Leadfree high-strength and corrosion-resistance silicon brass alloy easy to be cut and preparation method and application

A technology of easy cutting and silicon brass, which is applied in the field of alloy materials, can solve the problems of alloy plasticity reduction and affecting cutting performance, etc., and achieve the effect of good casting performance, high yield rate and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The content of Cu, Zn, Si, and Al alloy elements is designed to be 58wt% Cu, 40.2wt% Zn, 1.0%wt% Si and 0.8%wt% Al respectively, and the zinc equivalent of the alloy is calculated to be 48.7%; in addition, The contents of grain refiner B and Ti in the alloy are designed to be 0.005%wt%B and 0.03%wt%Ti respectively;

[0034] (2) First preheat the crucible to 400-500°C, then place the raw materials of red copper and copper-silicon intermediate alloy at the bottom of the crucible, and raise the temperature to 1050-1100°C until the red copper and copper-silicon intermediate alloy are completely melted and the composition is homogenized. When adding a small amount of borax on the surface of the melt as a covering agent;

[0035] (3) Lower the temperature to 400-700°C, and add aluminum ingots and zinc ingots in sequence;

[0036] (4) After the aluminum ingots and zinc ingots are completely melted, the temperature is raised to 1050-1100 ° C, and the graphite rod is fully ...

Embodiment 2

[0042] (1) The content of Cu, Zn, Si, and Al alloy elements is designed to be 58wt% Cu, 40.1wt% Zn, 0.6%wt% Si and 1.3%wt% Al respectively, and the zinc equivalent of the alloy is calculated to be 48.1%; in addition, The contents of grain refiner B and Ti in the alloy are designed to be 0.008%wt%B and 0.05%wt%Ti respectively;

[0043] (2) First preheat the crucible to 400-500°C, then place the raw materials of red copper and copper-silicon intermediate alloy at the bottom of the crucible, and raise the temperature to 1050-1100°C until the red copper and copper-silicon intermediate alloy are completely melted and the composition is homogenized. When adding a small amount of borax on the surface of the melt as a covering agent;

[0044] (3) Lower the temperature to 400-700°C, and add aluminum ingots and zinc ingots in sequence;

[0045] (4) After the aluminum ingots and zinc ingots are completely melted, the temperature is raised to 1050-1100 ° C, and the graphite rod is fully ...

Embodiment 3

[0051] (1) Design the content of Cu, Zn, Si, Al alloy elements to be 60wt% Cu, 38wt% Zn, 1.5%wt% Si and 0.5%wt% Al respectively, the zinc equivalent of the alloy is calculated to be 49.6%; In addition, the alloy The contents of grain refiner B and Ti in the medium are designed to be 0.008%wt%B and 0.05%wt%Ti respectively;

[0052] (2) First preheat the crucible to 400-500°C, then place the raw materials of red copper and copper-silicon intermediate alloy at the bottom of the crucible, and raise the temperature to 1050-1100°C until the red copper and copper-silicon intermediate alloy are completely melted and the composition is homogenized. When adding a small amount of borax on the surface of the melt as a covering agent;

[0053] (3) Lower the temperature to 400-700°C, and add aluminum ingots and zinc ingots in sequence;

[0054] (4) After the aluminum ingots and zinc ingots are completely melted, the temperature is raised to 1050-1100 ° C, and the graphite rod is fully stir...

PUM

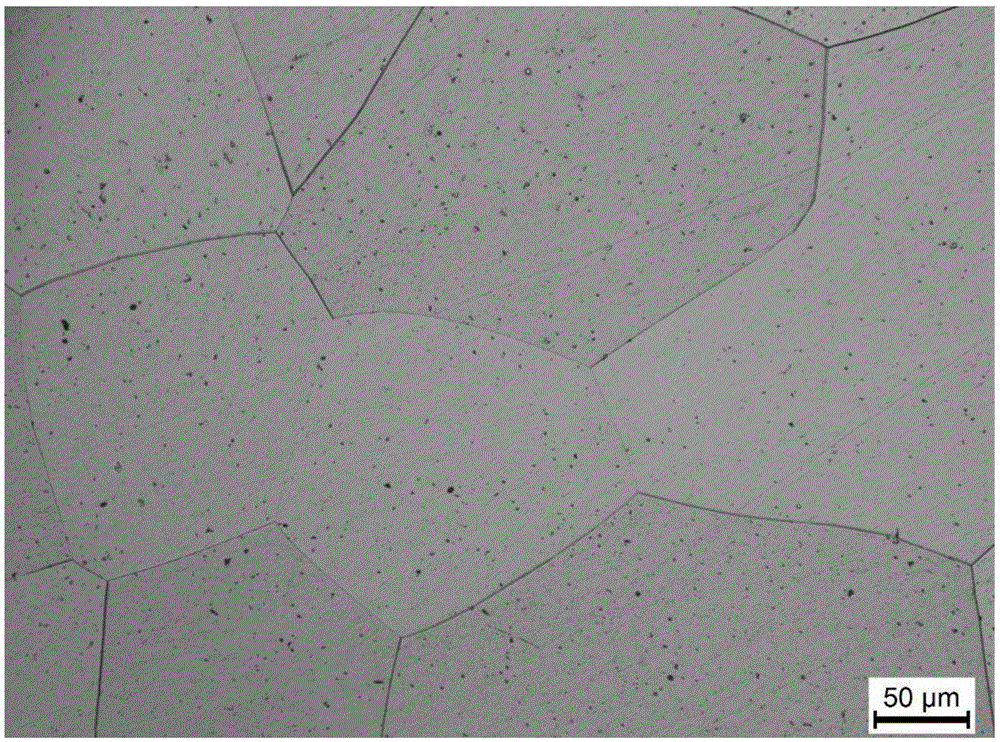

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

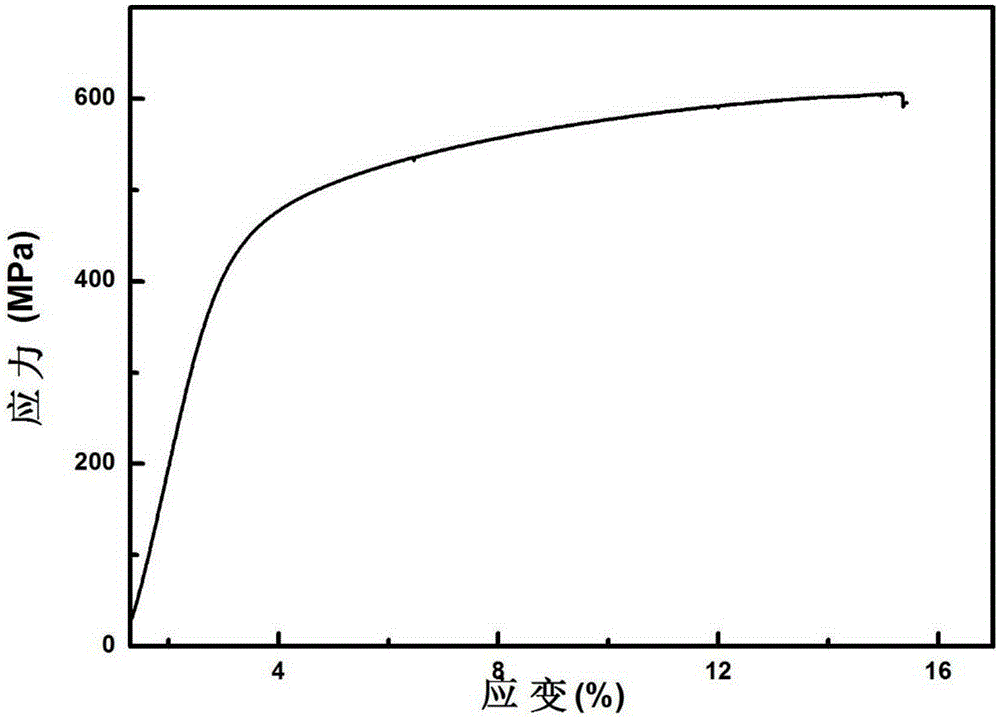

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com