Preparation method of long-period stacking order (LPSO) structural phase enhanced magnesium gadolinium zinc calcium aluminium alloy plate

A calcium-aluminum alloy, magnesium-gadolinium-zinc technology is applied in the field of preparation of long-period ordered stacking structure phase reinforced magnesium-gadolinium-zinc-calcium-aluminum alloy sheets, which can solve the problem of long production cycle, difficulty in forming LPSO phase, and small number of X phases, etc. problems, to achieve the effect of reducing the corrosion rate, increasing the corrosion voltage, and improving the corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with accompanying drawing:

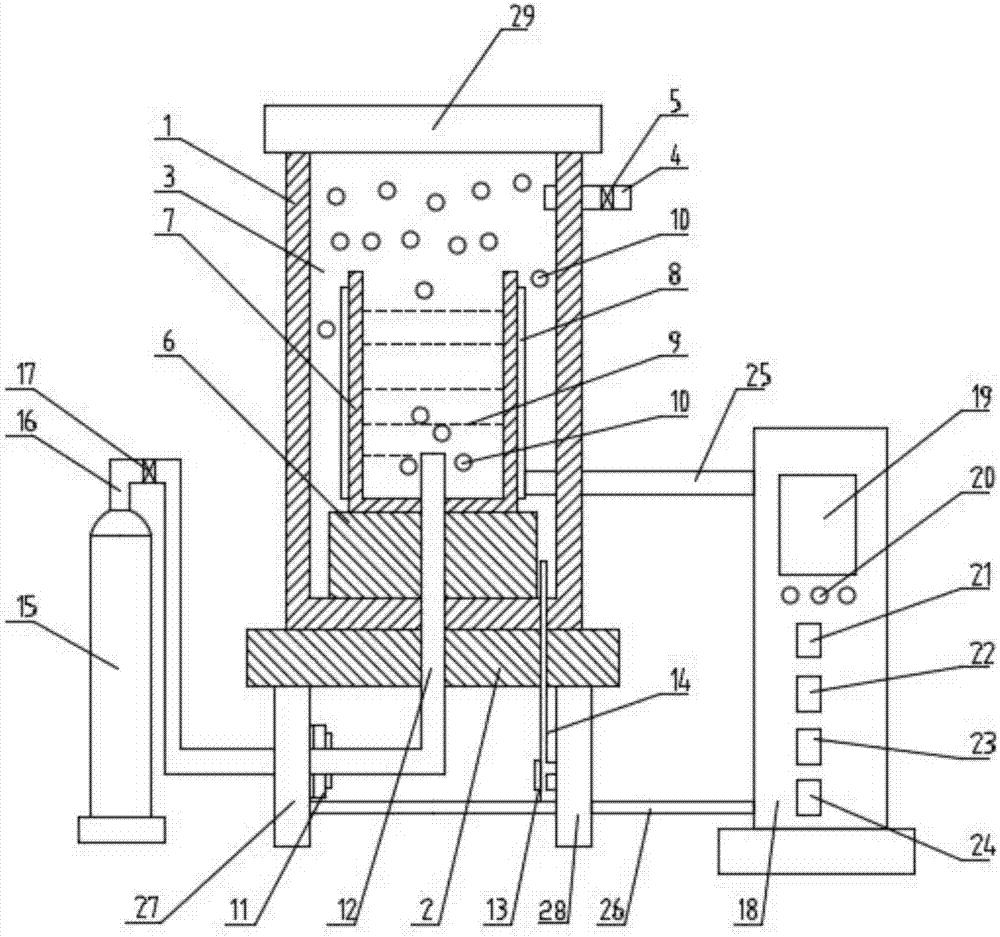

[0084] figure 1 As shown, it is the smelting state diagram of magnesium-gadolinium-zinc-calcium-aluminum alloy with phase-reinforced magnesium-gadolinium-zinc-calcium-aluminum alloy in the as-cast long-period orderly stacking structure.

[0085] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0086] The vacuum melting furnace is vertical, the bottom of the vacuum melting furnace 1 is a furnace base 2, the top is a furnace cover 29, and the interior is a furnace chamber 3; a left bracket 27 and a right bracket 28 are arranged at the bottom of the furnace base 2; The upper right part of 1 is provided with an outlet pipe 4 and a control valve 5; a workbench 6 is provided at the inner bottom of the furnace chamber 3, and a melting crucible 7 is placed on the upper part of the melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com