Cu-Ni-Co-Fe-Si-Zr-Zn copper alloy material and preparation method thereof

A cu-ni-co-fe-si-zr-zn, copper alloy technology, applied in the direction of metal rolling, can solve the problems of coarse grain, reduced material strength, low addition of alloy elements, etc., to achieve comprehensive mechanical Good performance and electrical conductivity, prevent excessive growth of grains, high tensile strength and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

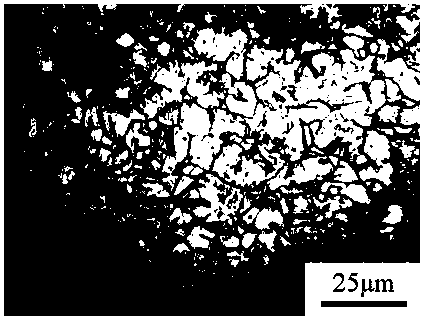

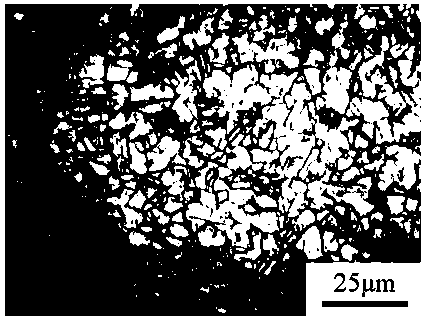

Image

Examples

Embodiment 1

[0036] The mass percent of the alloy composition is: 2.5 wt% Ni, 0.5 wt% Co, 0.5 wt% Fe, 0.8 wt% Si, 0.15 wt% Zr, 0.2 wt% Zn, and the rest is Cu. The Cu, Ni, Fe, and Si used for smelting are bulk raw materials with purity ≥ 99.9wt%, Cu-Zn master alloy containing 20wt% Zn, Cu-Co master alloy containing 30wt% Co, Cu-Co master alloy containing 10wt% Zr Zr master alloy.

[0037] (1) Alloy melting and casting: Put the raw materials into the crucible of the induction furnace according to the above mass percentage, and evacuate to 10 - 3 Pa, then pass through 1.1×10 5 Pa pure argon (Ar ≥ 99.99%) is smelted under the protection of pure argon. After the solid is completely melted and the alloy melt is formed, keep it for 10 minutes, then cast the alloy melt into a graphite mold, and open it after cooling. The alloy ingot was taken out from the mold, and the thickness of the ingot was 18mm.

[0038] (2) Homogenization treatment: put the cast ingot into a heat treatment furnace, and ...

Embodiment 2

[0045] The mass percent of the alloy composition is: 2.0 wt% Ni, 0.6 wt% Co, 0.3 wt% Fe, 0.6 wt% Si, 0.2 wt% Zr, 0.3 wt% Zn, and the rest is Cu. The Cu, Ni, Fe, and Si used for smelting are bulk raw materials with purity ≥ 99.9wt%, Cu-Zn master alloy containing 20wt% Zn, Cu-Co master alloy containing 30wt% Co, Cu-Co master alloy containing 10wt% Zr Zr master alloy.

[0046] (1) Alloy melting and casting: Put the raw materials into the crucible of the induction furnace according to the above mass percentage, and evacuate to 10 - 3 Pa, then pass through 1.1×10 5 Pa pure argon (Ar ≥ 99.99%) is smelted under the protection of pure argon. After the solid is completely melted and the alloy melt is formed, keep it for 10 minutes, then cast the alloy melt into a graphite mold, and open it after cooling. The alloy ingot was taken out from the mold, and the thickness of the ingot was 18mm.

[0047] (2) Homogenization treatment: put the cast ingot into a heat treatment furnace, and p...

Embodiment 3

[0054] The mass percent of the alloy composition is: 3.0 wt% Ni, 0.3 wt% Co, 0.6 wt% Fe, 1.1 wt% Si, 0.1 wt% Zr, 0.1 wt% Zn, and the rest is Cu. The Cu, Fe and Si used for smelting are bulk raw materials with a purity ≥ 99.9wt%, Cu-Ni master alloy containing 50wt% Ni, Cu-Zn master alloy containing 20wt% Zn, Cu-Co master alloy containing 30wt% Co Alloy, Cu-Zr master alloy containing 10wt% Zr.

[0055] (1) Alloy melting and casting: Put the raw materials into the crucible of the induction furnace according to the above mass percentage, and evacuate to 10 - 3 Pa, then pass through 1.1×10 5 Pa pure argon (Ar ≥ 99.99%) is smelted under the protection of pure argon. After the solid is completely melted and the alloy melt is formed, keep it for 10 minutes, then cast the alloy melt into a graphite mold, and open it after cooling. The alloy ingot was taken out from the mold, and the thickness of the ingot was 18mm.

[0056] (2) Homogenization treatment: put the cast ingot into a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com