Connection frame for automobile engine exhaust emission system and production process of connection frame

A technology of automobile engine and exhaust system, applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve the problems of poor stability performance, inconvenient parts replacement, peeling, etc., achieve good stability performance, simple structure, and convenient replacement and the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

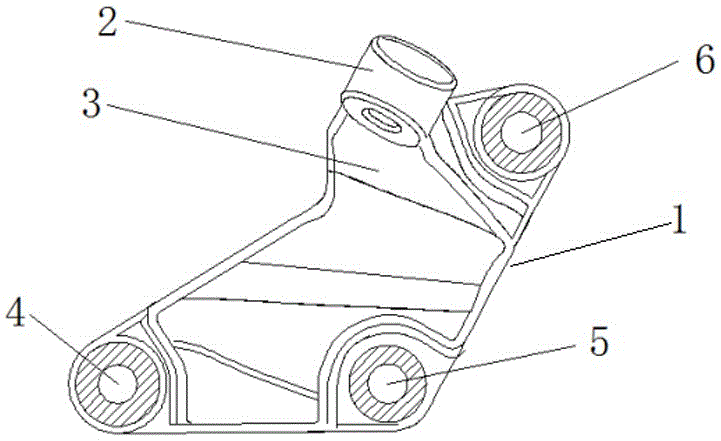

[0031] The present invention provides such as figure 1 A connecting bracket for an automobile engine exhaust system shown includes a bracket body 1, an upper fixing hole 2, a rib plate 3, a hole 4, a hole 5 and a hole 6, and the bracket body 1 is provided with a hole 4, a hole Hole 2 5 and hole 3 6, hole 1 4 and hole 2 5 are placed on one side of the bracket body 1, hole 2 5 and hole 3 6 are placed on the other side of the bracket body 1, the upper side of the bracket body 1 and the rib The lower end of the plate 3 is connected, and the top of the rib plate 3 is connected with the fixing hole 2 at the upper end.

[0032] The surface of the bracket body 1 is coated with a layer of wear-resistant metal coating 12. The components of the wear-resistant metal coating are: C: 0.21%, Mg: 0.13%, Cu: 0.62%, W: 0.45%, Ti: 0.55 %, Cr: 5.32%, Ni: 0.37%, Mo: 0.42%, Co: 0.23%, Ca: 3.42%, rare earth: 11%, the rest is Fe and trace impurities;

[0033] Among the rare earths, the following co...

Embodiment 2

[0045] The present invention provides such figure 1 A connecting bracket for an automobile engine exhaust system shown includes a bracket body 1, an upper fixing hole 2, a rib plate 3, a hole 4, a hole 5 and a hole 6, and the bracket body 1 is provided with a hole 4, a hole Hole 2 5 and hole 3 6, hole 1 4 and hole 2 5 are placed on one side of the bracket body 1, hole 2 5 and hole 3 6 are placed on the other side of the bracket body 1, the upper side of the bracket body 1 and the rib The lower end of the plate 3 is connected, and the top of the rib plate 3 is connected with the fixing hole 2 at the upper end.

[0046] The surface of the bracket body 1 is coated with a layer of wear-resistant metal coating 12. The components of the wear-resistant metal coating are: C: 0.23%, Mg: 0.17%, Cu: 0.65%, W: 0.48%, Ti: 0.58 %, Cr: 5.35%, Ni: 0.39%, Mo: 0.45%, Co: 0.25%, Ca: 3.45%, rare earth: 13%, the rest is Fe and trace impurities;

[0047] Among the rare earths, the following compo...

Embodiment 3

[0059] The present invention provides such figure 1 A connecting bracket for an automobile engine exhaust system shown includes a bracket body 1, an upper fixing hole 2, a rib plate 3, a hole 4, a hole 5 and a hole 6, and the bracket body 1 is provided with a hole 4, a hole Hole 2 5 and hole 3 6, hole 1 4 and hole 2 5 are placed on one side of the bracket body 1, hole 2 5 and hole 3 6 are placed on the other side of the bracket body 1, the upper side of the bracket body 1 and the rib The lower end of the plate 3 is connected, and the top of the rib plate 3 is connected with the fixing hole 2 at the upper end.

[0060] The surface of the bracket body 1 is coated with a layer of wear-resistant metal coating 12. The components of the wear-resistant metal coating are: C: 0.22%, Mg: 0.15%, Cu: 0.63%, W: 0.47%, Ti: 0.56 %, Cr: 5.34%, Ni: 0.38%, Mo: 0.43%, Co: 0.24%, Ca: 3.43%, rare earth: 12%, the rest is Fe and trace impurities;

[0061] Among the rare earths, the following compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com