Method and device for producing zinc alloy used for hot dipping by using zinc slag

A zinc alloy and zinc slag technology, which is applied in hot-dip galvanizing process, process efficiency improvement, metal material coating process, etc., can solve the problem that the physical components cannot meet the 0# zinc standard, the added value of recycled products is low, and energy consumption and other issues, to achieve the effect of reducing energy consumption, low production cost, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

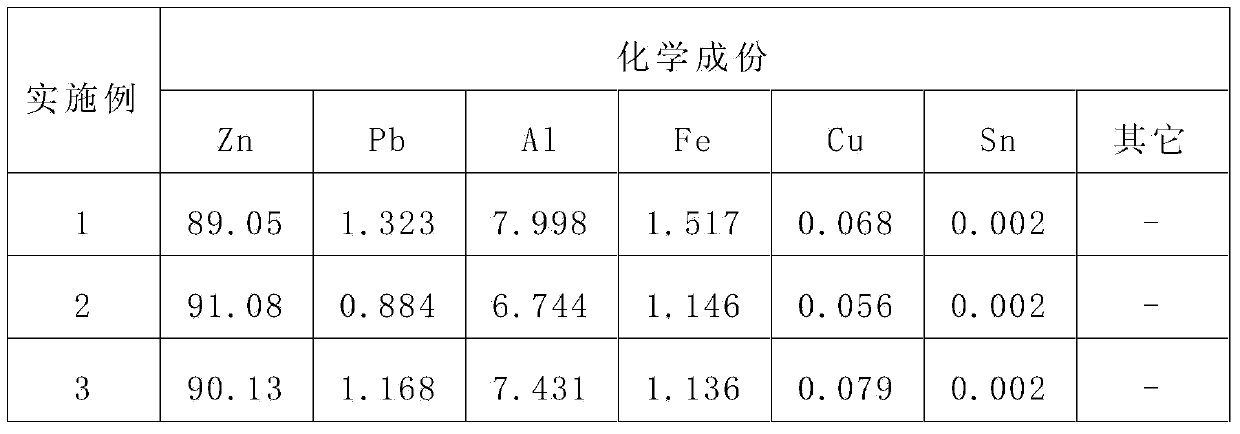

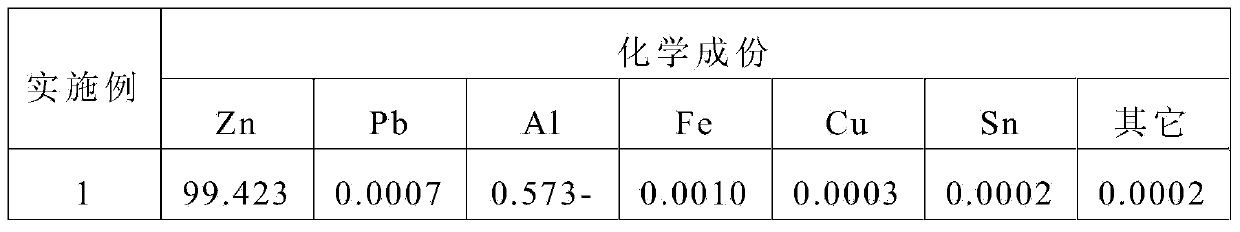

Examples

Embodiment Construction

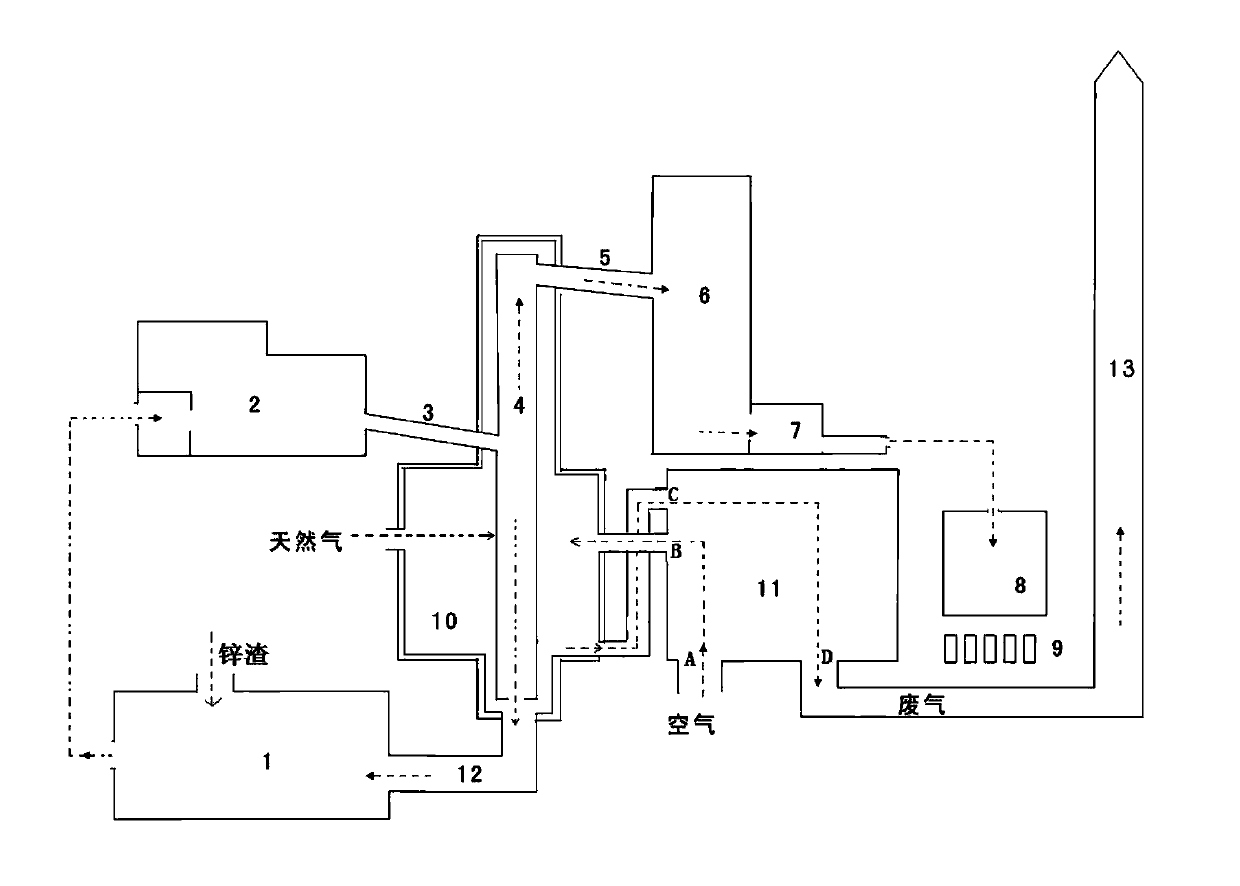

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0024] As shown in the figure, the present invention utilizes zinc slag to produce the equipment for hot-dip zinc alloy, including refining furnace 1, heat preservation meter 2, rectification tower 4, condenser 6, zinc storage pool 7, combustion chamber 10 and chimney 13, It is characterized in that: the output end of the thermal insulation meter 2 is connected with the inlet of the rectifying tower 4 through the feeding pipe 3 through the automatic feeding device, and the upper zinc vapor outlet of the rectifying tower 4 is connected with the input end of the condenser 6 through the chute 5, The output end of the condenser 6 is connected with the inlet of the zinc storage pool 7, and the outlet of the zinc storage pool 7 is connected with the smelting electric furnace; the lower part of the rectifying tower 4 is connected with the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com