High-strength cast magnesium alloy and preparation method thereof

A technology for casting magnesium alloys and magnesium alloys is applied in the fields of non-rare earth low-cost, high-strength casting magnesium alloys and their preparation, Mg-Bi-Al-Zn-Sr alloys and their preparation fields, and can solve problems such as increasing the cost of alloys and achieve Energy saving, low alloy cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

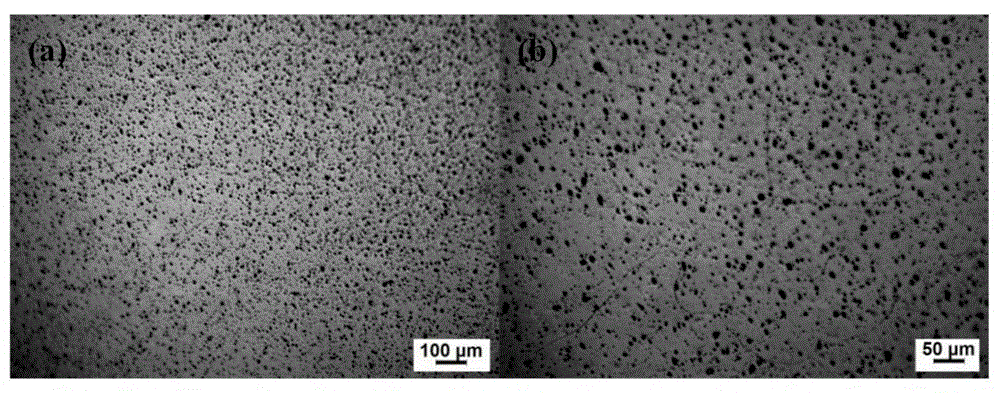

Embodiment 1

[0035] (1) Take raw material by the mass percent of alloy Mg-3.8Bi-3.2Al-0.5Zn-0.05Sr (wt%): pure Bi, pure Al, pure Zn and Mg-5Sr master alloy, all the other are Mg (per 1000 The gram target alloy can be prepared by 10 grams of Mg-5Sr, 32 grams of Al, 5 grams of Zn, 38 grams of Bi and 917 grams of Mg); and do a good job of surface treatment of raw materials (such as removing dirt, scale, etc.).

[0036] (2) First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, and slowly heat the heating rate to 20-40°C / min And maintain the set furnace temperature.

[0037] (3) After the pure magnesium ingots are completely melted, respectively add pure Bi, pure Al, pure Zn and Mg-5Sr intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep warm 5 to 10 minutes, then mechanically stirred for 3 to 5 minutes, then ...

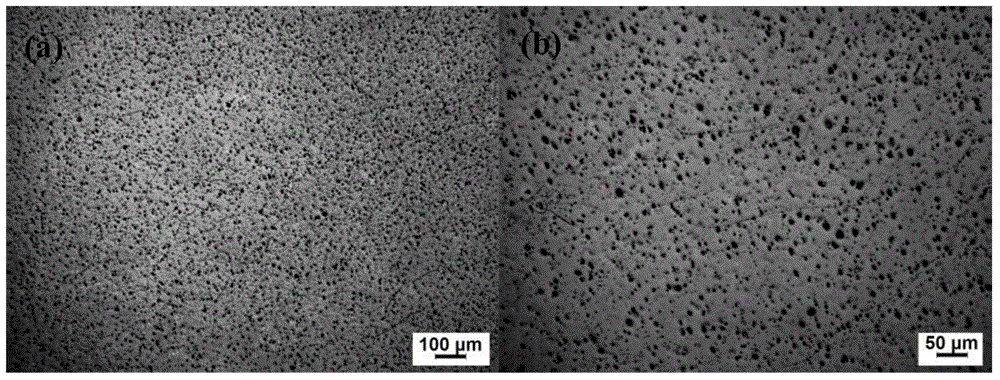

Embodiment 2

[0042] (1) Take raw material by the mass percent of alloy Mg-6Bi-2.0Al-0.6Zn-0.08Sr (wt%): pure Bi, pure Al, pure Zn and Mg-5Sr master alloy, all the other are Mg; And do well Surface treatment of raw materials (such as removal of dirt, scale, etc.).

[0043] (2) First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, and slowly heat the heating rate to 20-40°C / min And maintain the set furnace temperature.

[0044] (3) After the pure magnesium ingots are completely melted, respectively add pure Bi, pure Al, pure Zn and Mg-5Sr intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep warm 5 to 10 minutes, then mechanically stirred for 3 to 5 minutes, then filled with argon for refining and degassing, then adjusted the furnace temperature to the pouring temperature of 720°C, stood for 2 to 10 minutes,...

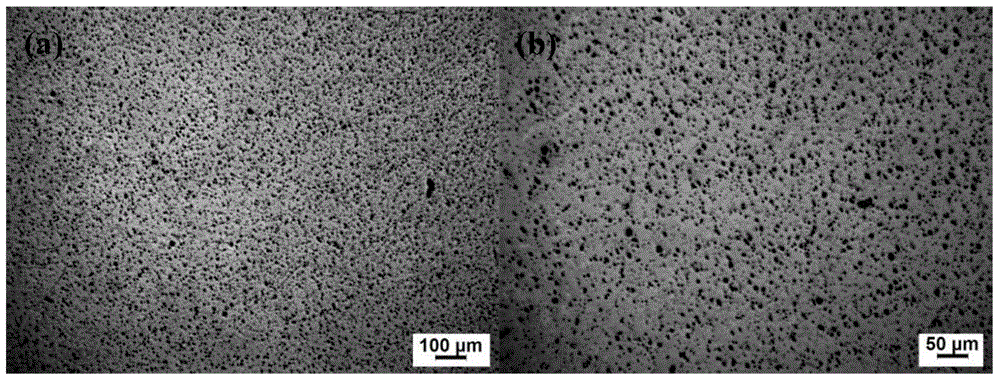

Embodiment 3

[0049] (1) Take raw material by the mass percent of alloy Mg-7.0Bi-1.0Al-1.0Zn-0.08Sr (wt%): pure Bi, pure Al, pure Zn and Mg-5Sr master alloy, all the other are Mg; And do Good raw material surface treatment (such as removal of dirt, scale, etc.).

[0050] (2) First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, and slowly heat the heating rate to 20-40°C / min And maintain the set furnace temperature.

[0051] (3) After the pure magnesium ingots are completely melted, respectively add pure Bi, pure Al, pure Zn and Mg-5Sr intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep warm 5 to 10 minutes, then mechanically stirred for 3 to 5 minutes, then filled with argon for refining and degassing, then adjusted the furnace temperature to the pouring temperature of 720°C, stood for 2 to 10 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com