Air outlet flange for automobile engine and production technique thereof

A technology for automobile engines and flanges, which is applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve the problems of affecting the service life of equipment, damage to air outlet flanges, and short service life, so as to increase corrosion resistance and improve Strength and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

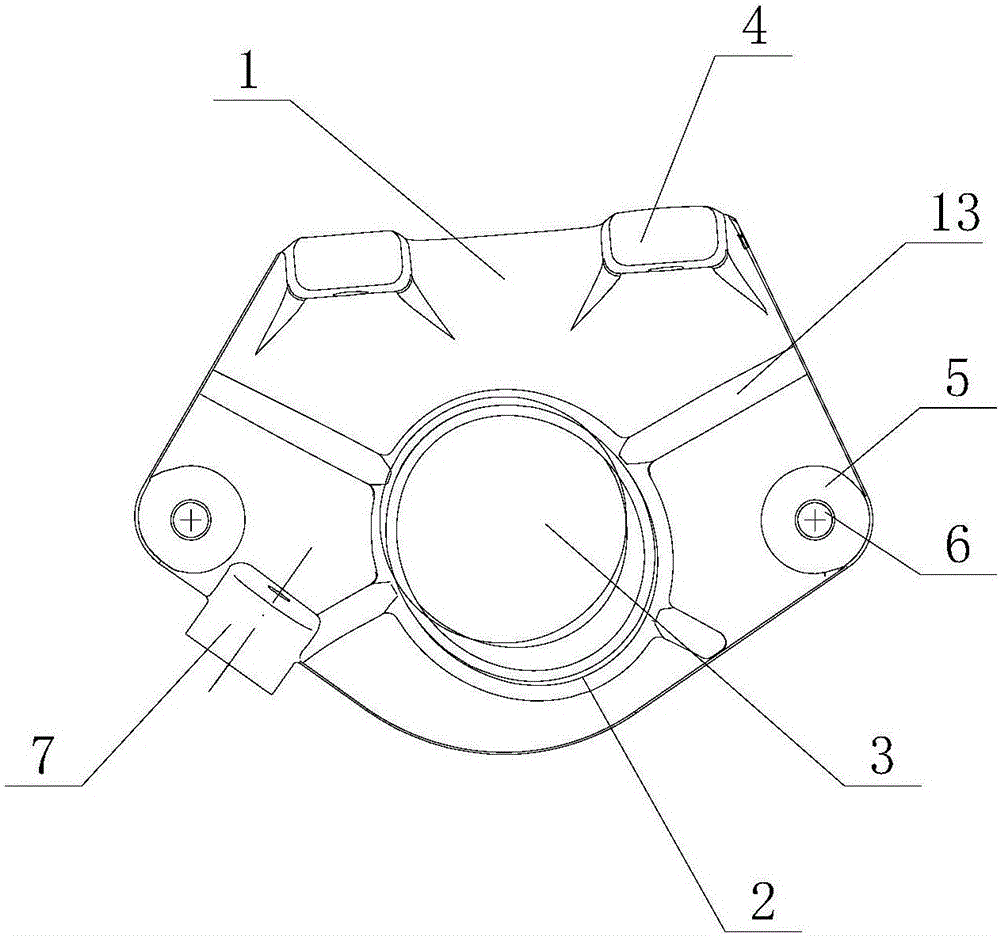

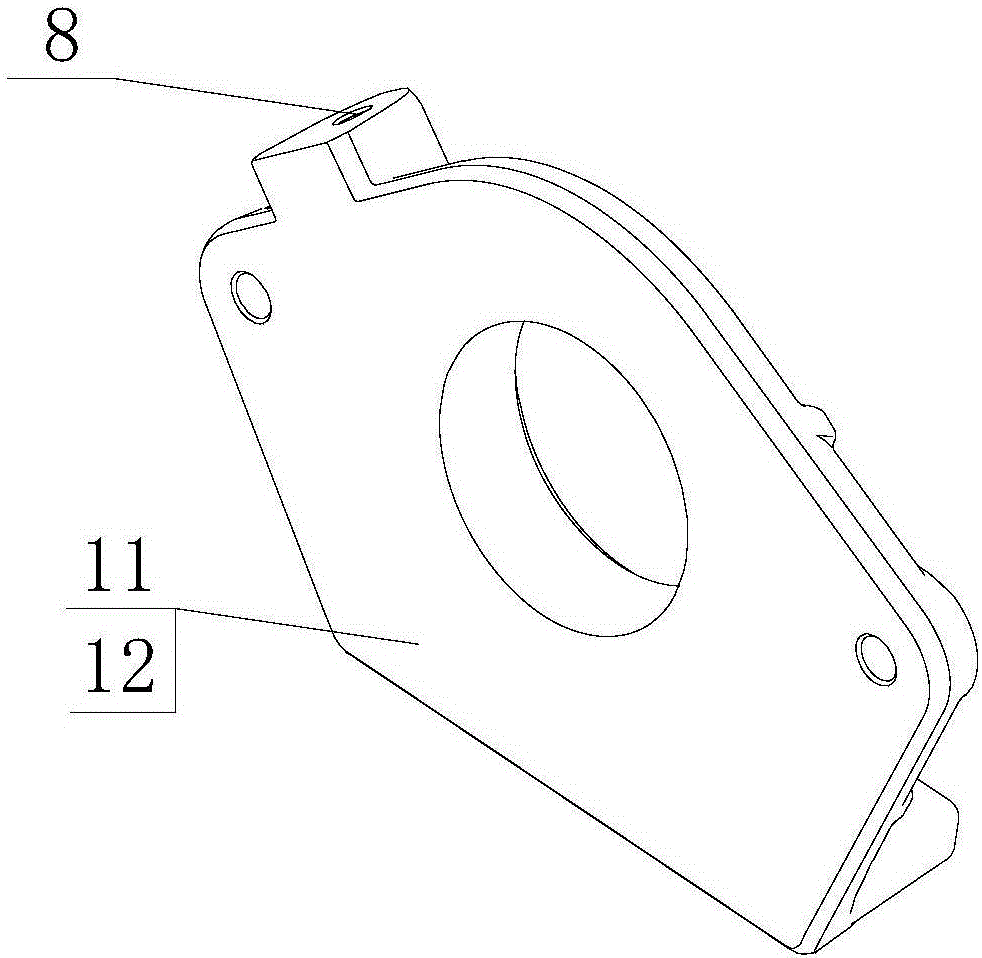

[0030] An automobile engine air outlet flange provided in this embodiment includes an air outlet flange body, the air outlet flange body includes a base 1, the base 1 is pentagonal, and a There is an outwardly protruding boss 2, the central position of the boss 2 is provided with an opening 3, and the upper end of the base 1 is provided with an anchor 4, and the anchor 4 is rectangular, and on both sides of the base 1 A connecting platform 5 is provided on the side, and a first threaded hole 6 is opened on the connecting platform 5. A second mounting platform 7 is also provided on the base 1, and a second mounting platform 7 is provided along the horizontal direction. Threaded hole 8, the direction in which the anchor 4, the boss 2 and the connecting platform 5 protrude outward are the same;

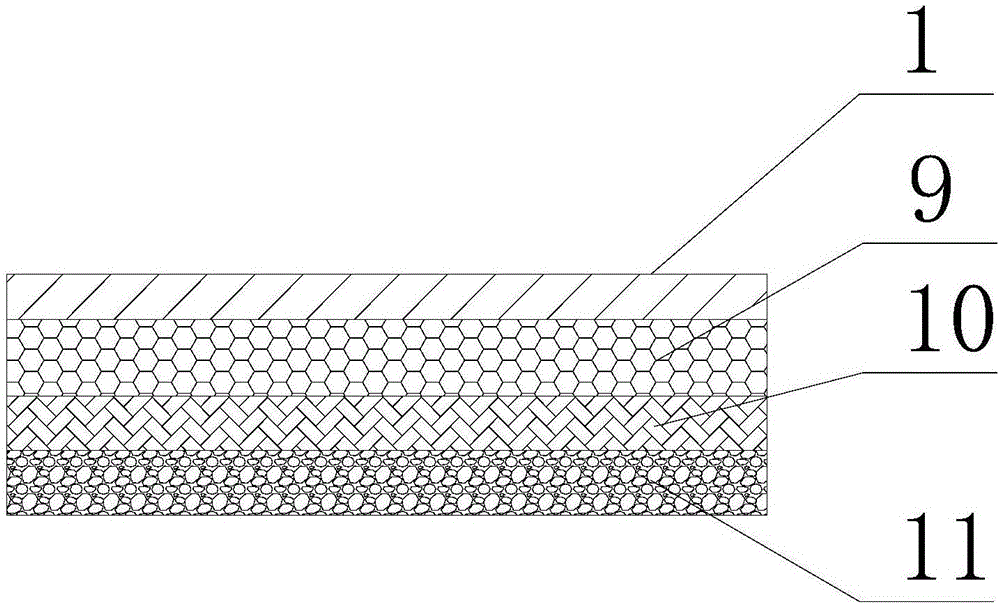

[0031] A buffer layer is provided on the back of the base 1, and the buffer layer includes a rubber layer 9 connected to the back, a wear-resistant layer 10, and a steel plate 11. The we...

Embodiment 2

[0039] A kind of automobile engine air outlet flange provided by this embodiment, the present embodiment has the same structure as that of Embodiment 1, wherein the projection angle between the opening 3 and the horizontal plane is 45°; the thickness of the rubber layer 9 is 0.8mm, The thickness of the wear-resistant layer 10 is 0.9mm, and the thickness of the steel plate 11 is 3mm;

[0040] The surface of the steel plate 11 is coated with a layer of wear-resistant metal coating 12, and the components of the wear-resistant metal coating are: C: 0.23%, Mg: 0.17%, Cu: 0.65%, W: 0.48%, Ti: 0.58%, Cr: 5.35%, Ni: 0.39%, Mo: 0.45%, Co: 0.25%, Ca: 3.45%, rare earth: 13%, the rest is Fe and trace impurities;

[0041] The rare earth contains the following components by weight percentage: La: 5.5%, Ce: 7.8%, Pm: 5.6%, Nd: 5.8%, Eu: 3.3%, Sm: 5.8%, and the balance is Gd;

[0042] The preparation method of wear-resistant metal coating is carried out according to the following steps:

[...

Embodiment 3

[0047] An automobile engine air outlet flange provided in this embodiment has the same structure as in Embodiment 1, wherein the projected angle between the opening 3 and the horizontal plane is 36°; the thickness of the rubber layer 9 is 0.6mm, The thickness of the wear-resistant layer 10 is 0.8mm, and the thickness of the steel plate 11 is 2mm;

[0048] The surface of the steel plate 11 is coated with a layer of wear-resistant metal coating 12, and the components of the wear-resistant metal coating are: C: 0.22%, Mg: 0.15%, Cu: 0.63%, W: 0.47%, Ti: 0.56%, Cr: 5.34%, Ni: 0.38%, Mo: 0.43%, Co: 0.24%, Ca: 3.43%, rare earth: 12%, the rest is Fe and trace impurities;

[0049] The rare earth contains the following components by weight percentage: La: 5.3%, Ce: 7.7%, Pm: 5.4%, Nd: 5.6%, Eu: 3.2%, Sm: 5.7%, and the balance is Gd;

[0050] The preparation method of wear-resistant metal coating is carried out according to the following steps:

[0051] Step (1): Divide the rare earth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com