Method for increasing copper tensile strength

A technology of tensile strength and deformation temperature, used in the field of non-ferrous metal plastic processing, can solve the problems of small copper material and equipment difficult to achieve such a high strain rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, a commercial extruded pure copper rod with a diameter of 10mm is processed into a dog bone shape (thick at both ends, thin in the middle parallel section, and the diameter of the parallel section is 4mm); then it is placed on a torsion testing machine for torsional plastic deformation, torsion Deformation At room temperature, with a torsional speed of 2rpm, the maximum shear strain rate of the edge is 1.5×10 -2 the s -1 , reversed 11 times.

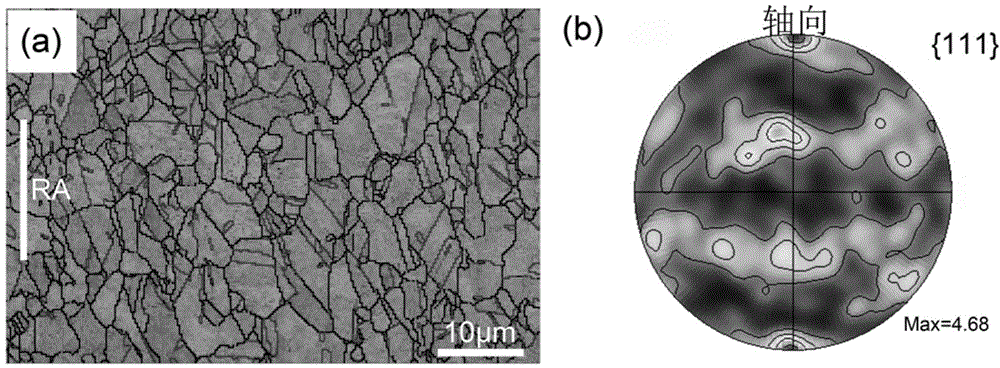

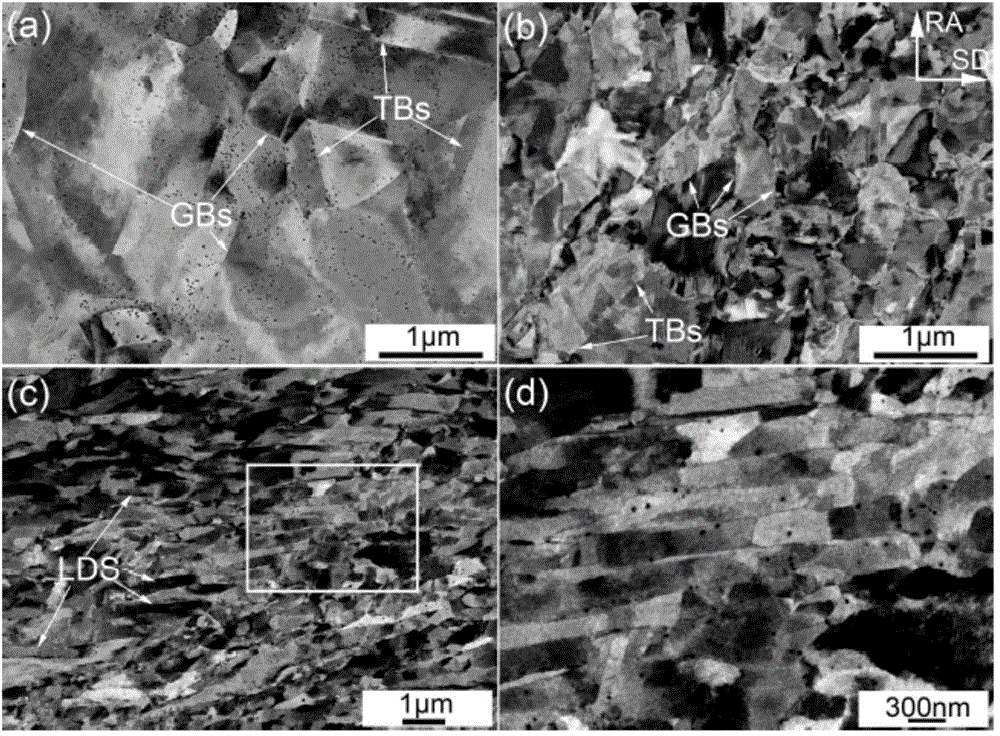

[0032] figure 1 is the initial microstructure of extruded pure copper, where figure 1 a is the electron backscatter diffraction (EBSD) grain boundary (GBs) composition map of the initial copper rod, figure 1 b is the pole figure of the initial copper rod {111}, figure 1 It shows that the bar grains before torsion are equiaxed, and have relatively weak {111} fiber texture parallel to the bar axis (RA), and there are a large number of 60° twins in the bar grains before torsion (TBs).

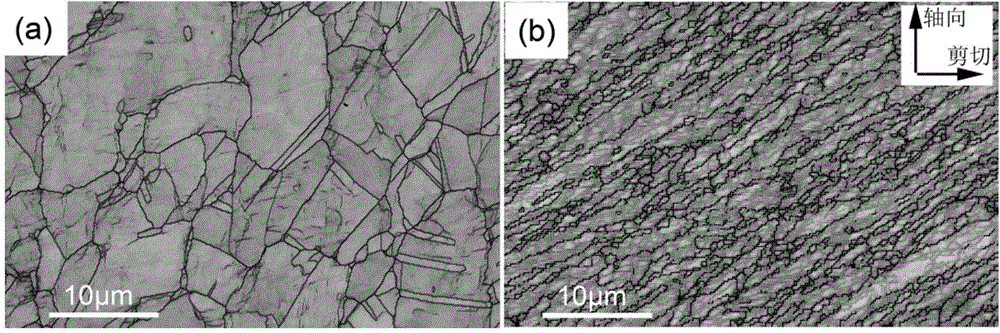

[0033] figure 2 It is the microst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com