Flange of automobile engine exhausting system and production process of flange

A technology of automobile engine and exhaust system, which is applied in the direction of engine components, machines/engines, exhaust devices, etc., and can solve the problems of three-way catalytic converter carrier sintering, engine overheating, tempering, and flange size inconsistency, etc. Achieve the effect of being suitable for popularization, increasing service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

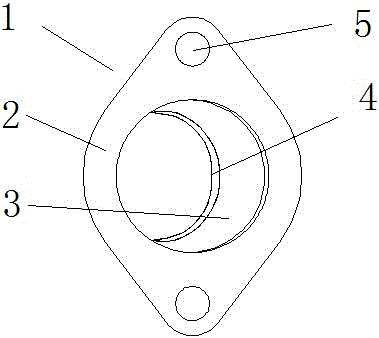

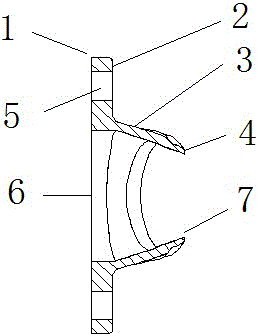

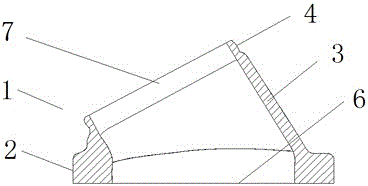

[0034] The present invention provides such as figure 1 The one shown includes a flange body 1, a bottom plate 2, a connector 3, a top plate 4, a hole 5, a bottom hole 6, and a top hole 7. The flange body 1 is provided with a bottom plate 2, and the center of the bottom plate 2 is provided with a Bottom hole 6, two holes 5 are respectively arranged on both sides of the bottom hole 6, the upper end of the bottom plate 2 is connected with the lower end of the connector 3, the upper end of the connector 3 is connected with the top plate 4, and the center of the top plate 4 is provided with a top hole 7;

[0035] The surface of the bracket body is coated with a layer of wear-resistant metal coating 12, and the components of the wear-resistant metal coating are: C: 0.21%, Mg: 0.13%, Cu: 0.62%, W: 0.45%, Ti: 0.55% , Cr: 5.32%, Ni: 0.37%, Mo: 0.42%, Co: 0.23%, Ca: 3.42%, rare earth: 11%, the rest is Fe and trace impurities;

[0036] Among the rare earths, the following components ar...

Embodiment 2

[0049] The present invention provides such as figure 1 The shown flange of an automobile engine exhaust system includes a flange body 1, a bottom plate 2, a connector 3, a top plate 4, a hole 5, a bottom hole 6 and a top hole 7, and the flange body 1 is provided with a bottom plate 2 , the center of the bottom plate 2 is provided with a bottom hole 6, and the two sides of the bottom hole 6 are respectively provided with two holes 5, the upper end of the bottom plate 2 is connected with the lower end of the connector 3, the upper end of the connector 3 is connected with the top plate 4, and the top plate The center of 4 is provided with a top hole 7;

[0050] The surface of the bracket body 1 is coated with a layer of wear-resistant metal coating 12. The components of the wear-resistant metal coating are: C: 0.23%, Mg: 0.17%, Cu: 0.65%, W: 0.48%, Ti: 0.58 %, Cr: 5.35%, Ni: 0.39%, Mo: 0.45%, Co: 0.25%, Ca: 3.45%, rare earth: 13%, the rest is Fe and trace impurities;

[0051] A...

Embodiment 3

[0064] The present invention provides such as figure 1 The shown flange of an automobile engine exhaust system includes a flange body 1, a bottom plate 2, a connector 3, a top plate 4, a hole 5, a bottom hole 6 and a top hole 7, and the flange body 1 is provided with a bottom plate 2 , the center of the bottom plate 2 is provided with a bottom hole 6, and the two sides of the bottom hole 6 are respectively provided with two holes 5, the upper end of the bottom plate 2 is connected with the lower end of the connector 3, the upper end of the connector 3 is connected with the top plate 4, and the top plate The center of 4 is provided with a top hole 7;

[0065] The surface of the bracket body 1 is coated with a layer of wear-resistant metal coating 12. The components of the wear-resistant metal coating are: C: 0.22%, Mg: 0.15%, Cu: 0.63%, W: 0.47%, Ti: 0.56 %, Cr: 5.34%, Ni: 0.38%, Mo: 0.43%, Co: 0.24%, Ca: 3.43%, rare earth: 12%, the rest is Fe and trace impurities;

[0066] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com