Aluminum alloy for new energy automobile battery case and production process thereof

A new energy vehicle and production process technology, applied in the field of metallurgy, can solve problems such as inability to meet performance requirements at the same time, and achieve the effect of meeting performance requirements, uniform metallographic structure, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

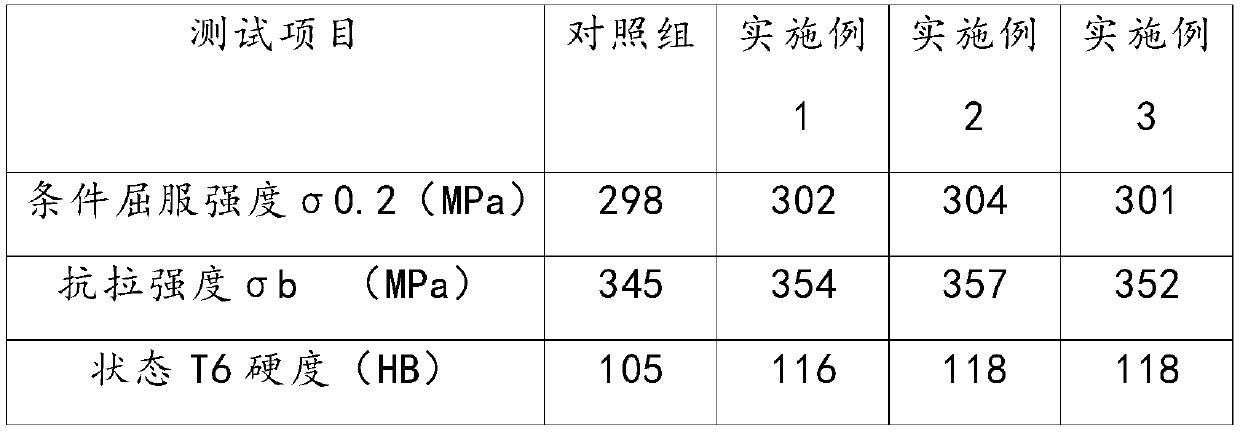

Examples

Embodiment 1

[0029] An aluminum alloy for a new energy vehicle battery case. According to the mass percentage, the element composition of the aluminum alloy product is: Zn: 3.4; Mg: 2.3; Cu: 1.7; Fe: 0.3; Mn: 0.1; Si: 0.1; Cr: 0.15 ; Ti: 0.12; the balance is Al and unavoidable impurities.

[0030] The elemental composition of the aluminum alloy also includes 0.4% of Zr elements and 0.15% of Re elements, and the Re elements include La, Pr, and Nd.

[0031] The mass ratio of La, Pr, and Nd in the Re element is 4:2:3.

[0032] The production process of this type of aluminum alloy for the battery case of new energy vehicles includes the following steps:

[0033] (1) Calculate the quality of each raw material according to the element formula, add electrolytic aluminum liquid to the furnace, control the temperature of the aluminum liquid to 725°C, and continue to add elemental metal and intermediate alloy to the aluminum liquid;

[0034] (2) Add refining agent to the molten aluminum according ...

Embodiment 2

[0045] An aluminum alloy for a new energy vehicle battery case. According to the mass percentage, the element composition of the aluminum alloy product is: Zn: 5.1; Mg: 2.7; Cu: 1.9; Fe: 0.8; Mn: 0.4; Si: 0.3; Cr: 0.26 ; Ti: 0.15; the balance is Al and unavoidable impurities.

[0046] The elemental composition of the aluminum alloy also includes 0.3% of Zr elements and 0.16% of Re elements, and the Re elements include La, Pr, and Nd.

[0047] The mass ratio of La, Pr, and Nd in the Re element is 4:2:3.

[0048] The production process of this type of aluminum alloy for the battery case of new energy vehicles includes the following steps:

[0049] (1) Calculate the quality of each raw material according to the element formula, add electrolytic aluminum liquid to the furnace, control the temperature of the aluminum liquid to 745°C, and continue to add elemental metal and intermediate alloy to the aluminum liquid;

[0050] (2) Add refining agent to the molten aluminum according to...

Embodiment 3

[0061] An aluminum alloy for a new energy vehicle battery case. According to the mass percentage, the element composition of the aluminum alloy product is: Zn: 3.9; Mg: 2.5; Cu: 1.8; Fe: 0.6; Mn: 0.3; Si: 0.2; Cr: 0.21 ; Ti: 0.14; the balance is Al and unavoidable impurities.

[0062] The elemental composition of the aluminum alloy also includes 0.35% of Zr elements and 0.18% of Re elements, and the Re elements include La, Pr, and Nd.

[0063] The mass ratio of La, Pr, and Nd in the Re element is 4:2:3.

[0064] The production process of this type of aluminum alloy for the battery case of new energy vehicles includes the following steps:

[0065] (1) Calculate the quality of each raw material according to the element formula, add electrolytic aluminum liquid into the furnace, control the temperature of the aluminum liquid to 735°C, and continue to add elemental metal and intermediate alloy to the aluminum liquid;

[0066] (2) Add refining agent to the molten aluminum accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue limit | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com