Heat-resistant creep-resistant magnesium alloy and preparing method thereof

A technology of anti-creep and magnesium alloy, which is applied in the field of metal materials and metallurgy, can solve the problems that magnesium alloys cannot be well applied, and achieve the effects of increasing the aging precipitation strengthening effect, refining grains, and improving plasticity and casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

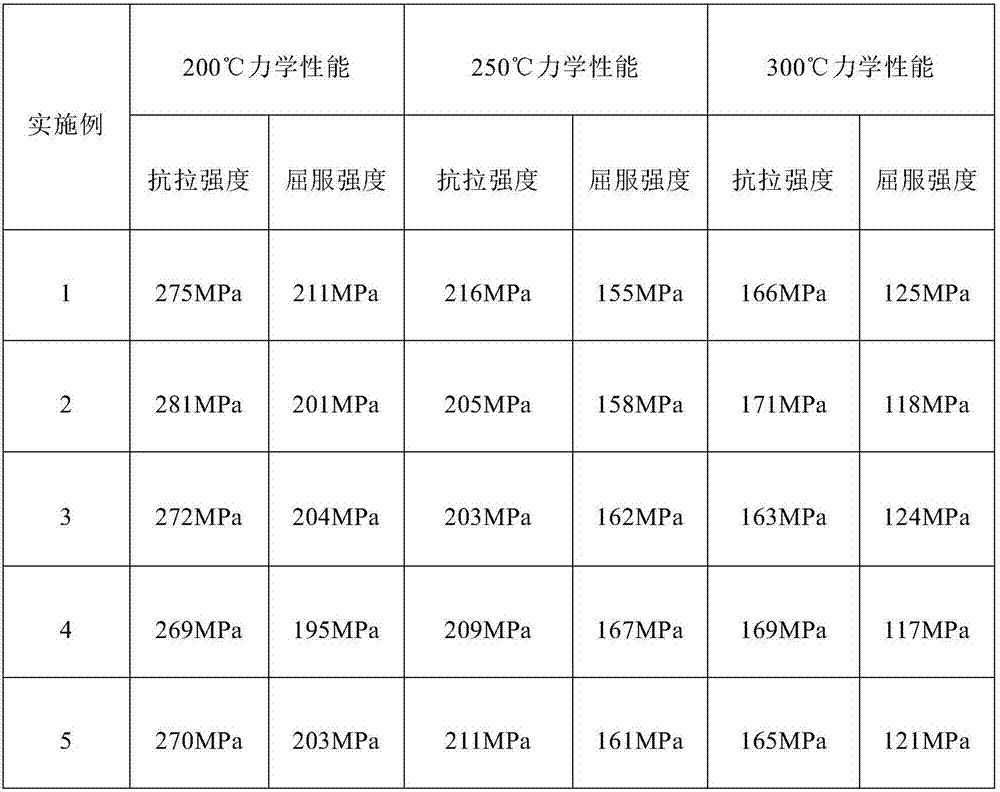

Examples

Embodiment 1

[0035] In this embodiment, the heat-resistant and creep-resistant magnesium alloy is composed of the following components in mass percentage: 7% Sm, 0.8% Nd, 1.8% Zn, 1.0% Ca, 1.5% Mn, 1.1% Al, and the balance is Mg and not Avoid impurities. The inevitable impurity elements are Si, Fe, Cu, Ni; the sum of the mass percentages of Si, Fe, Cu, Ni is less than 0.015%.

[0036] The preparation method of the heat-resistant and creep-resistant magnesium alloy in this embodiment comprises steps:

[0037] (1) Place the pure magnesium, pure aluminum, pure zinc and magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy, magnesium manganese master alloy respectively in the dry box of 200 ℃ for separate preheating, preheat The heating time is 2 hours;

[0038] (2) in CO 2 with SF 6 In the mixed gas atmosphere, melt the magnesium, aluminum and zinc preheated in step (1), and when heated to 740 ° C, add the magnesium samarium master alloy, magnes...

Embodiment 2

[0042] In this embodiment, the heat-resistant and creep-resistant magnesium alloy is composed of the following components in mass percentage: 7.5% Sm, 0.7% Nd, 2.0% Zn, 1.3% Ca, 1.2% Mn, 1.3% Al, and the balance is Mg and not Avoid impurities. The inevitable impurity elements are Si, Fe, Cu, Ni; the sum of the mass percentages of Si, Fe, Cu, Ni is less than 0.015%.

[0043] The preparation method of the heat-resistant and creep-resistant magnesium alloy in this embodiment comprises steps:

[0044] (1) Place the pure magnesium, pure aluminum, pure zinc and magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy, magnesium manganese master alloy respectively in the dry box of 210 ℃ for separate preheating, preheat The heating time is 2 hours;

[0045] (2) in CO 2 with SF 6 In a mixed gas atmosphere, melt the preheated magnesium, aluminum, and zinc in step (1), and when heated to 750°C, add the preheated magnesium samarium master allo...

Embodiment 3

[0049] In this embodiment, the heat-resistant and creep-resistant magnesium alloy is composed of the following components in mass percentage: 7.8% Sm, 0.9% Nd, 1.9% Zn, 1.2% Ca, 1.5% Mn, 1.3% Al, and the balance is Mg and not Avoid impurities. The inevitable impurity elements are Si, Fe, Cu, Ni; the sum of the mass percentages of Si, Fe, Cu, Ni is less than 0.015%.

[0050] The preparation method of the heat-resistant and creep-resistant magnesium alloy in this embodiment comprises steps:

[0051] (1) Place the pure magnesium, pure aluminum, pure zinc and magnesium samarium master alloy, magnesium neodymium master alloy, magnesium calcium master alloy, magnesium manganese master alloy respectively in the dry box of 210 ℃ for separate preheating, preheat The heating time is 2 hours;

[0052] (2) in CO 2 with SF 6 In the mixed gas atmosphere, melt the magnesium, aluminum and zinc preheated in step (1), and when heated to 740 ° C, add the magnesium samarium master alloy, magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com