Aluminum alloy for battery case of new energy automobile and pressure casting preparation method thereof

A new energy vehicle and battery casing technology, applied in the field of metal materials for new energy vehicle products, can solve the problems of complex structure, thin product wall thickness, large battery tray product size, etc., and achieve the effect of excellent comprehensive performance and good casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

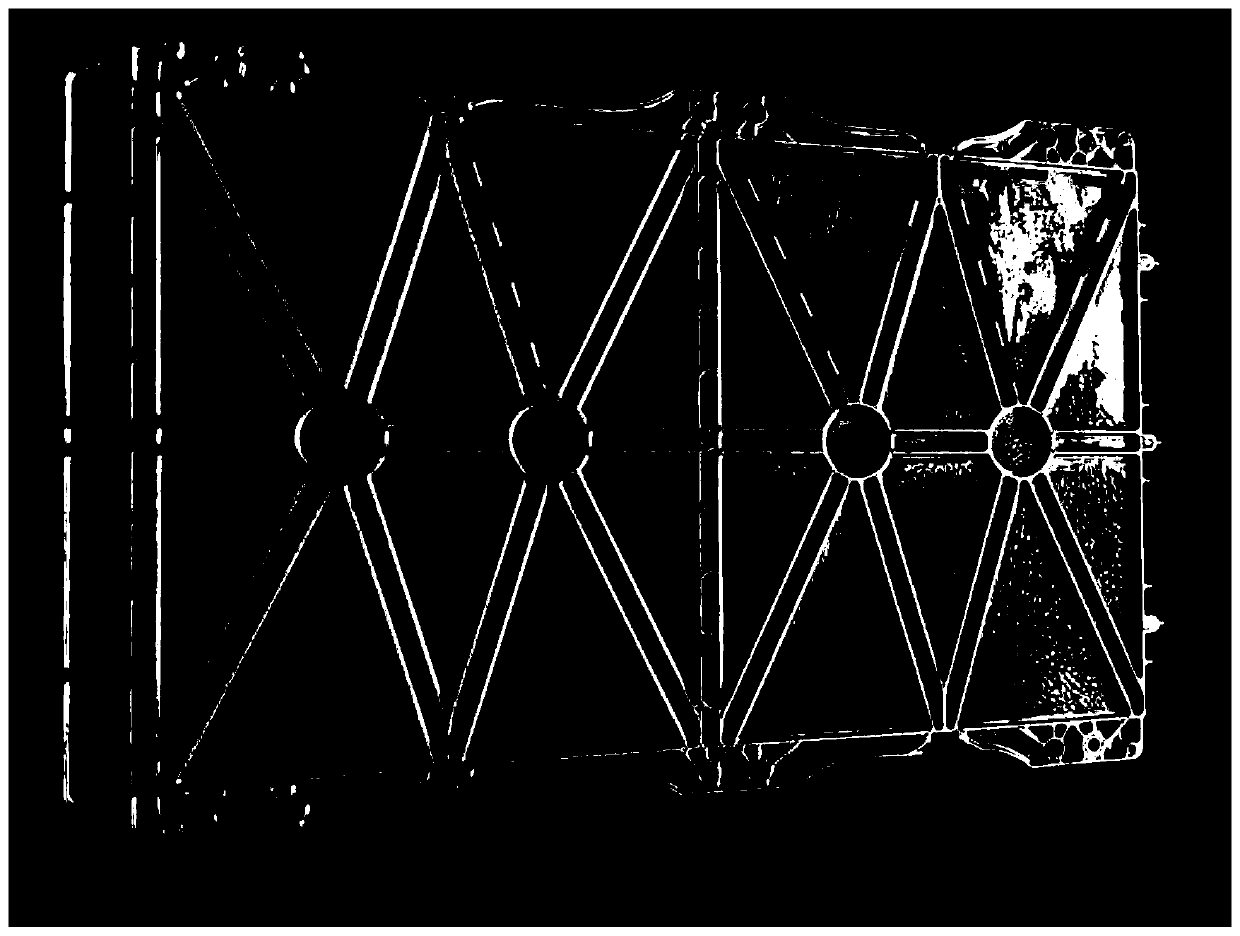

Image

Examples

Embodiment 1

[0040] This embodiment provides an aluminum alloy used in a new energy vehicle battery case and a method for preparing it by die casting. The percentage content of each element of the aluminum alloy is shown in Table 1;

[0041] In this embodiment, a method for preparing a die-casting aluminum alloy for a battery case of a new energy vehicle comprises the following steps:

[0042] 1) Preheat various intermediate alloy raw materials and operating tools such as pure aluminum, crystalline silicon, aluminum manganese, aluminum titanium boron, aluminum strontium, aluminum rare earth, pure magnesium to 200°C in proportion for 1~2h;

[0043] 2) Add the raw materials of pure aluminum, crystalline silicon, and aluminum-manganese intermediate alloy after preheating in step 1) into the side furnace according to a reasonable feeding sequence, and the temperature is 740~800°C until fully melted;

[0044] 3) Fully stir the melt obtained in step 2), and add slag remover and refining agent in s...

Embodiment 2

[0051] This embodiment provides an aluminum alloy used in a new energy vehicle battery case and a method for preparing it by die casting. The percentage content of each element of the aluminum alloy is shown in Table 1;

[0052] In this embodiment, a method for preparing a die-casting aluminum alloy for a battery case of a new energy vehicle comprises the following steps:

[0053] 1) On the basis of Example 1, according to the percentage content of the corresponding elements in Example 2, the ingredients are proportioned, and crystalline silicon, aluminum-manganese master alloy, aluminum strontium, aluminum-titanium-boron, and pure magnesium need to be added for load-bearing.

[0054] 2) Follow steps 1-6 in Example 1 to obtain the melt that meets the requirements of Example 2 with the above-mentioned raw materials that need to be added, and wait for pouring.

[0055] The die casting described in this embodiment uses the company's 5000T die casting machine, the pouring temperat...

Embodiment 3

[0058] This embodiment provides an aluminum alloy used in a new energy vehicle battery case and a method for preparing it by die casting. The percentage content of each element of the aluminum alloy is shown in Table 1;

[0059] In this embodiment, a method for preparing a die-casting aluminum alloy for a battery case of a new energy vehicle comprises the following steps:

[0060] 1) On the basis of Example 2, according to the percentage content of the corresponding elements in Example 3, the ingredients are proportioned, and the load-bearing needs to add crystalline silicon, aluminum-manganese intermediate alloy, aluminum strontium, aluminum-titanium-boron, pure magnesium, aluminum rare earth intermediate alloy.

[0061] 2) Follow steps 1-6 in Example 1 for the above-mentioned raw materials to be added to obtain a melt that meets the requirements of Example 3, and wait for pouring.

[0062] The die casting described in this embodiment uses the company's 5000T die casting mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com