Preparation method of intermetallic compound Al3-M particle reinforced aluminum matrix composite

A technology of intermetallic compounds and aluminum-based composite materials, which is applied in the fields of aluminum-based composite material preparation and metal smelting processing, can solve the problems of failure to improve the wettability of reinforcement and aluminum melt, low mass fraction of composite materials, and poor particle distribution. Uniformity and other issues to achieve the effect of improving production and labor conditions, excellent mechanical properties, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

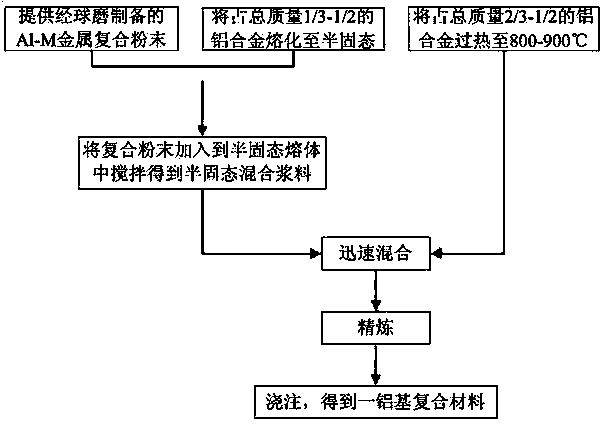

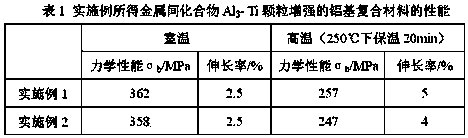

[0028] An intermetallic compound Al 3 - A preparation method for Ti particle reinforced aluminum matrix composite material, comprising the following steps:

[0029] (1) Prepare aluminum powder and metal Ti powder at a molar ratio of 3:1 to make composite powder, add 0.2% stearic acid of the total weight of the composite powder to the composite powder, and then ball mill for 60 hours under the protection of argon atmosphere, with a ball-to-material ratio of 20 : 1, ball milling speed 300r / min;

[0030] (2) The ball-milled composite powder is baked in a vacuum oven at 130°C for 4 hours, and then cooled in the furnace;

[0031] (3) Melt 66wt% aluminum alloy and overheat to 800°C, keep it warm for use;

[0032] (4) Melt the remaining 34wt% aluminum alloy to semi-solid and add pure magnesium, then add 2.5% composite powder of the total mass of aluminum alloy into the semi-solid aluminum alloy melt under the protection of argon atmosphere, and stir while adding , stirring for a t...

Embodiment 2

[0035] An intermetallic compound Al 3 - A preparation method for Ti particle reinforced aluminum matrix composite material, comprising the following steps:

[0036] (1) Prepare aluminum powder and metal Ti powder at a molar ratio of 3:1 to make a composite powder, add 0.1% stearic acid of the total weight of the composite powder to the composite powder, and then ball mill for 65 hours under the protection of an argon atmosphere, with a ball-to-material ratio of 30 : 1, ball milling speed 500r / min;

[0037] (2) The ball-milled composite powder is baked in a vacuum oven at 100°C for 5 hours, and then cooled with the furnace;

[0038] (3) Melt 68wt% aluminum alloy and overheat to 830°C, keep it warm for use;

[0039](4) Melt the remaining 32wt% aluminum alloy to semi-solid and add pure magnesium, then add 3% composite powder of the total mass of aluminum alloy into the semi-solid aluminum alloy melt under the protection of argon atmosphere, and stir while adding , stirring for...

Embodiment 3

[0042] An intermetallic compound Al 3 -The preparation method of Zr particle reinforced aluminum matrix composite material, comprises the following steps:

[0043] (1) Prepare aluminum powder and metal Zr powder at a molar ratio of 3:1 to make a composite powder, add 0.2% stearic acid of the total weight of the composite powder to the composite powder, and then ball mill for 70 hours under the protection of an argon atmosphere, with a ball-to-material ratio of 20 : 1, ball milling speed 400r / min;

[0044] (2) The ball-milled composite powder is baked in a vacuum oven at 120°C for 4.5 hours, and then cooled with the furnace;

[0045] (3) Melt 63wt% aluminum alloy and overheat to 820°C, keep it warm for use;

[0046] (4) Melt the remaining 37wt% aluminum alloy to semi-solid and add pure magnesium, then add 2.5% composite powder of the total mass of aluminum alloy into the semi-solid aluminum alloy melt under the protection of argon atmosphere, and stir while adding , stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com