum hot extrusion aging. The preparation method is advanced in technology, data is accurate and detailed, purity of the product is good and reaches 99.6%, strength reaches 417 MPa, elongation is 12%, corrosion voltage of the cast magnesium gadolinium zinc calcium aluminium alloy is minus 0.447 V, corrosion current density is 5.528 * 10<-6> A / cm<2>, corrosion voltage is improved by 3 times and corrosion rate is decreased by 500 times compared with those of the alloy in which Ca and Al are not added.

Owner:TAIYUAN UNIV OF TECH

Denitrfying agent and method for desulfurizing and denitrating refractory bricks by using denitrfying agent

ActiveCN112076618AHarmlessImplement resourcesGas treatmentDispersed particle separationAdhesiveFlue gas

The embodiment of the invention relates to the technical field of aluminum ash hazardous waste treatment, in particular to a denitrifying agent and a method for desulfurizing and denitrifying refractory bricks by using the denitrifying agent, and the denitrifying agent comprises the following components in percentage by weight: 95%-99% of aluminum ash powder and 1%-5% of an adhesive; the denitrifying agent is prepared by the following steps: grinding primary aluminum ash by a ball mill, and screening the ground aluminum ash by a screening machine to obtain a secondary aluminum ash powder raw material; adding the secondary aluminum ash powder raw material and the binder into a double-shaft stirrer according to the mixing amount, and performing uniform stirring and mixing to obtain a uniformly mixed material; and conveying the uniformly mixed material to a forming machine for agglomeration operation to obtain a denitration agent lump material. The denitration agent is used for carrying out deamination treatment on the aluminum ash, nitrogen in the aluminum ash is converted into ammonia gas to be recycled, other types of aluminum elements are prepared into aluminum oxide powder to berecycled, and harmlessness, resource utilization and benefit of aluminum ash treatment are achieved; the flue gas of the refractory brick is efficiently purified by roasting the denitrifying agent andthe refractory brick together.

Owner:刘保成

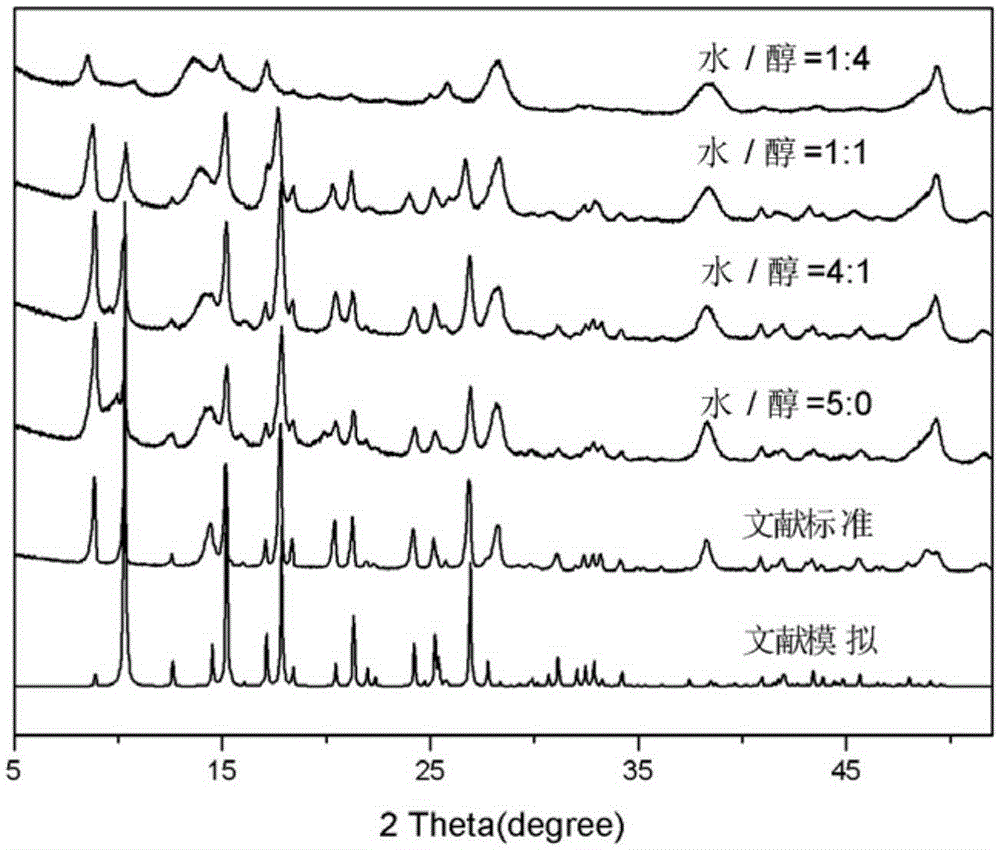

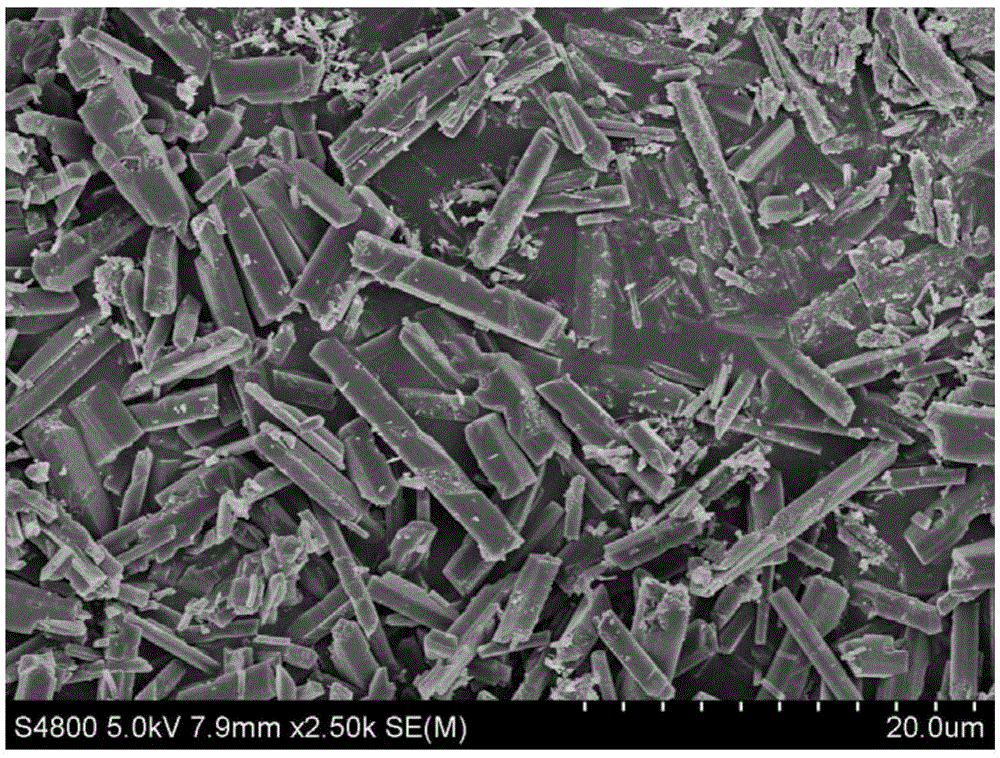

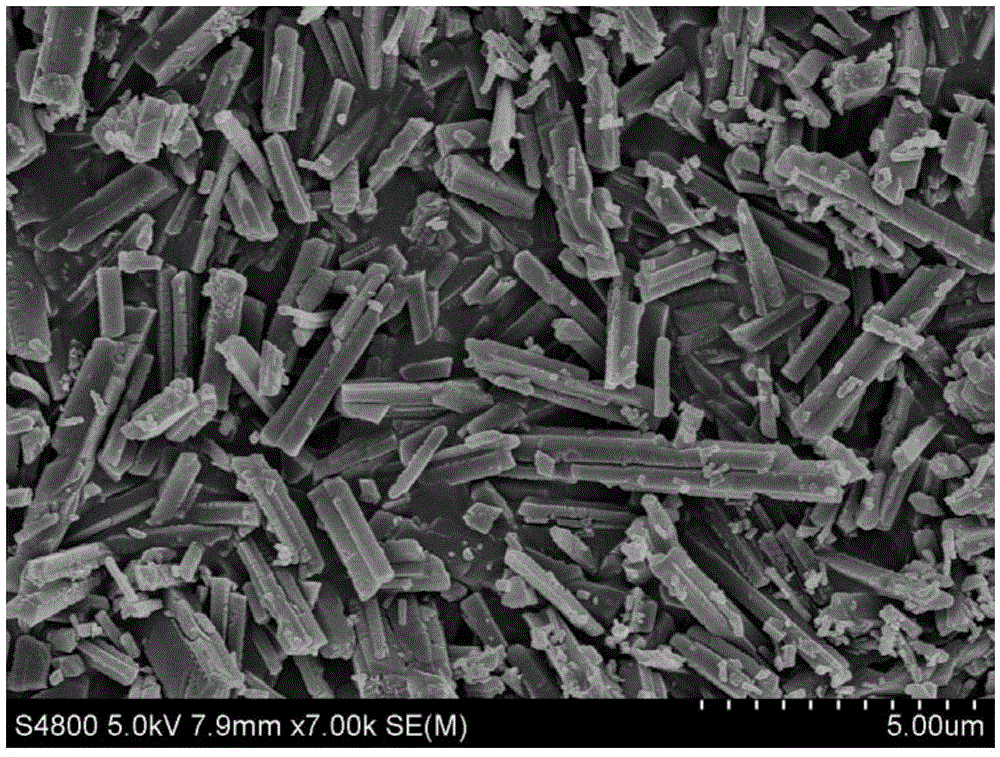

A nanoscale aluminum-based metal-organic framework material and its preparation method

InactiveCN104497032BControl release speedAchieving controllable synthesisOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkAluminum metal

A nanoscale aluminium-based metal-organic framework structure material and its preparation method belong to the field of new material technology. The preparation method comprises the following steps: weighing an organic aluminum source and 1,4-terephthalic acid and putting them in a teflon reaction vessel, adding a solvent, and uniformly mixing by stirring, ultrasound or concussion, wherein the molar ratio of aluminium in the organic aluminum source to 1,4-terephthalic acid is 1.5-4:1 and the solvent is a mixture of water and ethanol which accounts for 0-50% (vol) of the mixed solvent; sealing the reaction vessel, reacting at 200-220 DEG C for 60-80 hours, and cooling to room temperature; and filtering the above reaction liquid, washing precipitates with deionized water and ethanol respectively, drying at room temperature to obtain a light yellow powdery product, namely the nanoscale aluminium-based metal-organic framework structure material. By the above method, release speed of aluminium ion can be controlled effectively, and controllable synthesis of the MIL-53(Al) material can be realized at micro-level by changing the aluminium source.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preventing profiled steel plate from hydrogen fluoride corrosion and structure thereof

ActiveCN101927235AExtended service lifeTo overcome the disadvantage of instability of acid corrosion resistanceLiquid surface applicatorsAnti-corrosive paintsChemical reactionLacquer

The invention discloses a method for preventing profiled steel plate from hydrogen fluoride corrosion and a structure thereof. A substrate is subject to rust removing and cleaning pre-treatment, then surface treating agent is sprayed, and then phenolic resin anticorrosion paint is sprayed, drying is carried out for 24 hours, and then fluorocarbon lacquer is sprayed. The substrate of the inventionadopts galvanized steel plate with the thickness of 0.5-0.8mm, the defect that aluminium element and HF acid react as aluminium-plated zinc steel plate is adopted is overcome, and the service life ofthe substrate is prolonged. The inner layer and outer layer of the substrate adopt the composite way that epoxy anticorrosive paint primer is added with fluorocarbon finish paint, the defects that the acid corrosion resistance of monolayer protective layer is unstable and monolayer modified epoxy anticorrosion paint is not resistant to ultraviolet ray and is easy to be aged under sunlight are overcome, and fluorocarbon paint has good ultraviolet ray resistance and acid resisting capability, is difficult to be aged or invalid under sunlight and has the advantage of good combination with modified epoxy anticorrosion paint.

Owner:GUIYANG AL-MG DESIGN & RES INST

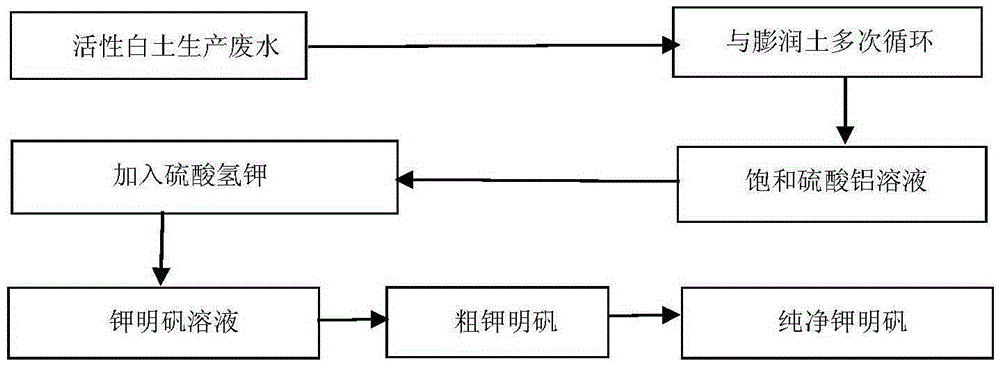

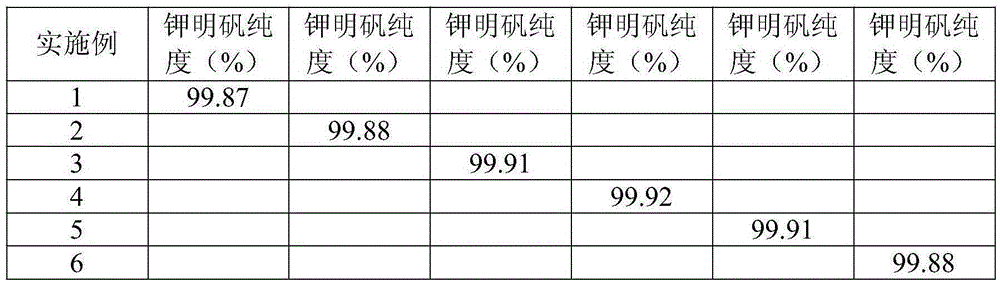

Method used for recovery preparation of aluminum potassium sulfate from activated clay production waste water

InactiveCN105399126AReduce manufacturing costShorten the production cycleAluminium sulfatesHydrogen SulfatePotassium

The invention discloses a method used for recovery preparation of aluminum potassium sulfate from activated clay production waste water, and belongs to the technical field of waste water treatment and inorganic salt preparation. According to the invention, activated clay production waste water and bentonite are recycled for a plurality of times until saturation of aluminum sulfate dissolved in the mixture of activated clay production waste water and bentonite is achieved, the mixture is reacted with potassium hydrogen sulfate, and aluminum potassium sulfate with the purity raging from 99.87 to 99.92% is obtained via two times of crystallization. The method can be used for treating activated clay production waste water effectively, full utilization of aluminium element in activated clay production waste water is realized, energy is saved, emission is reduced, waste is changed into valuables, effective utilization of energy of coal smoke exhausted gas is realized, and aluminum potassium sulfate is dried at a higher temperature, so that production period of the method is shorter than that of the prior art.

Owner:罗永城

Environment-friendly high-corrosion-resistance copper-aluminum rare earth alloy material for electric power and preparation method thereof

InactiveCN110029253AHigh strengthGrain refinementConductive materialMetal/alloy conductorsRare-earth elementPliability

The invention relates to the technical field of alloy materials, in particular to an environment-friendly high-corrosion-resistance copper-aluminum rare earth alloy material for electric power and a preparation method thereof. The composition comprises the following components in percentage, by weight, 3.0 wt% to 4.5 wt% of Cu, 0.05 wt% to 0.15 wt% of Ti, 0.01 wt% to 0.3 wt% of Mn, 0.01 wt% to 0.3wt% of Cr, 0.02 wt% to 2 wt% of rare earth Re and the balance of Al. the copper is added to improve the casting surface quality and form a copper-aluminum compound with aluminum, so that the strengthof the alloy is improved, and the corrosion resistance of the copper element is improved, under the synergistic effect of the aluminum element and the aluminum element, when the surface is oxidized,the conductivity can not be reduced; the titanium can be added to refine grains, the casting surface quality is improved, the titanium and aluminum form an aluminum-titanium compound, and the strengthof the alloy is improved; meanwhile, due to the synergistic effect of the titanium element, the electric conductivity is not reduced; the rare earth element is added, so that the metal crystal structure in the alloy can be better optimized, the toughness of the alloy is improved, the bending cracks are greatly improved, the overall conductivity of the product is improved, and meanwhile, the physical and mechanical properties of the alloy are greatly improved.

Owner:合肥磊科机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com