Method for efficiently leaching lithium from high-aluminum waste lithium iron phosphate battery positive electrode material

A technology for lithium iron phosphate batteries and positive electrode materials, which is applied in secondary batteries, battery recycling, circuits, etc., can solve the problem that lithium and other metals are difficult to selectively recycle, and achieve easy industrial production, low corrosion, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

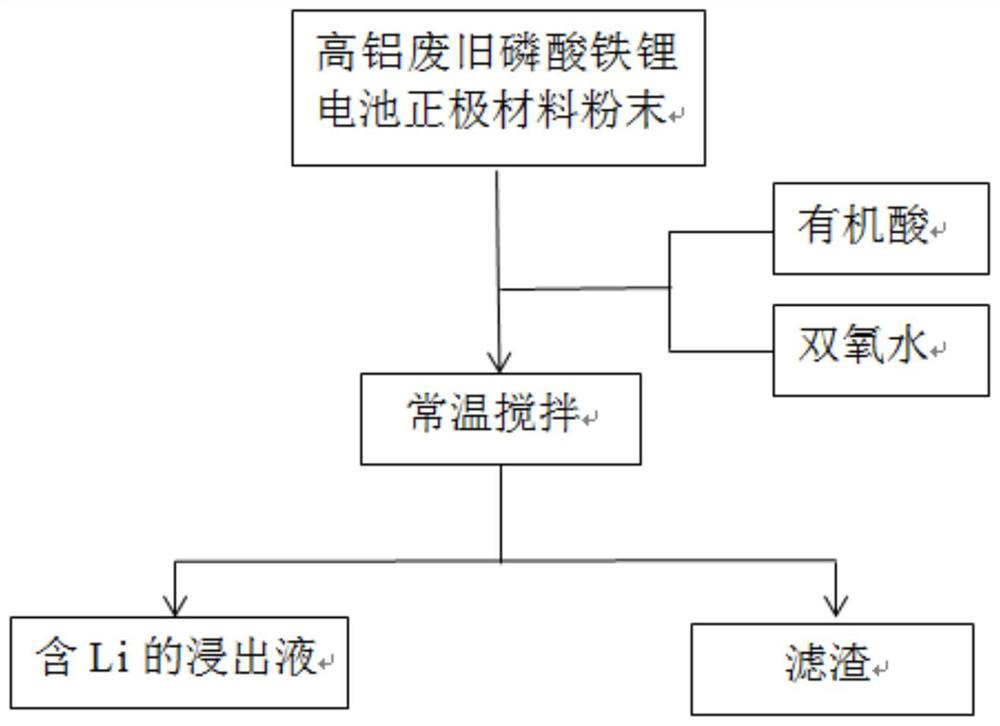

Image

Examples

Embodiment 1

[0025] A method for efficiently extracting lithium from the cathode material of high-alumina scrap lithium iron phosphate battery, comprising the following steps:

[0026] (1) Weigh 10g of high alumina waste lithium iron phosphate battery cathode material powder in a 250ml three-mouth flask, add 100ml, pH = 1.5 citric acid, and add 4ml of hydrogen peroxide with a mass fraction of 30% drop by drop;

[0027] (2) Place the three-mouth flask in step 1 above at room temperature, and react at a stirring speed of 300 rpm for 60 min;

[0028](3) After the reaction is completed, the reaction liquid is filtered and washed, and the filtrate is a solution containing lithium, phosphorus, iron and aluminum.

[0029] Measure li in its filtrate + The leaching rate is 90.03% Fe 2+ / Fe 3+ The leaching rate is 2.3%, Al 3+ The leaching rate is 28.9%.

Embodiment 2

[0031] A method for efficiently extracting lithium from the cathode material of high-alumina scrap lithium iron phosphate battery, comprising the following steps:

[0032] (1) Weigh 10g of high alumina waste lithium iron phosphate battery cathode material powder in a 250ml three-mouth flask, add 100ml, pH = 2 citric acid, and add 4ml of hydrogen peroxide with a mass fraction of 30% drop by drop;

[0033] (2) Place the three-mouth flask in step 1 above at room temperature, and react at a stirring speed of 300 rpm for 60 min;

[0034] (3) After the reaction is completed, the reaction liquid is filtered and washed, and the filtrate is a solution containing lithium, phosphorus, iron and aluminum.

[0035] Measure li in its filtrate + The leaching rate is 92.3% Fe 2+ / Fe 3+ The leaching rate is 8.4%, Al 3+ The leaching rate is 35.3%.

Embodiment 3

[0037] A method for efficiently extracting lithium from the cathode material of high-alumina scrap lithium iron phosphate battery, comprising the following steps:

[0038] (1) Weigh 10g of high alumina waste lithium iron phosphate battery cathode material powder in a 250ml three-mouth flask, add 100ml, pH = 2 citric acid, and add 10ml of hydrogen peroxide with a mass score of 30% drop by drop;

[0039] (2) Place the three-mouth flask in step 1 above at room temperature, and the reaction at 300 rpm stirring speed is 90min;

[0040] (3) After the reaction is completed, the reaction liquid is filtered and washed, and the filtrate is a solution containing lithium, phosphorus, iron and aluminum.

[0041] Measure its filtrate where Li + The leaching rate is 91.5% Fe2+ / Fe 3+ The leaching rate was 12.3% Al 3+ The leaching rate was 41.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com