Method used for recovery preparation of aluminum potassium sulfate from activated clay production waste water

A technology for the production of waste water and activated clay, applied in chemical instruments and methods, aluminum sulfur compounds, aluminum sulfate, etc., can solve the problems of waste of aluminum elements, and achieve the effects of short production cycle, high purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

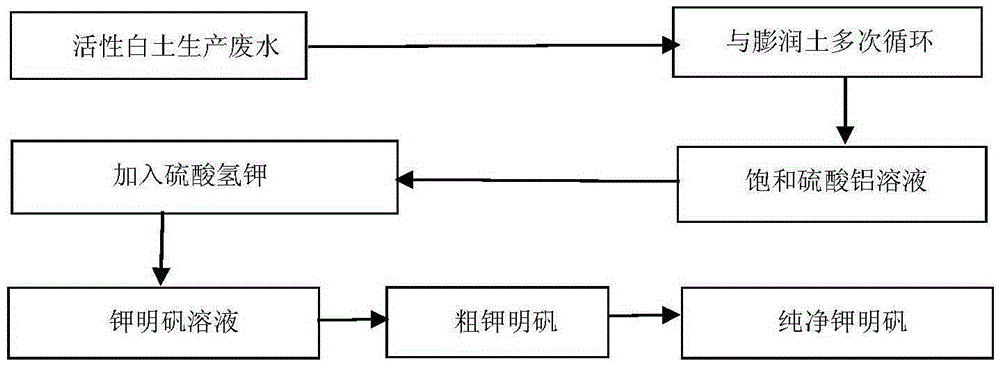

Image

Examples

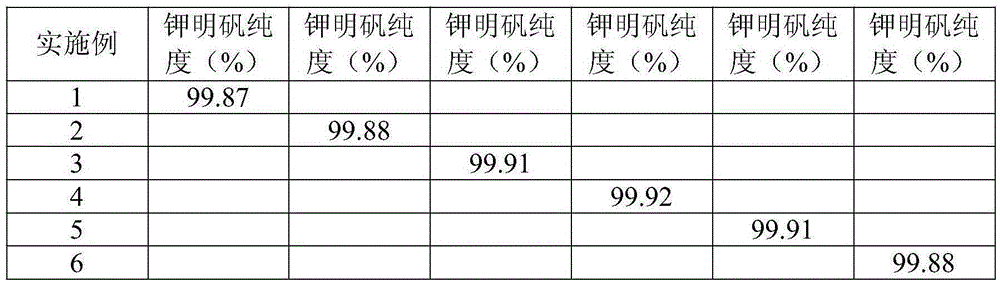

Embodiment 1

[0030] A method for reclaiming potassium alum from activated clay production wastewater, comprising the following steps:

[0031] S1: The activated clay production wastewater is mixed with bentonite at a temperature of 90°C to dissolve the aluminum oxide of bentonite in the activated clay production wastewater, and then the activated clay production wastewater with increased concentration of aluminum sulfate is recycled and mixed with the newly added bentonite , so that the aluminum sulfate dissolved in the activated clay production wastewater reaches saturation;

[0032] S2: The activated clay production waste water that the aluminum sulfate obtained in step S1 reaches saturation is 86 ℃ through controlling temperature, and potassium hydrogensulfate is added under the pH value of 4.1, and the amount of potassium hydrogensulfate added is such that K in potassium alum + :Al 3+ :SO 4 2- The molar concentration ratio is 1.01:1:2.02, and the reaction generates potassium alum; ...

Embodiment 2

[0037] A method for reclaiming potassium alum from activated clay production wastewater, comprising the following steps:

[0038] S1: The activated clay production wastewater is mixed with bentonite at a temperature of 92°C, so that the aluminum oxide of bentonite is dissolved in the activated clay production wastewater, and then the activated clay production wastewater with an increased concentration of aluminum sulfate is recycled and mixed with the newly added bentonite , with such a process step cycle operation 4 times, until the aluminum sulfate dissolved in the activated clay production wastewater reaches saturation;

[0039] S2: the activated clay production waste water that the aluminum sulfate obtained in step S1 reaches saturation is 88 ℃ through controlling temperature, and potassium hydrogensulfate is added under the pH value of 4.2, and the amount of potassium hydrogensulfate added is to make NH in potassium alum 4 + :Al 3+ :SO 4 2- The molar concentration rat...

Embodiment 3

[0044] A method for reclaiming potassium alum from activated clay production wastewater, comprising the following steps:

[0045] S1: The activated clay production wastewater is mixed with bentonite at a temperature of 91°C, so that the aluminum oxide of bentonite is dissolved in the activated clay production wastewater, and then the activated clay production wastewater with an increased concentration of aluminum sulfate is recycled and mixed with the newly added bentonite , cyclically operate 3 times with such process steps, until the aluminum sulfate dissolved in the activated clay production wastewater reaches saturation;

[0046] S2: The activated clay production waste water that the aluminum sulfate obtained in step S1 reaches saturation is 87 ℃ through controlling temperature, and potassium hydrogensulfate is added under the pH value of 4.2, and the amount of potassium hydrogensulfate added is to make NH in potassium alum 4 + :Al 3+ :SO 4 2- The molar concentration r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com