Patents

Literature

51results about How to "Reduce melt surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyimide foam plastic and preparation method thereof

ActiveCN103275319AImprove mechanical propertiesGood flexibilityAdhesivesPolymer scienceHeat resistance

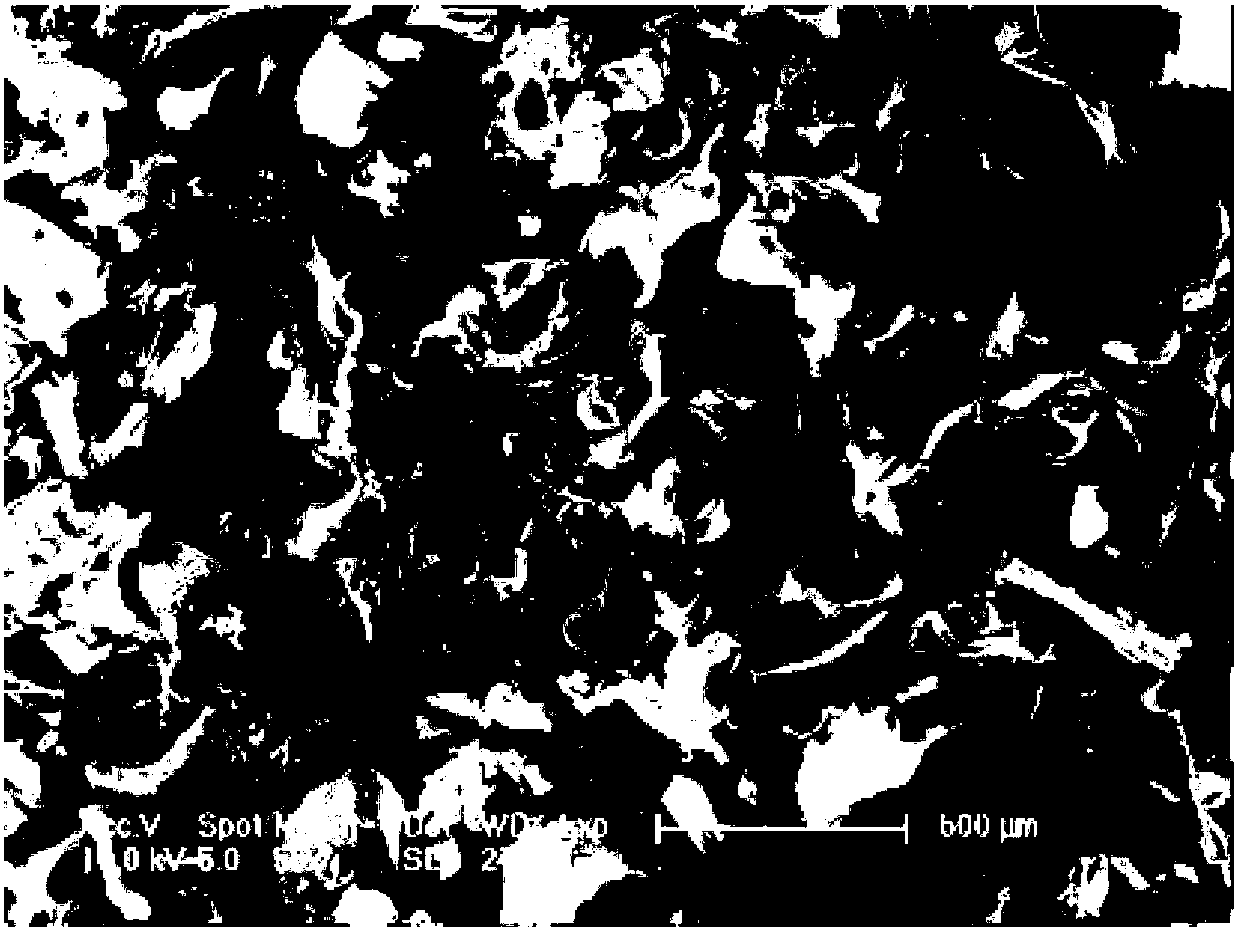

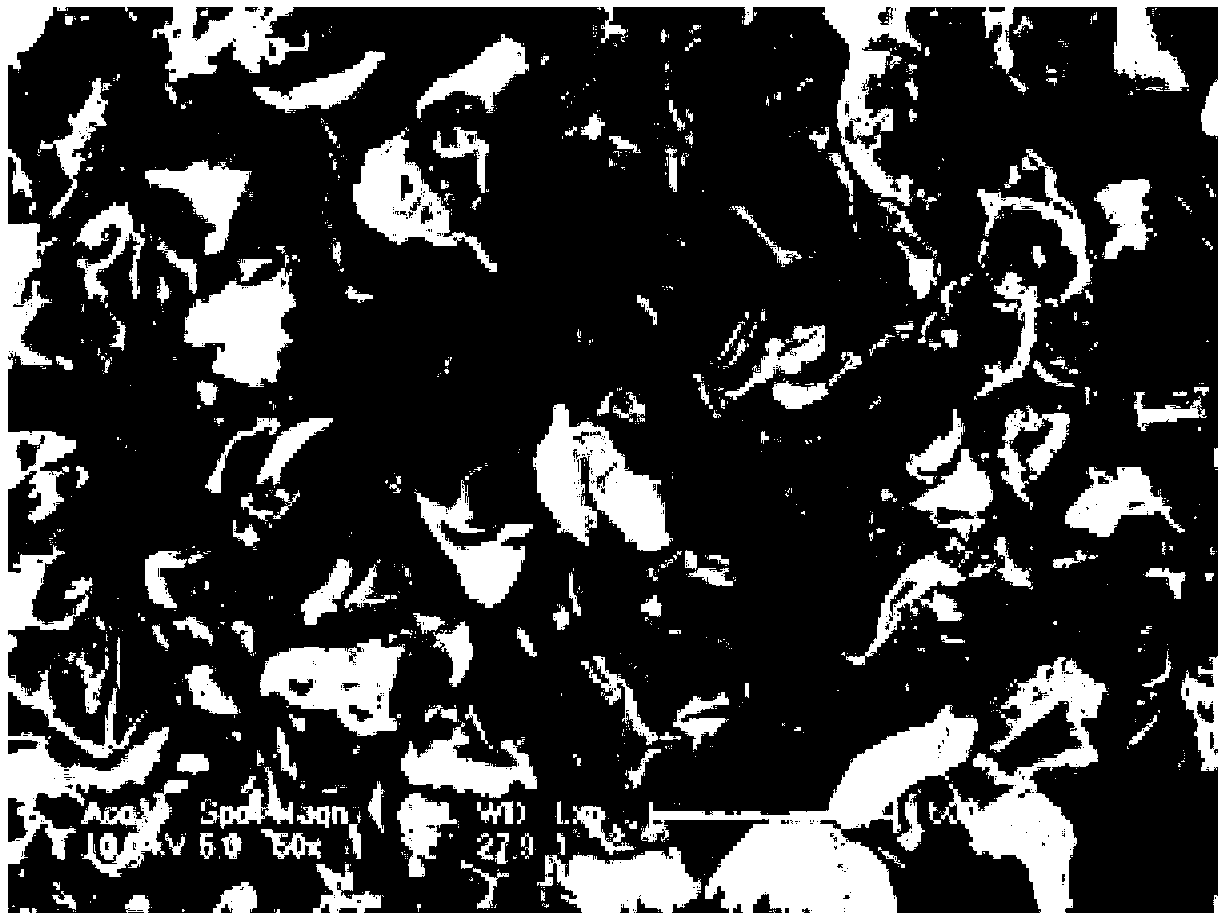

The invention provides a preparation method of polyimide foam plastic. The method comprises the steps as follows: firstly, after dianhydride is mixed with low-level aliphatic alcohol, an esterification reaction is performed, and a diacid diester solution is obtained; then the obtained diacid diester solution is mixed with polymerized monomer amine and polyamic acid powder to obtain a mixed solution; and finally, the obtained mixed solution is sequentially subjected to foaming and thermal imidization after concentration to obtain the polyimide foam plastic. The invention further provides the polyimide foam plastic and the preparation method thereof, and the method comprises the step that polyamic acid powder is added when dianhydride and isocyanate are used for preparing the polyimide foam plastic. According to the invention, the polyamide acid powder serves as a nucleating agent, so that a cell of an objected formed by foaming of polyimide is fine and smooth, that is, the size distribution of the cell is improved, the cell uniformity is better, then the flexibility performance and the like of the polyimide foam plastic are improved; meanwhile, the heat resistance is not influenced; and besides, the preparation method of the polyimide foam plastic is concise in processing, and low in energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

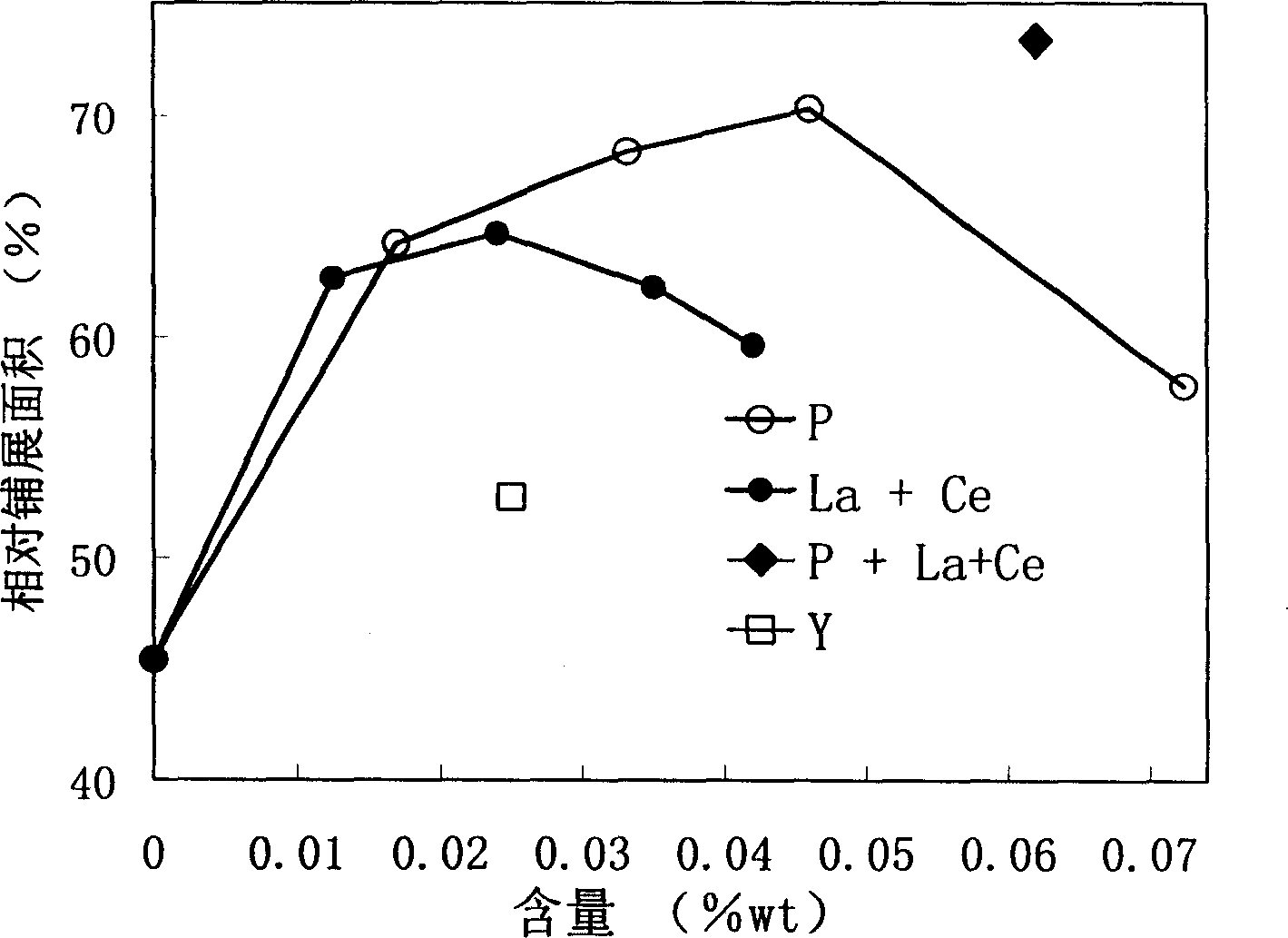

Tin-zinc base plumbum-free solder alloy and its preparing technology

InactiveCN1481970AImprove wettabilityLow costWelding/cutting media/materialsSoldering mediaGraphiteRound bar

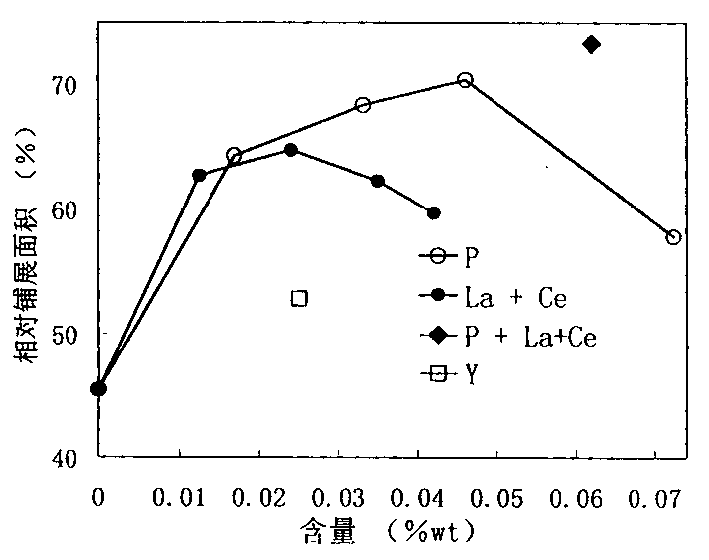

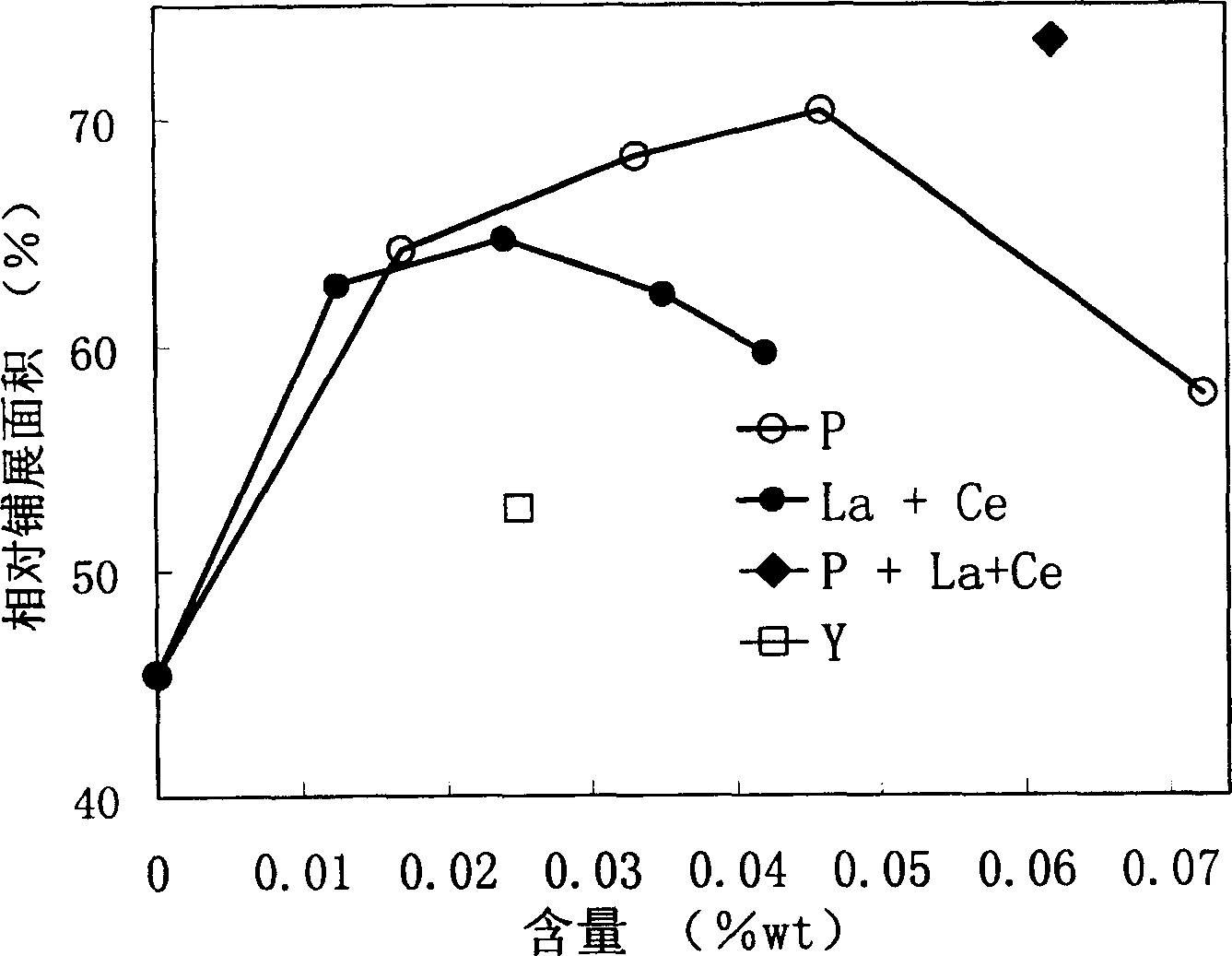

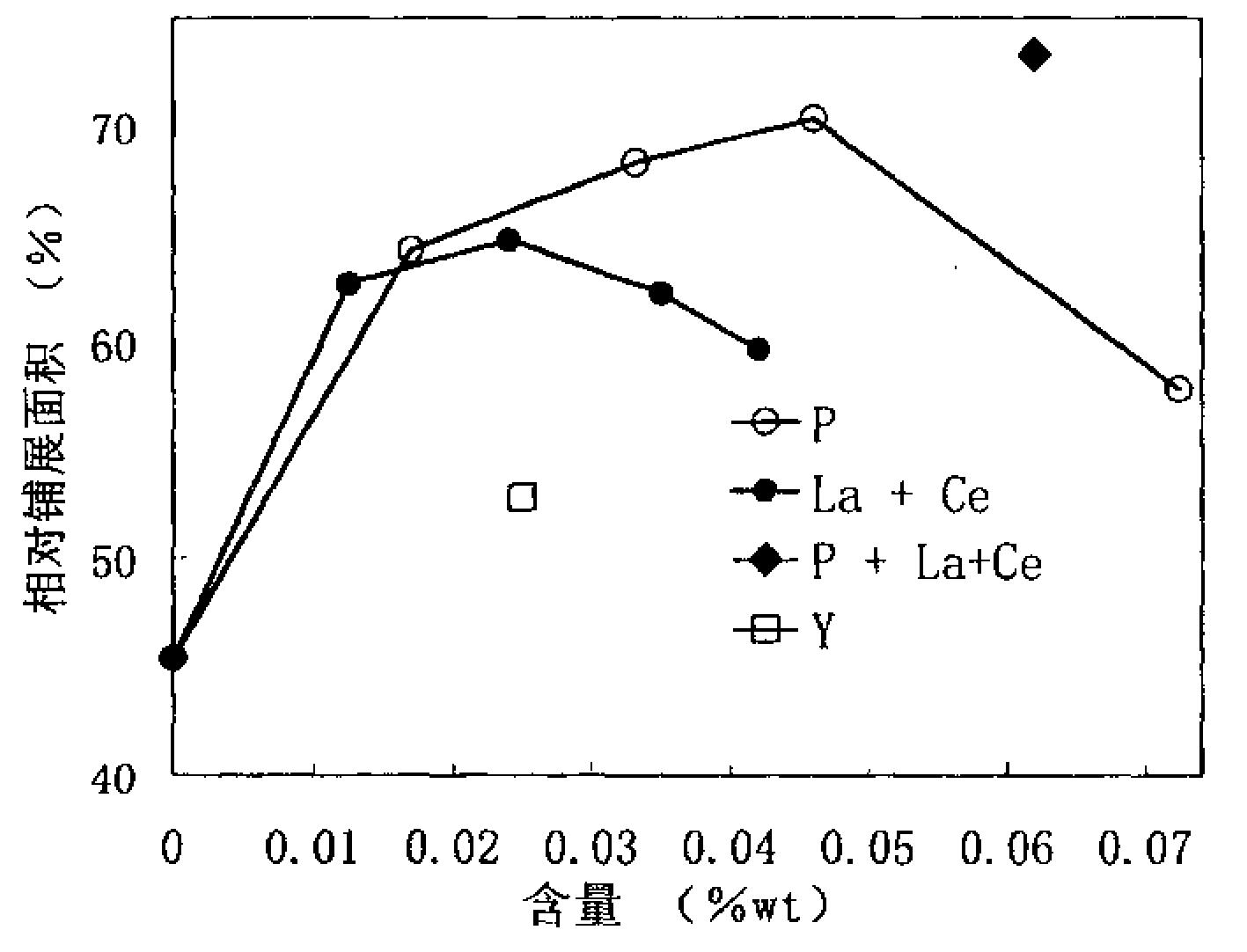

The present invention relates to non-ferrous alloy material. The alloy contains Zn 4-11 wt%, P 0.001-1 wt%, except Sn, and may have some La and / or Ce. The preparation process of the alloy includes smelting Sn-Zn mother material with Zn content of 9.0 wt% and graphite protected surface in a resistive furnace; smelting intermediate alloy in a vacuum inducing furnace via adding La and Ce; melting the mother material inside a corundum crucible inside the resistive furnace and raising the temperature to 350 deg.c, pressing Sn foil coated intermediate alloy and red phosphorus powder into the melt quickly via stirring, maintaining the temperature for 10 min before reducing to 290-320 deg.c; and casting in iron mold into circular rod of 20 mm diameter. The alloy has copper moistening and spreading area greater than that of corresponding Sn-Zn alloy, up to 62 %.

Owner:NANCHANG UNIV

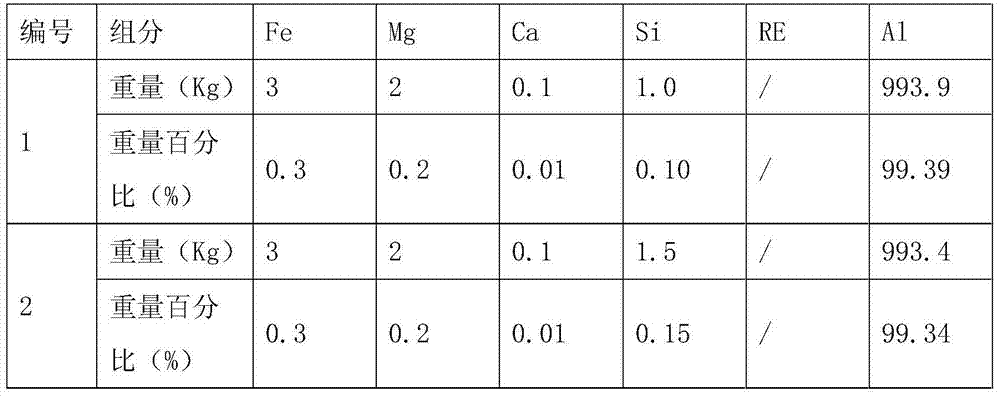

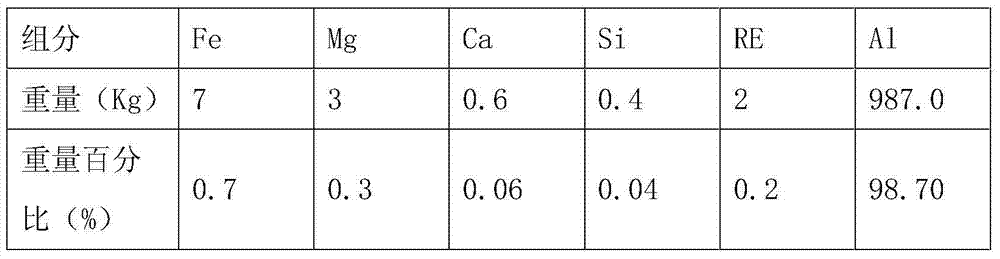

Aluminum alloy for battery case of new energy automobile and pressure casting preparation method thereof

The invention discloses an aluminum alloy for a battery case of a new energy automobile and a pressure casting preparation method thereof. The aluminum alloy comprises the following elements in percentage by mass: 9.5-13.5% of Si, 0.03-0.15% of Fe, 0.22-0.50% of Mg, 0.45-0.80% of Mn, 0.05-0.15% of Ti, 0.01-0.03% of B, 0.012-0.05% of Sr, 0.05-0.2% of RE, less than or equal to 0.03% of a single impurity element, less than or equal to 0.2% of the sum of the impurity elements, and the balance Al. According to the aluminum alloy and the preparation method thereof, the raw materials used for a common aluminum alloy are organically combined, then the multielement mixed rare earth elements are scientifically and reasonably added, various effects of microalloying the multielement mixed rare earth elements are fully exerted, and therefore the comprehensive performance of the material is improved, so that the light weight requirement is met, and then the product material quality is improved.

Owner:安徽镁美科技有限公司

Al-Mn-Mg-Cu-Ni-Ce alloy and manufacturing method thereof

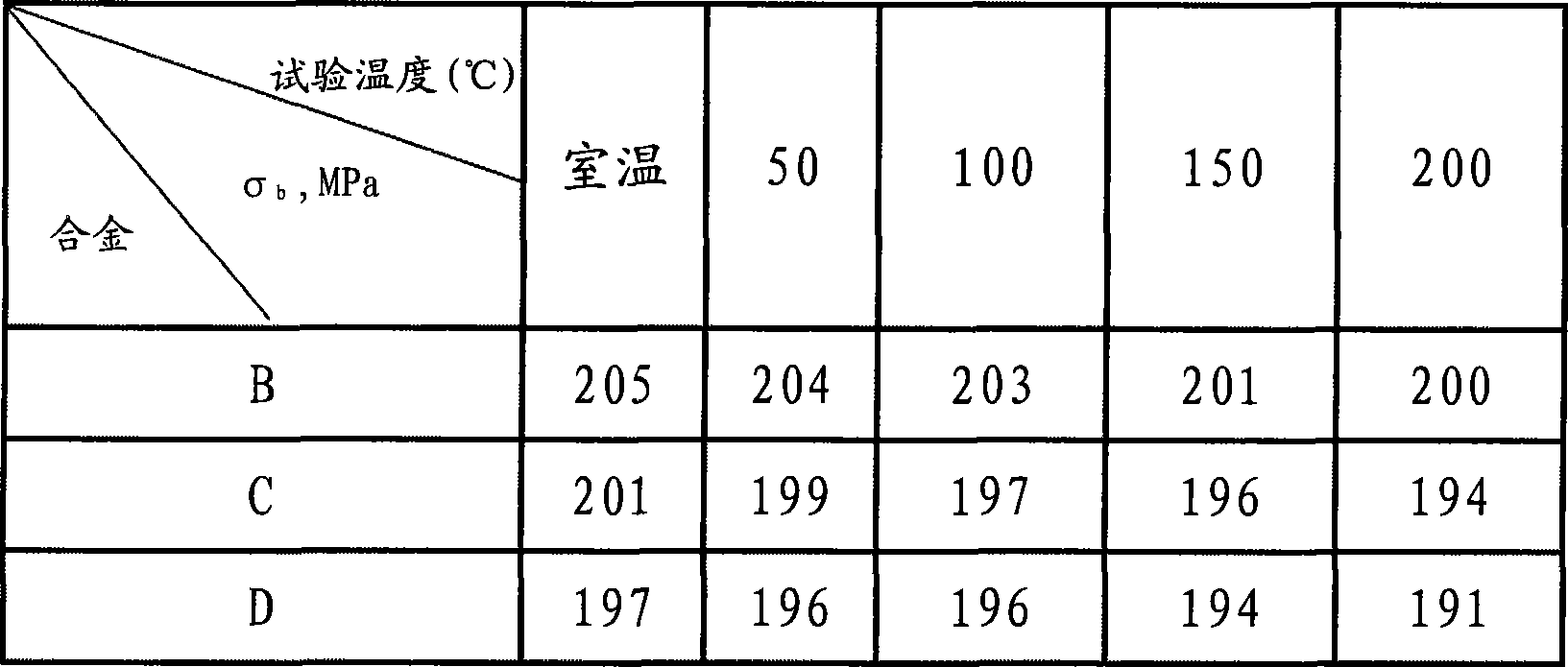

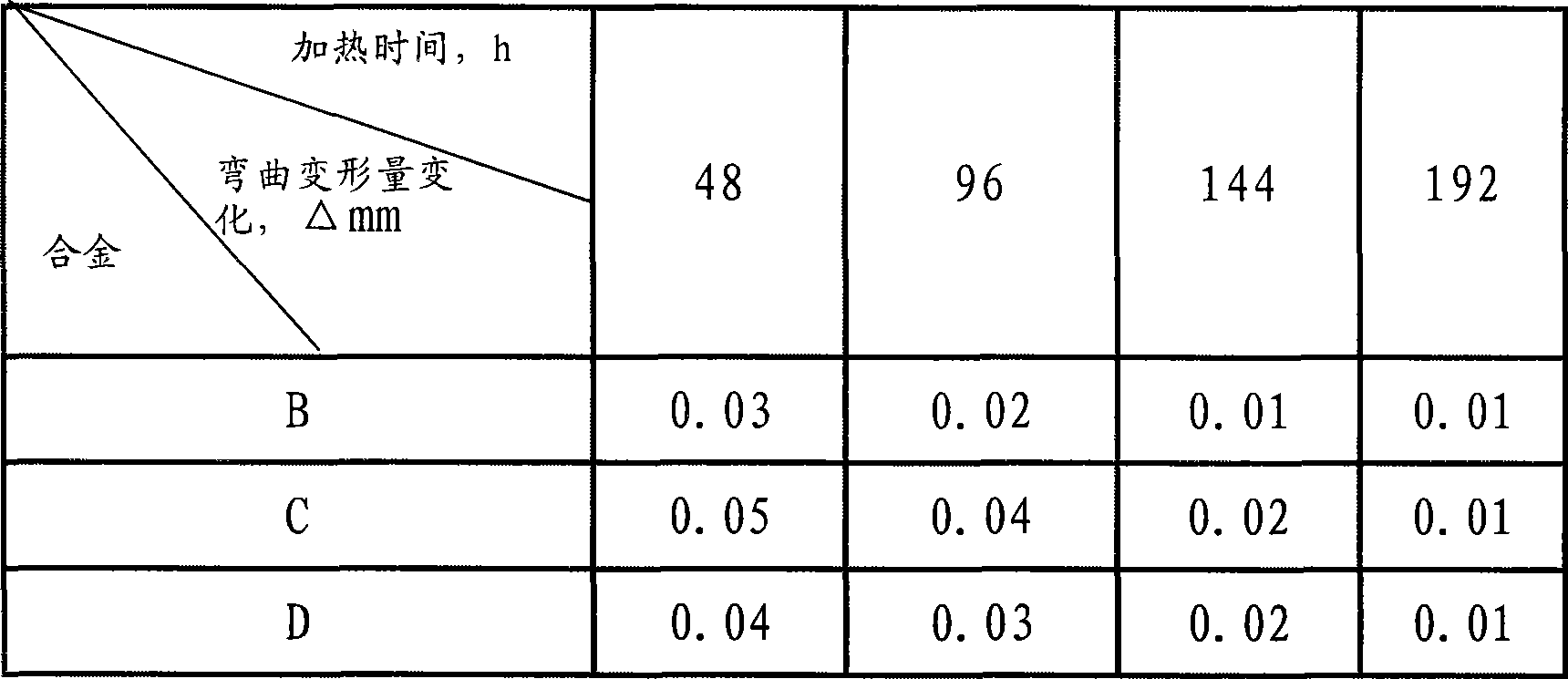

The invention relates to a novel aluminum alloy material, in particular to an aluminum-manganese-magnesium base alloy containing copper, nickel and cerium. The compositions in weight percentage of the aluminum-manganese-magnesium-copper-nickel-cerium alloy are 0.4 to 0.7 percent of copper, 0.2 to 0.7 percent of nickel, 0.02 to 0.05 percent of cerium, 0.8 to 1.3 percent of manganese, 0.6 to 1.2 percent of magnesium, and the balance being aluminum and inevitable impurity elements. The aluminum-manganese-magnesium-copper-nickel-cerium alloy has the advantages that the alloy can simultaneously have high strength and good thermal stability, thermal fatigue property and fluidity, and is suitable for manufacturing thin-wall pipe fittings after adoption of multicomponents of the copper, the nickel and the cerium for composite microalloying on the basis of the aluminum-manganese-magnesium base alloy. The invention also provides a method for manufacturing the aluminum-manganese-magnesium-copper-nickel-cerium alloy.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

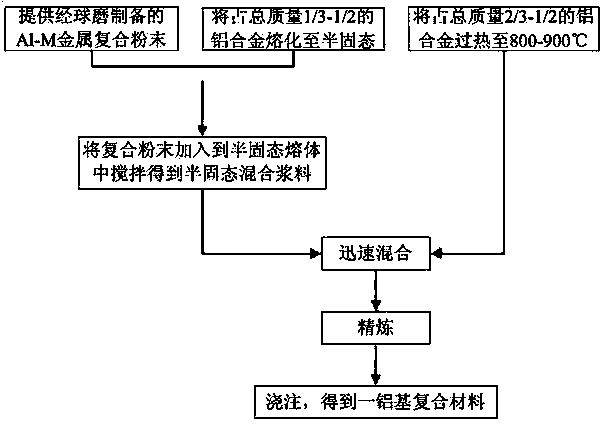

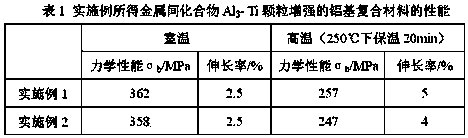

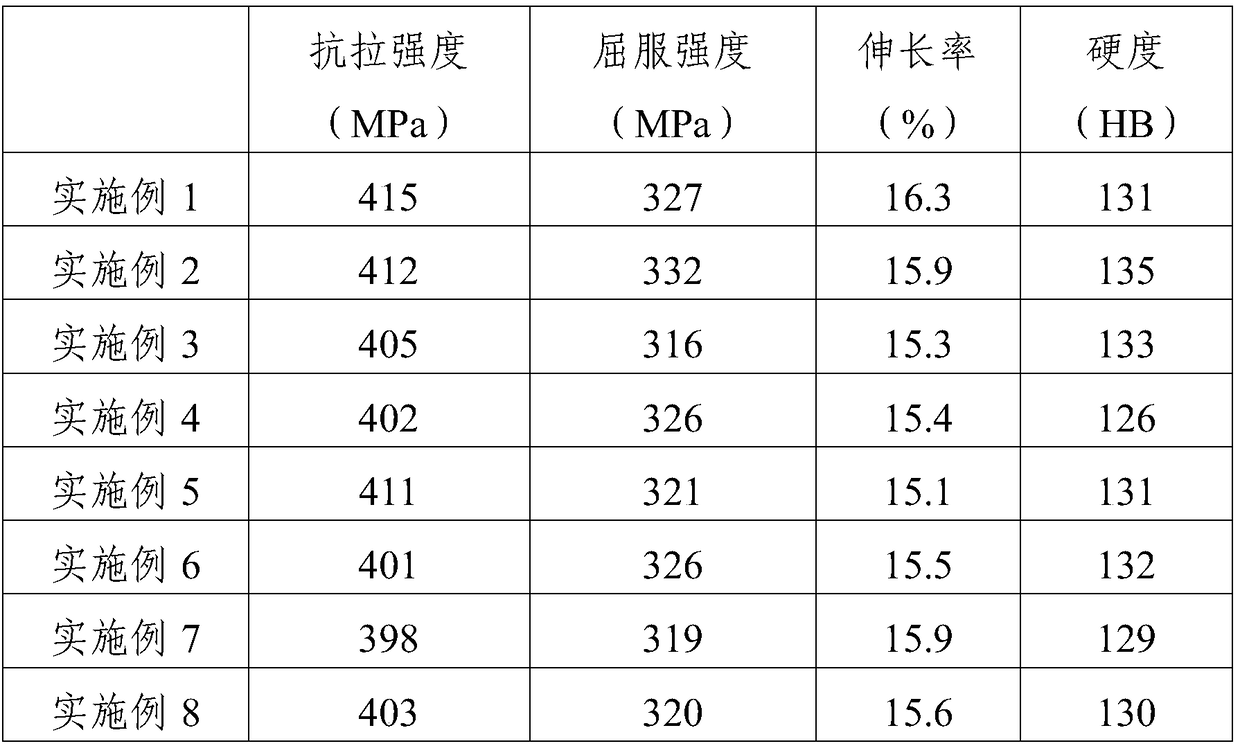

Preparation method of intermetallic compound Al3-M particle reinforced aluminum matrix composite

The invention relates to a preparation method of an intermetallic compound Al3-M particle reinforced aluminum matrix composite and belongs to the technical field of aluminum matrix composite preparation and metal smelting. The invention aims at providing the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite, and provides the intermetallic compound Al3-M particle reinforced aluminum matrix composite prepared by the method at the same time. The invention adopts the technical scheme that the preparation method of the intermetallic compound Al3-M particle reinforced aluminum matrix composite well solves the problem of no infiltration between an intermetallic compound reinforced particle and molten metal by a stepped method of firstly increasing the magnesium concentration in aluminum melt and adding the intermetallic compound particle.

Owner:ZHONGBEI UNIV

Silicon-and-magnesium-containing aluminum alloy sheet for air-conditioning radiator and preparation method of silicon-and-magnesium-containing aluminum alloy sheet

The invention relates to a silicon-and-magnesium-containing aluminum alloy sheet for an air-conditioning radiator. The silicon-and-magnesium-containing aluminum alloy sheet comprises the following chemical elements by mass percent: 0.25-0.35% of Si, 0.48-0.55 of Mg, 0.01-0.02 of Cr, 0. 05-0.15 of Fe, 0.01-0.03 of Ti, 0.01-0.03 of Cu, 0.005-0.02 of La, and the balance being Al. The aluminum alloy sheet provided by the invention has high strength and toughness, is added with lanthanum, the composition undercooling is carried out during gold casting, crystal grains are refined, a secondary crystal spacing is reduced, gas and inclusions in an alloy are reduced, and an inclusion tends to be nodulized, the surface tension of a melt can also be reduced, the mobility is increased, and ingots are favorably cast. According to a production method provided by the invention, the phenomena of layering, peeling, bubbling and cracking of aluminum alloy are reduced, and the yield is improved; a refining agent has a good refining effect, so that the pores and slag inclusion phenomena are obviously reduced.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

High-toughness and high-strength aluminum alloy hub for automobile and manufacturing method of high-toughness and high-strength aluminum alloy hub

ActiveCN109252074ARefined recrystallized grainsRaise the recrystallization temperatureHubsMass ratioHigh intensity

The invention provides a high-toughness and high-strength aluminum alloy hub for an automobile and a manufacturing method thereof, and relates to the technical field of automobile hub manufacturing. The aluminum alloy hub is prepared from the following components in percentage by mass: 3.3-4.8% of Si, 1.2-1.7% of Mg, 0.45-0.7% of Mn, 0.2-0.6% of V, 0.35-0.7% of Ti, 0.05-0.13% of Zr, 0.05-0.12% ofRE, and the balance of Al; RE is composed of Yb, Pr, Nd and Sc with the mass ratio being 1:(0.2 to 0.6):(0.3 to 0.8):(0.6 to 1.2). The manufacturing method comprises the steps of smelting, refining, casting, solid solution treatment, deep cold treatment, aging treatment and the like. The manufactured aluminum alloy hub is uniform and dense in structure, high in toughness, high in strength, good incorrosion resistance, high in dimensional stability, excellent in comprehensive performance and long in service life, and has great using prospects.

Owner:江苏创斯达科技有限公司

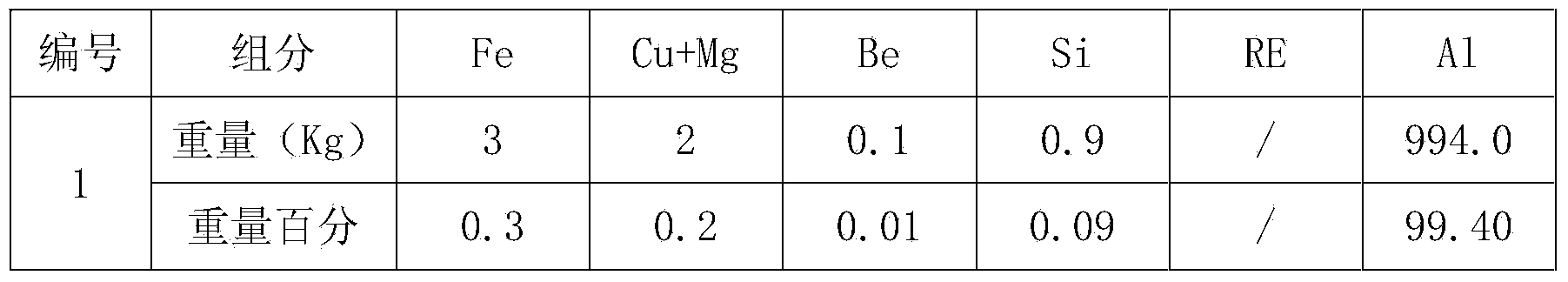

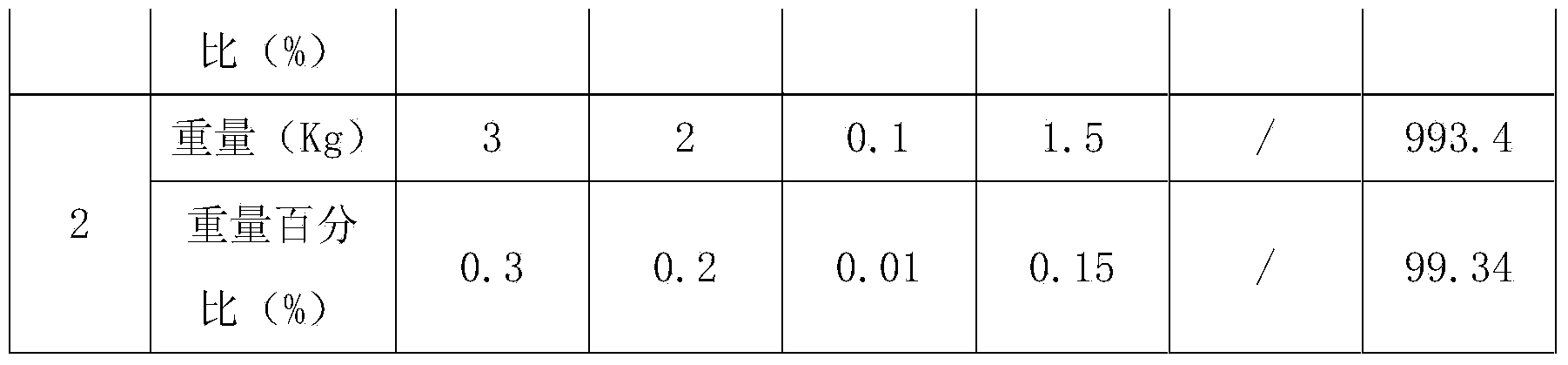

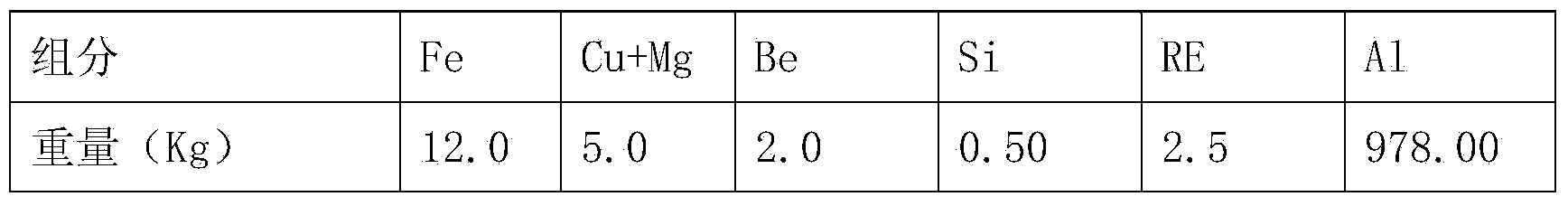

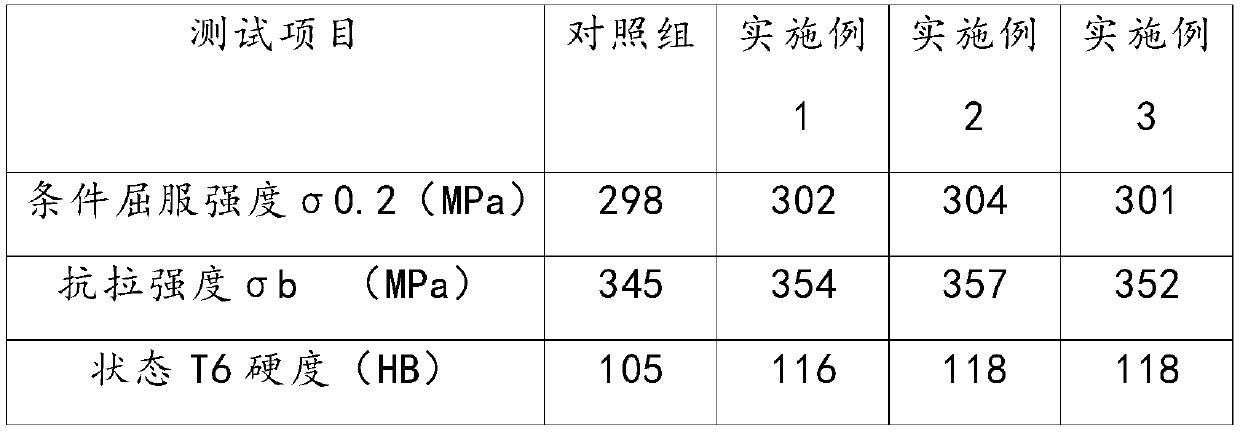

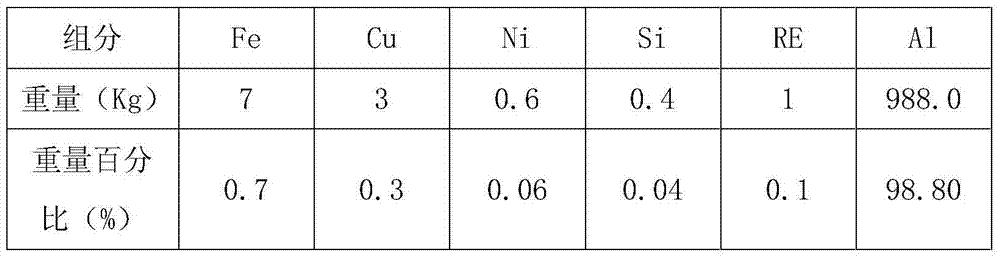

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

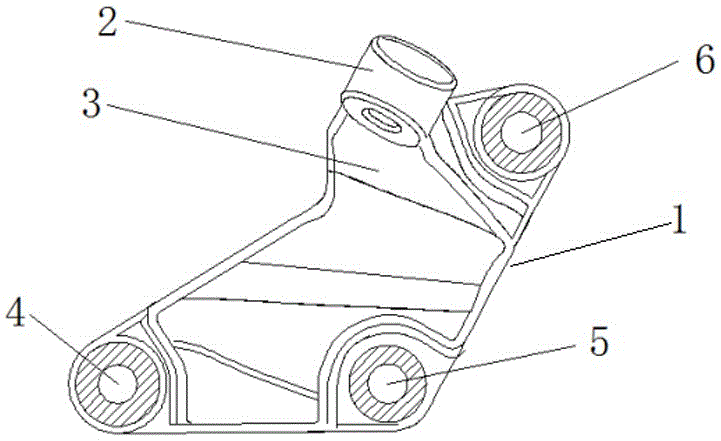

Engine steering bracket processing process

InactiveCN107858561AImprove corrosion resistanceReduce gasMetallic material coating processesRare-earth elementHolmium

The invention discloses an engine steering bracket processing process. A blank is selected, and the blank comprises the following components of, in percentage by mass, 0.05-0.06% of C, 0.5-1% of Mn, 0.5-0.8% of Ni, 2-4% of Cr, 0.4-0.6% of Nb, 0.1-0.2% of Si, 0.1-0.12% of N, 0.2-0.5% of Fe, 1.5-2.0% of Mg, less than or equal to 0.2% of Cu, less than or equal to 0.015% of s, less than or equal to 0.025% of p, 0.3-0.5% of Mo, 2-4% of Al, 0.3-0.5% of Ti, 0.02-0.03% of B, 0.0018-0.0022% of v, 0.1-0.3% of composite rare earth, 0.2-0.4% of rare earth elements and the balance Al; and the composite rare earth comprises the following components of, in percentage by weight, 13-15% of cerium, 15-18% of praseodymium, 5-8% of holmium, 8-10% of gadolinium, 8-10% of gadolinium and the balance lanthanum, and the sum of all the components of the composite rare earth is 100%.

Owner:苏州威斯道智能科技有限公司

Heat treatment method of aluminum magnesium alloy

ActiveCN105839036AEvenly heatedReduce temperature differenceRoom temperatureUltimate tensile strength

The invention relates to the technical field of heat treatment of alloy, in particular to a heat treatment method of aluminum magnesium alloy. The heat treatment method comprises the following steps: placing the aluminum magnesium alloy in a vacuum heat treatment furnace at first; controlling the temperature to be 490-510 DEG C along with the temperature of the furnace in a mode of heating and then cooling; cooling after insulation is finished; placing the aluminum magnesium alloy in an environment at the temperature of 360-380 DEG C and insulating for 1-2 hours; carrying out single-pass deformation at the insulating temperature, wherein deformation is 25-45%; then carrying out cold rolling, wherein the rolling speed is 0.08-0.25 m / s, and reduction in cold rolling is 30+ / -5%; and finally cooling the aluminum magnesium alloy in air until the temperature of the aluminum magnesium alloy reaches room temperature. The heat treatment method is simple to operate and easy to implement; and the machining time is shortened. The aluminum magnesium alloy treated by the method has the characteristics of dimensional stability, corrosion resistance, mechanical property and excellent extrusion performance, and further has the advantage that the strength of the aluminum magnesium alloy is reasonably matched with plasticity.

Owner:贵州航天风华精密设备有限公司

Anti-cracking low-temperature-resistant oil-immersed transformer shell

InactiveCN106756232AHigh strengthImprove antioxidant capacityTransformers/inductances casingsMetallic material coating processesRare-earth elementChemical composition

The invention discloses an anti-cracking low-temperature-resistant oil-immersed transformer shell, comprising a shell and an oil conservator arranged in the shell. The top of the shell communicates with the oil conservator through a pipeline, and the bottom of the shell also communicates with the oil conservator through another pipeline; the outer wall of the oil conservator is provided with cooling fins; the chemical composition of the alloy blank used in the cooling fins, by mass, are: 11.3-14.4% Al, 14.6-17.5% of Mg, 1.25-1.50% of Fe, 0.40-0.7% of Si, 0.01-0.10% of Cu, 1.5-1.7% of Mn, 1.4-2.0% of Zn, 0.10-0.25% of Zr, 1.10-3.12% of rare-earth element, less than 0.015% of impurity content, and the balance Ti; and the rare-earth element comprises, by weight, 15-18% of Gd, 3-5% of Pr, 7-9% of Dy, 12.5-12.8% of Ac, 15-20% of Nd, 11-13% of Sm, and the balance La.

Owner:SUZHOU CHENHENG WEAVING

Aluminum alloy for new energy automobile battery case and production process thereof

The invention relates to the metallurgy field, in particular to an aluminum alloy for a new energy automobile battery case and a production process thereof. By weight percent, the aluminum alloy product consists of elements of 3.4-5.1 of Zn, 2.3-2.7 of Mg, 1.7-1.9 of Cu, 0.3-0.8 of Fe, 0.1-0.4 of Mn, 0.1-0.3 of Si, 0.15-0.26 of Cr, 0.12-0.15 of Ti, the balance Al and inevitable impurities. The preparation process includes multiple procedures of refining, filtering, casting, calendaring, homogenization treatment, artificial aging, hot static pressure treatment and the like. The aluminum alloy sheet produced by using the production process is characterized by being high in tensile strength and yield strength, large in hardness and excellent in fatigue resistance, and is suitable for manufacture of the new energy automobile battery case.

Owner:山东创新精密科技有限公司

Filter net of sewage purifying treatment system

InactiveCN106582111AHigh strengthImprove antioxidant capacityFiltration separationCoatingsCeriumCobalt

The invention discloses a filter net of a sewage purifying treatment system. An anti-corrosive metal coating is plated at the surface of the filter net, and comprises the following components in percentage by mass: 0.21 to 0.23% of C (carbon), 0.13 to 0.17% of Mg (magnesium), 0.62 to 0.65% of Cu (copper), 0.45 to 0.48% of W (tungsten), 0.55 to 0.58% of Ti (titanium), 5.32 to 5.35% of Cr (chromium), 0.37 to 0.39% of Ni (nickel), 0.42 to 0.45% of Mo (molybdenum), 0.23 to 0.25% of Co (cobalt), 3.42 to 3.45% of Ca (calcium), 11 to 13% of rare earth, and the balance of Fe (iron) and trace impurities, wherein the rare earth comprises the following components in percentage by weight: 5.2 to 5.5% of La (lanthanum), 7.6 to 7.8% of Ce (cerium), 5.2 to 5.6% of Pm (promethium), 5.5 to 5.8% of Nd (neodymium), 3.1 to 3.3% of Eu (europium), 5.5 to 5.8% of Sm (samarium), and the balance of Gd (gadolinium); chemical catalyst active components are attached into grid gaps of the filter net, and comprise the following components in percentage by weight: 5 to 60% of nanometer manganese dioxide, 1 to 3% of silver nitrate, 1 to 6% of lanthanum nitrate, and the balance of composite adsorbing material with micropore structure, the composite adsorbing material comprises the following components in percentage by weight: 30 to 50% of diatomite, 25 to 45% of sepiolite, 25 to 35% of molecular sieve, 5 to 10% of bentonite, and 1 to 10% of silica gel, and the sum of percentages of components is 100%.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

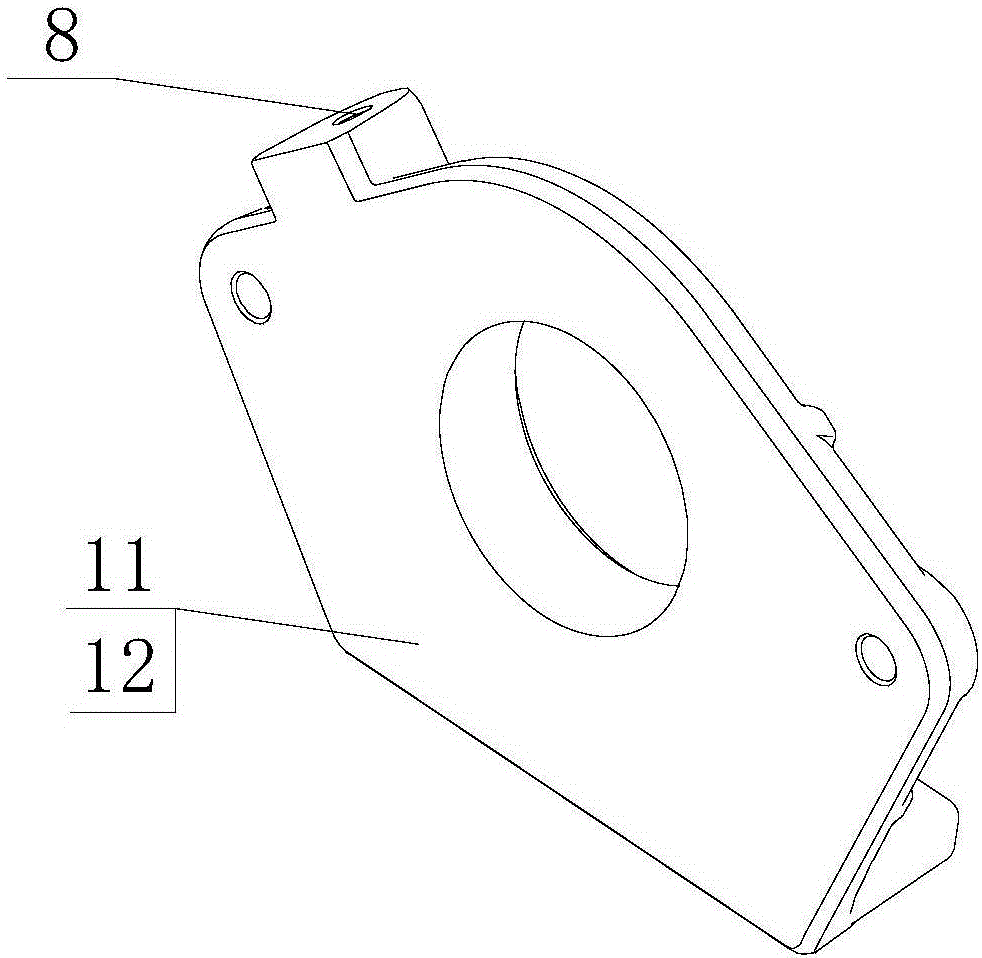

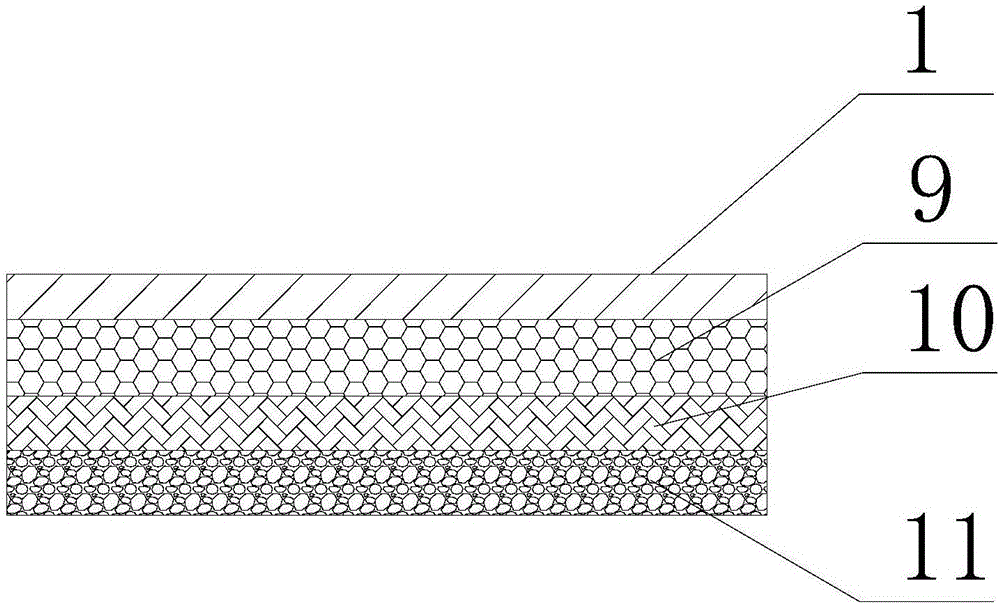

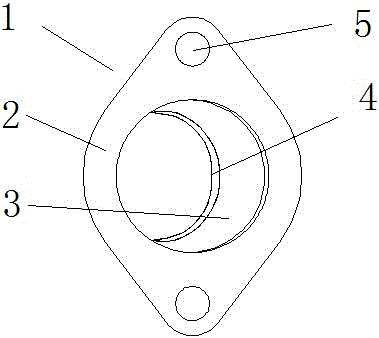

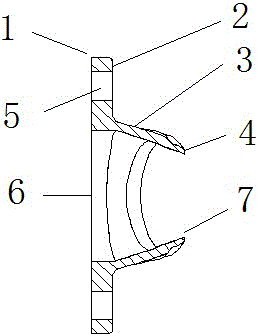

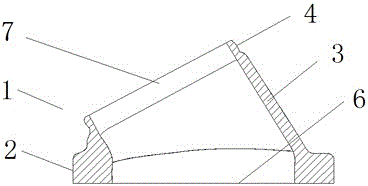

Air outlet flange for automobile engine and production technique thereof

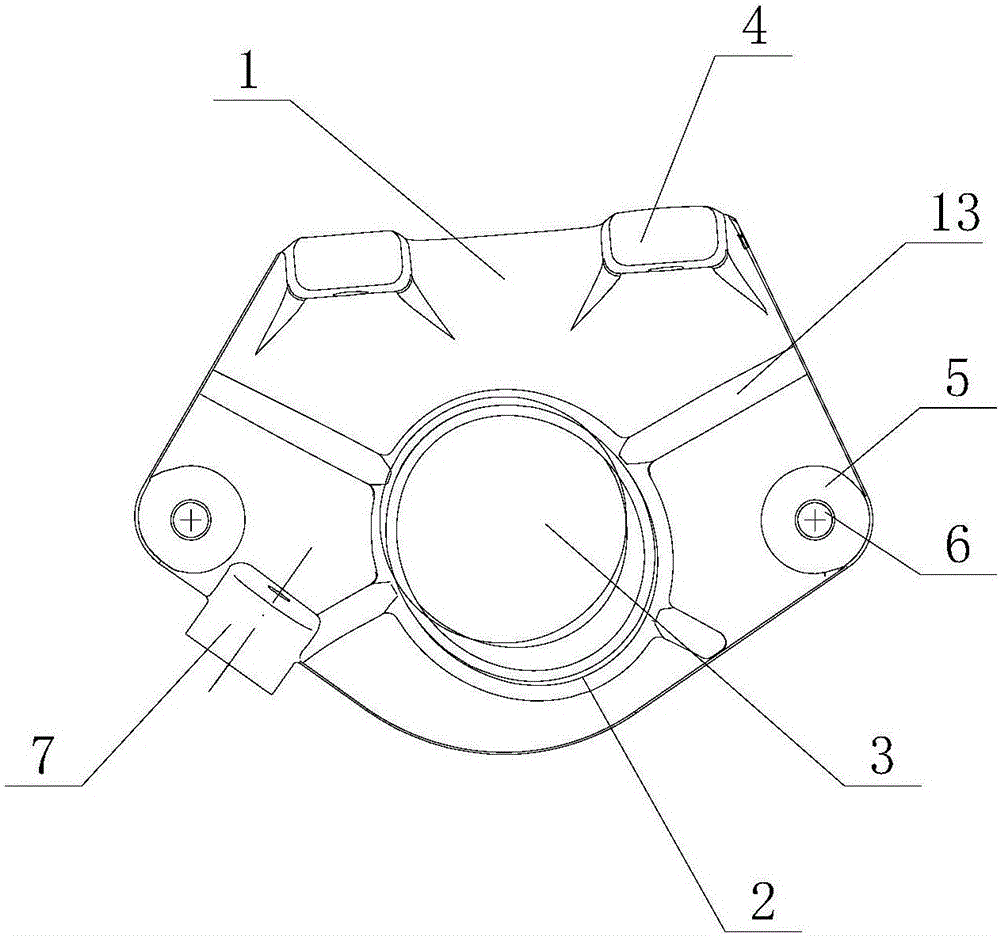

ActiveCN106756586AIncreased cost and maintenance effortSimple structureExhaust apparatusSilencing apparatusSteel platesFlange

The invention discloses an air outlet flange for an automobile engine. The air outlet flange comprises an air outlet flange body, the air outlet flange body comprises a base, and the base is pentagonal. A boss outwards protruding is arranged in the center of the base in the thickness direction of the base. A hole is formed in the center of the boss, foot margins are arranged at the upper end of the base and rectangular, connecting tables are arranged on the two sides of the base, and a first threaded hole is formed in each connecting table. A second mounting table is arranged on the base, a second threaded hole is formed in the second mounting table in the horizontal direction, and the outwards-protruding directions of the foot margins and boss are the same with those of the connecting tables. A buffering layer is arranged on the back portion of the base and comprises a rubber layer body connected with the back face, a wear-resisting layer body and a steel plate, the wear-resisting layer body is connected with the rubber layer body, and the steel plate is connected with the wear-resisting layer body. The invention further provides a production technique of the air outlet flange for the automobile engine. The air outlet flange for the automobile engine is simple in structure, convenient to machine, provided with a buffering structure and capable of improving the service life of pats, saving materials and reducing cost.

Owner:盐城市大丰区生产力促进中心

Preparing method of high-strength aluminum alloy material used for building door and window machining

The invention discloses a preparing method of high-strength aluminum alloy material used for building door and window machining. The aluminum alloy material comprises, by mass percent, 0.9% of silicon, 6.8% of copper, 0.3% of magnesium, 0.8% of iron, 0.8% of manganese, 0.35% of chromium, 0.15% of titanium, 0.07% of strontium, 0.3% of zirconium, 0.8% of boron, 0.1% of rhenium, 0.2% of rare earth and the balance raw material aluminum. Manganese and titanium are added for improving the high-temperature strength of alloy containing copper and silicon, the recrystallization process of the aluminumalloy can be prevented, the recrystallization temperature is increased, the recrystallization grains can be obviously refined, through adding of chromium and zirconium, recrystallization nucleation and growing can be obstructed, the alloy can be subjected to certain strengthening, the toughness of the alloy can be improved, stress corrosion cracking sensitivity can be reduced, strontium has the advantages of being long in metamorphic effective time, good in effect and reproducibility and the like, the casting ingot homogenizing time is reduced, the material mechanical property and plastic machining can be improved, the product surface roughness is improved, and hot rolling and cold rolling are smoothly carried out.

Owner:安徽博安门窗有限公司

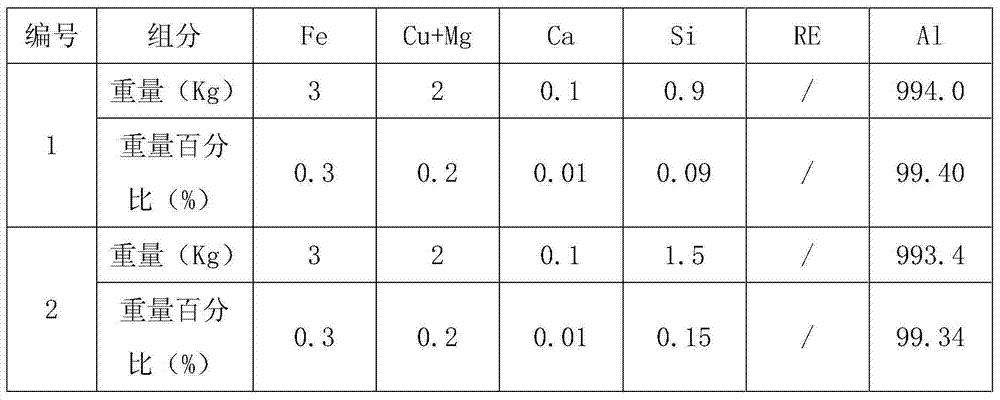

Al-Fe-Mg-Ca aluminum alloy for automobile wire and wire harness thereof

PendingCN103757488AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsUltimate tensile strengthImpurity

The invention discloses an Al-Fe-Mg-Ca aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Mg-Ca aluminum alloy. The Al-Fe-Mg-Ca aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Mg, 0.001-0.2wt% of Ca and the balance of Al and inevitable impurities. According to the Al-Fe-Mg-Ca aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Mg, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; by adding Ca, the electrical conductivity of the alloy can be improved.

Owner:ANHUI JOY SENSE CABLE

Tin-zinc base plumbum-free solder alloy and its preparing technology

InactiveCN1235718CImprove wettabilityLow costWelding/cutting media/materialsSoldering mediaCeriumLanthanum

The present invention relates to non-ferrous alloy material. The alloy contains Zn 4-11 wt%, P 0.001-1 wt%, except Sn, and may have some La and / or Ce. The preparation process of the alloy includes smelting Sn-Zn mother material with Zn content of 9.0 wt% and graphite protected surface in a resistive furnace; smelting intermediate alloy in a vacuum inducing furnace via adding La and Ce; melting the mother material inside a corundum crucible inside the resistive furnace and raising the temperature to 350 deg.c, pressing Sn foil coated intermediate alloy and red phosphorus powder into the melt quickly via stirring, maintaining the temperature for 10 min before reducing to 290-320 deg.c; and casting in iron mold into circular rod of 20 mm diameter. The alloy has copper moistening and spreading area greater than that of corresponding Sn-Zn alloy, up to 62 %.

Owner:NANCHANG UNIV

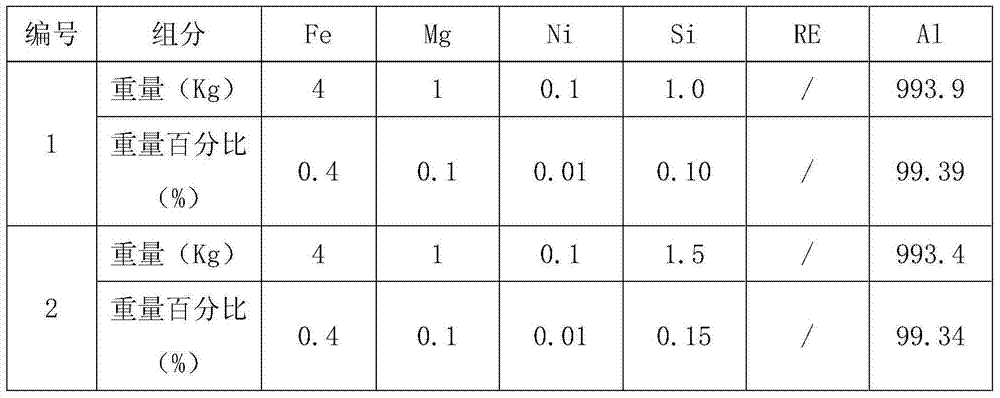

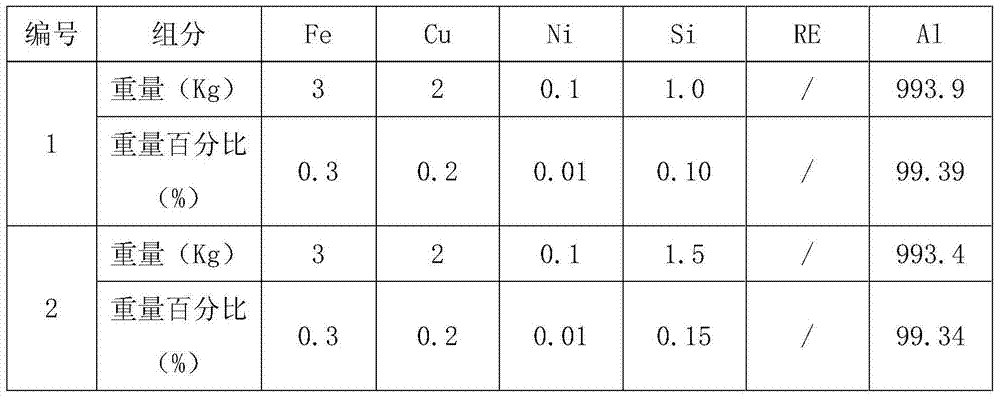

Al-Fe-Mg-Ni aluminum alloy for automobile wire and wire harness thereof

PendingCN103757487AOvercoming processabilityAchieving Lightweight IssuesMetal/alloy conductorsSurface tensionGrain boundary

The invention discloses an Al-Fe-Mg-Ni aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Mg-Ni aluminum alloy. The Al-Fe-Mg-Ni aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Mg, 0.001-0.2wt% of Ni and the balance of Al and inevitable impurities. According to the Al-Fe-Mg-Ni aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Mg, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; Ni has multiple effects of refining grains, filling a grain boundary of a matrix and forming a near-aluminum electric potential metal compound, and can obviously weaken the surface tension of a melt, reduce the viscosity of the melt and significantly improve the flowability of the melt and the mechanical properties of the alloy.

Owner:ANHUI JOY SENSE CABLE

Connection frame for automobile engine exhaust emission system and production process of connection frame

InactiveCN106703961AEasy to replaceEasy to useExhaust apparatusSilencing apparatusMetal coatingWear resistant

The invention provides a connection frame for an automobile engine exhaust emission system. The connection frame comprises a frame body with a hole I, a hole II and a hole III formed in the frame body, wherein the hole I and the hole II are formed in one side edge of the frame body; the hole II and the hole III are formed in the other side edge of the frame body; the upper side surface of the frame body is connected with the lower ends of rib plates; the top ends of the rib plates are connected with an upper end fixing hole; the two rib plates are connected below the upper end fixing hole into a whole to be connected with the upper end fixing hole; and the surface of the frame body is coated with a wear-resistant metal coating. The wear-resistant metal coating comprises the following components by mass percent: 0.21-0.23% of C, 0.13-0.17% of Mg, 0.62-0.65% of Cu, 0.45-0.48% of W, 0.55-0.58% of Ti, 5.32-5.35% of Cr, 0.37-0.39% of Ni, 0.42-0.45% of Mo, 0.23-0.25% of Co, 3.42-3.45% of Ca, 11-13% of rare earth, and the balance of Fe and trace impurities.

Owner:江苏多为机械工业有限公司

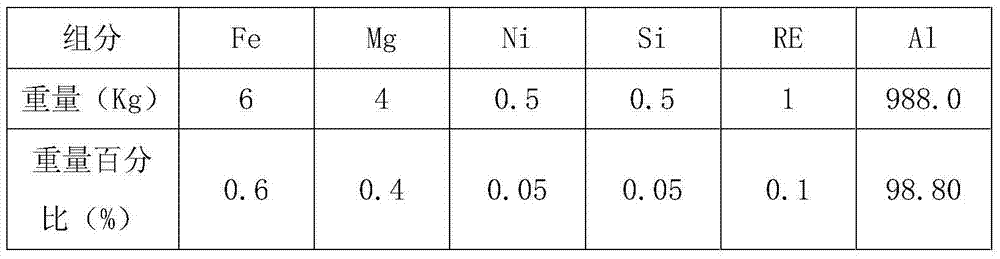

Al-Fe-Cu-Ni aluminum alloy for automotive wire and wire harness thereof

PendingCN103757493AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsUltimate tensile strengthMechanical property

The invention discloses an Al-Fe-Cu-Ni aluminum alloy for an automotive wire and a wire harness thereof. The Al-Fe-Cu-Ni aluminum alloy for the automotive wire comprises the following components by weight percent: 0.2 to 1.4wt% of Fe, 0.01 to 0.5wt% of Cu, 0.001 to 0.2wt% of Ni, and the balance being Al and inevitable impurities. According to the Al-Fe-Cu-Ni aluminum alloy, Fe element added improves the mechanical strength and the tensile property of the alloy, obviously improves the resistance to high temperature creep, as well as improves the antifatigue performance of the alloy; Cu added improves the alloy strength and high temperature creep performance as well as improves the antifatigue performance; and Ni realizes the effects of refining crystal grain, filling a matrix crystal boundary, forming a near aluminum potential metal compound, weakening the surface tension of a melt, reducing melt viscosity, as well as obviously improving melt fluidity and mechanical performance of the alloy.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Cu-Mg-Ca aluminum alloy for automotive wire and wiring harness thereof

PendingCN103757496AOvercoming processabilityAchieving Lightweight IssuesMetal/alloy conductorsFe elementAluminium alloy

The invention discloses an Al-Fe-Cu-Mg-Ca alloy for an automotive wire, a preparation method thereof and a prepared automotive wiring harness, wherein the Al-Fe-Cu-Mg-Ca alloy for the automotive wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Ca, and the balance of Al and inevitable impurities. The mechanical property and the tensile property of the alloy can be improved by adding an Fe element; the high-temperature creep resistance and the fatigue resistance of the alloy also can be obviously improved by the Fe; the strength and the high-temperature creep property of the alloy can be improved and the fatigue resistance can be improved by adding the Cu and Mg; the conductivity of the aluminum alloy can be improved by adding the Ca; meanwhile, the cutting property of the aluminum alloy can be improved, and removal of hydrogen in molten aluminum is facilitated.

Owner:ANHUI JOY SENSE CABLE

Treatment process of spinning vacuum silk boiling box

InactiveCN107955483AReduce gasReduce inclusionsAnti-corrosive paintsEpoxy resin coatingsRare-earth elementHolmium

The invention provides a treatment process of a spinning vacuum silk boiling box. Blanks comprise, in weight percent, 0.05-0,06% of C, 0.5-1% of Mn, 0.5-0.8% of Ni, 2-4% of Cr, 0.4-0.6% of Nb, 0.1-0.2% of Si, 0.1-0.12% of N, 0.2-0.5% of Fe, 1.5-2.0% of Mg, lower than or equal to 0.2% of Cu, lower than or equal to 0.015% of s, lower than or equal to 0.02% of p, 0.3-0.5% of Mo, 2-4% of Al, 0.3-0.5%of Ti, 0.02-0.03% of B, 0.0018-0.0022% of v, 0.1-0.3% of composite rare earth, 0.2-0.4% of rare earth elements and the balance Al. The composite rare earth comprises, in weight percent, 13-15% of cerium, 15-18% of praseodymium, 5-8% of holmium, 8-10% of gadolinium, 8-10% of yttrium and the balance lanthanum, and the sum of the weight percent of components of the composite rare earth is 100%.

Owner:苏州天亦辰针织有限公司

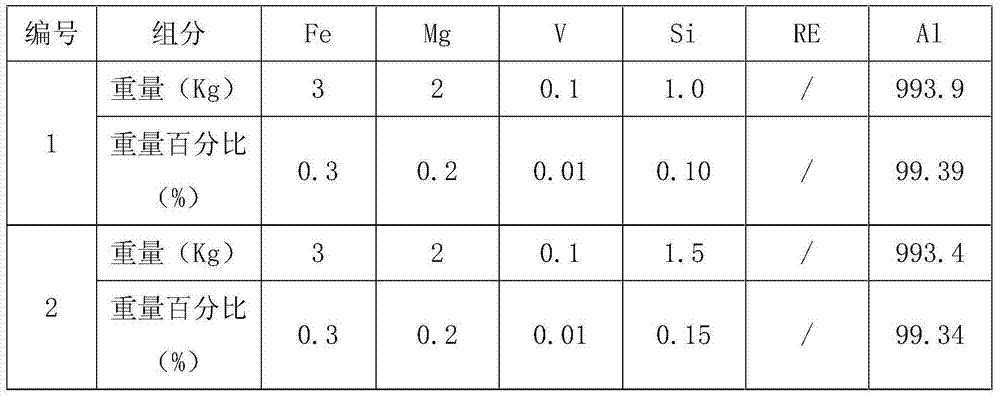

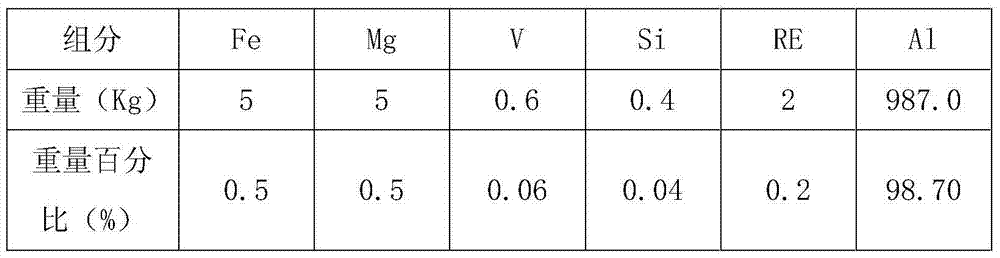

Al-Fe-Mg-V aluminum alloy for automotive wire and wiring harness prepared from aluminum alloy

PendingCN103757486AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsImpurityFe element

The invention discloses an Al-Fe-Mg-V aluminum alloy for an automotive wire, a preparation method of the Al-Fe-Mg-V aluminum alloy and a wiring harness prepared from the aluminum alloy. The Al-Fe-Mg-V aluminum alloy for the automotive wire comprises the following components in percentage by weight: 0.2%-1.4% of Fe, 0.01%-0.5% of Mg, 0.001%-0.2% of V and the balance being Al and inevitable impurities. According to the invention, the mechanical strength and tensile performance of the alloy can be improved by adding the Fe element, and Fe can further remarkably improve the high-temperature creep resistance and the anti-fatigue performance of the alloy; the strength and the high-temperature creep resistance of the alloy can be improved by adding Mg, and the anti-fatigue performance of the alloy can be improved; V has the effect of refining grains in a casting process and further has the effects of refining recrystallized structures and improving the recrystallization temperature.

Owner:ANHUI JOY SENSE CABLE

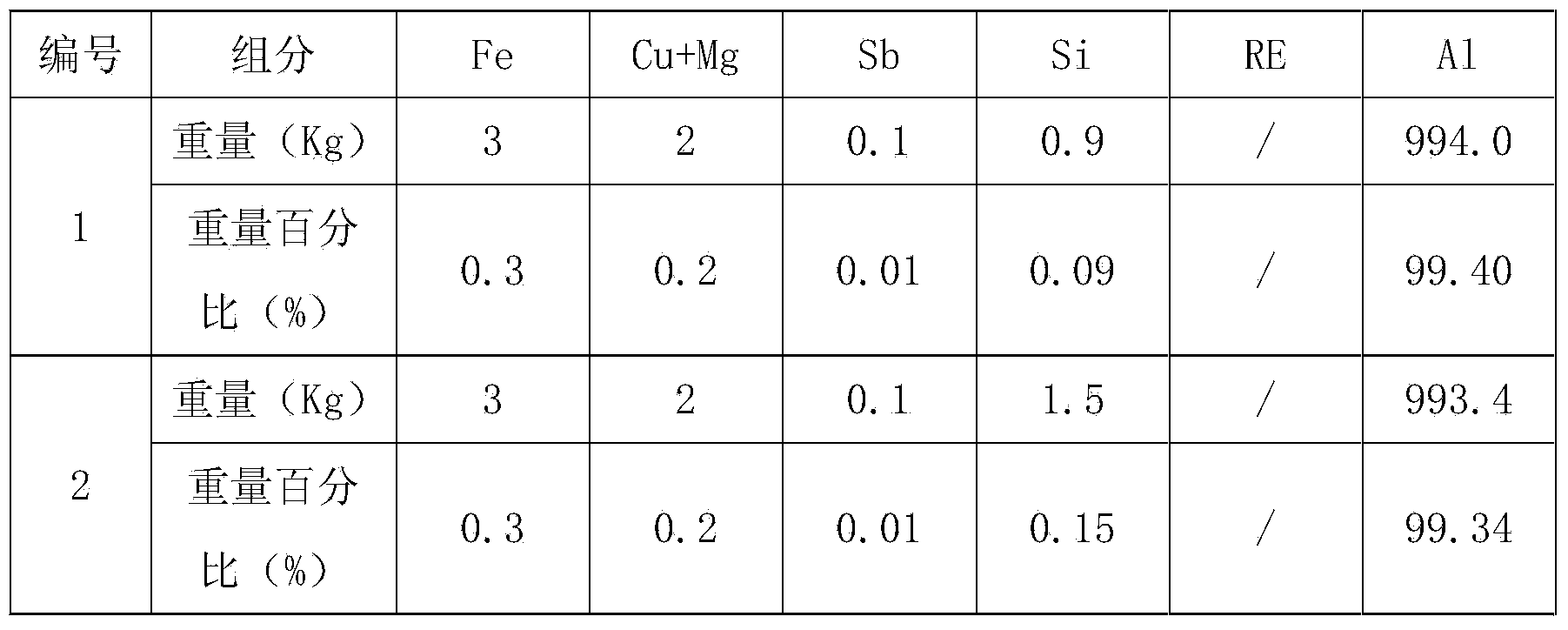

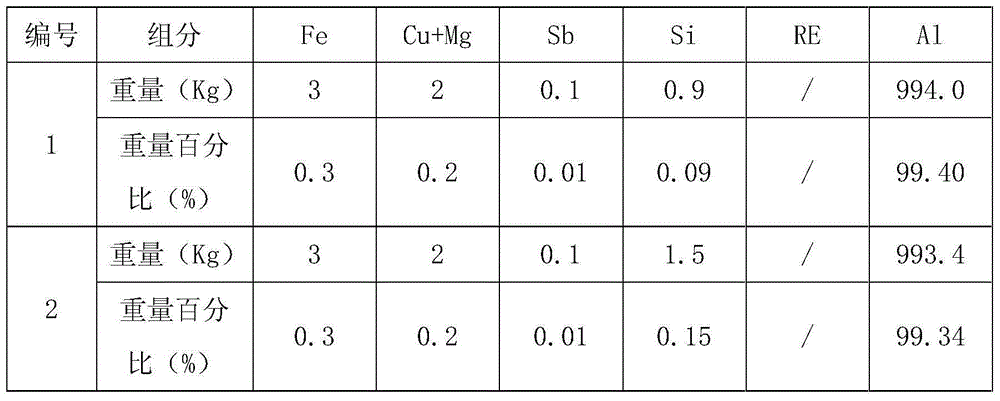

Al-Fe-Cu-Mg-Sb aluminum alloy for automotive wire and wiring harness made of aluminum alloy

ActiveCN103725929AOvercoming processabilityOvercoming creep resistanceManufacturing wire harnessesMetal/alloy conductorsFe elementAluminium alloy

The invention discloses an Al-Fe-Cu-Mg-Sb aluminum alloy for an automotive wire, a manufacturing method of the aluminum alloy, and a wiring harness made of the aluminum alloy. The Al-Fe-Cu-Mg-Sb aluminum alloy for the automotive wire comprises the following ingredients in percentage by weight: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Sb, and the balance of Al and inevitable impurities. The mechanical strength and the tensile properties of the alloy can be improved by adding an Fe element; the high temperature creep resistance also can be obviously improved by Fe; the anti-fatigue performance of the alloy is improved; the strength and the high-temperature creep properties of the alloy can be improved by adding Cu and Mg; the anti-fatigue performance can be improved; the yield limit of the alloy can be improved by adding Sb; meanwhile, the alloy has superplasticity, so as to be drawn into a very thin alloy wire.

Owner:ANHUI JOY SENSE CABLE

A kind of al-fe-cu-mg-sb aluminum alloy for automobile wire and its wire harness

ActiveCN103725929BHigh mechanical strengthImprove tensile propertiesManufacturing wire harnessesMetal/alloy conductorsAdditive ingredientUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Sb aluminum alloy for an automotive wire, a manufacturing method of the aluminum alloy, and a wiring harness made of the aluminum alloy. The Al-Fe-Cu-Mg-Sb aluminum alloy for the automotive wire comprises the following ingredients in percentage by weight: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Sb, and the balance of Al and inevitable impurities. The mechanical strength and the tensile properties of the alloy can be improved by adding an Fe element; the high temperature creep resistance also can be obviously improved by Fe; the anti-fatigue performance of the alloy is improved; the strength and the high-temperature creep properties of the alloy can be improved by adding Cu and Mg; the anti-fatigue performance can be improved; the yield limit of the alloy can be improved by adding Sb; meanwhile, the alloy has superplasticity, so as to be drawn into a very thin alloy wire.

Owner:ANHUI JOY SENSE CABLE

Anti-seismic and corrosion-resistant connection rod of horizontal transmission mechanism of rewinding machine

InactiveCN106544598AHigh strengthImprove antioxidant capacityFurnace typesHeat treatment furnacesHorizontal transmissionRare-earth element

The invention discloses an anti-seismic and corrosion-resistant connection rod of a horizontal transmission mechanism of a rewinding machine. The anti-seismic and corrosion-resistant connection rod is characterized by being composed of a main rod and fixing rods, and further comprising a fixing hole arranged in the middle part of the main rod, wherein the two ends of the main rod are fixedly connected with the fixing rods through bolts respectively, and the fixing rods are vertical to the main rod; and the surface of the main rod is plated with a wear-resistant metal coating, and the wear-resistant metal coating comprises the following components in percentage by mass: 0.21-0.23% of C, 0.13-0.17% of Mg, 0.62-0.65% of Cu, 0.45-0.48% of W, 0.55-0.58% of Ti, 5.32-5.35% of Cr, 0.37-0.39% of Ni, 0.42-0.45% of Mo, 0.23-0.25% of Co, 3.42-3.45% of Ca, 11-13% of rare earth elements, and the balance Fe and trace impurities; and the rare earth elements comprise the following components in percentage by weight: 5.2-5.5% of La, 7.6-7.8% of Ce, 5.2-5.6% of Pm, 5.5-5.8% of Nd, 3.1-3.3% of Eu, 5.5-5.8% of Sm and the balance Gd.

Owner:SUZHOU CHENHENG WEAVING

Low zinc hot dipping aluminum alloy coating material

InactiveCN103131992BHigh strengthImprove high temperature performanceHot-dipping/immersion processesAlloy coatingAluminium alloy

The invention discloses a low zinc hot dipping aluminum alloy coating material. Alloy compositions comprise, by element weight percentage, 20-30 parts of Zn, 0.01-0.15 part of Pd, 1.5-3.8 parts of alloy enhancers, 0.1-0.5 part of Cr, 0.01-0.05 part of Sn, 0.1-0.3 part of a grain refiner, 0.01-0.1 part of a rare earth addition, 0.01-2.0 parts of Fe, and the rest are Al and inevitable microimpurity. According to the low zinc hot and high performance dipping aluminum alloy coating material, the Zn is replaced by the Al.

Owner:贵州铝厂有限责任公司

Al-Fe-Cu-Zn aluminum alloy for automobile wire and wire harness thereof

PendingCN103757490AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsElectrical conductorCreep rate

The invention discloses an Al-Fe-Cu-Zn aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Cu-Zn aluminum alloy. The Al-Fe-Cu-Zn aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu, 0.001-0.2wt% of Zn and the balance of Al and inevitable impurities. According to the Al-Fe-Cu-Zn aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Cu, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; by adding Zn, the electrical conductivity of the aluminum alloy can be slightly reduced, the strength can be effectively improved to a certain extent, and the creep rate of a conductor is simultaneously improved.

Owner:ANHUI JOY SENSE CABLE

Treatment process of corrosion-resistant and wear-resistant type water pump piston

InactiveCN106590077AHigh strengthImprove antioxidant capacityFireproof paintsAnti-corrosive paintsMetal coatingWear resistant

The invention discloses a treatment process of a corrosion-resistant and wear-resistant type water pump piston. From inside to outside, the surface of the piston is sequentially coated with a corrosion-resistant metal coating and a strippable anticorrosive coating, and the corrosion-resistant metal coating comprises the following components in percentage by mass: 0.02-0.05% of C, 0.33-0.37% of Zn, 0.32-0.35% of Cu, 0.25-0.28% of W, 0.75-0.78% of Nb, 8.32-8.35% of Cr, 0.27-0.29% of Si, 0.52-0.55% of Mo, 0.13-0.15% of Co, 3.4-3.6% of Al, 2.65-2.68% of rare earth, and the balance of Fe and trace impurities, wherein the rare earth comprises the following components in percentage by weight: 3.2-3.5% of La, 2.6-2.8% of Tm, 5.2-5.6% of Ho, 5.5-5.8% of Tb, 4.1-4.3% of Eu, 12.5-12.8% of Sm, and the balance of Gd.

Owner:苏州富艾姆工业设备有限公司

Flange of automobile engine exhausting system and production process of flange

InactiveCN106636941AIn line with the operational relationshipImprove flexibilitySilencing apparatusMachines/enginesMetal coatingRare earth

The invention provides a flange of an automobile engine exhausting system. The flange comprises a flange body, a bottom plate, a connecting part, a top plate, holes, a bottom-end hole and a top hole, wherein the flange body is provided with the bottom plate; the bottom-end hole is formed in the center of the bottom plate and two holes are formed in each of two sides of the bottom-end hole; the upper end of the bottom plate is connected with the lower end of the connecting part; the upper end of the connecting part is connected with the top plate; the top hole is formed in the center of the top plate; a wear-resisting metal coating is plated on the surface of the flange body; the wear-resisting metal coating is prepared from the following components in percentage by mass: 0.21 percent to 0.23 percent of C, 0.13 percent to 0.17 percent of Mg, 0.62 percent to 0.65 percent of Cu, 0.45 percent to 0.48 percent of W, 0.55 percent to 0.58 percent of Ti, 5.32 percent to 5.35 percent of Cr, 0.37 percent to 0.39 percent of Ni, 0.42 percent to 0.45 percent of Mo, 0.23 percent to 0.25 percent of Co, 3.42 percent to 3.45 percent of Ca, 11 percent to 13 percent of rare earth and the balance of Fe and trace impurities; the rare earth includes the following components in percentage by weight: 5.2 percent to 5.5 percent of La, 7.6 percent to 7.8 percent of Ce, 5.2 percent to 5.6 percent of Pm, 5.5 percent to 5.8 percent of Nd, 3.1 percent to 3.3 percent of Eu, 5.5 percent to 5.8 percent of Sm and the balance of Gd.

Owner:江苏多为机械工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com