Magnesium-zinc-manganese-gadolinium magnesium alloy with high strength and high plasticity as well as preparation method thereof

A magnesium-zinc-manganese-gadolinium-magnesium and high plasticity technology is applied in the field of high-strength and high-plasticity magnesium-zinc-manganese-gadolinium-magnesium alloys and their preparation, which can solve the problems of limited application of magnesium alloys, difficult plastic deformation, low room temperature strength, etc., and achieve a good interface Stability, dislocation propagation inhibition, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0030] Carry out microscopic analysis and performance test to embodiment 1-3 and comparative example preparation magnesium alloy

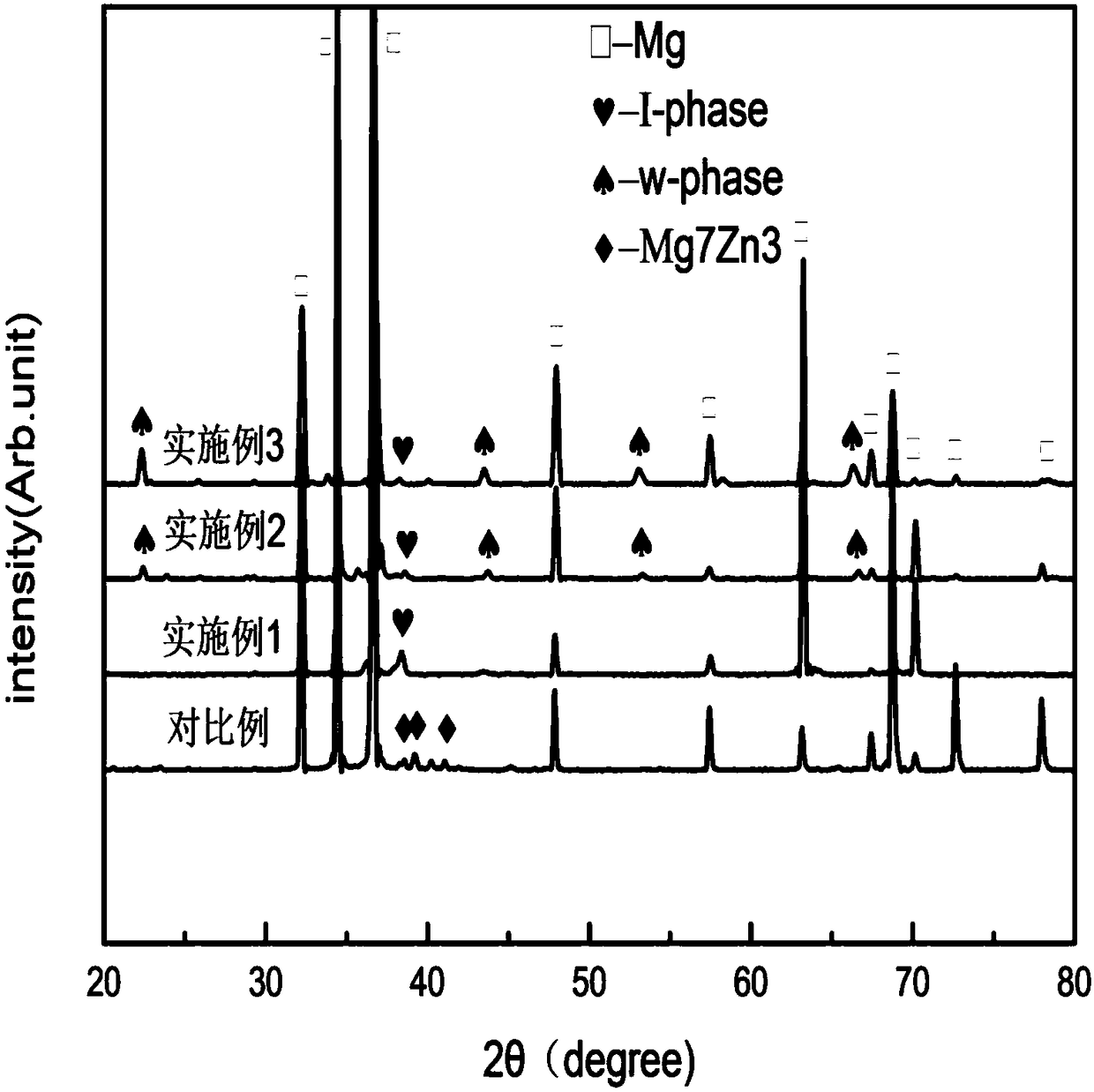

[0031] 1. Microstructure characterization

[0032] After the surface of the magnesium alloy prepared in Examples 1-3 and Comparative Example was polished flat by No. 400-1200 silicon carbide water-grinding paper, each sample was carried out to phase analysis with an X-ray diffractometer, and the results were as follows: figure 1 shown by figure 1 It can be seen that the diffraction peaks of phase I in the magnesium alloys prepared in Examples 1-3 gradually weaken, indicating that the content of phase I decreases gradually with the increase of Gd content. The diffraction peak of the W phase is gradually enhanced, indicating that the content of the W phase is gradually increasing, and there is no diffraction peak of the W phase in Example 1, indicating that there is no W phase. In the magnesium alloy prepared in the comparative example, the peaks o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com